Intel's 45 nm Penryn CPU: 4 GHz Air Cooled

New Dielectric Minimizes Leakage Currents

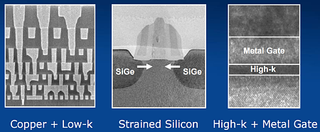

Since 1960, all MOSFETs - that is, all transistors in today's processors - have been produced using silicon and silicon dioxide exclusively. With the launch of the Penryn processor, and the simultaneous switch to 45 nm technology for its processors, Intel is the first manufacturer to add another material to the production process.

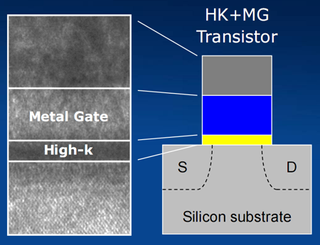

In each transistor, Intel has replaced two layers (depicted in blue and yellow here) with a different material. In the yellow layer, which is responsible for the switching ratio between the source and the drain of the MOSFETs, the previously used silicon oxide has been replaced with a high-K dielectric material based on Hafnium (Hf). Additionally, the silicon-gate layer above it (in blue) has been replaced with a metal layer.

Compared to the conventional process, which is still in use for the 65 nm processors, this changes the following characteristics:

- The switching speed of the transistors increases by 20%.

- The leakage current, which is responsible for the high thermal power dissipation (especially of the Pentium 4 Prescott) are reduced by a factor of 10.

Ann Kelleher explains the switching behavior of the transistors using the new materials...

...with the help of a few formulas.

Thus, the switching time of the individual transistors in the new Penryn CPU has decreased, and the switching behavior provides clearer signals.

It is thanks to these two new materials that the Penryn CPU has such extraordinary overclocking potential. Even clock speeds of 4 GHz and above no longer pose a problem, as we witnessed at this year's Intel Developer Forum.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Current page: New Dielectric Minimizes Leakage Currents

Prev Page Revamping The Core 2 Architecture - New Flagship: Extreme QX9650 Next Page 45 nm - Higher Yield, Smaller Die AreaTom's Hardware's dedicated news crew consists of both freelancers and staff with decades of experience reporting on the latest developments in CPUs, GPUs, super computing, Raspberry Pis and more.

Most Popular