Adding ceramic powder to liquid metal thermal paste improves cooling up to 72% says researchers

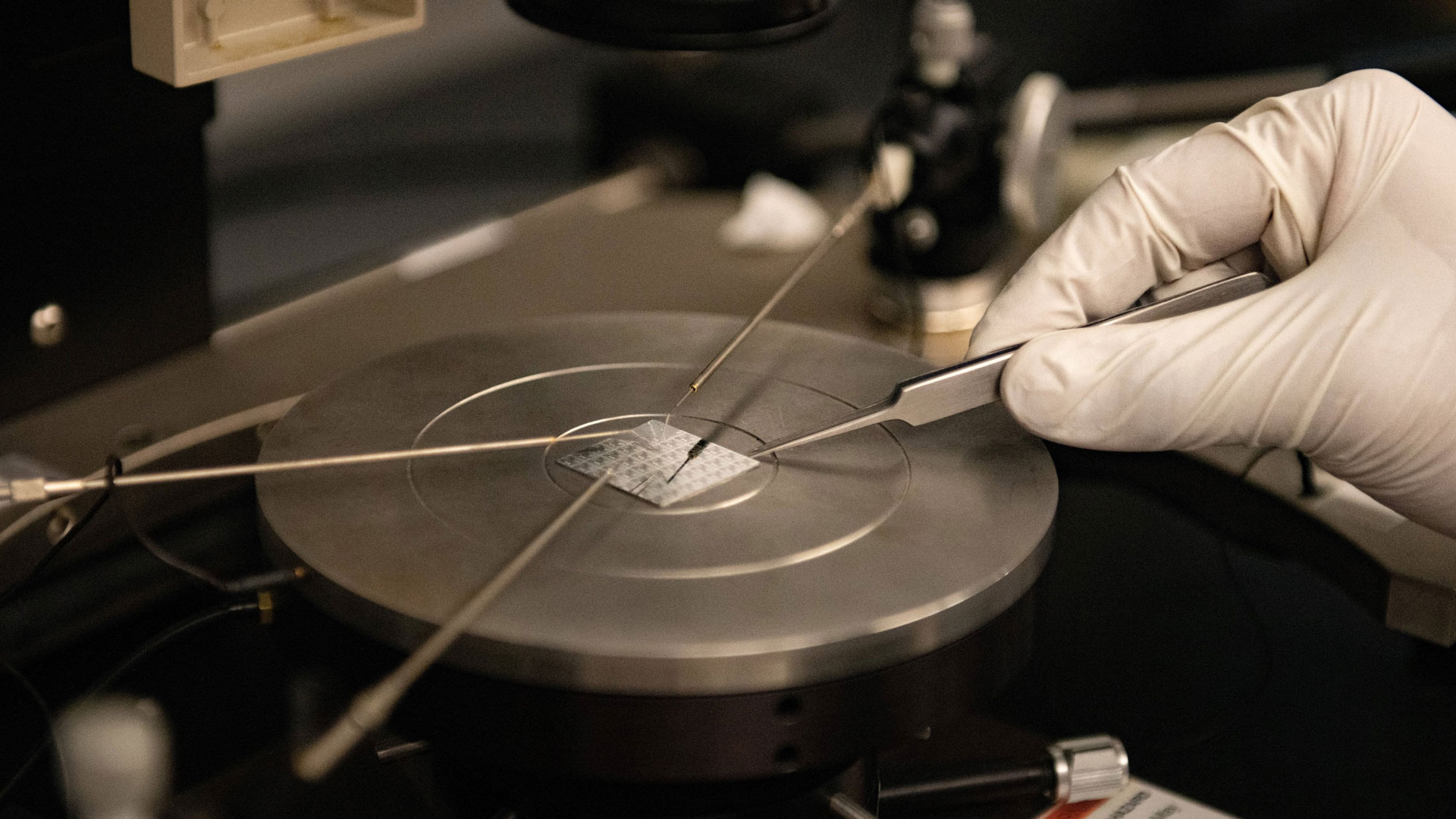

Researchers mix Galinstan alloy with ceramic aluminum nitride using mechanochemistry tech.

A new colloidal thermal interface material (TIM) promises to significantly outperform commercially available liquid metals like Thermalright, Thermal Grizzly, and Coollaboratory products. Researchers at the Cockrell School of Engineering, part of the University of Texas, summarize their new invention as a mechanochemistry-engineered mix of Galinstan alloy and ceramic aluminum nitride. The bottom line is that the new TIM can outperform the best commercial liquid metal alternatives by between 56% and 72%, highlights Golem.de.

According to the researchers, the new TIM could reduce the cost and complexity of cooling power-hungry systems. “The power consumption of cooling infrastructure for energy-intensive data centers and other large electronic systems is skyrocketing,” noted Guihua Yu, professor in the Cockrell School of Engineering’s Walker Department of Mechanical Engineering and Texas Materials Institute. “That trend isn’t dissipating anytime soon, so it’s critical to develop new ways, like the material we’ve created, for efficient and sustainable cooling of devices operating at kilowatt levels and even higher power.” The scientists go on to underline the fact that around 40% of a data center's energy expenditure is on cooling.

A key cooling performance figure shared by the researchers is that the new TIM can cut the energy needed for the cooling pump by 65%. Its performance is such that it “can enable sustainable cooling in energy-intensive applications, from data centers to aerospace, paving the way for more efficient and eco-friendly technologies,” said Kai Wu, lead author in Yu’s lab. It is expected to be a compelling solution in AI data centers.

The major difference with this new TIM is how it is made into a colloidal substance using mechanochemistry. Basically, a liquid metal alloy called Galinstan (gallium, indium, and tin), is mixed with microscopically dispersed insoluble particles of ceramic aluminum nitride. A mechanochemistry technique ensures the optimal dispersion of the ceramic in the liquid metal – resulting in its attractive thermal properties.

Golem.de, which seems to have accessed the full scientific paper, notes that the researchers “achieved heat transfer resistances that were between 56 and 72 percent lower than the best liquid metals.”

Unsurprisingly, the Texas-based boffins frame the new thermal material as a great solution for energy-hungry data centers. However, their awareness of the commercially available liquid metal TIM products that are popular among PC enthusiasts is encouraging – it should speed the new colloidal TIM into the hands of Tom’s Hardware readers. In other words, we hope the researchers’ mention of brands like Thermal Grizzly will mean this new TIM’s manufacturing method and ingredients can be commercially licensed sooner rather than later.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

rluker5 Aluminum nitride is still a thermal insulator compared to copper so if it makes the mixture considerably thicker than just liquid metal the gains won't be especially big.Reply

Also Aluminum Nitride powder is pretty expensive. If it was close to boron nitride prices then I might have checked this out. -

Hooda Thunkett Is it just me, or does "mechanochemistry" sound like marketing-speak for "grad student go smack-smack-smack!"Reply -

dwd999 But is this mixture electrically non-conductive, which many thermal paste users prefer?Reply -

hotaru251 Question would be longevity of drying outReply

...its liquid metal w/ ceramic mixed in....its still metal and thus conductive same as liquid metal.dwd999 said:But is this mixture electrically non-conductive, which many thermal paste users prefer? -

JohnyFin This is very know physic mechanism knowledge since hundred year? Used very often for creating subzero liquids.Reply -

TJ Hooker Reply

Nope, galinstan (or similar) alloy. https://en.m.wikipedia.org/wiki/GalinstanFuzzwood said:Liquid metal, so... Mercury? -

_Shatta_AD_ You know everytime I read an article about some new tech breakthroughs claiming they could make things cheaper whether it be through manufacturing cost, longevity of the item, mass production or some otherworldly methodology, it’s never turned out to be true for the consumer when the item comes to market. Even if the person(s) making the breakthrough wish it to be true, the supply chain ensures it’ll absolutely not. Everyone know ‘new’ and ‘improved’ is where the money’s at and even if it turns out to be a flop in reality, marketing will work overtime to convince you otherwise. World of capitalism and corporate greed baby!Reply -

_Shatta_AD_ Closest thing I could think of that comes close to being true would be TLC NAND tech, and even that took ages, a whole decade at least before it approaches the initially promised cost. This of course doesn’t even take into account the unpredictability and issues that arise from the new tech. PLC you say? Maybe try 2027 for mainstream use 😂Reply