Samsung races to beat Intel to market with glass substrates for chips — revolutionary tech boosts processing capabilities

Samsung teams up with partners to develop glass substrates.

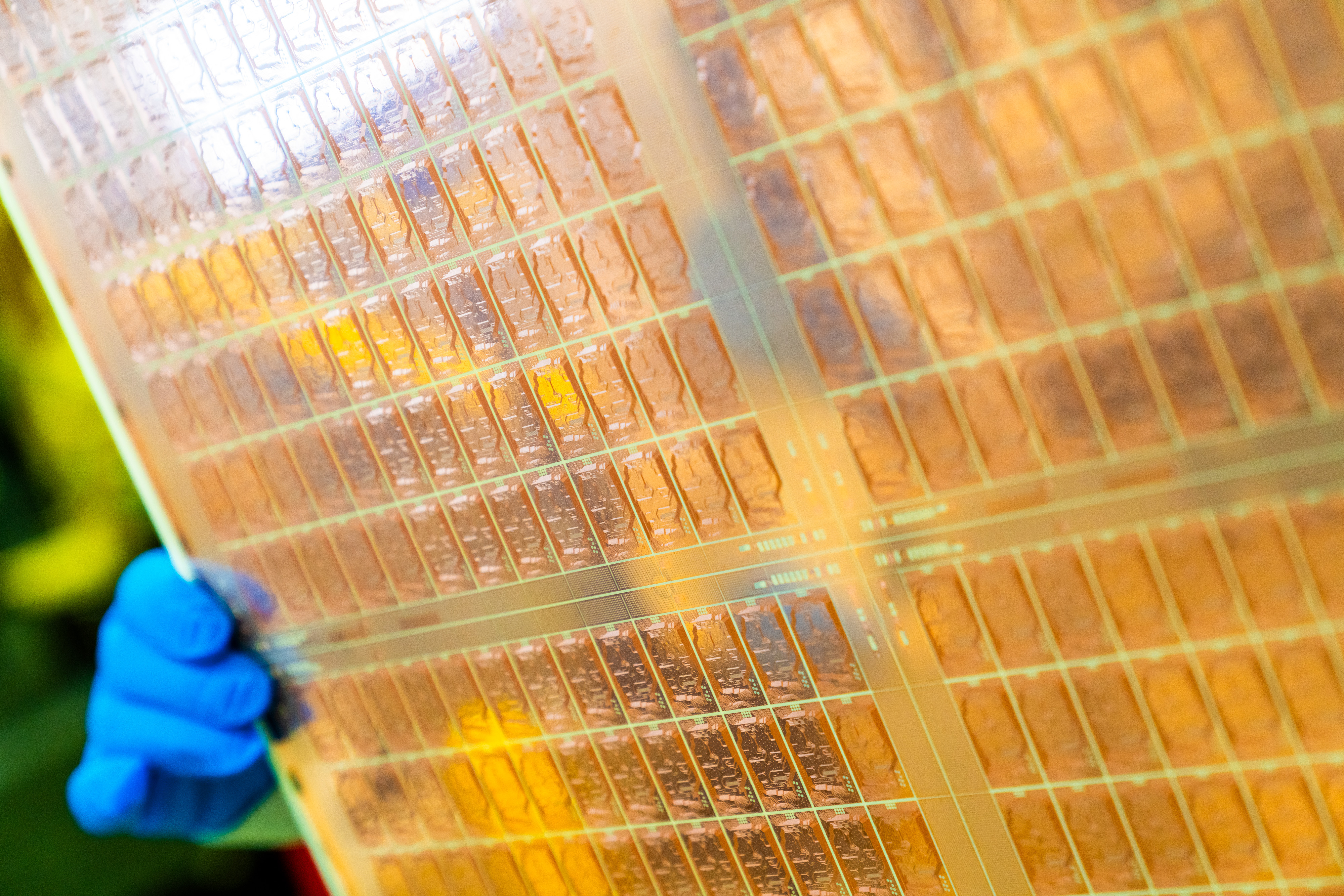

Glass substrates promise to offer substantial benefits for multi-chiplet system-in-package (SiP) designs that are expected to become increasingly popular in the coming years. Being one of the world's largest chipmakers, Samsung cannot omit glass substrates, so it recently assembled a coalition of its own groups to research, develop, and commercialize glass substrates by 2026, reports Sedaily.

Samsung has assembled a coalition consisting of its Samsung Electro-Mechanics, Samsung Electronics, and Samsung Display divisions to develop and commercialize glass substrates in the shorted time possible. In fact, Samsung Electro-Mechanics announced back at CES its intention to mass-produce glass substrates by 2026.

"As each company possesses the world's best technology [on their markets], synergy will be maximized in the promising field of glass substrate research, and it is also necessary to watch how the glass substrate ecosystem of the Samsung alliance will be established," an industry insider told Sedaily.

Samsung Electronics is expected to focus on the integration of semiconductors and substrates, while Samsung Display will specialize in glass processing. This collaborative approach is aimed at enhancing the group's competitive edge.

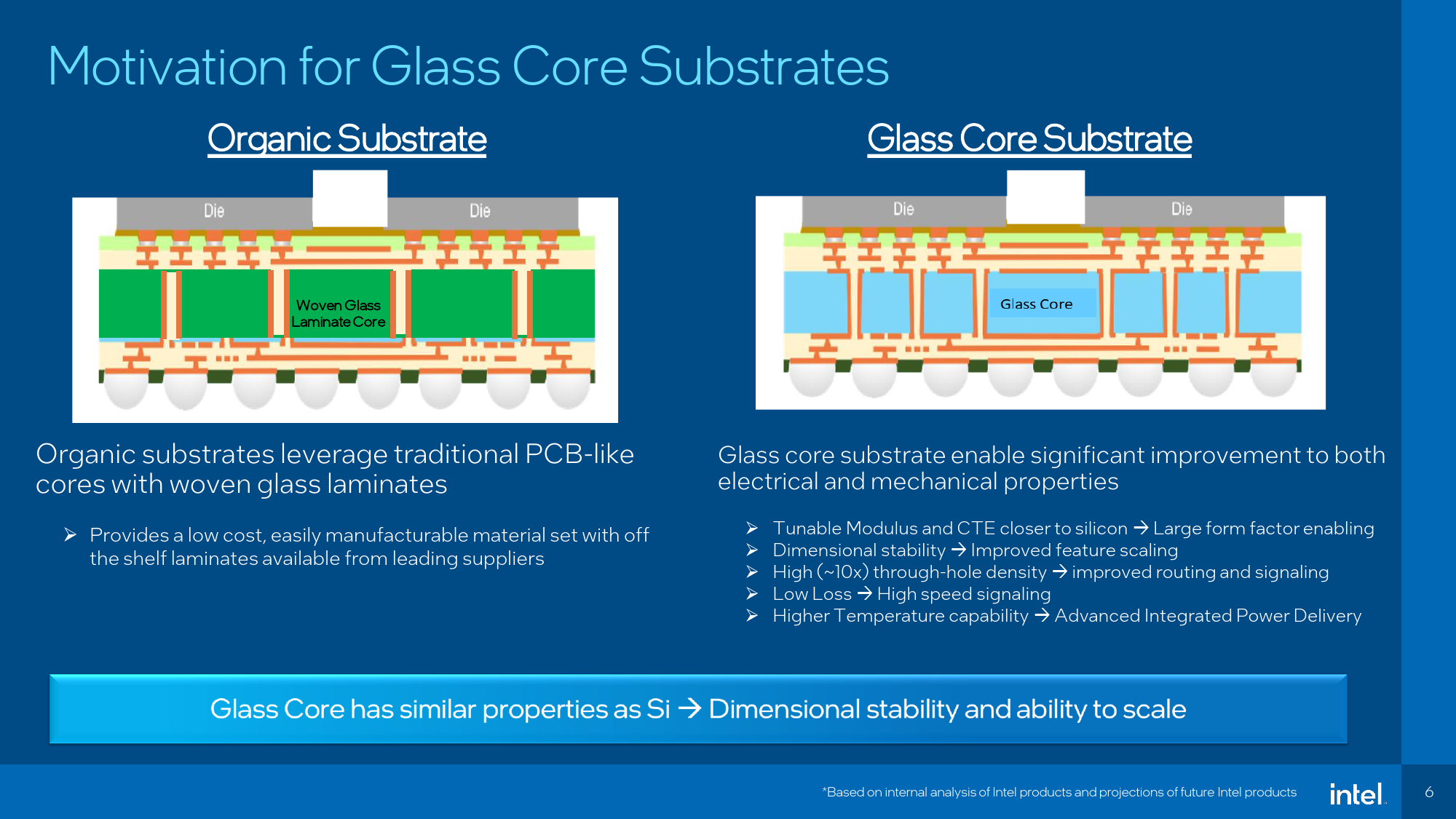

Glass substrates provide numerous advantages over conventional organic substrates. They offer exceptional flatness, which enhances the depth of focus for lithography, and outstanding dimensional stability for interconnects. These properties are crucial for next-generation SiPs that incorporate multiple chiplets. Additionally, glass substrates exhibit superior thermal and mechanical stability, enabling them to withstand higher temperatures while making them more durable for datacenter applications. Intel, which has been working on glass substrates for almost a decade, announced plans to adopt glass substrates for commercial products by 2030, anticipates that these characteristics will allow for a significant increase in interconnect density, which is essential for the power delivery and signal routing of next-generation SiPs.

In addition to Intel, Japanese company Ibiden, a leading semiconductor substrate manufacturer, has entered the glass substrate R&D arena, according to Sedaily. Ibiden announced its plans to focus on glass substrates as a new business venture in October last year. Similarly, in South Korea, SKC, an affiliate of SK Group, has established a subsidiary, Absolics, to explore mass production of substrates in collaboration with top semiconductor companies like AMD, which emphasizes the importance of substrates for next-generation processors.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

vanadiel007 While the article speaks about mechanical stability, I am wondering about mechanical strength? Because it's glass, it sounds fragile and I am thinking that might be a reason Intel has been working on it for 10 years and is looking at bringing it to market by 2030.Reply -

washmc Reply

Glass actually has a very high tensile strength when rigorously manufactured without flaws. https://en.wikipedia.org/wiki/Strength_of_glassvanadiel007 said:While the article speaks about mechanical stability, I am wondering about mechanical strength? Because it's glass, it sounds fragile and I am thinking that might be a reason Intel has been working on it for 10 years and is looking at bringing it to market by 2030. -

husker So a glass substrate is better than an organic substrate. What about conventional silicon substrates? Why is there no comparison provided in the story? Better to build a house out of paper instead of ice cream, but you might want to mention wood in the analysis.Reply -

Pierce2623 Reply

So…I’m probably wrong, but I got the idea that it would replace the PCB substrate rather than replacing silicon.husker said:So a glass substrate is better than an organic substrate. What about conventional silicon substrates? Why is there no comparison provided in the story? Better to build a house out of paper instead of ice cream, but you might want to mention wood in the analysis. -

Geef This made me think of the movies 2001 and 2010. HAL's memory was on what looked like glass modules.Reply -

hotaru251 my concern is if its normal glass its fragile & if its tempered glass it could randomly shatter (you see rare cases of glass side pales randomly shattering as its a rare flaw in tempered glass) & how warranty would work should those rare cases happen to ppl ;/Reply -

chych7 Reply

That's roughly correct. The standard microprocessor packaging substrate is some kind of fiber glass composite, which is similar to what PCBs are made with.Pierce2623 said:So…I’m probably wrong, but I got the idea that it would replace the PCB substrate rather than replacing silicon.

Silicon would be ridiculously expensive to make it a package substrate material, which has to be large and thick. -

chych7 Reply

You'd be surprised what kind of fragile materials are already used in microprocessors, like foamy glass-like materials in the dielectric layers. Ultimately semiconductor manufacturers have to certify their products against standard testing, which involve various mechanical and thermal tests. During the engineering of these technologies, these are entirely considered during development.vanadiel007 said:While the article speaks about mechanical stability, I am wondering about mechanical strength? Because it's glass, it sounds fragile and I am thinking that might be a reason Intel has been working on it for 10 years and is looking at bringing it to market by 2030. -

Co BIY Subtitle : Samsung teams up with partners to develop glass substrates.Reply

but...

Samsung's "coalition" is just parts of their conglomerate working together. -

thisisaname Reply

I just assumed (at the time) that the chips optical chip, using light rather than electricity.Geef said:This made me think of the movies 2001 and 2010. HAL's memory was on what looked like glass modules.