Console repairer discovers groovy PS5 Pro heatsink structure — machined grooves thought to help prevent solder paste from leaking from the socket

Should reduce the chance of heatsink dry spots and oxidization.

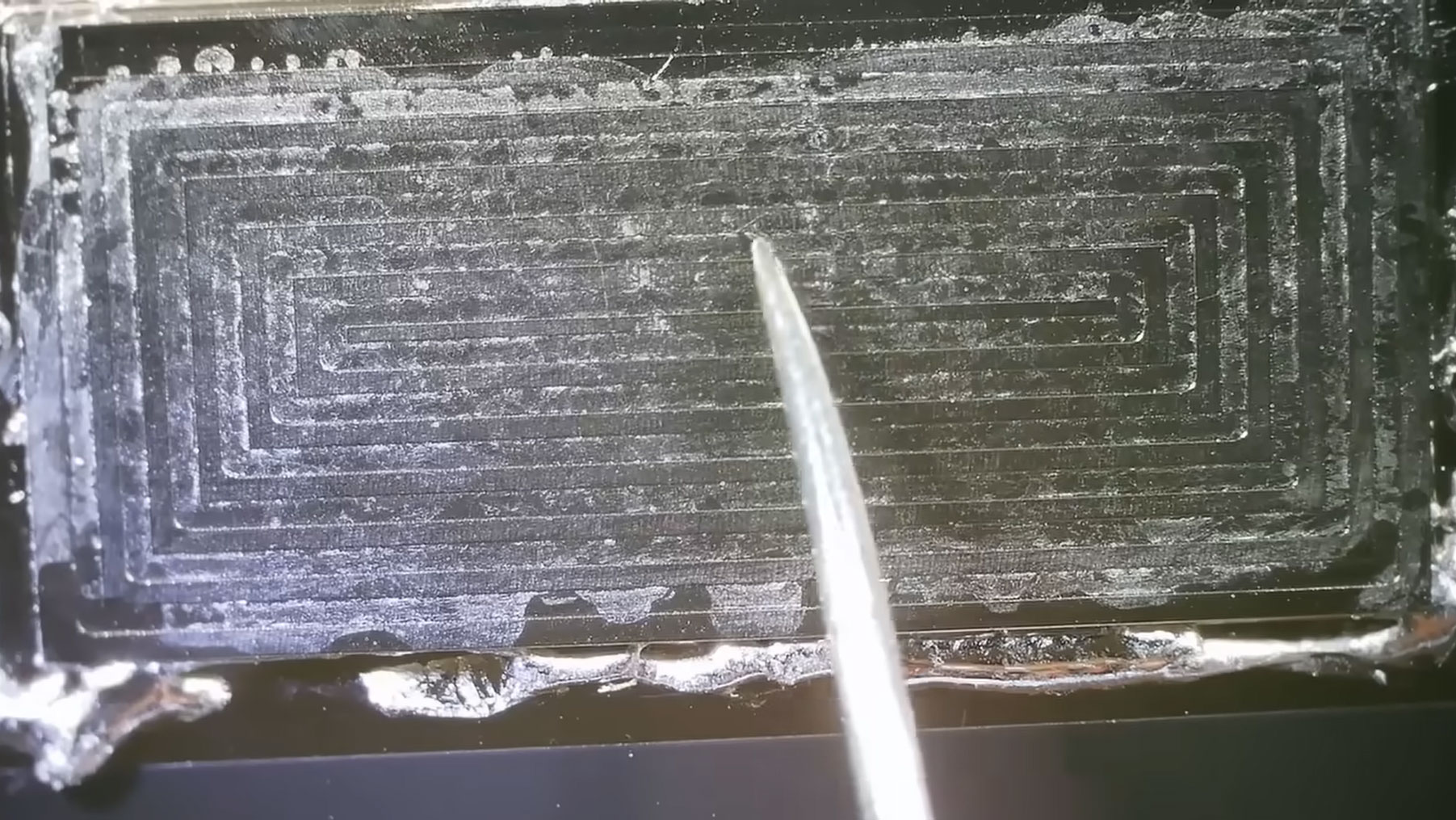

Sony’s new PlayStation 5 Pro has quietly introduced a very interesting heatsink design change. Popular console repair YouTube channel TronicsFix discovered that the PS5 Pro heatsink isn’t glossy-smooth – it features a rectangular spiral surface detail.

TronicsFix postulates that the deliberately machined surface pattern was implemented to reduce the occurrence of dry spots and surface oxidation caused by liquid metal thermal interface material (TIM) migrating across the heatsink. He also reckons it slightly increases the contact surface area.

If you’ve ever tried to evenly spread liquid metal, you will probably be aware that the material likes to form pools. It is also much more susceptible to flowing where you don’t want it, compared to traditional pastes. Systems designed for liquid metal heatsinks will therefore use a seal or dam around the heatsink to make sure this electrically conductive substance can’t get out and contaminate or cause damage to other system components.

TronicsFix also thinks that the movement of liquid metal over time is exacerbated in PlayStation systems that are kept and used in their vertical orientation. We know Steve at Tronicsfix has repaired and tuned a considerable number of PS5s (and other consoles), so his observations probably aren’t far from the ground truth of the situation.

It is interesting to see Sony has implemented the rectangular spiral ‘grooves’ on the heatsink that interfaces with the AMD APU as in some ways it goes against conventional cooling wisdom. Extreme overclockers and tuning enthusiasts sometimes spend a lot of time ‘lapping’ the processor surface and making sure the heatsink is just as polished and flat - but liquid metal has shifted the goalposts. Sony must surely have A/B tested this new heatsink vs a mirror-smooth one and found it a worthwhile thermal design change to implement.

With the PS5 Pro's boost in processing power – the much beefier GPU in particular - we assume these heatsink ‘grooves’ are one of the changes made to keep the specter of thermal throttling at bay.

The PS5 Pro was officially unveiled in early September but only started to become available to consumers earlier this month. Enthusiast and expert teardowns are still uncovering the secrets of the new design, but we learned most of the technical details from lead architect Mark Cerny during a launch live stream.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

hotaru251 ReplyIf you’ve ever tried to evenly spread liquid metal, you will probably be aware that the material likes to form pools

have these people learned how to apply liquid metal? If you have pools you are leaving too much on.

you apply thin layer (not enoguh to have pools) to both surfaces so when they touch they stay put via tension of the liquid state & if you are moving it maybe a barrier around it (laptop makers do this)

Extreme overclockers and tuning enthusiasts sometimes spend a lot of time ‘lapping’ the processor surface and making sure the heatsink is just as polished and flat - but liquid metal has shifted the goalposts.

liquid metal hasn't shifted the goalpost else you'd see these professionals in the industry actually doing it..they literally experiment because any advantage can get them record. -

uplink-svk LM is yesterday news. Just use PTM or graphene with high pressure. Yes, You'll have lower heat transfer effeciency, but it'll never decay and You'll have 0 issues using PTM and only conductivity and requirement of high pressure with graphene.Reply

Applying LM correctly using machine is close to impossible and according to the residue around the cold plate base of LM in the photo it was standardly overapplied. It requires a really thin application without any pools and overly thick places, whilst keeping the surface homogeneous without as little as possible/any interruptions. You need to sacrifice a person and a 3 - 5 minutes of time for correct application on both surfaces, which is impossible for the amount of products required made on the production line.

Just use graphene and/or PTM in the next revision/generation.

LM degrades after 3 - 5 years anyway regardless of the quality of LM, so all the PS5's are practically thermal disaster ticking time bombs. Corrosion, drying out and a really bad heat conductivity will be the least of the problems after 5+ years without correct cleaning and re-application of new LM. -

bit_user Reply

I guess PTM is in reference to this, but I'm still puzzled by the fact that it's not PCM (Phase Change Material):uplink-svk said:LM is yesterday news. Just use PTM or graphene with high pressure. Yes, You'll have lower heat transfer effeciency, but it'll never decay and You'll have 0 issues using PTM and only conductivity and requirement of high pressure with graphene.

https://www.thermal-grizzly.com/en/phasesheet-ptm/s-tg-ps-50-40

Do you have any insight or background to share about this material? -

bit_user BTW, this makes me even more grateful I waited for the respin of the original PS5 on TSMC N6 (1200 series model numbers). Hopefully, that version of the SoC reduces thermal output enough to mostly skirt these issues, although I can tell you I'm not happy about how much power the machine still uses at idle. I'm also not too worried, since I'm not a serious gamer and mostly just use it as a glorified streaming box.Reply

idle: 51 W

video streaming: 72 W

standby: 3 W

off: < 0.1 W

BTW, I did forget to unplug the USB keyboard, which might've still been drawing a little power during standby. -

Notton I can't believe they didn't use PTM7950.Reply

He also reckons it slightly increases the contact surface area.

Yes, it increases surface area

But not in a meaningful way.

I'd reckon it's detrimental to performance because it created a large gap that needs to be filled with more liquid metal.

That's how the ultra low quality heatsinks were in the early days of computing. Huge gaps left over by machining marks. -

Notton Reply

Honeywell has a PCM series.bit_user said:I guess PTM is in reference to this, but I'm still puzzled by the fact that it's not PCM (Phase Change Material):

https://www.thermal-grizzly.com/en/phasesheet-ptm/s-tg-ps-50-40

Do you have any insight or background to share about this material?

No idea why they changed it to PTM for 5000, 6000, and 7000 series.

It turns out there is even a paste form of PCM called the LTM.

https://advancedmaterials.honeywell.com/cn/en/products/semiconductor-materials/thermal-management/phase-change-materialshttps://prod-edam.honeywell.com/content/dam/honeywell-edam/pmt/oneam/en-us/electronic-materials/thermal-interface-materials/documents/pmt-am-brochure-tims-2608-english-final-9-6-2022.pdf?download=false -

bit_user Reply

I suspect it's due to cost. For a product with sales volumes potentially into the tens of millions of units, they need the cheapest reliable solution that's adequate to the need. Any cooling performance over and above that is of negligible value to them.Notton said:I can't believe they didn't use PTM7950.

And since they already seem to have experience dealing with liquid metal, I assume they're content just to find incremental improvements that mitigate the downsides. If the grooves are cast (i.e. not machined), they could come at zero additional cost.

For a TIM with lower thermal conductivity, you'd be right that the effect of the gap is worse than the benefits of increasing surface area. However, for Liquid metal, this might not be the case. If the liquid metal's thermal conductivity is comparable to that of the heatsink, then it could be a wash (or even a win) to increase the surface area.Notton said:Yes, it increases surface area

But not in a meaningful way.

I'd reckon it's detrimental to performance because it created a large gap that needs to be filled with more liquid metal. -

raminpro use liquid metal or thermal paste is stupid(after 3-4 year they turn solid and little heatsink hit, movment couse it break and temp go high) , best way is Solid pad , thermal pad like thermal grizly padReply -

uplink-svk Reply

I use both. Graphene requires high pressure. In low pressure scenario it performs poorly . PTM from TG is great, but requires a bit more skill not to damage the pad when You're peeling down the protection foils. They're on both sides.bit_user said:I guess PTM is in reference to this, but I'm still puzzled by the fact that it's not PCM (Phase Change Material):

https://www.thermal-grizzly.com/en/phasesheet-ptm/s-tg-ps-50-40

Do you have any insight or background to share about this material?

Regarding performance PTM is better by 1 - 2°C when Kryosheet is applied correctly.