TSMC 1.6nm update: Tangible improvements, but new challenges emerge

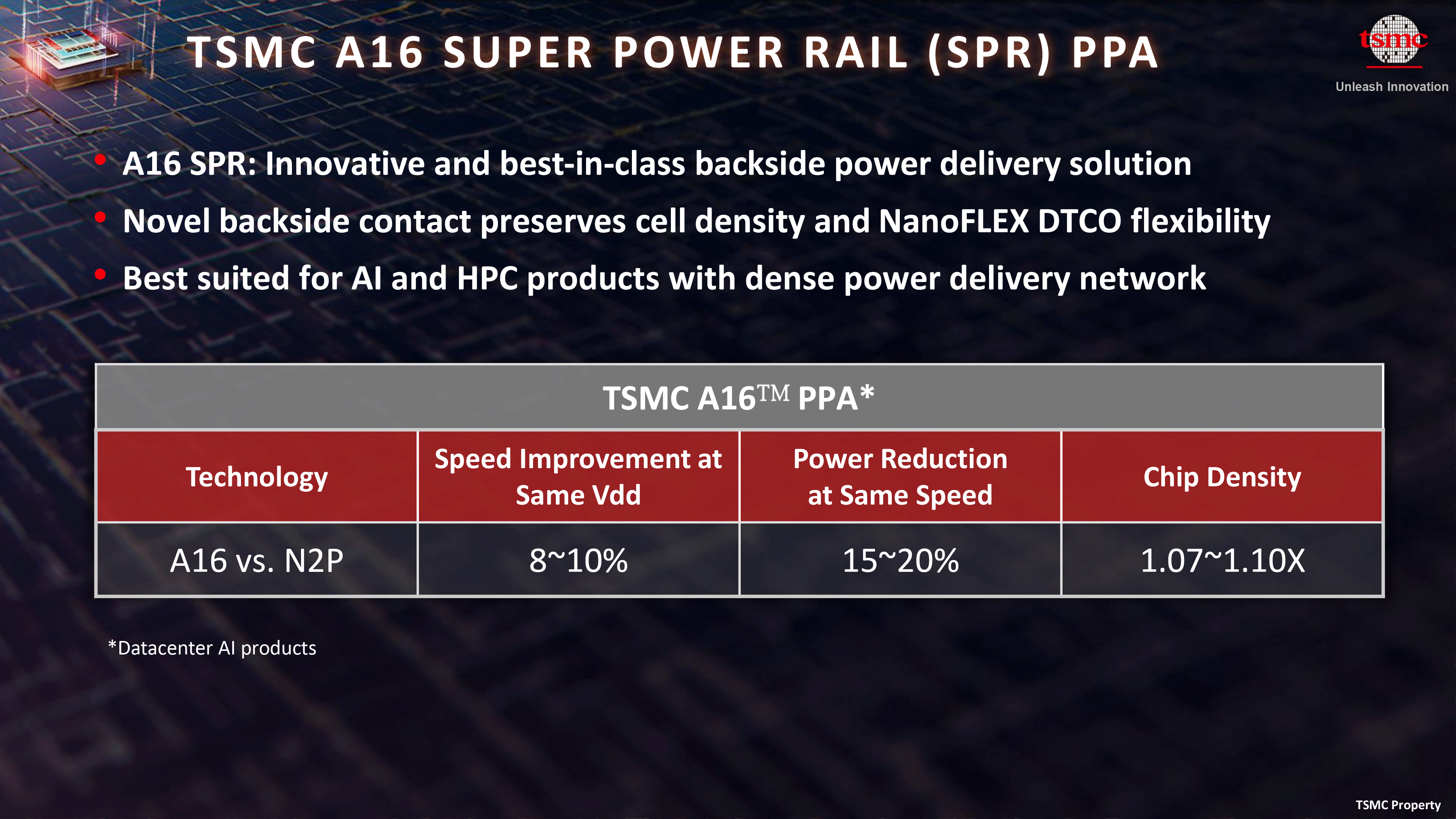

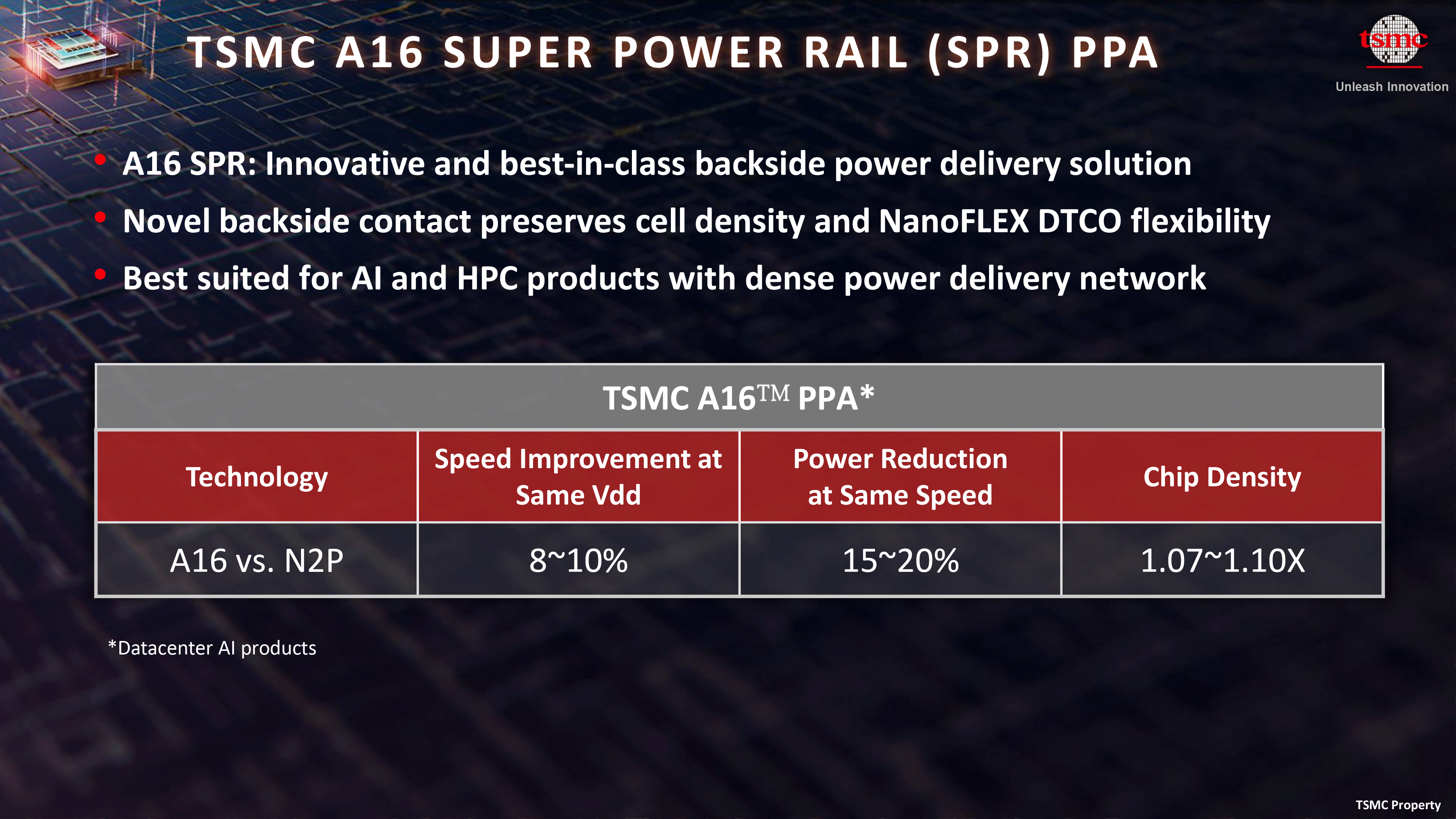

Best suited for AI and HPC processors.

TSMC is on track to mass produce the first chips on its A16 (1.6nm-class) process technology in late 2016, the company announced at its European Open Innovation Platform (OIP) Ecosystem Forum in Amsterdam, the Netherlands, earlier this week. The new production node features TSMC's Super Power Rail (SPR) backside power delivery network (BSPDN), which enables enhanced power delivery, which routes all power through the back side of the chip, and higher transistor density. But while this BSPDN solves some challenges, it adds others, so additional design efforts are required.

TSMC's A16 process will use gate-all-around (GAAFET) nanosheet transistors with an architecture similar to those featured by TSMC's N2-series process technologies (2nm-class) and include a backside power rail to enhance power delivery and boost transistor density. Compared to the N2P fabrication technology, A16 promises an 8%-10% performance gain at the same voltage and complexity or a 15%-20% power reduction at the same frequency and transistor count. In addition, TSMC estimates a 1.07x to 1.10x increase in chip density for high-end AI processors, depending on transistor types and libraries used.

Architecturally, A16 transistors are similar to N2 transistors, according to Ken Wang, TSMC's director of design solution exploration and tech benchmarking division. This simplifies migration to this process technology from N2.

"The logic layout migration from N2P to A16 is actually quite straightforward because the cell structure and most of the layout patterns are quite the same," said Wang. "So, besides keeping the same front side structure, the beauty of A16 is that it inherits the NanoFlex feature from N2 device width modulation for the maximum driving strength."

TSMC's Super Power Rail connects the backside power delivery network directly to each transistor's source and drain through a specialized contact, minimizing wire length and resistance to maximize performance and power efficiency. Production-wise, this implementation is among the most intricate BSPDN designs, surpassing the complexity of Intel's Power Via.

However, advanced BSPDN implementation also means that chip designers must completely redesign their power delivery network, route it in a new way, and, therefore, apply new place-and-route strategies, which is to be expected. Also, they have to do some thermal mitigation because hot spots of the chip will now be located under a set of wires, making heat dissipation harder.

Designing chips with a backside PDN essentially means adopting new implementation methods as many things change, including the design flow itself. Wang mentioned the usage of new thermal aware place-and-route software, new clock tree construction, different IR-Drop analysis, dissimilar power domains, and different thermal analysis sign-off, among others.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Considering the new implementation flow, new versions of EDA tools and simulation software are required. Since we're talking about a node similar to TSMC's N2, many things are ready, albeit in a pre-0.5 version of EDA tools from leading makers like Cadence and Synopsys.

"A16 is a technology suited for designs with complex routes and dense PDN," said Wang. "However, it also creates new challenges, so additional design effort is needed. Our backside contact VB also needs complete silicon validation with diligence. In the meantime, we have a comprehensive A16 EDA enablement program, which is ongoing, and we will continue to update the A16 EDA status."

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

The Historical Fidelity Hi just want to point out a typo, the year should be 2026.Reply

“TSMC is on track to mass produce the first chips on its A16 (1.6nm-class) process technology in late 2016”

Thanks -

truerock I think CPUs are going to need heat-spreaders on both the top and the bottom.Reply

A heat-spreader on the bottom with the contact-pins going through it. But, even if the backside heat spreader is made of diamond, it seems like it could get complicated. And, nobody is using diamond as a heat spreader. -

Unolocogringo Some people are working on that idea already.Reply

https://www.tomshardware.com/tech-industry/diamond-cooled-gpus-are-coming-soon-startup-claims-20c-temp-reduction-25-percent-more-overclocking-headroom-as-it-seeks-us-govt-funding-for-diamond-encrusted-chip-cooling-solutions

We can already grow defect free diamonds in the lab/start up industry.

This has been happening for several years. The goal is to get chip size diamonds grown first.

Then these are sliced into "SEEDS". These seeds would grow more in thickness and slightly larger in diameter . Then would then be sliced into thin wafers for sale or new seeds.

Originally Started as a final replacement for silicon. when shrinking node size is no longer possible. -

thestryker I wonder if BSPDN is going to be an optional feature like it is on Intel's 18A. Given that both Intel and TSMC have indicated the cost increase isn't negligible it makes me wonder if we're going to see a separation of major features like this as nodes shrink in general.Reply -

usertests Reply

It seems like the whole point of this half-node (BSPDN was supposed to be introduced earlier but moved to A16). Expense is to be expected with bleeding edge nodes anyway. They might have further budget nodes that remove it but I hope they don't since there is a significant impact on performance and particularly efficiency.thestryker said:I wonder if BSPDN is going to be an optional feature like it is on Intel's 18A. Given that both Intel and TSMC have indicated the cost increase isn't negligible it makes me wonder if we're going to see a separation of major features like this as nodes shrink in general. -

NinoPino Reply

I suppose it is intended that who don't benefit from BSPD will stay on N2P.thestryker said:I wonder if BSPDN is going to be an optional feature like it is on Intel's 18A. Given that both Intel and TSMC have indicated the cost increase isn't negligible it makes me wonder if we're going to see a separation of major features like this as nodes shrink in general. -

Dani_2077 Reply

😄😄😄 ... 🤑truerock said:Мисля, че процесорите ще се нуждаят от разпределители на топлина както отгоре, така и отдолу.

Топлоразпределител на дъното с контактните щифтове, минаващи през него. Но дори задният разпределител на топлина да е направен от диамант, изглежда, че може да стане сложно. И никой не използва диаманта като разпределител на топлина.