Intel's 45 nm Penryn CPU: 4 GHz Air Cooled

45 nm - Higher Yield, Smaller Die Area

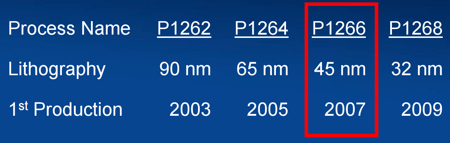

Like clockwork, Intel shrinks the structures of its processors every two years, and has already planned ahead as far as 2009. While 45 nm processors are only now set to enter the channel, the first prototypes of chips built on a 32 nm process are being tested in Intel's labs.

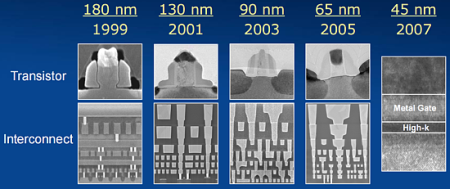

Beginning with the 45 nm technology, new materials need to be investigated that can be used in the production process. While it has thus far been possible to use the practically same materials across a variety of different processes, a new material now needs to be found for such small structures.

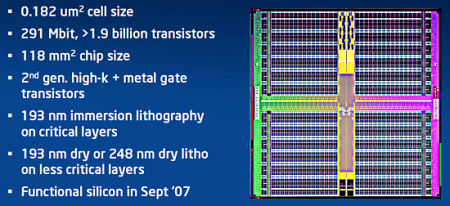

The 45 nm production process offers the following advantages over the 65 nm process:

- Almost twice as many transistors can fit onto the same chip area.

- Power consumption is reduced by about 30%.

This is in line with "Moore's Law", the prediction originally made by Gordon Moore that states that the number of transistors roughly doubles with each process generation.

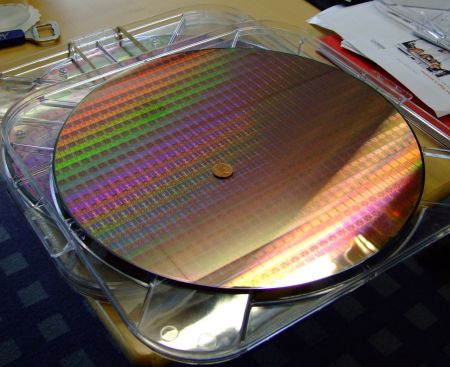

At Intel's press event in Munich, each of the journalists present had the opportunity to hold a 300 mm wafer in his hands.

300 mm wafer with Penryn cores.

The Penryn core is smaller than a penny.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Intel's research on 32 nm structures is in full swing. Functional SRAM chips have been running in Intel's labs since September of this year.

Current page: 45 nm - Higher Yield, Smaller Die Area

Prev Page New Dielectric Minimizes Leakage Currents Next Page 12 MB L2 Cache And SSE 4Tom's Hardware is the leading destination for hardcore computer enthusiasts. We cover everything from processors to 3D printers, single-board computers, SSDs and high-end gaming rigs, empowering readers to make the most of the tech they love, keep up on the latest developments and buy the right gear. Our staff has more than 100 years of combined experience covering news, solving tech problems and reviewing components and systems.