Cooler Master Builds World's Thinnest Vapor Chamber

Just slightly thicker than human hair.

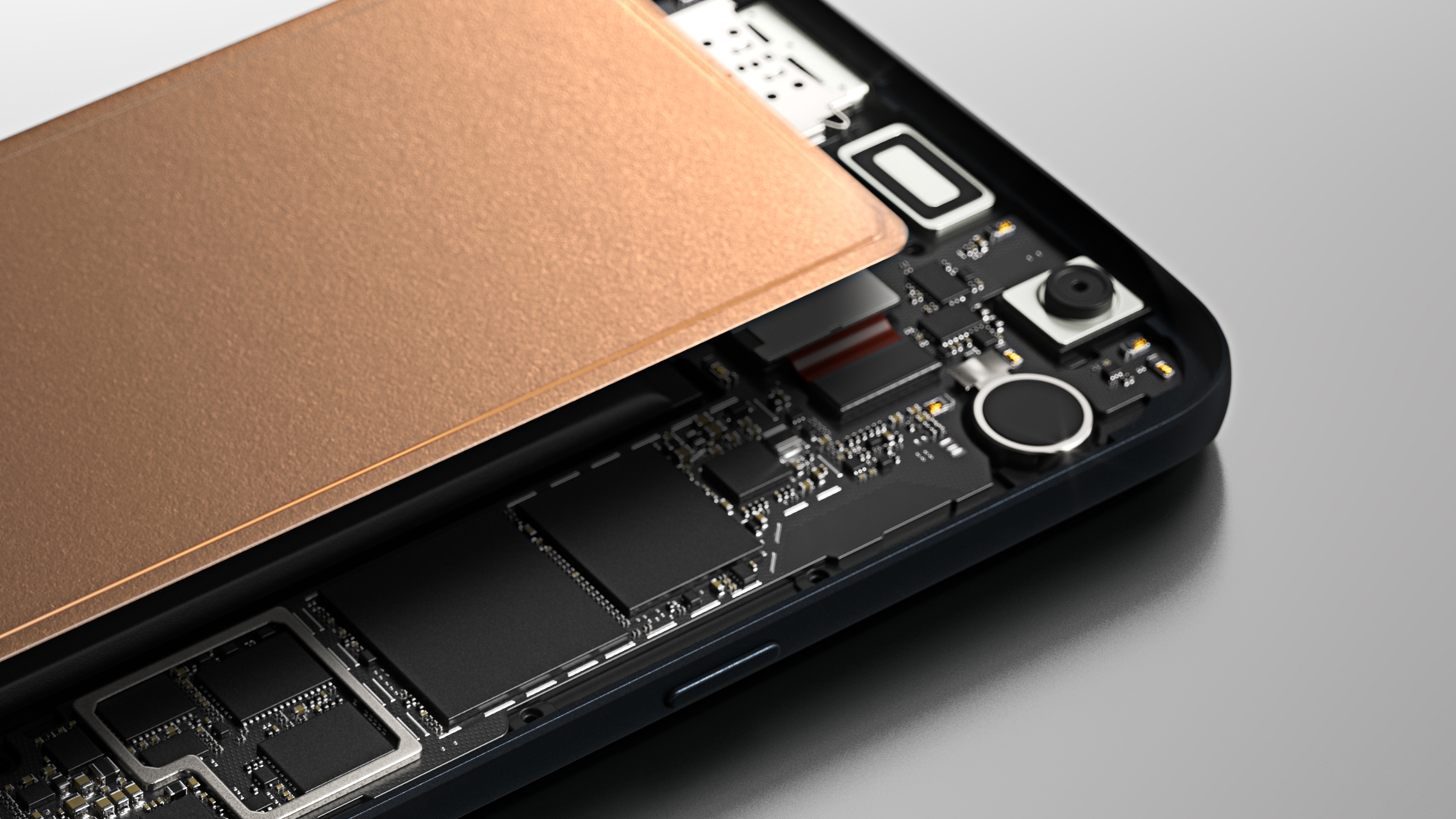

Cooler Master, in partnership with Murata, is developing the world's smallest vapor chamber cooler, which is just a little thicker than human hair. In other words, that's just 200 micrometers tall. This vapor chamber is planned to be a full replacement for standard heat pipe air coolers in devices such as smartphones, tablets, and laptops.

Cooler Master noted in its reveal that microchip processors, whether that be CPUs, chipsets, GPUs, or other types of processors, are becoming so small that conventional cooling is becoming inadequate for them. More specifically, coolers that use regular heat pipes are becoming incapable of transferring enough heat away from our modern tiny microchip processors, simply because they are too large.

This is mostly a problem in more compact devices, like phones, tablets, and laptops. For now, at least, standard desktop computers don’t really have this issue, since they don’t have the same size constraints as other devices.

The new vapor chamber cooler from Cooler Master aims to solve the problems of conventional cooling on small devices by using vapor chamber technology instead of heat pipes. The beauty of vapor chambers is that they use liquid instead of air alone to cool heat source. Liquid has more mass than air, allowing it to soak up more energy (i.e. heat).

Vapor chambers work in a similar way to water cooling in that the cooling system is filled with a fluid that is responsible for transferring heat away. When the fluid makes contact with a lot of heat, it turns into a vapor causing the mass to move in another direction, preferably where a heatsink is located. Once that vapor cools off, it turns back into liquid causing the fluid to change direction.

In layman's terms, the liquid in a vapor chamber cooler acts like its own pump in a liquid cooling system, flowing mass from the heat source to the cooling source and back to the heat source.

But, the biggest benefit with Cooler Master’s ultra thin vapor chamber cooler is its 200 micrometer size. It's so small that it's almost guaranteed to fit in any device you can think of, whether that be a smartphone, tablet, 2-in-1 laptop or anything else that requires a very thin cooler.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Cooler Master and Murata will be cooperating in building this new heatsink device, and Cooler Master will go out of its way to build brand new testing facilities with the same conditions as Murata’s facilities to ensure development goes smoothly. The testing facilities will be completed in the second half of 2021 so depending on how the development and testing goes, we could see a product release sometime in 2022 or 2023.

Aaron Klotz is a contributing writer for Tom’s Hardware, covering news related to computer hardware such as CPUs, and graphics cards.

-

Eximo Yes, something to fill in the surface gaps. Either a very thin thermal pad or a thermal compound. I imagine compound between the ICs and the chamber and a thermal pad on the other side to carry it to the body of the phone/tablet.Reply -

Endymio From the article:Reply

The beauty of vapor chambers is that they use liquid instead of air alone to cool heat source. Liquid has more mass than air, allowing it to soak up more energy (i.e. heat)...

Sheeze ... there are at least three separate factual errors in the above statement. The largest, of course, is that heat pipes don't use "air"; they use a heat transfer liquid just like a vacuum chamber. You can in fact think of a vacuum chamber as a big flat heat pipe. -

zodiacfml false background information on VP, could have easily copied the facts from a good source. I don't know about this thin VP, performance advantage could be negligble due to less liquid available, might as well go with a copper sheet since cooling is limited by the surface area of the device.Reply -

Endymio Reply

You've forgotten that convection trumps conduction.zodiacfml said:...might as well go with a copper sheet since cooling is limited by the surface area of the device. -

cryoburner If it were just a thin copper sheet, you would have a hot spot directly behind the chip, with significantly less heat reaching the outer edges. A vapor chamber should allow the heat to get distributed more evenly. And it's not like vapor chambers and heat pipes contain much liquid anyway. It's mostly a vacuum inside them, with a residual amount of liquid vaporizing into a gas and recondensing to carry the heat elsewhere.Reply

I suspect these things would be fragile, considering how thin they are. Perhaps they could be permanently adheared to the back side of a device's shell to increase their rigidity though. -

Co BIY Using these as the fins of an air cooler might be very interesting.Reply

How to get useful capillary pull to the hot spots seems like a challenge to me -

cryoburner Reply

It would probably be a bit too fragile for that. And too expensive to make for a viable product. Having it transfer its heat to a traditional fin stack would likely make more sense, but being thin wouldn't exactly serve much purpose for that. I also suspect that the thinness of this vapor chamber may limit the amount of heat it can transfer quite a bit, so it might not be suitable for something like desktop CPUs.Co BIY said:Using these as the fins of an air cooler might be very interesting.

One thought I had would be to integrate a vapor chamber into the heat-spreader of a processor though. Chiplet-based designs have very little contact area between the cores and the overlaying heatspreader, which can limit their ability to transfer heat to a cooler. A vapor chamber under the heat spreader could potentially disperse that heat more evenly. -

Eximo I like that heatspreader idea, but I imagine that a more traditional vapor chamber would serve that purpose. Certainly an interesting experiment. I wonder if anyone has gotten a vapor chamber and slapped it on to a threadripper.Reply