Cubic Boron Arsenide Promises 10x Better Heat Dissipation for Chips

The best semiconductor in existence - in a few decades' time.

A team of researchers from the Massachusetts Institute of Technology (MIT), the University of Houston, and others may have just stolen a glance at the future of computing. And according to their report, published in Science, it looks much less silicon-based than we might think. Scuttle over, silicon. Cubic boron arsenide is here with lower temperatures, better electrical conductivity, and improved performance that could thus soar alongside compute density.

However, as these things usually go, we're likely talking decades of research before an actual product - let alone a new age of semiconductor manufacturing - can be brought to etch. Silicon's dominion on almost all things compute - from the processor inside your calculator through the world's most powerful supercomputer - is too entrenched in decades of expert problem-solving to be dislodged that fast. The same isn't true of boron arsenide, which still has to prove its operational longevity.

The issue with silicon is that it's a compromise. It is a laughably bad thermal conductor - which is part of the reason why our electronics heat so much that one could cook an egg on a CPU if we so chose. Silicon also only really has a good handle on the negatively-charged electrons - whose ordered movement, as you might have learned in school, is what electrical current is made of. "Holes" - electrons' positively charged inversions - don't gel so well with silicon. Despite these hiccups, silicon is abundant and relatively easy to manufacture.

Cubic boron arsenide (c-BAs) - made out of boron and arsenic - fixes both of silicon's problems. It's equally accommodating of electrons and holes, leading MIT professor of mechanical engineering Gang Chen to call it "really unique" in the world of semiconductors. “That’s important because of course in semiconductors we have both positive and negative charges equivalently. So, if you build a device, you want to have a material where both electrons and holes travel with less resistance,” Chen said.

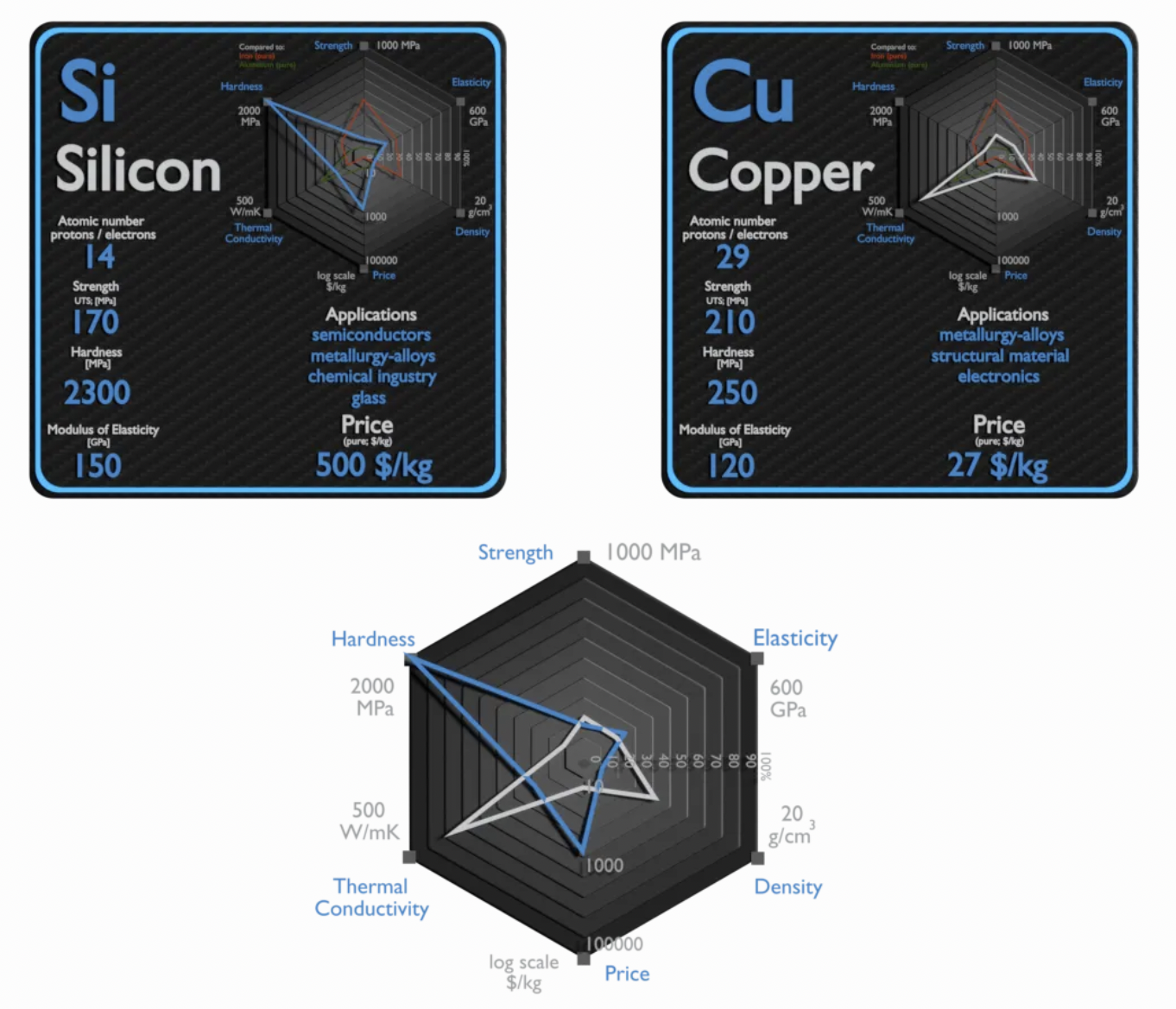

It also conducts thermal distress up to 10x better. This means heat dissipates much faster from its surface - much faster, actually, than it does even in copper, the element of choice for your aftermarket cooling solutions. While silicon has a typical 148 W/mK thermal conductivity, copper improves that by a factor of three, at 401 W/mK. The researchers' cubic boron arsenide, on the other hand, can dissipate heat around the 1200 W/mK mark. It's like comparing the Little League against its bigger, badder, more competitive MLB brother.

“This is impressive, because I actually don’t know of any other material, other than graphene, that has all these properties,” Chen added. “And this is a bulk material that has these properties.”

“Heat is now a major bottleneck for many electronics,” said MIT postdoc Jungwoo Shin Shin, the paper’s lead author. “Silicon carbide is replacing silicon for power electronics in major EV industries including Tesla, since it has three times higher thermal conductivity than silicon despite its lower electrical mobilities. Imagine what boron arsenides can achieve, with 10 times higher thermal conductivity and much higher mobility than silicon. It can be a gamechanger.”

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

By all current accounts, boron arsenide is the ideal semiconductor. The issue with boron arsenide is that it's exceedingly more difficult to produce than silicon. So far, only lab-scale production runs of the compound have been made. The batches aren't uniform, either - further muddying up the waters for an eventual adoption as a mass-transformable semiconductor. The researchers currently aren't sure whether it can be harnessed in a practical and economical form. Likely, it wouldn't be as ubiquitous as silicon in the computing world. Still, it could be used for critical, particularly heat-producing components or even as a heat transfer medium embedded into silicon designs.

“Silicon is the workhorse of the entire industry,” says Chen. “So, OK, we’ve got a material that’s better, but is it actually going to offset the industry? We don’t know.”

So perhaps silicon doesn't need to break a sweat anytime soon (although, being a poor conductor as it is, it probably will anyway). But even as power efficiency and compute density hit materials bottlenecks - especially as we enter the Angstrom era of computing - maybe it does need to worry about sharing the world's stage.

Francisco Pires is a freelance news writer for Tom's Hardware with a soft side for quantum computing.

-

Kamen Rider Blade I want to CNC a new IHS for my CPU along with Heat-Pipe Fan units using this Cubic Boron Arsenide.Reply -

Jchang647 It’s not just the thermal conductivity of the bulk semiconductor material, but also at the interface to heat sink or spreader. An oxide layer always forms on exposed metal. Special techniques are necessary to remove the oxide layer and bonding to the heat sink.Reply

also , isotopically pure Si 28 has much better thermal conductivity than natural. A company tried this 20years ago -

Exploding PSU I like this article, it's well written. I can understand all the science parts even though this isn't a field I'm familiar with.Reply

This piece made me hyped for a technology that probably wouldn't even arrive in my lifetime.

Kudos to the writer. -

InvalidError Better thermal performance is nice, but how is the wallet performance? I doubt very many buyers will be interested in chips with 3X better junction-case thermal resistance (the substrate's 1200W/mK still dumps into copper or whatever the case is made of at 400W/mK or worse) if the chips cost 10X as much to make for the same electrical or compute power.Reply