HRDs Faster than SSDs and HDDs

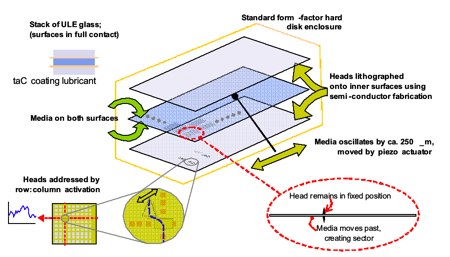

British researchers may have created the evolutionary step between current hard drives and solid state disks. Called the Hard Rectangular Drive (HRD), this new device primarily consists of three components: a double-sided "platter" of magnetic material mounted between two laminate read-write "heads" like a thin sandwich. All three components--joined by additional sets of three above and below--are lubricated and housed within in a standard 3.5-inch drive casing.

According to Register Hardware, the read-write layers actually comprise of millions of read-write heads aligned into a grid; the layers use the same lithography process used to make silicon chips. A signal is passed along the corresponding column and row in order to control a specific head. However, it's the magnetic middle layer that actually moves horizontally--accomplished by using piezo-electrics--that allows the stationary head to read the designated sector.

DataSlide, the group behind the research, said that the current version features 64 heads that can read or write simultaneously. Eventually, the technology will be able to achieve 160,000 random read/write IOPs (Input/Output Operations Per Second) and a 500 MB/sec. transfer rate. The HRD only uses 4W of power, a third of the power consumed by HDD, half of the typical SSD.

DataSlide is currently working on the new technology for commercial use, with plans to license the technology to storage manufacturers and other companies. Currently DataSlide is unable to provide a street date.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Kevin Parrish has over a decade of experience as a writer, editor, and product tester. His work focused on computer hardware, networking equipment, smartphones, tablets, gaming consoles, and other internet-connected devices. His work has appeared in Tom's Hardware, Tom's Guide, Maximum PC, Digital Trends, Android Authority, How-To Geek, Lifewire, and others.

-

Ciuy wow finally something better then SSD, i hate ssd.Reply

If this is atleast the same price as SSD , well bye bye ssd. -

eklipz330 i call the bullshit card.Reply

this information sounds like its being pulled from someone's ass, and if this does go through anytime before ssd's manage to take over the market with insane GB read/write speeds, i doubt it'll last too long.

and besides Hard Rectangular Drive (HRD) sounds a bit generic. Solid State Drive sounds the way of the foooooturee!!! -

cl_spdhax1 This is new news? I seen these drives around when I had my flux capacitor working..Reply -

fabolous ReplyThe HRD only uses 4W of power, a third of the power consumed by HDD, half of the typical SSD.

What "typical" SSD uses 8W of power? My 64GB Samsung SLC draws 1W at load and a mere 0.3W at idle. The more consumer-centric, "typical", SSDs max out at around 2W at load. So...where is this silly number coming from? -

I also call shenanigans. Apparently the HRD needs 4 watts, half of what an SSD needs. What kind of mainstream SSD consumes 8 watts? Eventually, an HRD will speed along at 500 MB/s. By the time this happens, SSDs will have saturated the SATA 6.0Gbps link.Reply

The only way this thing ever makes it to market is if it can offer MTBF's in the 100-million-hour range, and i seriously doubt that is possible given the mechanical nature of the middle medium in motion.

This would be a great idea if there were no such thing as a solid-state disk. -

Belardo The concept of this drive is "good", but its timing is BAD. If it came out about 10 years ago, it would be amazing. But this HRD wouldn't hit the market for 3~5 years, at best considering its at the prototype stage.Reply

In 3 years, 512GB SSDs should be well under $100 if the capacity and price scales the same as Flash drives. Currently, the 64GB drive is $150~225. 128GB are $225~350. And then theres SATA3 to allow even faster drive.

The grand-daddy SSD? The PCIe Drives which can transfer about 1500mb a second, these start at about $1500+ Imagine having such a drive for under $500, Windows7 (or 8) will boot in about 5 seconds on a bad day.

-

Tindytim ReplyEventually, the technology will be able to achieve 160,000 random read/write IOPs (Input/Output Operations Per Second) and a 500 MB/sec. transfer rate.

SSDs can already do that, just look at the ioDrive. Eventually, they'll be consumer products. -

Ciuy the ioDrive is an SSD on steroids and btw that costs like what? 15000$ ? i forgot anyway something no1 will buy....Reply

theres always something better but its price is outrageous. You can get a 100$ CPU Beat a 500$ CPU with the liquid cooling and stuff but no1 wants that cause its outrageous expensive. io is crap