Some RTX 3080, RTX A6000 GPUs Are Prone to Vapor Chamber Cracks: Report

Question is, how widespread is the issue.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

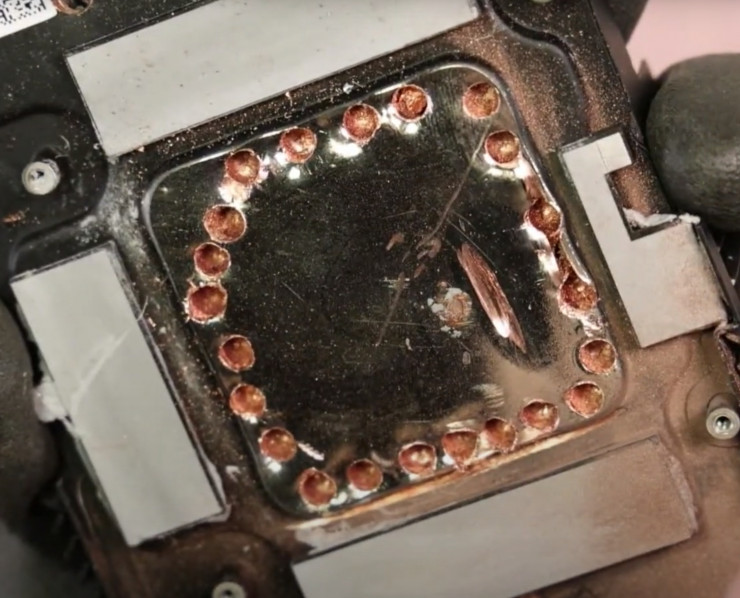

A recent investigation by a Quasarsone forum member revealed significant defects in the vapor chamber heatsinks of Nvidia's GeForce RTX 3080 Founders Edition and RTX A6000 graphics cards (via @harukaze5719). Some heatsinks oxidize and leak. It is unclear how widespread the issue is and whether this only happens in specific conditions.

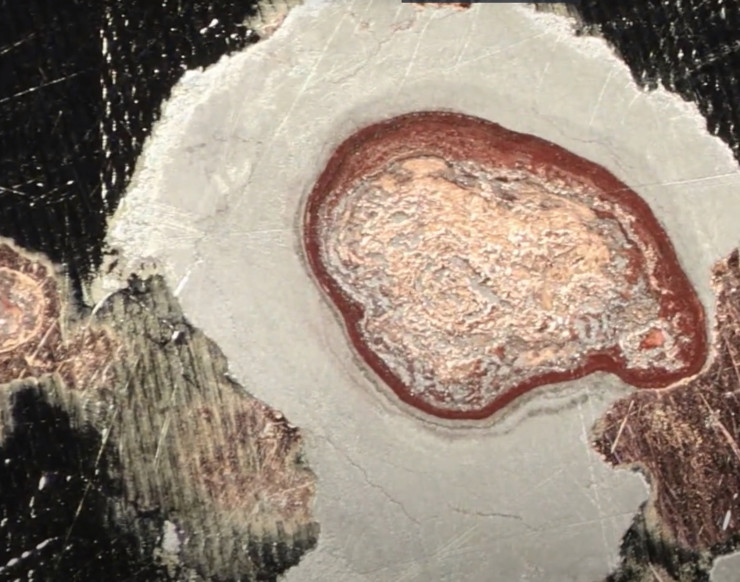

The study identified unusual chemical reactions and physical deformities within the heatsinks, raising concerns about the cooling solution's efficiency and longevity. As it turns out, heatsinks develop copper oxide formations and holes in the vapor chambers over time, leading to failure and overheating of graphics cards.

The exploration began with disassembling an Nvidia GeForce RTX 3080 Founders Edition, still among the best graphics cards after three years. During this process, peculiar red copper exposures surfaced in the vapor chamber heat sinks. Further examination revealed signs of a chemical reaction and copper appearing as if it had melted.

The forum member then observed an Nvidia RTX A6000 graphics card for ProViz and engineering applications that cost about $4,000 despite being a product released in 2020. The board presented similar issues. This repetition of the unusual copper exposure and signs of chemical reaction suggested a more widespread problem, possibly inherent in the vapor chamber cooling solution employed in these graphics cards.

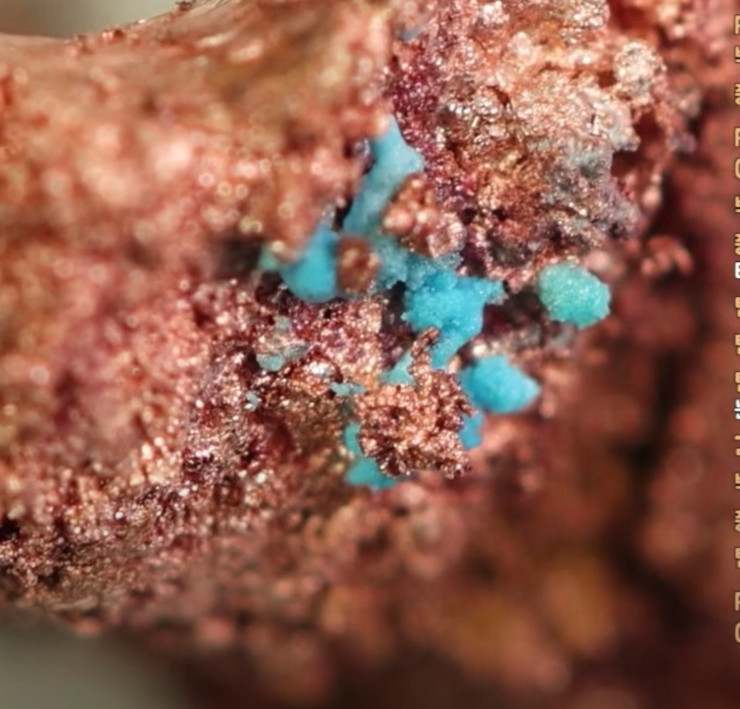

Detailed analysis, including cleaning and magnifying the affected areas, exposed blue substances on the surfaces, presumably copper oxides. This discovery pointed to the possibility of chemical reactions within the chambers, likely involving the copper components. The nature and extent of these reactions seem to suggest a susceptibility to damage and functional impairment due to internal pressures or similar adversities within the vapor chamber heat sinks.

Vapor chambers are functioning through a continuous cycle of evaporation and condensation. A liquid inside the chamber evaporates by absorbing heat from a hot component, like a CPU or GPU, turning into vapor. This vapor then moves to a cooler area, condenses back into a liquid, and releases the absorbed heat and dissipates. Vapor chambers effectively manage high heat loads, ensuring uniform heat distribution and maintaining optimal operating temperatures of chips. Meanwhile, coolants inside vapor chambers are rather tricky substances that can quickly evaporate and condense.

Coolants inside vapor chambers can potentially react with copper, but this is relatively uncommon and typically occurs under specific unfavorable conditions. If there is contamination or impurity in the coolant, or if the integrity of the vapor chamber is compromised (e.g., leaks, cracks, or manufacturing defects), it might facilitate reactions between the coolant and the copper. For instance, copper may oxidize in the presence of oxygen or other reactive substances, forming copper oxides or other compounds on the surface.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

It is unclear whether this is a source of the issue and if it is widespread. After all, we have seen only one report on the matter and have no idea about the conditions leading to the development of copper oxide and holes. Yet, we can only recommend checking the cooling system when purchasing used graphics cards.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

Kamen Rider Blade That hole looks some-what similar to the issues you would experience with normal Copper Pipes in plumbing.Reply

What Causes Pinhole Leaks in Copper Pipes?A common but hazardous plumbing problem exclusive to copper pipes is pinhole leaks. They develop slowly when interior corrosion in the copper pipe works its way through the metal to the exterior, causing tiny holes to occur. Pinhole leaks may go undetected for a long time due to their size, silently worsening the problem and increasing the extent of the damage. They may seem insignificant but can wreak havoc on the plumbing system, increase the utility bills, and cost hundreds or thousands of dollars in repairs.

Before looking for ways to prevent or fix pinhole leaks, it is necessary to understand what causes them. Here are a few reasons why copper pipes can experience pinhole leaks:

If the Distilled water used in the Vapor Chamber isn't perfectly pH balanced neutral to 7.0, there could be damage developing in the long term.

Pitted corrosionPitted corrosion, a localized corrosion type, can cause pinhole leaks in copper pipes. Acidic water slowly corrodes copper, eventually leading to a pinhole leak. Pitted corrosion is usually of three types.

Type one usually occurs in cold water, and the primary cause is hard water with pH levels between 7 and 7.8. It causes deep and narrow pitting, resulting in pipe failure.

Type two is narrower than type one pitting but can also cause pipe failure. It is associated with soft water with a pH below 7.2.

Type three is associated with cold soft water with a pH over 8. The pitting is wide and low and results in pipe clogs and blue water. -

digitalgriffin This is called galvanic corrosion. It happens when you mix two metals. And it's something copper and brass coils/tubing experience when they come in contact with iron/steel. Ships go through something similar with steel and salt water. Aluminum is used as a sacrificial anodeReply

Also same thing that cause water heaters to go bad. Copper pipes corrode. -

Alvar "Miles" Udell The WCCFTech article on this is a bit more detailed, and includes this statement the Tomshardware article does not:Reply

Plus, it is also mentioned that both of these GPUs had their heatsinks removed and had TIM applied on several occasions so they've been through a lot.

So between Covid time manufacturing (which we know can easily be subpar, remember the GPUs which overheated due to thermal pad stickers being left on?) and a rough life, I don't think most people have anything to worry about.

https://wccftech.com/aging-nvidia-geforce-rtx-3080-a6000-gpus-show-rare-symptoms-vapor-chamber-cracks/