Taiwan Government Looks to Protect TSMC Tech from US — Report

Keeping TSMC's best tech at home.

An official from the Taiwanese government said at a news conference that the country would deploy a special team to protect TSMC's technologies and trade secrets as the foundry is expanding to the United States. Sources close to the company reportedly said that the company's fabs in the USA will always be one generation behind those in Taiwan reports DigiTimes.

The Taiwanese government will deploy a team to monitor TSMC's key technologies, as they are important parts of the nation's interest, said Tsung-Tsong Wu, the Minister of Taiwan's National Science and Technology Council (NSTC), according to the report.

It is unclear how this team will operate and whether Taiwan will require TSMC deploy enhanced security measures or even attempt to limit export of certain process technologies or knowhow to the U.S. Yet the minister made it clear that the government wants Taiwan to stay TSMC's stronghold and the global center of contract chip production.

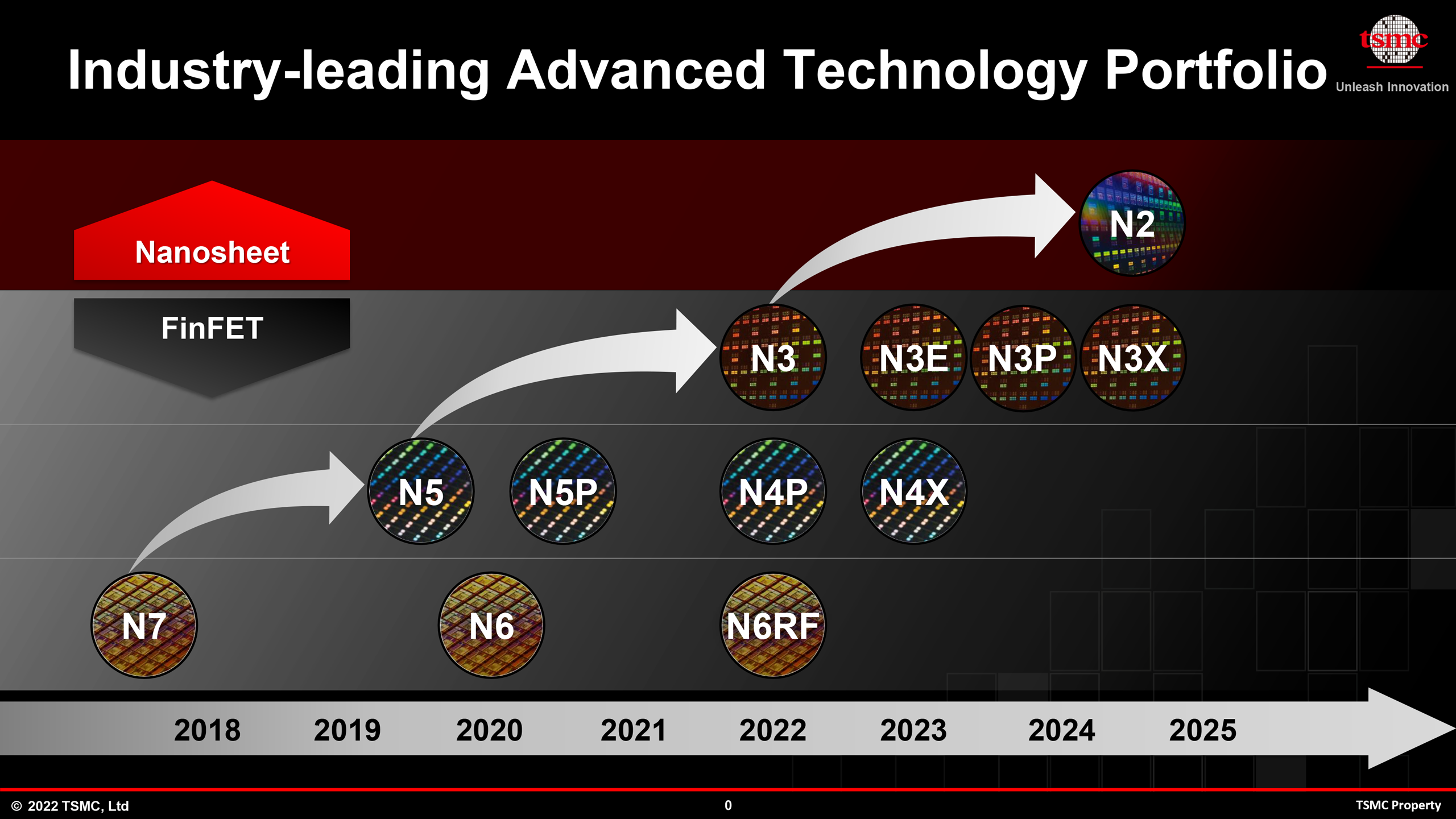

In fact, TSMC itself plans to keep its most advanced production technologies in Taiwan. The company's Fab 21 in Arizona will produce chips using TSMC's N5 (5 nm-class) fabrication processes when it comes online in early 2024. By that time TSMC's manufacturing facility at the Southern Taiwan Science Park near Tainan will be mass producing chips on TSMC's N3 (3 nm-class) manufacturing technologies. Furthermore, when the second — N3-capable — phase of Fab 21 starts operations by 2026, TSMC's fabs in Taiwan will make chips on its N2 node.

"TSMC's U.S. presence will continue to follow the principle of N minus 1," said a person close to the company in a conversation with Financial Times earlier this week. Other sources indicated that the fab in the U.S. will be used to make chips for applications used, among other things, by the U.S. defense industry supply chain.

But process technologies themselves are not the only knowhows that TSMC must protect. The world's No. 1 foundry does not seem to have a program similar to Intel's Copy Exactly, which deploys best known manufacturing practices at different fabs across the world to ensure maximum yields. Therefore, the fabs in the U.S. will be slightly different than the fabs in Taiwan and may not offer the same yield rates as those in Taiwan. Those yield improving techniques unique to each fabs are proficiencies that TSMC wants to protect, whereas Taiwanese government is inclined to keep knowhows applicable to local fabs in Taiwan.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

helper800 Reply

I would liken it to the following. Having / owning a CNC machine is vastly different than knowing how to make use of it.lmcnabney said:What technologies? Aren't the key lithographic equipment all imported from Europe? -

anonymousdude Replylmcnabney said:What technologies? Aren't the key lithographic equipment all imported from Europe?

ASML is Dutch. Their major partner is Zeiss which is German. Then throw in whatever other companies they also contract or subcontract from.

TSMC technologies really just means their know-how. So their process engineering, R&D, etc. Just because you have the same equipment doesn't you know how to use it and use it well. That's the exact issue that any semiconductor fabrication firm will run into. See Intel, Samsung, or the most apt example SMIC.

SMIC has DUV machines, but it took them a long while to build up the knowledge on how to use them to make a 7nm class node. Reports say that it has similarities to the original 7nm node used by TSMC, that also used DUV. That's not a coincidence at all and something that TSMC,like any company, would like to avoid in the future if at all possible. -

lmcnabney Replyanonymousdude said:TSMC technologies really just means their know-how.

That know-how is hardly a secret. There are people with the exact same know-how all over the world. The only thing that Taiwan has is a whole bunch of fabs making and etching wafers. This is not a secret. -

Co BIY Technology transfer is a tricky business. Some of the keys to good performance may not be able to be protected as intellectual property.Reply

OTOH in the US TSMC will have access to the full power of global IP protection. The Taiwanese government and TSMC management may have different ideas about what is wise to move "overseas" because they could have quite different goals. -

Co BIY Replylmcnabney said:That know-how is hardly a secret. There are people with the exact same know-how all over the world. The only thing that Taiwan has is a whole bunch of fabs making and etching wafers. This is not a secret.

Actually building, running and producing at world leading economic scale indicates that they have knowledge others don't. -

lmcnabney Reply

They have dedicated and lower-cost labor and are comfortable handling the environmental impacts of microprocessor fabrication. Western nations have to dole out huge incentives to compete because of the higher labor cost and environmental restrictions.Co BIY said:Actually building, running and producing at world leading economic scale indicates that they have knowledge others don't. -

anonymousdude Replylmcnabney said:That know-how is hardly a secret. There are people with the exact same know-how all over the world. The only thing that Taiwan has is a whole bunch of fabs making and etching wafers. This is not a secret.

By your logic, then Intel, Samsung, and TSMC who all have effectively the same equipment should have node parity right now. And yet they don't. Guess what the difference is? R&D, process engineering, etc. What people would call the know-how. You're discounting how truly complicated the fabrication process is. It's likely the most complicated thing humankind has ever done.

lmcnabney said:They have dedicated and lower-cost labor and are comfortable handling the environmental impacts of microprocessor fabrication. Western nations have to dole out huge incentives to compete because of the higher labor cost and environmental restrictions.

Then what about China? Russia? NK? Any foreign adversary to the US? You think they care about money or would be unwilling to bear the environmental impact if it meant they could have their own chip fabrication? No, it's cause they can't cause they don't have the equipment nor the know-how. -

DavidLejdar TSMC is not really like a sweat-shop, which could be easily replicated at that level of sophistication, as some here seem to be implying. To expand a bit on what some other commenters already pointed out, at that level, there are world-wide only 3 players, TSMC, Intel, and Samsung, who are producing or about to produce with the 3nm process. In comparison, e.g. GlobalFoundries has 12 nm "at best". And for a range of electronics, it doesn't need the most sophisticated semiconductors. But talking e.g. mobile phones, tablets and GPUs, there is a reason why companies such as Apple, AMD, Nvidia and also e.g. Qualcomm are customers of in particular TSMC. The high transistor density simply does a lot for such consumer products. And entering the market with something first, such as TSMC did with 7 nm and 5 nm, that helps a lot to get more orders in, such as e.g. by Apple for the A14 and M1 SoC.Reply

So, while it is technically possible to "catch up", realistically that would require to invest a lot in (successful) R&D for own patents including having the qualified staff for it, then it would also require software development (in particular for the machines), and then about $20 billion for the newest-gen foundry. All in all, quite a different dimension than to simply get a simple sewing machine to start producing T-Shirts with common know-how.

Also, the worldwide median annual compensation for TSMC employees, excluding pensions and benefits, was $56,505 two years ago, and has since been raised reportedly. This median is something even most in the U.S. and Europe wouldn't mind earning. Which isn't to say that some staff in the U.S. wouldn't expect a bit more than that, working e.g. as principal engineer. But it is a quite different situation to a sweat-shop, where the minimum wage e.g. in Bangladesh is way below $1 per hour.