Enermax D.F. 500W PSU Review

The Enermax D.F. 500W is a fully modular PSU featuring high efficiency, quiet operation, and individually sleeved cables. But are those enough to justify its premium price tag?

Why you can trust Tom's Hardware

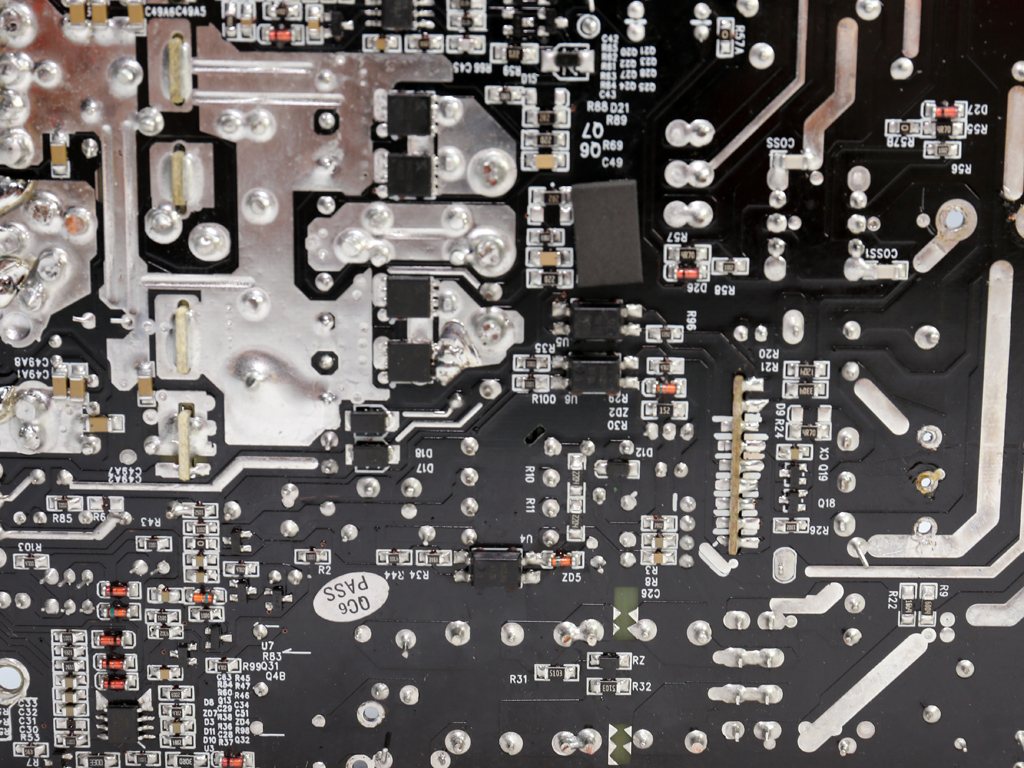

A Look Inside And Component Analysis

Parts Description

Before proceeding with this page, we strongly encourage you to a look at our PSUs 101 article, which provides valuable information about PSUs and their operation, allowing you to better understand the components we're about to discuss. Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station, and a Hakko FR-300 desoldering gun.

| General Data | |

|---|---|

| Manufacturer (OEM) | Fortech Electronics |

| Original Model | Segotep ZP500P-SG |

| Primary Side | |

| Transient Filter | 4x Y caps, 3x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | NTC Thermistor & Diode |

| Bridge Rectifier(s) | 2x |

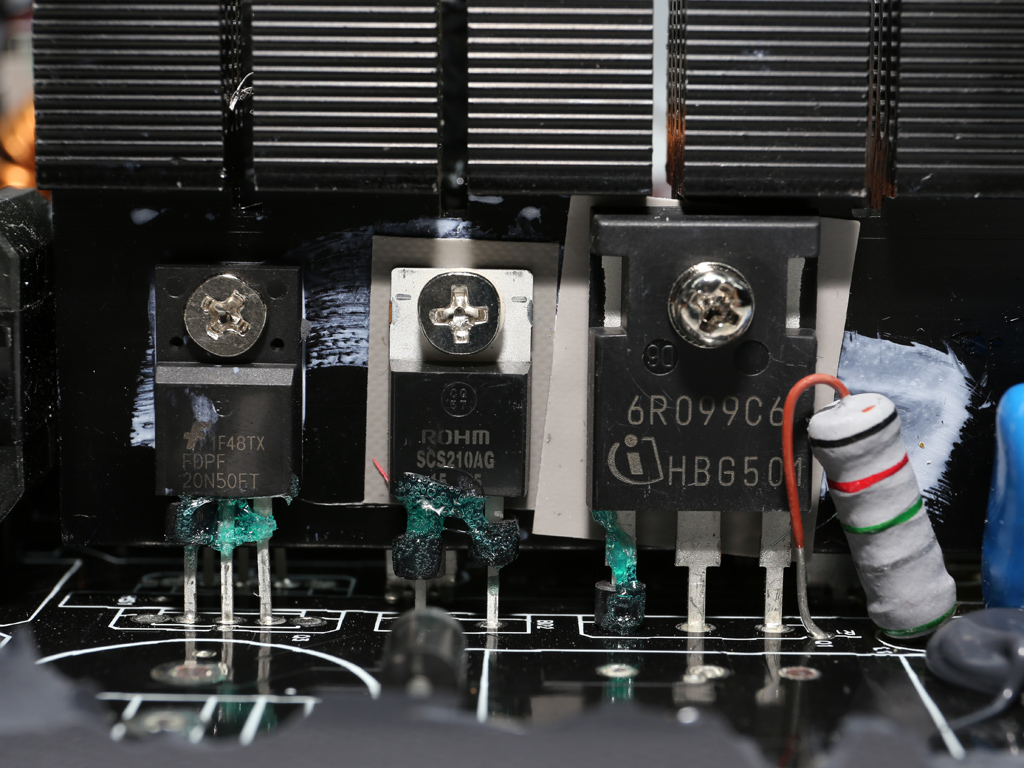

| APFC MOSFETs | 1x Infineon IPW60R099C6 (650V, 24A @ 100°C, 0.099Ω) |

| APFC Boost Diode | 1x SiC SCS210AG (650V, 10A @ 133°C) |

| Hold-up Cap(s) | 1x Chemi-Con (400V, 330uF, 2000h @ 105°C, KMR) |

| Main Switchers | 2x Fairchild FDPF20N50FT (500V, 12.9A @ 100°C, 0.26Ω) |

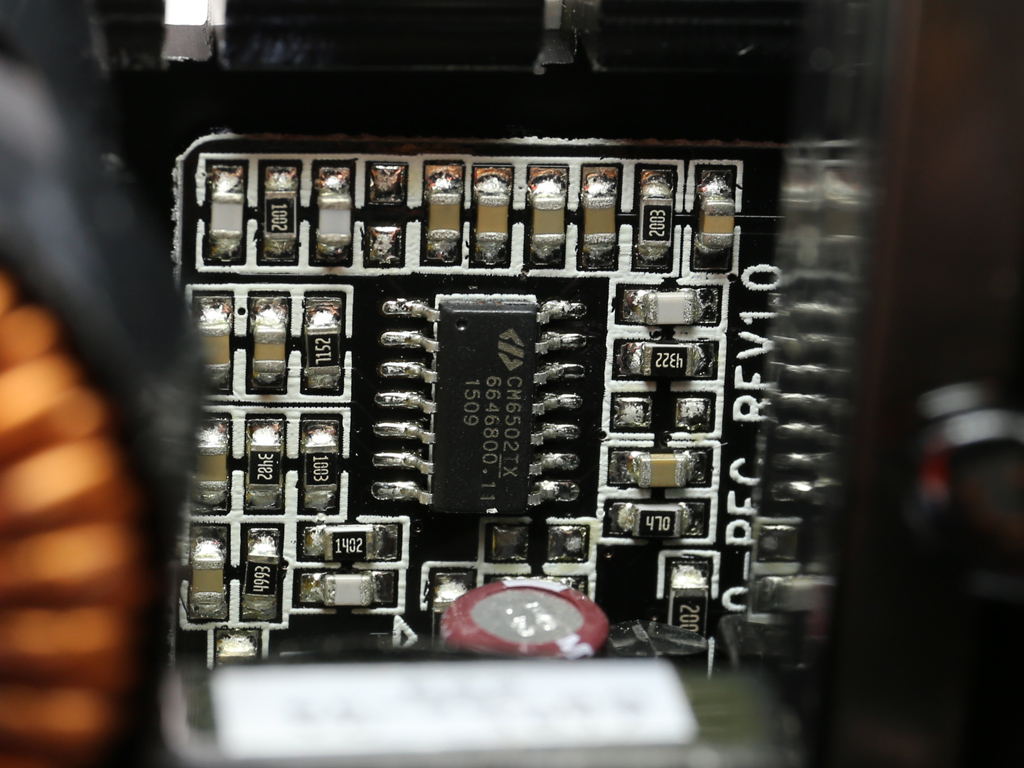

| Combo APFC/PWM Controller | Champion CM6502S |

| Topology | Primary side: Half-Bridge & LLC Resonant Controller Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

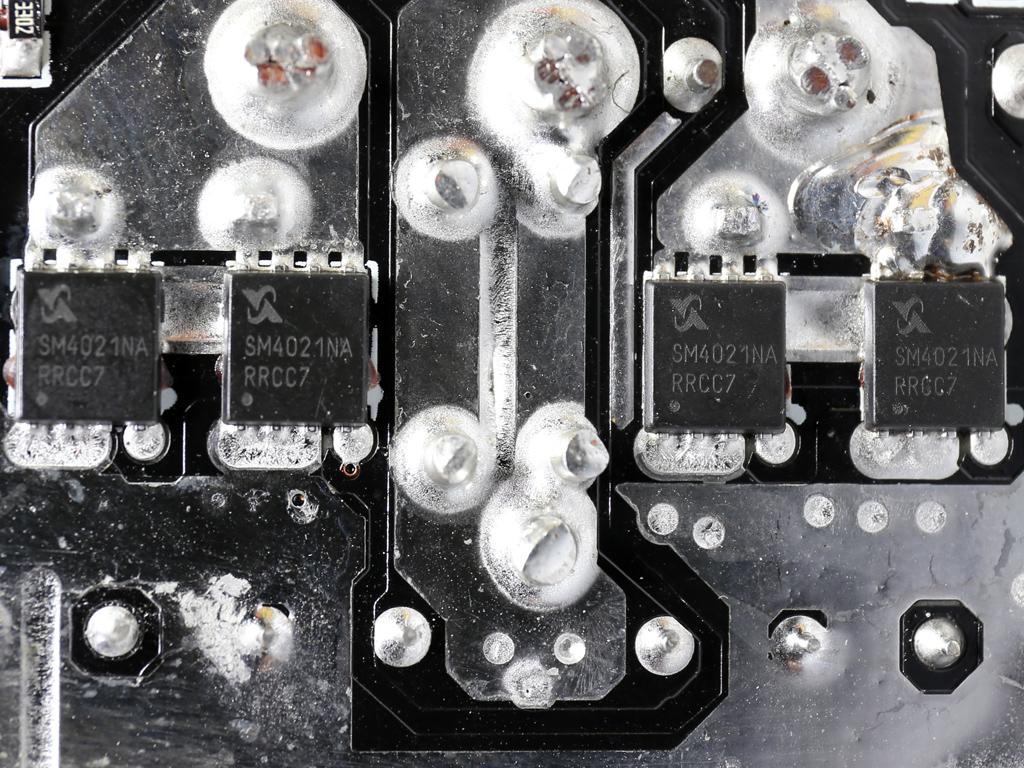

| +12V MOSFETs | 4x Sinopower SM4021NA (40V, 100A @ 100°C, 1.6mΩ) |

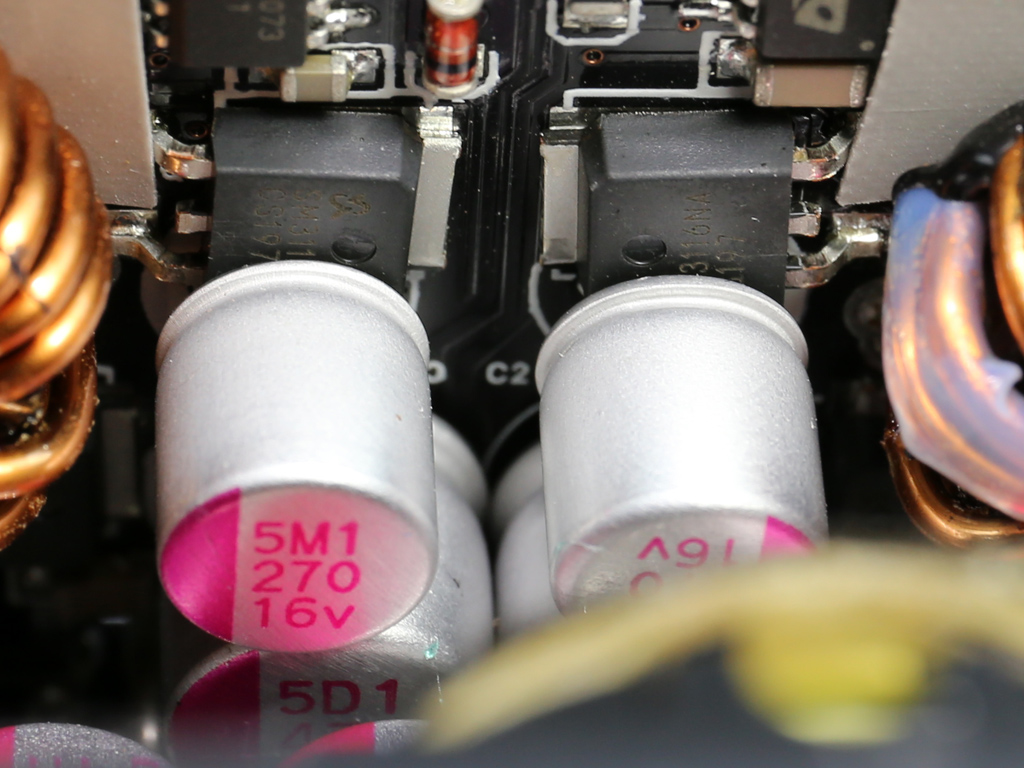

| 5V & 3.3V | DC-DC Converters: 4x Sinopower SM3116NAU (30V, 48A @ 100°C, 9.0mΩ) PWM Controller: 2x Anpec APW7073A |

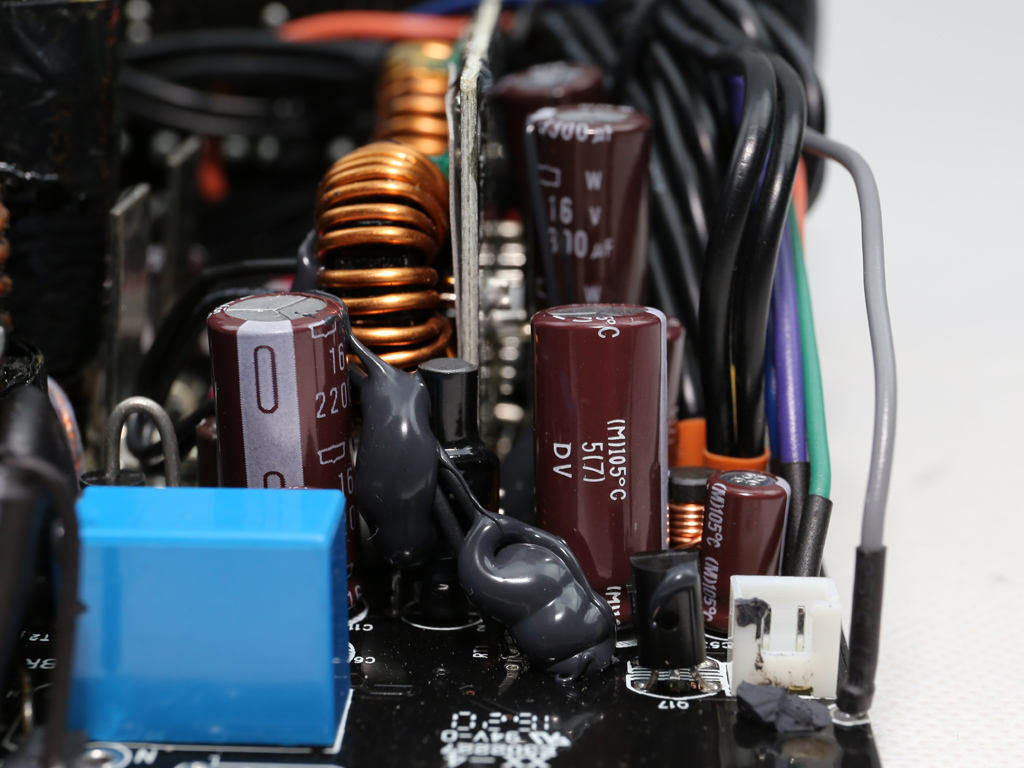

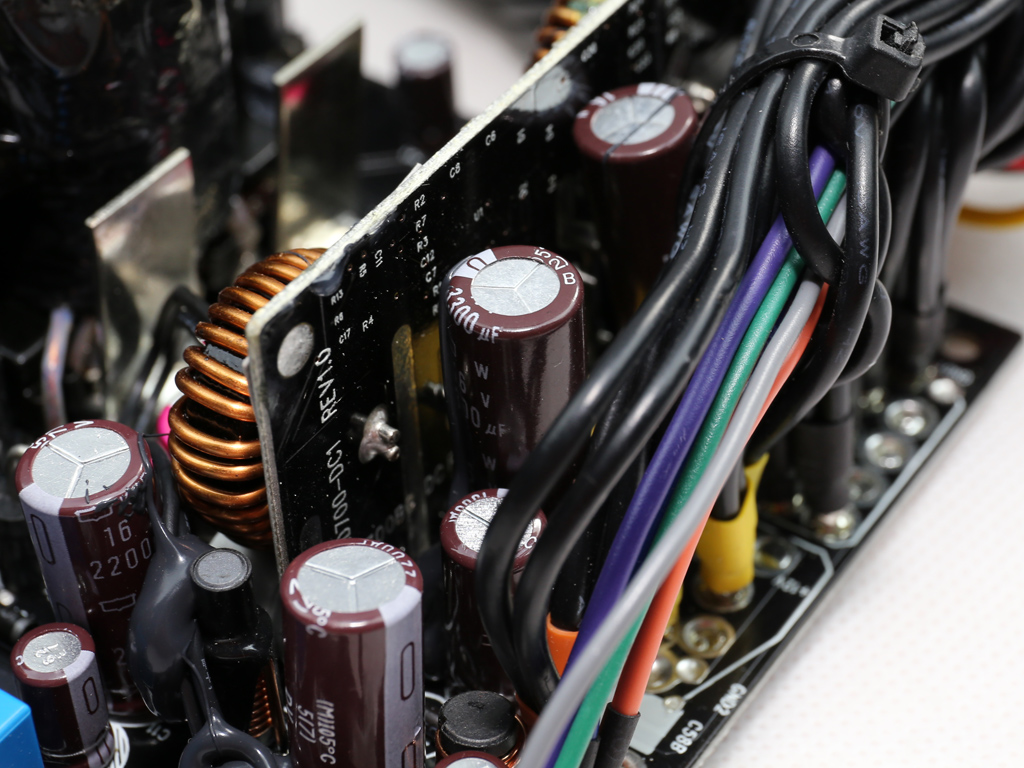

| Filtering Capacitors | Electrolytics: Chemi-Con (1-5,000 @ 105°C, KZE), Chemi-Con (4-10,000 @ 105°C, KY) Polymers: Man Yue (Samxon) X-CON ULR, Enesol |

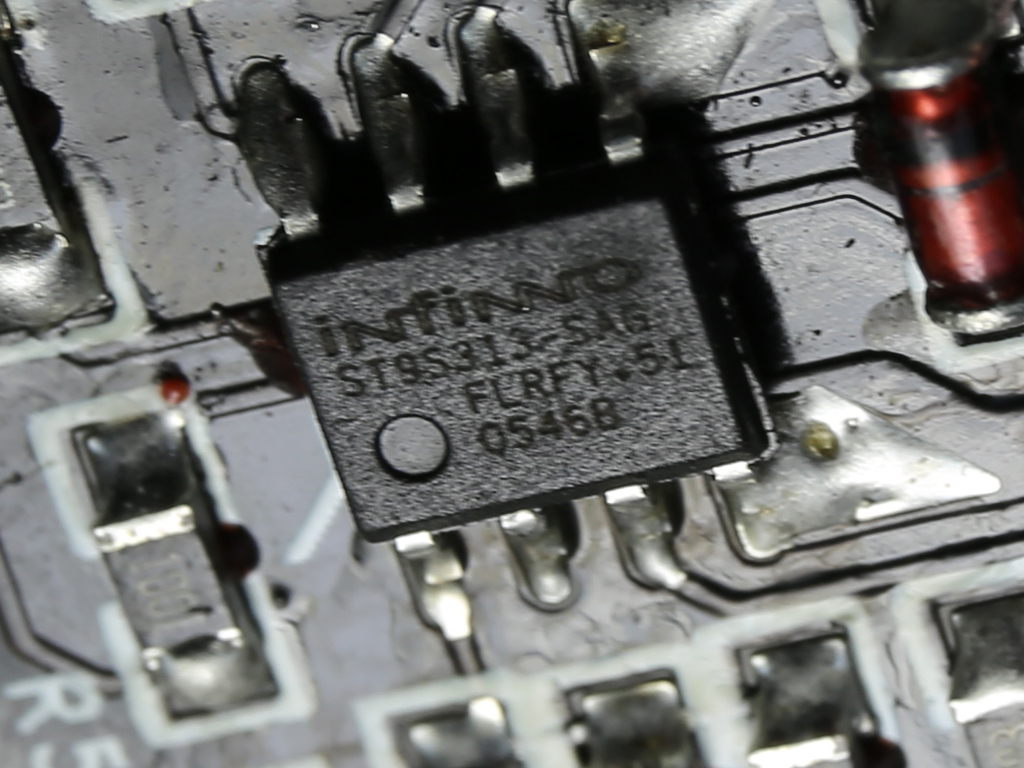

| Supervisor IC | Infinno ST9S313-SAG (OVP, UVP, SCP, PG) |

| Fan Model | Enermax ED142512W-CA (139mm, 12V, 0.25A, Twister Bearing) |

| 5VSB Circuit | |

| Standby PWM Controller | Power Integrations TinySwitch TNY278PN |

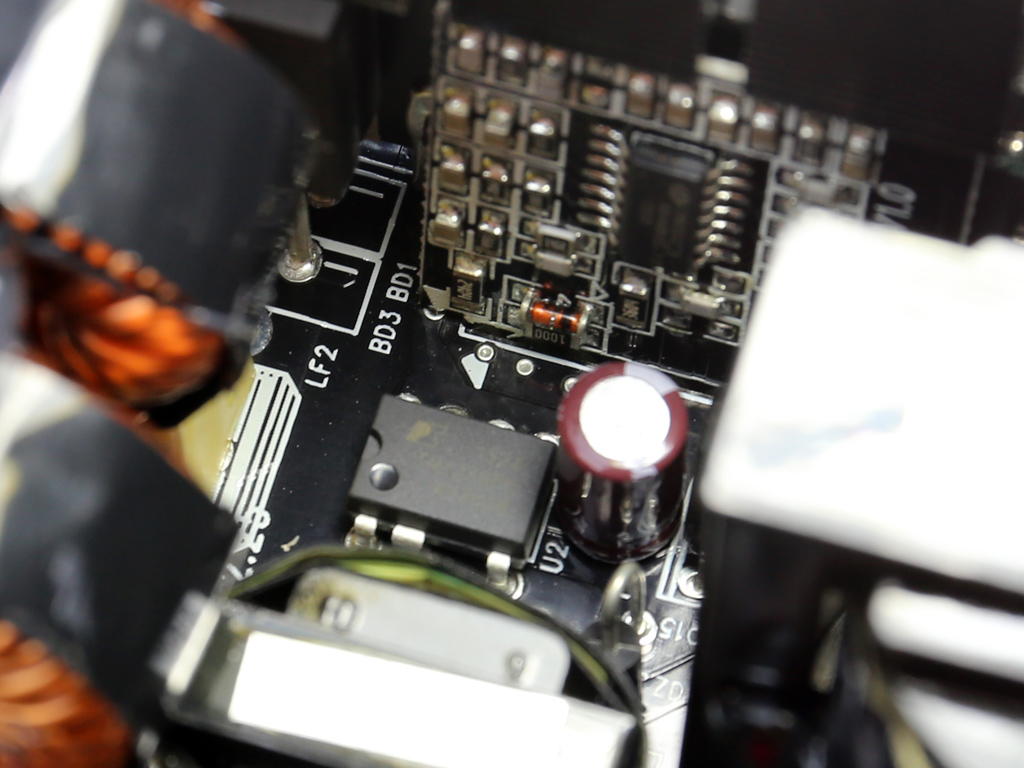

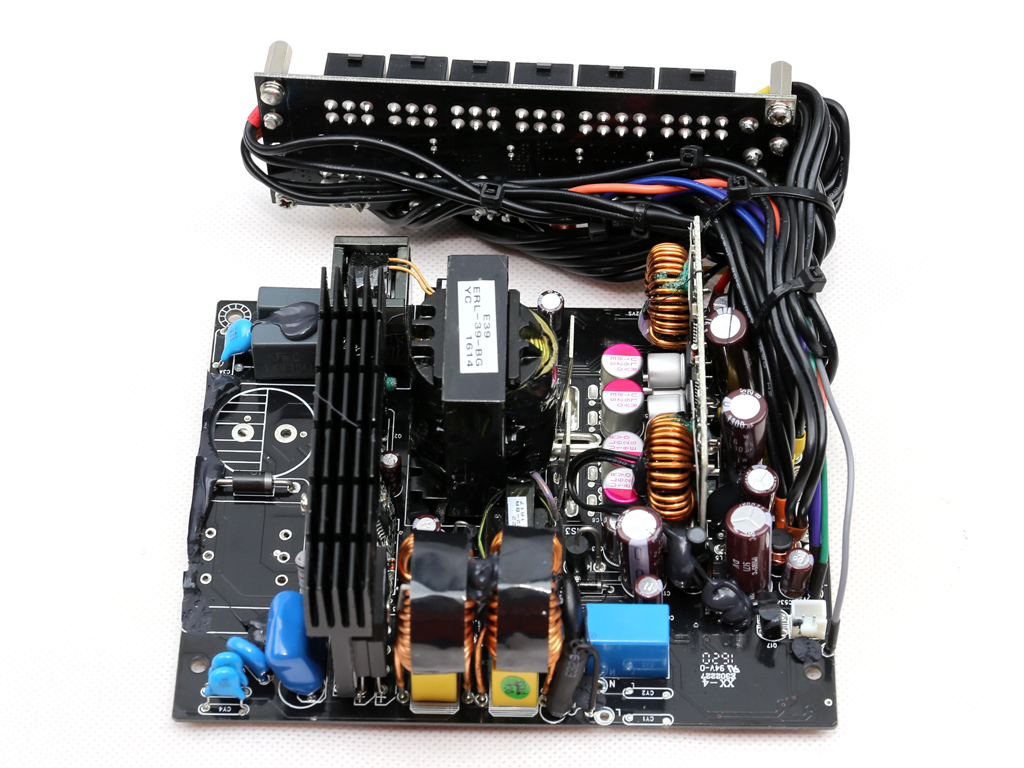

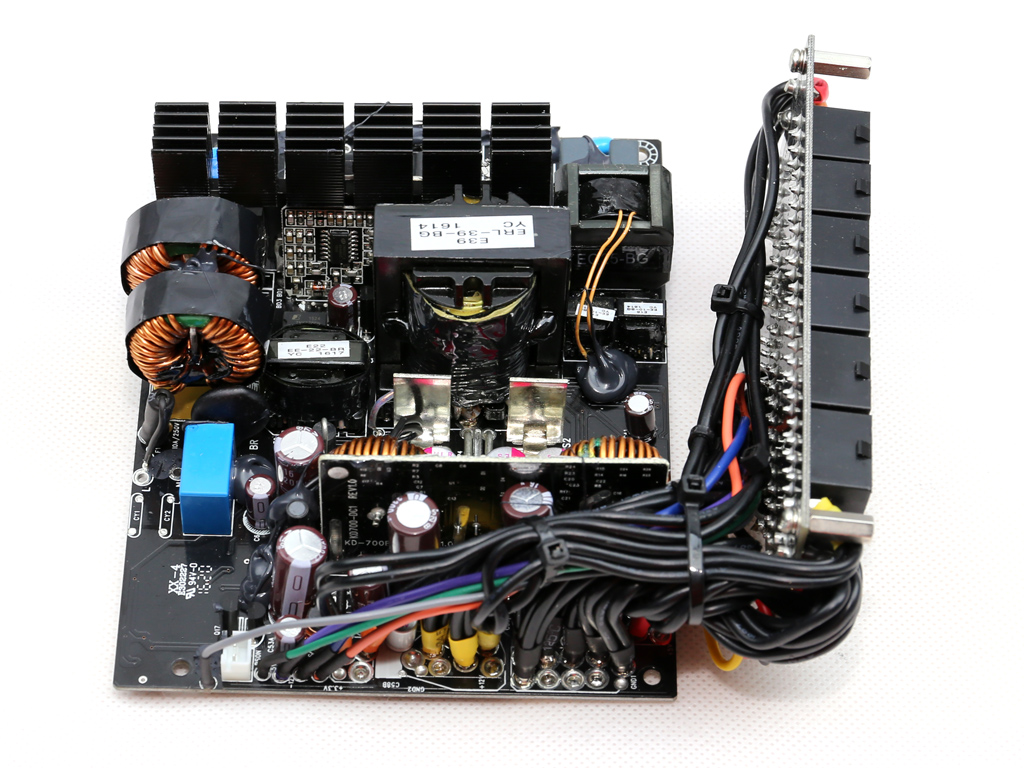

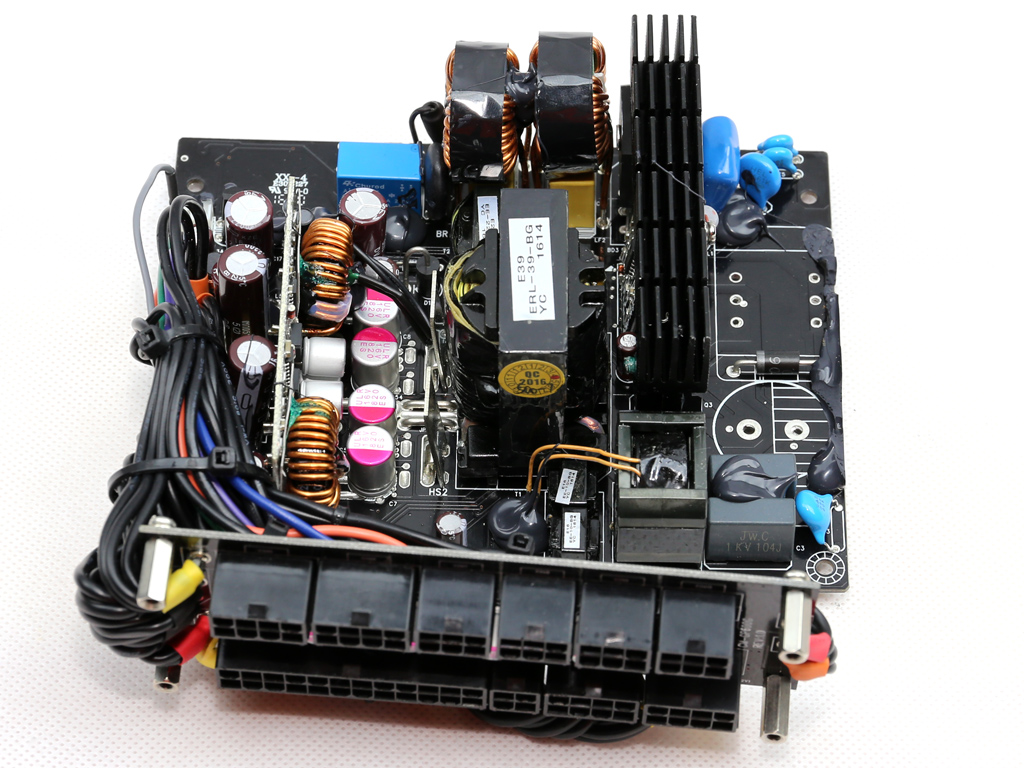

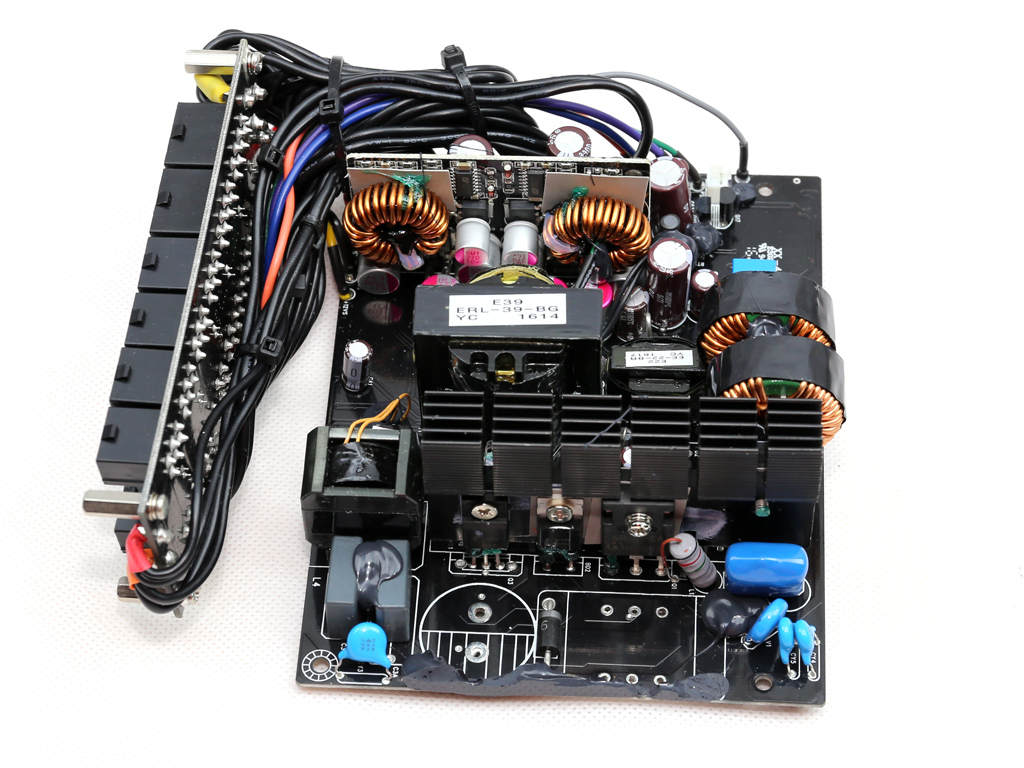

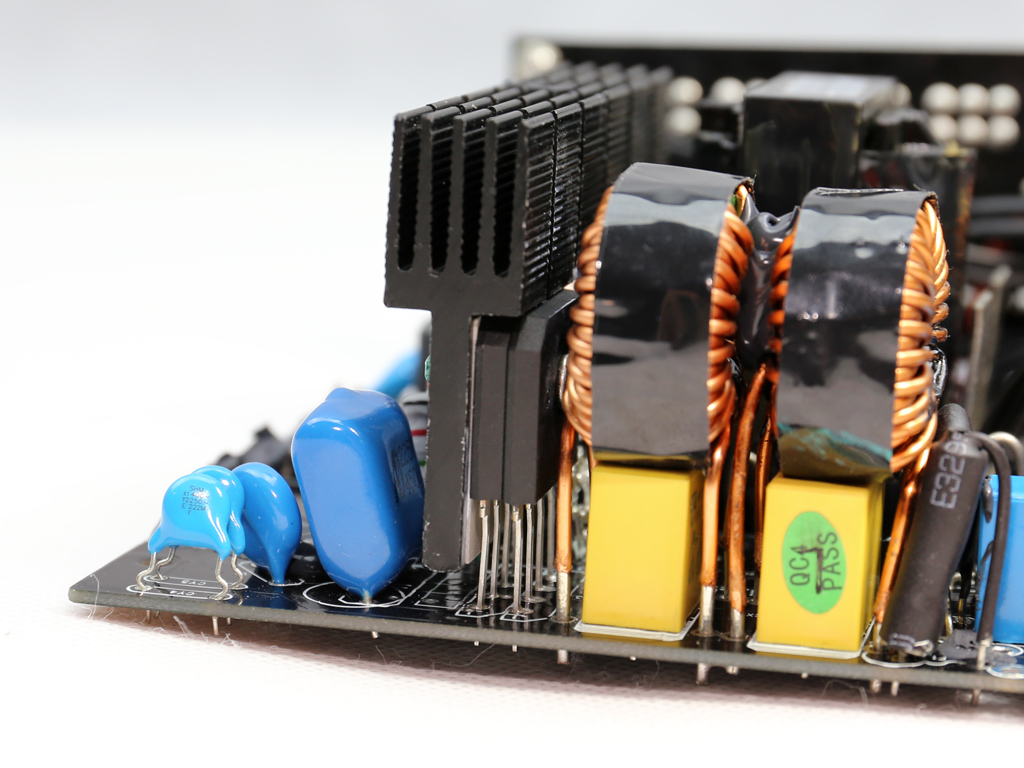

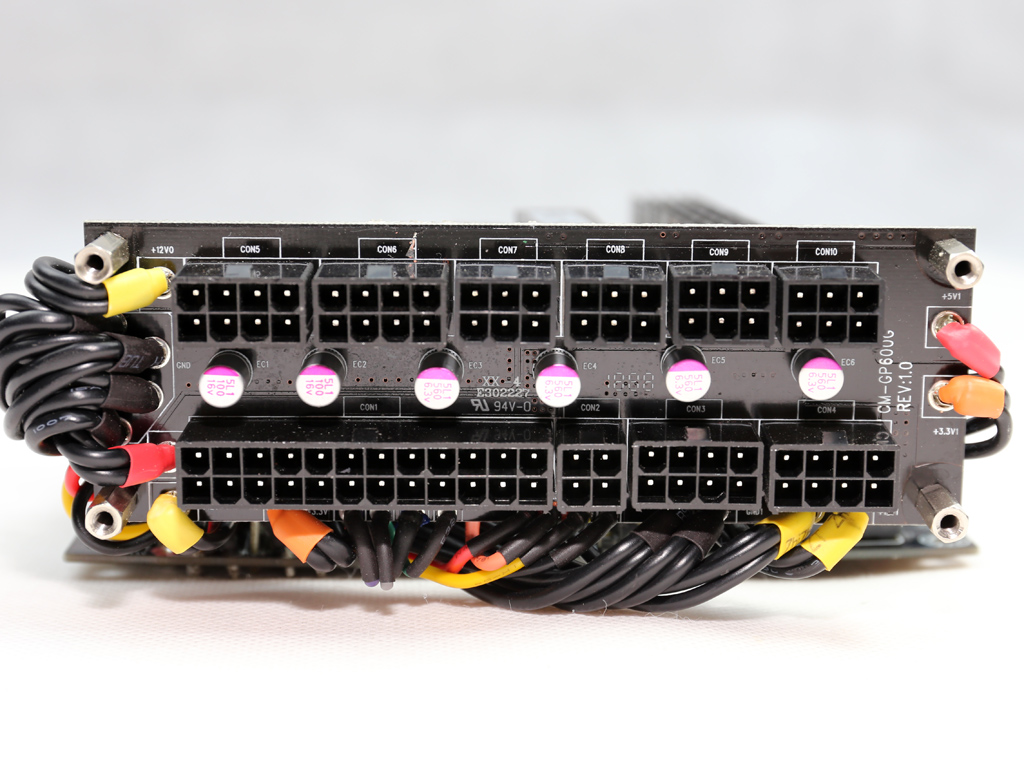

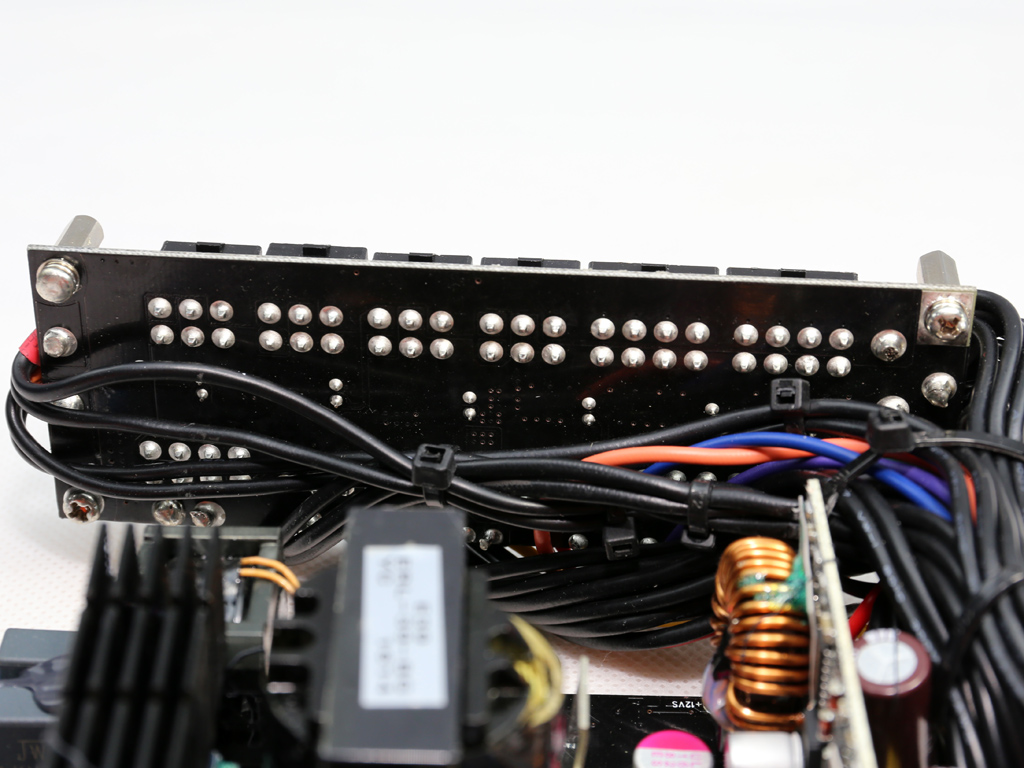

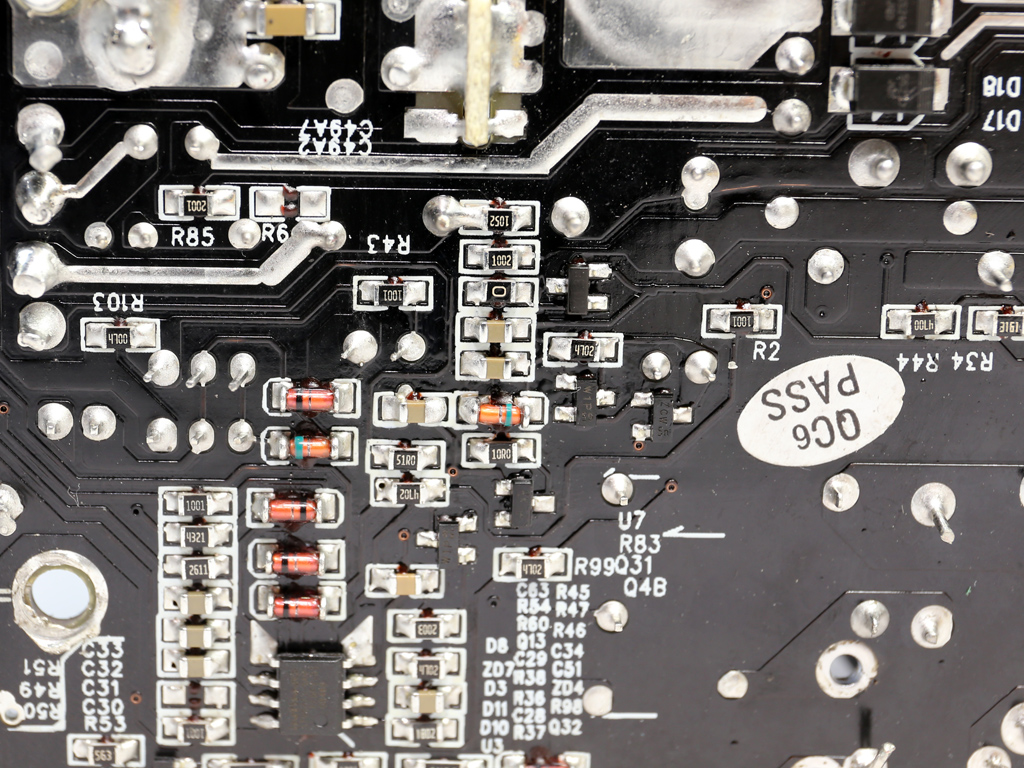

As mentioned, this PSU is made by Fortech Electronics and appears to be based on the Segotep ZP500P-SG. The heat sink on the primary side is large enough for an efficient 80 PLUS Platinum unit, since it also hosts the pair of bridge rectifiers. The design isn't particularly clean, though; a lot of cables are used to transfer power to the modular board. Most modern designs don't use this many cables, if they have any at all. Rather, power is usually transferred through bus bars to the modular sockets. Eliminating those power transfer cables reduces energy losses and enhances the secondary side's cooling, since nothing blocks the air flow.

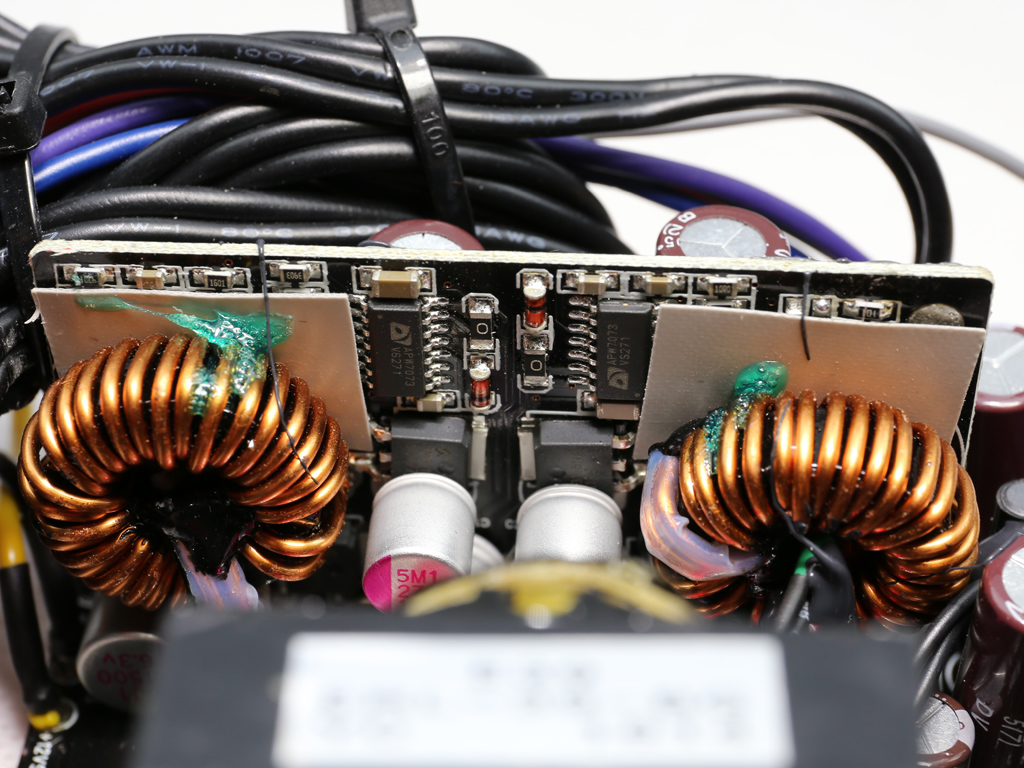

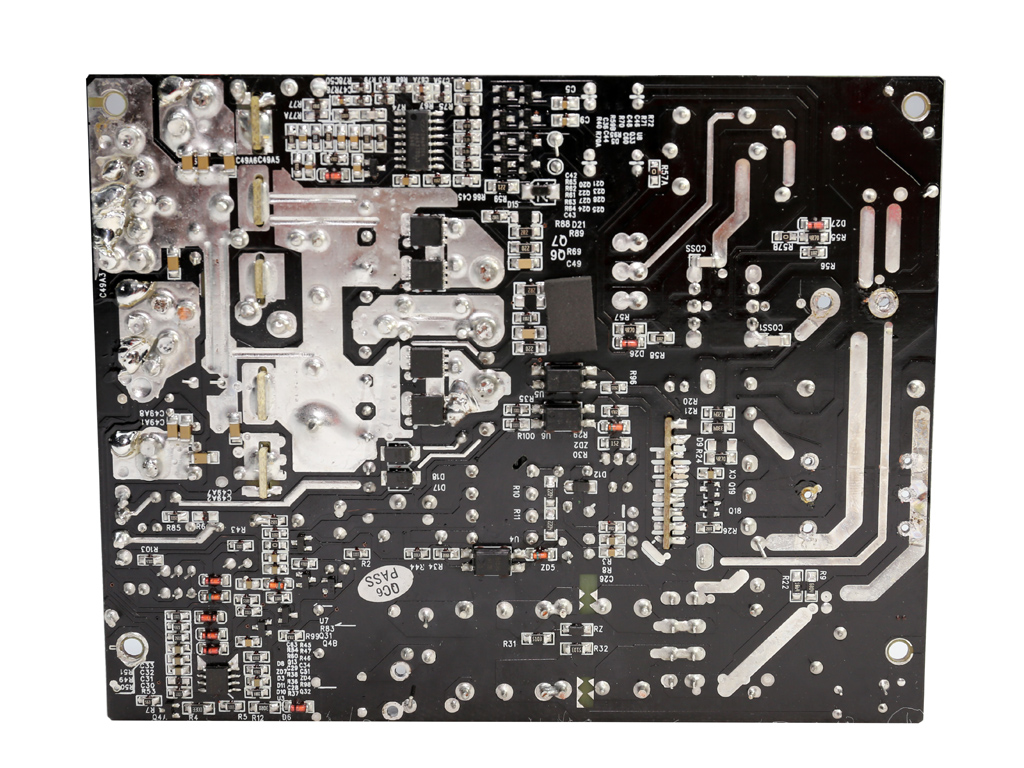

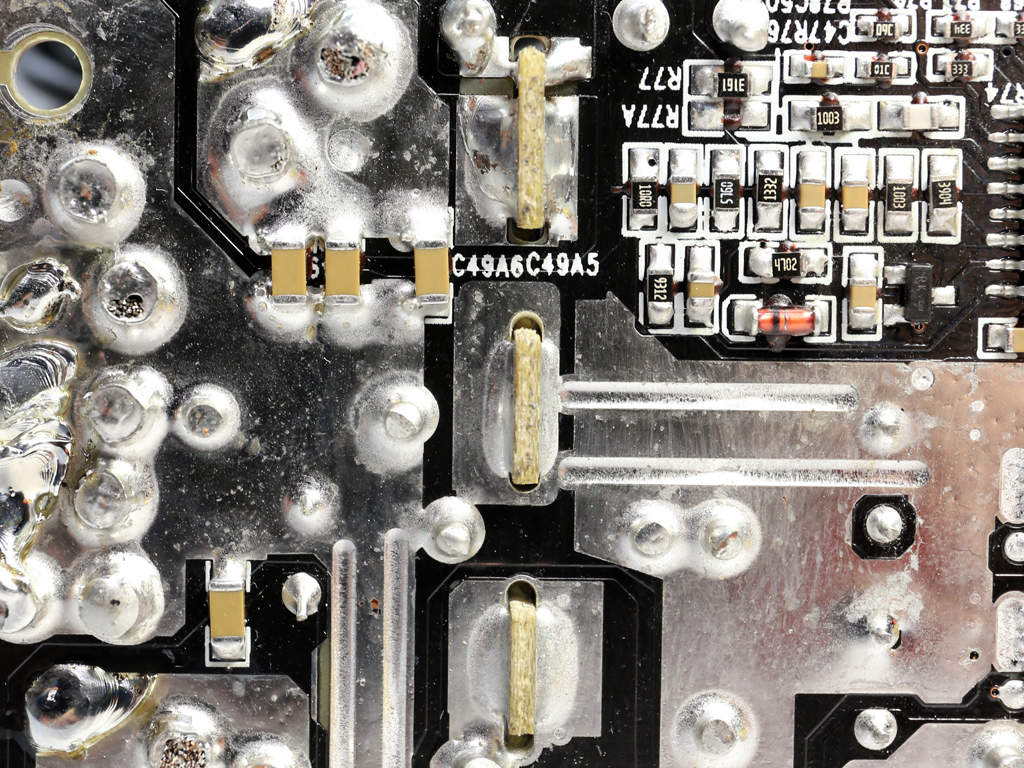

A half-bridge and LLC resonant converter are utilized on the primary side, while a synchronous design is used on the secondary side for the +12V rail, along with a pair of DC-DC converters for generating the minor rails. There are no large heat sinks on the secondary side, since the +12V FETs are installed on the PCB's solder side.

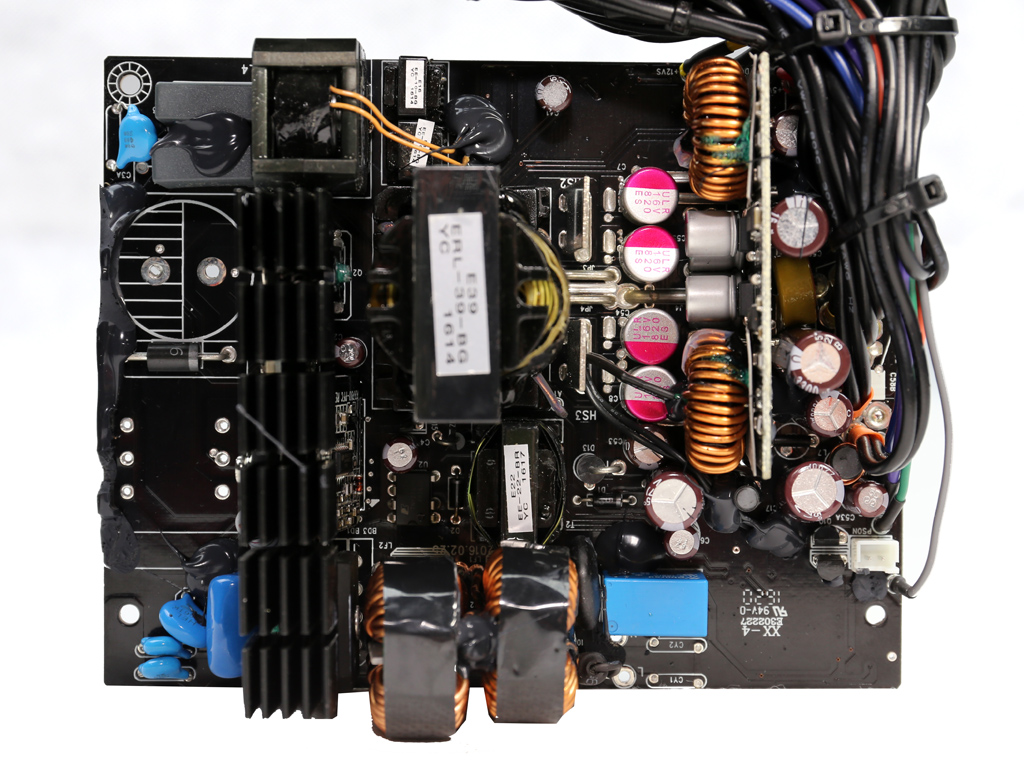

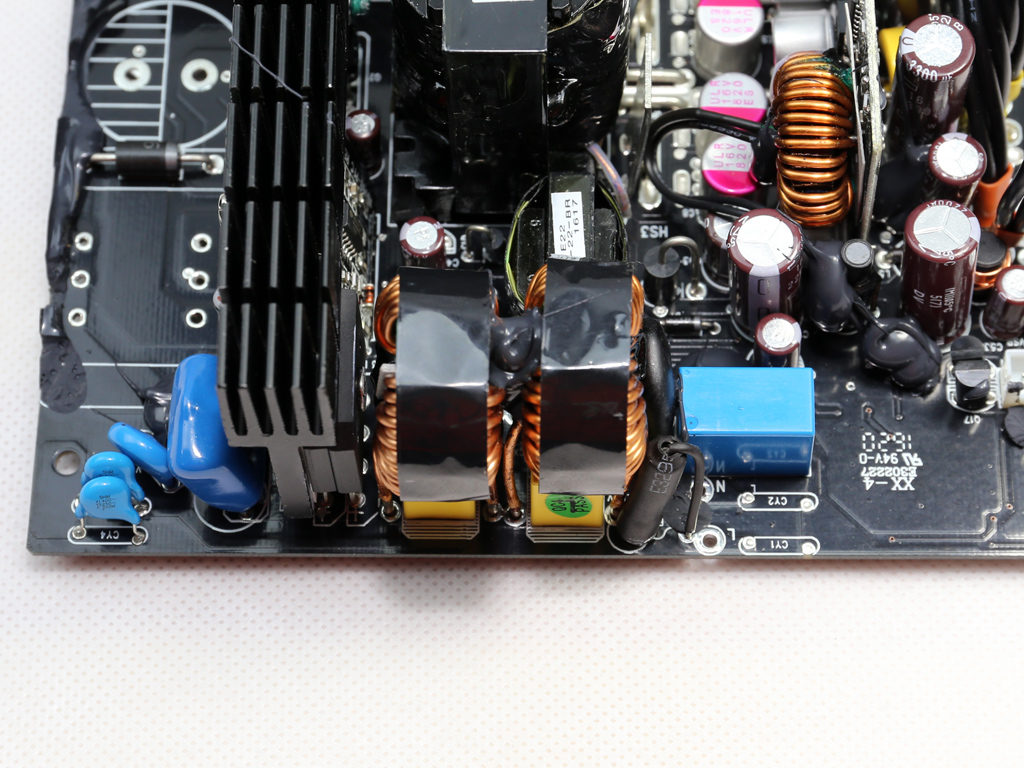

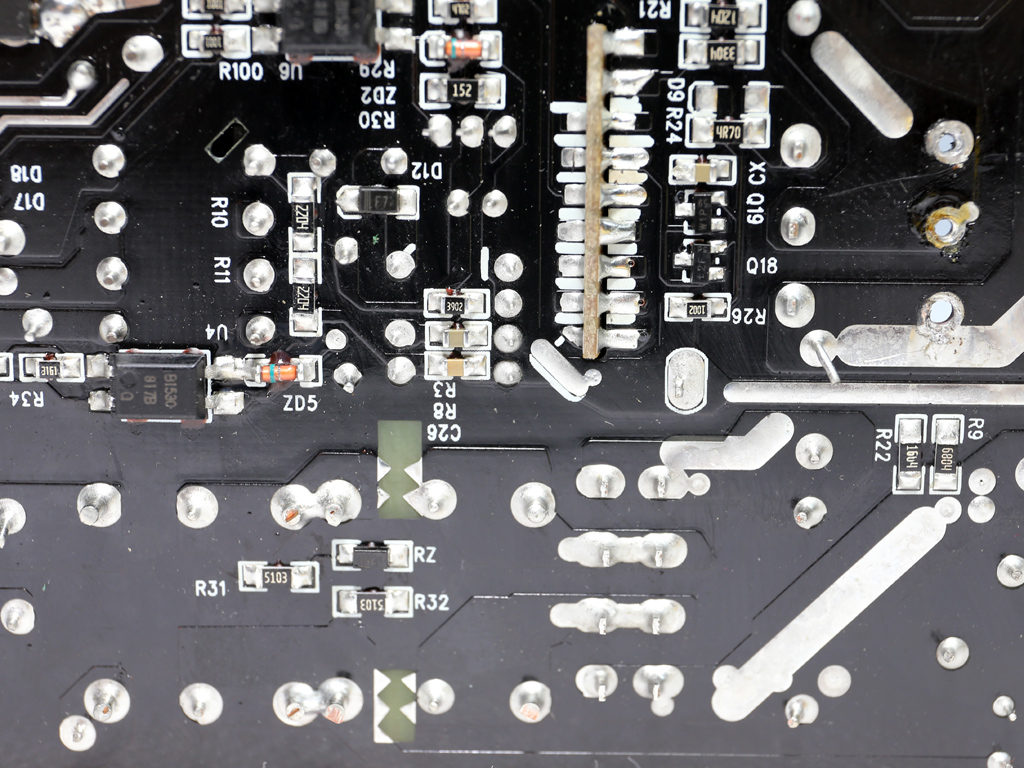

The PCB behind the AC receptacle hosts the power switch, along with two Y caps and a single X one. The EMI filter typically continues on the main PCB with two more Y caps, another two X ones, an MOV, and two CM chokes. The EMI filter is complete.

An NTC thermistor reduces the increased inrush currents, and a bypass relay isolates it from the circuit once its job is finished. This improves efficiency and cools the thermistor down faster so it can do its job when it's called upon.

The bridge rectifiers are bolted together on the primary heat sink.

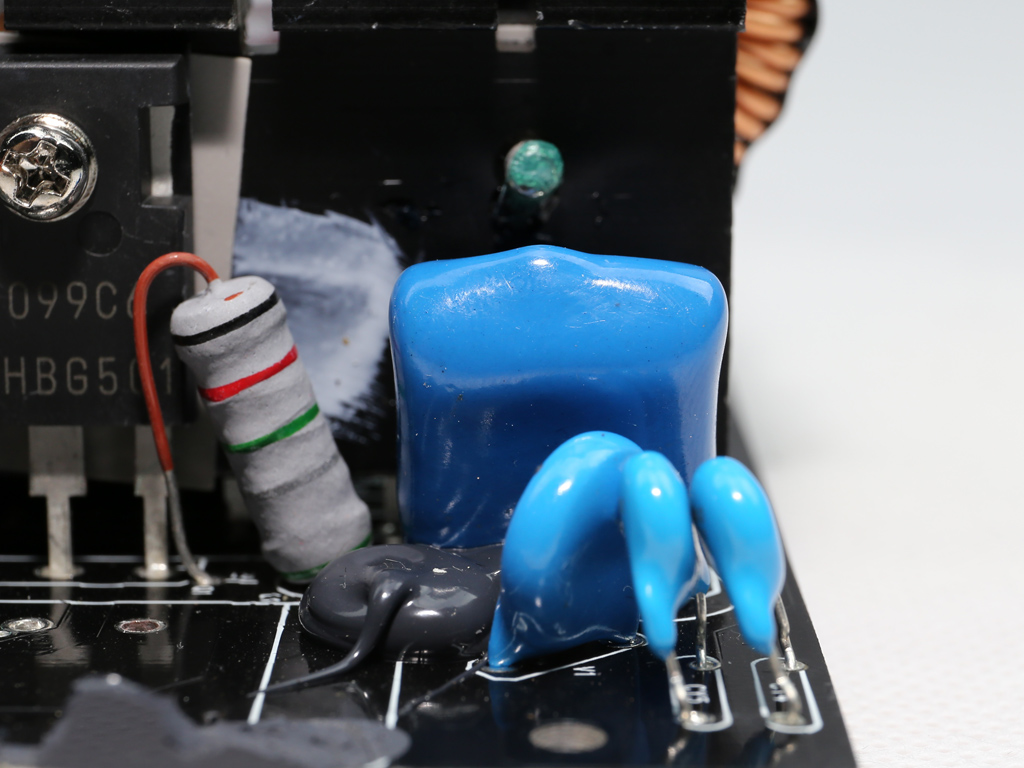

Clearing a view to the APFC converter's parts required de-soldering the PFC choke and bulk cap. A single Infineon IPW60R099C6 FET and SiC SCS210AG boost diode shape the current's waveform to match the voltage waveform, bringing the power factor (PF) as close as possible to unity. The bulk cap is provided by Chemi-Con (400V, 330uF, 2000h @ 105°C, KMR), and although its capacity is low, it still enables a greater-than 17ms hold-up time. This clearly shows that, in addition to the bulk cap's capacity, a solid design also plays a crucial role in achieving the required hold-up time.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The APFC controller is a Champion CM6502S, installed on a small vertical board.

The primary FETs, two Fairchild FDPF20N50FTs, appear to be arranged in a half-bridge topology. If you're into aviation, then you're already familiar with Fairchild and its division responsible for manufacturing planes. Perhaps the most recognizable Fairchild-made plane is the A-10 Thunderbolt II, the tank-killer also known as "The Warthog".

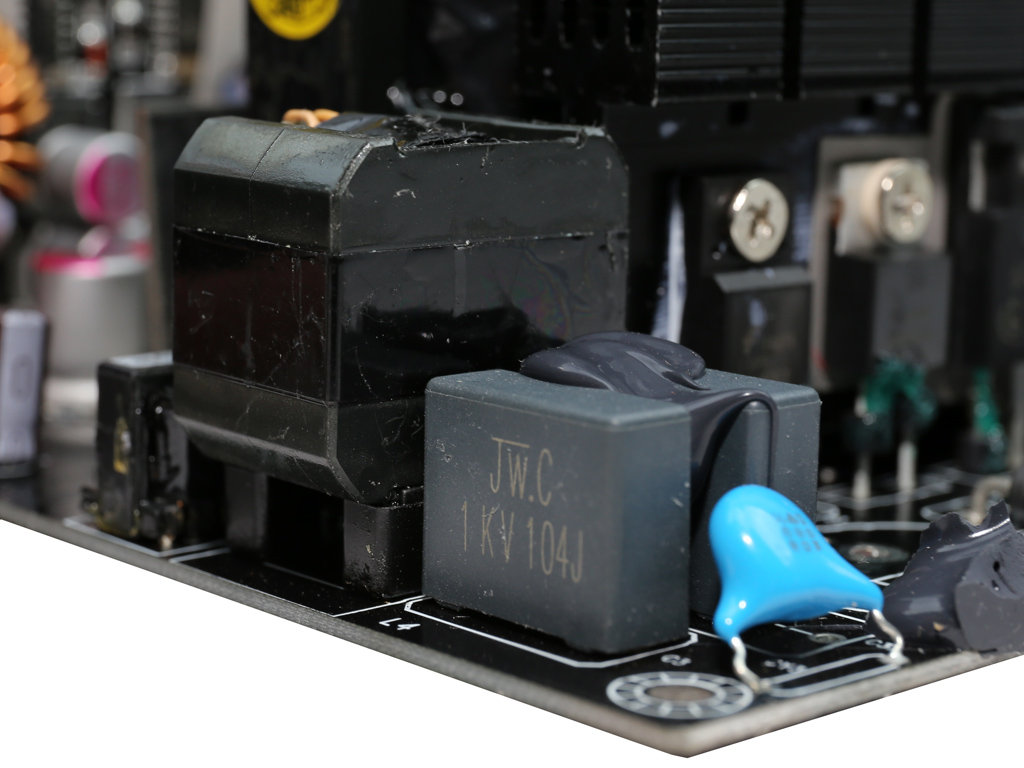

The primary FETs are supported by an LLC resonant converter, which decreases switching power losses.

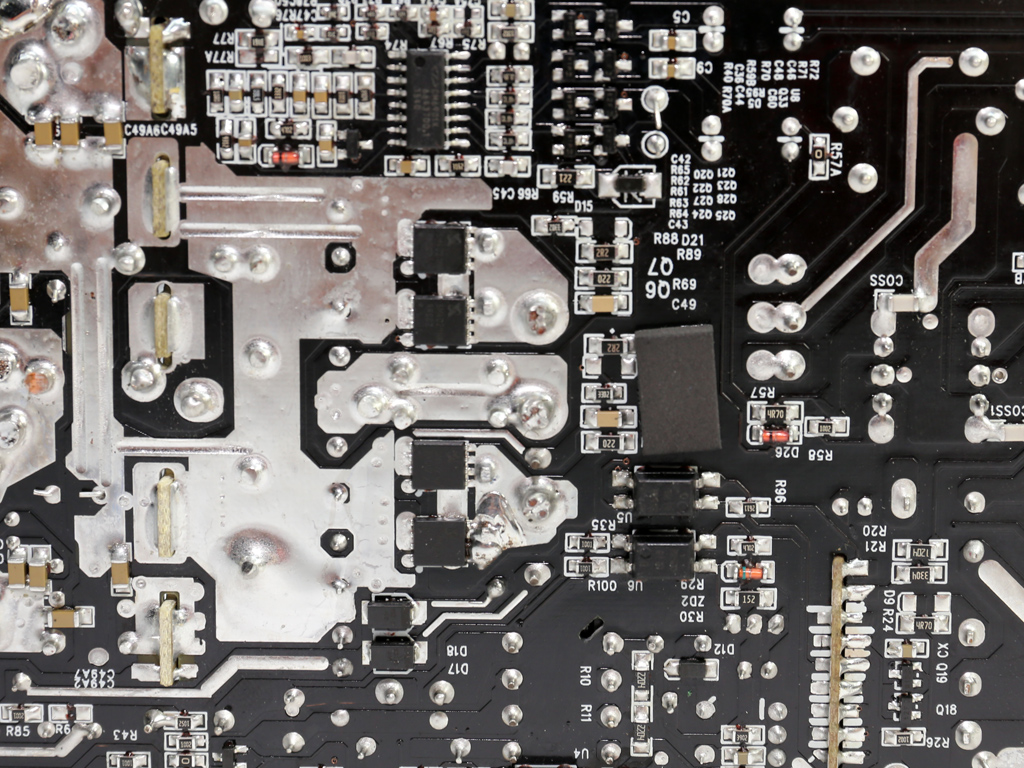

The LLC resonant controller is a CM6901 IC, installed on the PCB's solder side.

On the secondary side, four Sinopower SM4021NA FETs generate the +12V rail. Two small heat sinks above them, along with the PCB, cool the FETs down. Strangely enough, Fortech doesn't exploit the chassis' surface area to help draw heat away. It seems as though the Sinopower FETs are overkill for this unit's maximum capacity, so there's no need for additional cooling. Still, a thermal pad would have been cheap insurance against overheating.

The electrolytic filtering caps are provided by Chemi-Con and they belong to the KZE and KY lines. Besides electrolytics, polymer caps are also used. They're provided by X-Con (SamXon) and Enesol.

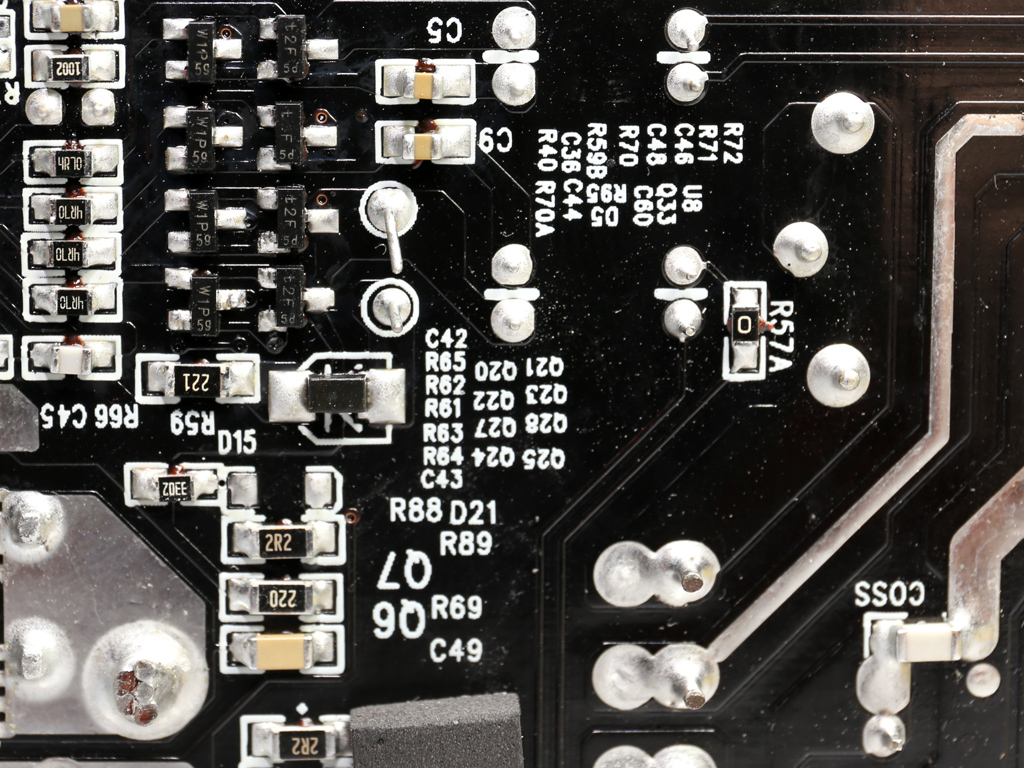

Both DC-DC converters are installed on the same PCB. Two Anpec APW7073A PWM controllers are used, along with four Sinopower SM3116NAU FETs.

The standby PWM controller is a Power Integrations TinySwitch TNY278PN.

On the front of the modular board, several Enesol polymer caps provide an extra ripple filtering layer.

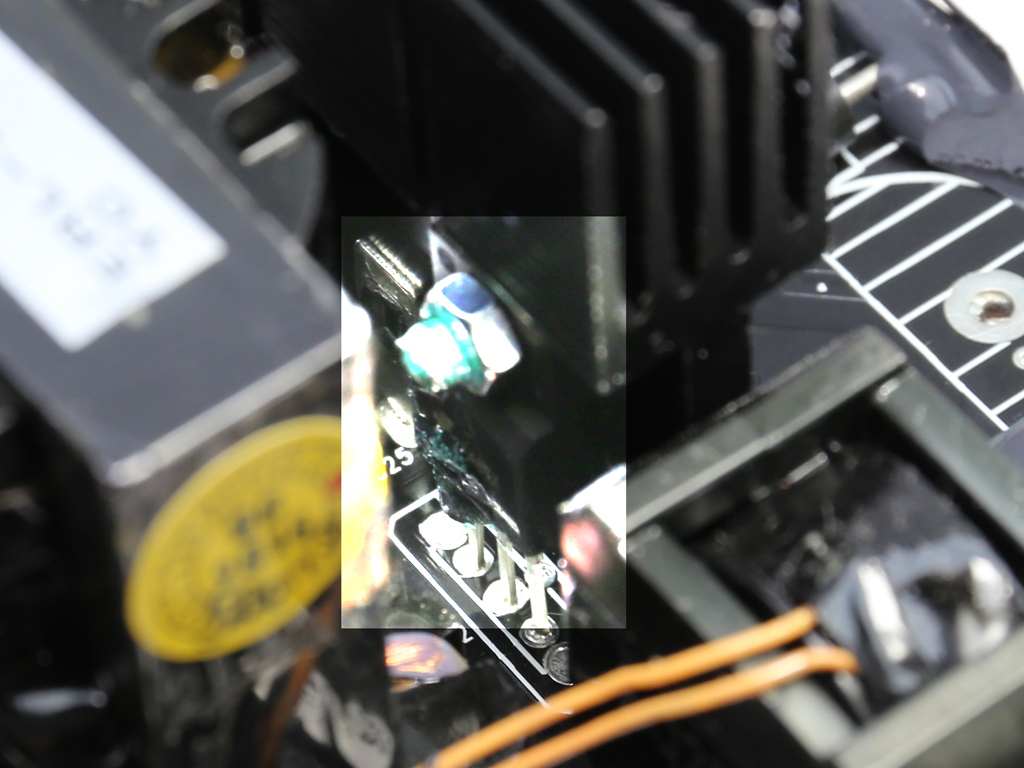

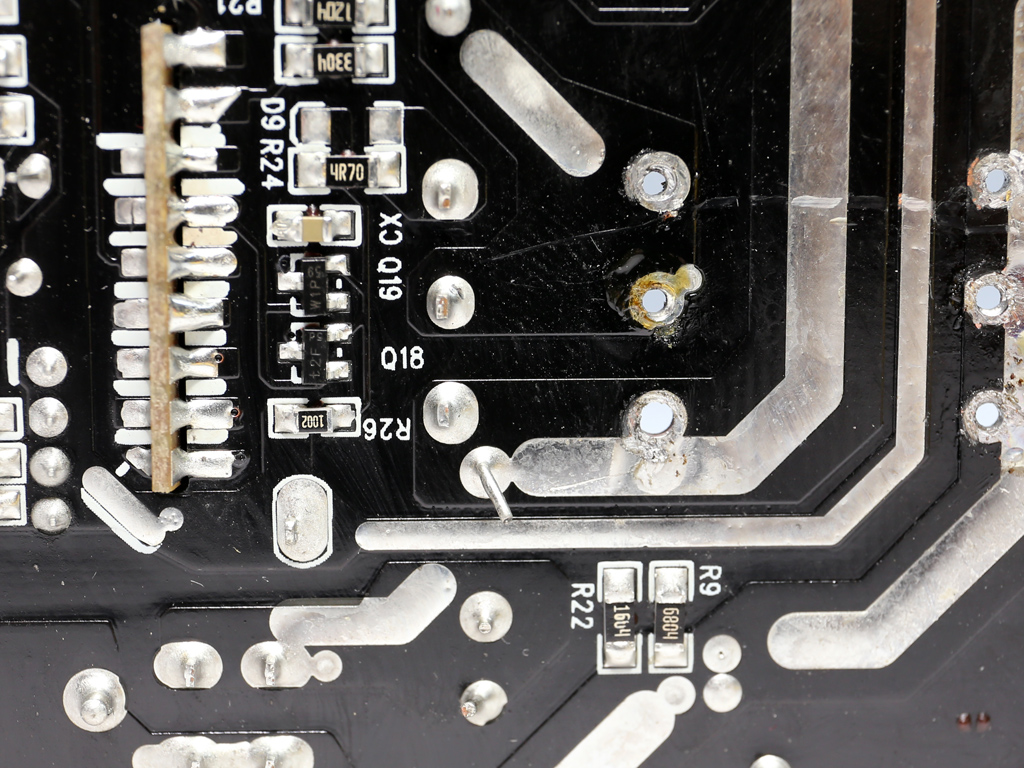

The soldering quality is mediocre. What troubles us most are the long component leads that we spotted in numerous spots on the PCB's solder side. Those can easily cause dangerous shorts. Fortech needs to upgrade its manufacturing line and quality control. In such an expensive PSU, we expected to find top build/soldering quality and nothing less.

The supervisor IC is a Infinno ST9S313-SAG IC, which only offers basic protection features.

The cooling fan uses a twister bearing, which, according to Enermax, lasts forever. Its model number is ED142512W-CA and it is incredibly quiet, since its maximum speed stays close to 1000 RPM. On top of that, the fan control circuit is especially conservative.

Current page: A Look Inside And Component Analysis

Prev Page Packaging, Contents, Exterior, And Cabling Next Page Load Regulation, Hold-Up Time, And Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

eglass I'd probably buy it. I like those cables and I'm running a 500W Enermax Liberty that is now 11 years old.Reply -

Anathemata How well does the dust-removal feature work? I mean, Van der Waals force is still a thing, and you need more than just a simple fan to blow out dust. Wouldn't a simple filter suffice?Reply

The sleeved cables are a nice touch. It'll be cheaper than buying a different power supply and separate sleeved cables. -

daddywalter Build quality isn't bad but could be better; lack of OTP is troublesome; and I'll agree with the reviewer that sleeved cables would be better offered as an option for modders. 80 Plus Platinum rating is a plus, of course; and 500 watts is adequate for most general-purpose computers that don't require multiple GPUs -- this PSU would probably outlast most SOHO builds, but then the initial price becomes more of a factor. Nice PSU, but IMHO not worth $140 with only a five-year warranty; at ten years I might consider it since then it should be good for at least three builds.Reply -

dstarr3 Reply19274544 said:I'd probably buy it. I like those cables and I'm running a 500W Enermax Liberty that is now 11 years old.

11 years is plenty of time for a company to have since dropped an amount of build quality. -

Robert Cook I'll add my voice, that auto play video needs to go. It is obnoxious, and adds lag to weaker devices.Reply

I like that cable pattern, it reminds me of the cables on my Enermax revolution 85+ 850W. (a great PSU despite its lower efficiency and age.)

How are poorly trimmed leads going to cause shorts if everything is locked inside a case? I only see that as an issue if you go dropping screws in there. -

Aris_Mp they aren't poorly trimmed only, some of them are really long and only a hair away from the other. Under extreme conditions this can cause problems (shorts) and there can be of course an EMI issue when leads are so close to each other. Also with such long leads the plastic shield under the PCB can get punctured or during the PCB's installation into the chassis, which applies pressure to the leads, the long ones will bend and probably get shorted; this means that some PSUs might be already broken. I don't think that every PSU that leaves the production line is tested, but only a percentage of them.Reply

There is a purpose behind the proper trimming of excessively long leads in every PCB that is installed into a metallic chassis. The use of a plastic shield under the PCB doesn't automatically solves all possible problems. -

WFang I'm hoping for a resurgence in power supply choices in the 500W and *LESS* category!Reply

I would rather see something like the amazing Seasonic Prime supplies in a 400W flavor than 600W and over...

Before I go on, I realize that if you run two GPU's or you really like to OC, obviously you need more and want more.. Great.. you already have a ton of great choices for those use-cases... I just wonder why we don't have more great quality choices in the lower Wattage ranges where probably a good 75% of even the enthusiast group could live comfortably.

I also realize that TDP - Thermal Design Power is NOT the same as power consumption, but it is easy to find TDP numbers, and a part that is designed to deal with e.g. 100W TDP is likely to consume around 100W (or less) even in peak. As such it becomes a handy metric for back of the envelope power budgeting that still ends up being fairly conservative.

With CPU's now more often in the lower half of 45W, 65W, and 95W TDP and the more recent GPU's all sitting at 300W or less in TDP, I'd argue that for non-OC'ed systems with one GPU and 1 or 2 HDD's and maybe an SSD, a great high efficiency 350W to 400W PSU will be a great choice. Feeling like that is pushing it? Fine, go 500W... but I don't see why you'd shop higher than that (for this use-case). Yet, good quality Titanium, Platinum, or Gold efficiency PSU's seem so hard to find in the sub 500W range. :(

On a side note, since I'm here complaining anyway: A looong time ago I heard Tom's mention the Seasonic Prime 600W fanless PSU, anyone know if/when that will become available in the US? (Or anywhere?)??? -

Marcus52 Reply19274544 said:I'd probably buy it. I like those cables and I'm running a 500W Enermax Liberty that is now 11 years old.

Enermax was my favorite PSU maker when they made their own, but unfortunately they've chosen OEMs that are "adequate" not "great" to replace their manufacturing facility. I've paid their premium in the past, but right now EVGA is on the top of my list. Super Flower makes their top-of-the-line PSUs and build quality is superb, as are test bench results.

Seasonic is also on my list of "will buy", and several other brands use Seasonic or Super Flower, so I wouldn't be opposed to buying one from someone like Corsair - as long as it tested well on reputable hardware sites.

Never buy a PSU that doesn't review well. I've learned that the hard way. Build quality matters.