TSMC's Arizona Fab Construction Emerges at Breakneck Speed

Where there's a will (and $10 to $12 billion), there's a way.

TSMC's construction on its latest semiconductor fabrication facility in Arizona is progressing at breakneck speeds. Thanks to the photographic reporting skills of Matt Schrader on Twitter, we can now witness the incredible construction rate for what will soon become one of the most advanced silicon fabrication facilities across the world.

The construction grounds literally went from tumbleweeds to factory shells in under six months, spelling a good pace for the factory's expected spin-up in early 2024. That's what a cool $10 to $12 billion can do, as you can see when you expand the below tweet.

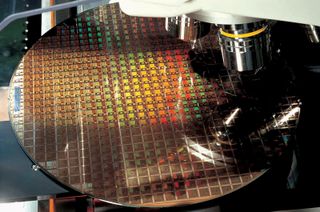

TSMC's Arizona fab, christened Fab21, will occupy at least 1,100 acres of land in Phoenix, Arizona, and will churn out tens of thousands of semiconductor wafers in the 5 nm class for the Taiwanese company's customers around the world (initial output is expected at 20K wafers, just short of the 25K TSMC considers for its GigaFab nomenclature). This includes chips fabricated in the N5, N5P, and even N4 processes.

N5 and N5P have been tapped by both AMD and Apple, powering AMD's already-announced Zen 4 CPUs and chiplet-based RDNA3 GPUs (which are sure to make it into our Best Picks for graphics cards), as well as Apple's evolution of its original Apple Silicon, the M2 SoC (System-on-Chip).

They continue to not be messing around at the TSMC fab site in Phoenix. Less than half a year later. https://t.co/bdGqWDpCFC pic.twitter.com/Ov5GVlumprJune 11, 2022

Naturally, Qualcomm and Nvidia are also prospective clients for TSMC's chips; the former is all but a given, especially considering how it recently moved production of its Snapdragon chips from Samsung to TSMC. It's hard to imagine the company going with another foundry for its upcoming Nuvia Arm-based chips as well, with which the company wants to officially go toe-to-toe against the Intels and AMDs of the world. Nvidia still hasn't confirmed that its next-gen consumer GPUs will use TSMC's manufacturing, but its monstrous, data center-focussed Hopper does.

The Arizona fab is of strategic importance for TSMC's bid to increase its 5 nm output beyond the 25% already planned for 2022. Intel has also become a customer of the Taiwanese manufacturer — Intel CEO Pat Gelsinger recently visited Taiwan in a bid to secure additional capacity for the company's silicon designs.

It's also a bid for the company to insulate its IP and production capacities from geopolitical concerns, considering the proximity of China — where some believe the country should seize TSMC for its treasure trove of technological innovation.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Francisco Pires is a freelance news writer for Tom's Hardware with a soft side for quantum computing.

-

nastastic Construction continues at breakneck speed, but reporting about images from Dec 2021 is not. There are lots of newer images out there. Google Maps has satellite images more recent.Reply

Check out image on this site reported June 3, with 38 cranes now operating ...

https://www.azcentral.com/story/news/local/phoenix/2022/06/03/see-taiwan-semiconductors-north-phoenix-office/7498673001/

All while the Verge reported in Feb TSMC may be experiencing a 3 to 6 month delay due to contruction delays.

https://www.theverge.com/2022/2/15/22935172/tsmc-arizona-factory-fab-construction-delays-semiconductor-shortage

If anyone would like to see a site plan, check out this page:

https://roselawgroupreporter.com/2022/05/major-gas-plant-planned-to-support-phoenix-semiconductor-manufacturing-facility/ -

hotaru.hino Part of me is thinking "well it's probably comparatively easy to set up the exterior and rooms, but once you start bringing in everything, doing all the wiring and plumping, testing the equipment, etc.."Reply -

2+2 Reply

I think China is well aware of when they should hurry up and blockade Taiwan before western fabs come online.peachpuff said:Hurry up before China invades Taiwan...

And, they would take advantage of a weak, compromised President of US.

So, my best guess is within a year. -

olin9 Reply

Too late, they would have had to do that before 2020. But they are using the same language that Russia was using before they stepped in to help, as Russia said.2+2 said:I think China is well aware of when they should hurry up and blockade Taiwan before western fabs come online.

And, they would take advantage of a weak, compromised President of US.

So, my best guess is within a year. -

Dragos Manea It is me or for 6 months isnt so impresive, rising the shells is the easy part, it will take a lot longer the plumbing and electrical installations, lets not say about the equipment itself.Reply -

digitalgriffin ReplyDragos Manea said:It is me or for 6 months isnt so impresive, rising the shells is the easy part, it will take a lot longer the plumbing and electrical installations, lets not say about the equipment itself.

From my reading, standard factory building construction is fairly quick. (As others have noted) Most of the components are made by 3rd parties and are modular in nature. HOWEVER the automation of the machines where wafers are carried station to station takes considerable time to get to run smoothly. "Dialing in" (node refinement) can also take several months. -

Co BIY Getting the fab tools may be the biggest challenge and somewhat outside of their control.Reply

Also building the factory shells requires none of the hiring and cross-cultural challenges that will be involved in TSMC's first major non-Taiwanese production facility. TSMC is somewhat unique in that it is a globally important company without yet being a really "Global Corporation.'" This is a big step in that direction and they know how to execute. -

Why_Me Reply

Russia invaded Ukraine in 2014 and 2022.olin9 said:Too late, they would have had to do that before 2020. But they are using the same language that Russia was using before they stepped in to help, as Russia said.

Most Popular