Apple 5W Adapter Knock-offs: The Colorful A1265 Tear-Down

Home Improvement

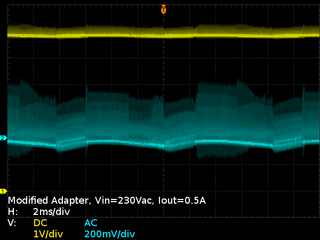

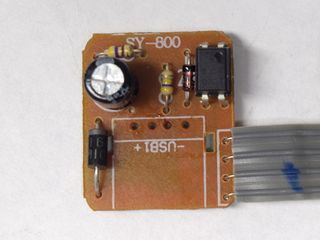

How much of this noise is directly attributable to one capacitor of questionable quality in the output filter? We could always supplement the electrolytic capacitor with multi-layer chip capacitors sporting extremely low ESR/ESL, and then measure the output noise again.

Here, I added both 10µF and 1µF capacitors to the back of the electrolytic’s pins.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

Modified Adapter Noise

Adding 11µF worth of ceramic capacitors to the adapter nearly eliminates negative ringing and cuts the positive switching transient spikes in half, leaving behind 630mVPP worth of combined ripple and noise (down from the horrendous 1.2-1.4VPP). That's a substantial improvement, but still far too noisy for comfort. Stacking capacitors can only do so much to suppress transients from fly-back current pulses.

We’d likely see Π filters (capacitor-inductor-capacitor) and perhaps even output common-mode chokes in adapters with smoother output, though I do not expect to find many (if any) in my no-name collection.

MORE: 10 Inexpensive Automotive USB Adapters Tested

Stay On the Cutting Edge: Get the Tom's Hardware Newsletter

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

MORE: Best Deals

Hitting The Bottom Of The Scale

According to the adapter’s label, its operating range begins at 100VAC where it can provide about 420mA before output voltage collapses well below 5V. Under very light load (as in 20mA output current), though, the oscillator continues operating all the way down to input voltages as low as 20VAC.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

The Upper Limit

At the other end of the scale, raising the input to 240VAC yields about 770mA before output voltage collapses again. Given almost double the output current at just over double the AC input voltage, we're looking at a near-linear relationship between input voltage and sustainable output current. Since AC input voltage directly affects the primary coil's current rise rate and the associated positive feedback to the transistor’s base driving the oscillator, this dependency was to be expected.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

Shorted Behavior

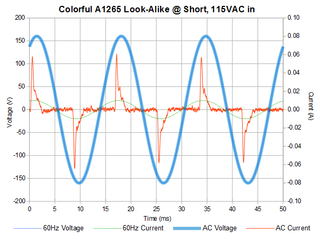

Using my ammeter to short the adapter’s output, I get a short-circuit current of 630mA as the oscillator pulls 757mW at 115V.

While continuous short circuit current may not be ideal, you can’t expect a simple oscillator circuit to do anything about it. On the plus side, output short-circuit is harmless in flyback converters, so long as the transformer doesn’t saturate. In an oscillator circuit like this one, the next switching cycle simply cannot begin until the transformer’s magnetic flux resets.

For all of its flaws in terms of output noise and regulation, this circuit may turn out to be surprisingly resilient.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

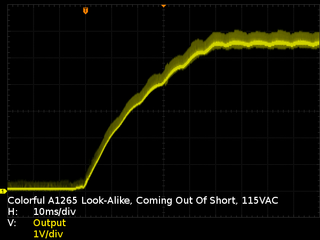

Coming Out Of Short

What happens coming out of short-circuit? It takes about 50ms for the adapter’s output voltage to creep back up to a steady 5.4V. Along the way, you can see ripples corresponding to the AC peaks every 8.33ms, courtesy of the previously mentioned relationship between input voltage and the oscillator’s operating current, which ultimately dictates output power.

Aside from the slow recovery time and horrible ~1VPP ripple+noise, there is nothing wrong or otherwise alarming here.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

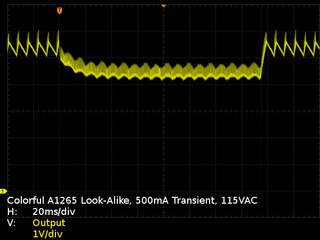

Transient Response

Since this adapter is unable to supply enough output current at 115V input to do the 250mA base + ~500mA transient (in the form of a 10Ω resistor) I originally intended, I went with 100mA base + 500mA instead.

Between the 470µF output filter capacitor and 10Ω resistor, we get a 4.7ms RC time constant (τ) with the capacitor discharge settling after 5τ, as expected. Under this 600mA combined load, the oscillator only manages to keep the output at about 4.4V. Once the resistor is removed, the output voltage returns to the same pattern as before the transient was applied with no other anomalies.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

Safety Isolation Testing, Part I

With all of the performance testing done, we can now proceed to the potentially destructive safety tests. To start, we'll try figuring out which of those clearance issues between traces causes the first failure. Or maybe it'll be the non-Y EMI suppression capacitor?

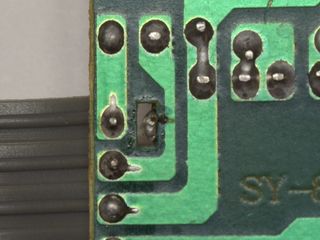

Using my variac and high-voltage transformer to apply a test voltage across the adapter’s power outlet prongs and USB connector, I progressively dialed up the angry pixies and got my first result at 1kVAC between the USB connector shield and nearby primary-side optoisolator trace. That’s 480VAC short of what UL requires for non-isolated appliances.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

First Safety Test Aftermath

Those few seconds of continuous arcing were enough to burn the trace's solder mask off and sputter some burnt material in between. While this did not appear to lower the arcing voltage in my limited testing, it is still cause for concern.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

Safety Isolation, Part II

That USB shield got in the way of finding out how good the transformer’s insulation is, so we'll repeat the test after knocking the USB connector out of the way. What fails next?

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

-

sitehostplus This is no joke. I once fried a mp3 player in a usb wall charger before. So I now only use either my computer, or a geniune apple charger.Reply -

laura.morris.ga Thank you for this incredibly valuable information. It's nice to see someone out there looking out for the regular guy who doesn't have this level of knowledge about electronics.Reply -

omegaman2 This manufacturing, and marketing of imitation goods, and in this case electronic products can have very serious consequences, to the point of death, or serious injury. Thank you for your awareness, and knowledge about chargers that are not worth saving a couple of dollars.Reply -

Lutfij In my case, I'd wait to see what folks had to say about it so they would be my guinea pigs, of sorts. In most cases, I stay away from off quality hardware.Reply

Thank you for the write up though!

;) -

canadianvice One of my critical rules for buying china: nothing connected to direct wall power.Reply

I do have one speaker lightbulb, but that's not powered when I'm not present, and it seems to have come from one of the better plants. Obviously, it's also less of a problem since I don't go out of my way to touch it on a regular basis. -

Kennyy Evony how about, listing an alternative without all the flaws? Complaining does not fix anything. List an adapter without all the flaws that costs exactly the same for people to buy? Wouldn't that be a better article? Same price, a lot less risks for consumers? win?Reply -

TMTOWTSAC Reply20566315 said:how about, listing an alternative without all the flaws? Complaining does not fix anything. List an adapter without all the flaws that costs exactly the same for people to buy? Wouldn't that be a better article? Same price, a lot less risks for consumers? win?

The title and description seem to imply that this is the first of several reviews to come. Since this first product presents an outright safety risk, I take zero issue with presenting it now rather than collating all results first. As far as producing a better article, you are presuming an alternative meeting your criteria does actually exists. While I have no doubt quality 5W adapters can be found cheaper than Apple's ($19 list price at Apple) I would be shocked if any of them could be found for $1.50. -

razor512 Reply20564820 said:This is no joke. I once fried a mp3 player in a usb wall charger before. So I now only use either my computer, or a geniune apple charger.

I fried mine also, but with a quality charger, Some MP# players do not play nicely with quickcharge 2.0 and 3.0 chargers.

Here are the photos of mine after it failed.

Funny thing was that the battery was perfectly fine, the protection circuit kicked in and cut the output and input to the battery for a few minutes, then it self-reset and the battery continued to work fine (it now runs a flashlight).

https://imgur.com/a/aOLQr

Beyond that, I have an old DIY USB charger that works really well, and has the lowest noise of any of the OEM chargers that I have used so far.

It is basically a USB port wired to the 5V rail of a 550 watt power supply. Even when charging my android tablet at 2 amps, the voltage is completely stable at 5V, and those cheap 5V amplifier circuits can run from it without filtering while on standard chargers that come with smartphones, will have lots of noise.

-

alextheblue Reply

Half my family uses Apple hardware and OE Apple accessories. The failure rate on the smaller Apple charging blocks is higher than I would have expected, given the cost. Since they have been conditioned to only use Apple accessories, I bought a couple of them the much larger Apple charging blocks you see used for iPads, to replace failed compact Apple blocks. Meanwhile I primarily use high-end third party chargers.20564820 said:This is no joke. I once fried a mp3 player in a usb wall charger before. So I now only use either my computer, or a geniune apple charger.

That depends on the charger. Just because it supports QC doesn't mean it is guaranteed to have issues like that. I've got a 2-port 39W (combined) Anker charger that supports QC 3.0 but it also supports what Anker calls PowerIQ. Works great with anything I've thrown at it, and I also use it with a 10W Qi mat.20566658 said:I fried mine also, but with a quality charger, Some MP# players do not play nicely with quickcharge 2.0 and 3.0 chargers. -

Daniel Sauvageau Reply

As the intro says, this adapter (hopefully) sets the low bar. I'm not "complaining" about the low quality, I am exposing it to drive awareness of how dangerous or even potentially lethal these cheap generics can potentially be. Increasing awareness reduces the number of people who will let themselves be tempted by suspiciously inexpensive adapters of questionable origins. Fewer people buying dangerous adapters will hopefully reduce demand and sufficiently reduced demand could potentially reduce offer. No awareness would allow propagation of these death traps to go completely unchecked.20566315 said:how about, listing an alternative without all the flaws? Complaining does not fix anything. List an adapter without all the flaws that costs exactly the same for people to buy?

As for suggesting better quality alternatives, as TMT already wrote, I seriously doubt there are any decent quality adapters around the $2 mark or at the very least, the chances of stumbling upon one are slim. There was an intro story to this series that was supposed to come out first but some publishing pipeline hiccups delayed it. I have about a dozen sub-$5 adapters in my presumed horror box and I'm not expecting them to achieve a passing grade. I also have a few $10 adapters which I'm hoping will at least get most of the way to a passing grade. I'll get to them in due time.

Right now, I'm half-way done testing a fairly promising aftermarket one (almost perfectly flat 5.06V from 0A through 8.6A regardless of test conditions with less than 20mV or RMS noise) but it is ~$25, so I'd be disappointed to get anything less. The next one after that will be a ~$10 adapter from a rising one-stop-for-everything home brand that I haven't taken out of its original box yet.

I'll probably rotate sub-$5, ~$10 and $20-and-up adapters until I exhaust my inventory for a given tier as exhausting my "horror-class" adapters first might get depressing. It also increases the chances that I may have something worth recommending once in a while, albeit at a higher cost.

Most Popular