GeIL Announces New Intense Memory Burn-In Technology

Memory maker GeIL has announced a new process that it claims will significantly reduce the number of memory modules that suffer from early failure. “Early failure” describes the malfunction of memory (and other electronic components) long before their expected demise.

GeIL calls the new process “Die-hard Burn-in Technology.” The process is designed to expose memory modules to enhanced stress before leaving the factory, thus (in theory at least), forcing weak chips to fail before they’re shipped to customers.

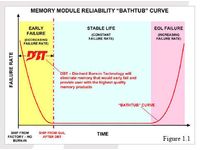

Premature component failure can be described using a “bathtub curve”

As GeIL explains “the conventional way of memory module burn-in is done by regular market-available motherboards with limited module accommodation and burn-in time of approximately20 minutes under room temperature... (further) each of the motherboard-based burn-in platforms requires manpowered monitoring. Therefore, the burn-in process… has not been fully utilized in improving the overall memory quality.”

Of course, that doesn’t explain every memory manufacturer’s procedure perfectly. For example, Corsair states that its Twin XMS modules are tested and packaged together, to ensure that they’ll work well together. Still, compared to current testing procedures, GeIL’s “Die-hard Burn-in Technology” (“DBT”) seems quite intense:

“The DBT process is conducted in the custom-made burn-in chamber – DBT-1, testing up to 1000 pieces of modules simultaneously. The modules are slotted onto custom-made boards in place of regular motherboards with GeIL’s own designed burn-in testing software and user interface. The DBT-1 is able to elevate temperature up to 100 degrees Celsius with burn-in time of as long as 24 hours aging modules to at least three months.”

GeIL’s DBT Logo will appear with memory that has endured DBT testing

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

We fully understand the usefulness of stressing electronic components with high temperatures and high voltages, but we have to wonder if 100 degrees Celsius, the boiling point of water, might be a little excessive. However, the most important question here seems to be “What kind of real life results will GeIL’s new technology create?” The new process could end up leading to a new breed of memory that almost never fails before its time. It could also raise prices by causing otherwise healthy memory to be discarded because the testing procedure is unrealistically intense.

Right now, all we have is speculation, and the memory experts that we contacted for their opinion were unwilling to publicly engage in speculation regarding GeIL’s new technology. One thing is certain: if it does lead to a new breed of memory, we will be impressed.

-

mfineman 1. Missing from the bathtub curve is a scale, so oneReply

wonders what the areas under the curve for the initial

period is and for the flat part. (Are we talking

1% in 3-months? How about the time scale: 1 year, 5 years,

100 years?

2. As the article touches on, does running at 100 C significantly

affect the total failures during the flat part of the curve

or the lifetime of the product? -

mr roboto Geil makes good memory. I had two GB of DDR-2700 from them in my Athlon 64 system. Very stable and overclocked very well for relatively inexpensive memory. I have since gone with Corsair but wasn't real impressed. Unless you buy the expensive Corsair memory it doesn't overclock well in my experience. Their higher end RAM is way overpriced and rarely dips below MSRP. I'd say for the best price\performance I'd go with Crucial or Kingston. Just my two cents.Reply -

liemfukliang Hopefully Geil make DBT for all their product line up, not just for their flagship.Reply