Intel Ramps Additional 14nm Manufacturing Site to Ensure Chip Supply

Intel has published a document that outlines the expansion of testing capabilities for 14nm processors to "assure a continuous supply" of some processors as it grapples with a shortage of manufacturing capacity. The move suggests that, aside from record demand, some of the issues with 14nm production capacity may stem from the availability of the company's chip-testing facilities.

Intel's 14nm CPU shortage impacts nearly every aspect of its business, including its desktop, server, and laptop processors. The shortages, which Intel self-reported during a recent earnings call, have exploded into the mainstream eye as OEM customers have revealed the impact to their businesses. The record demand, and resulting supply constraints, are likely the catalyst that led the company to produce the H310C chipset on the older 22nm node as it grapples with the consequences of its delayed 10nm node.

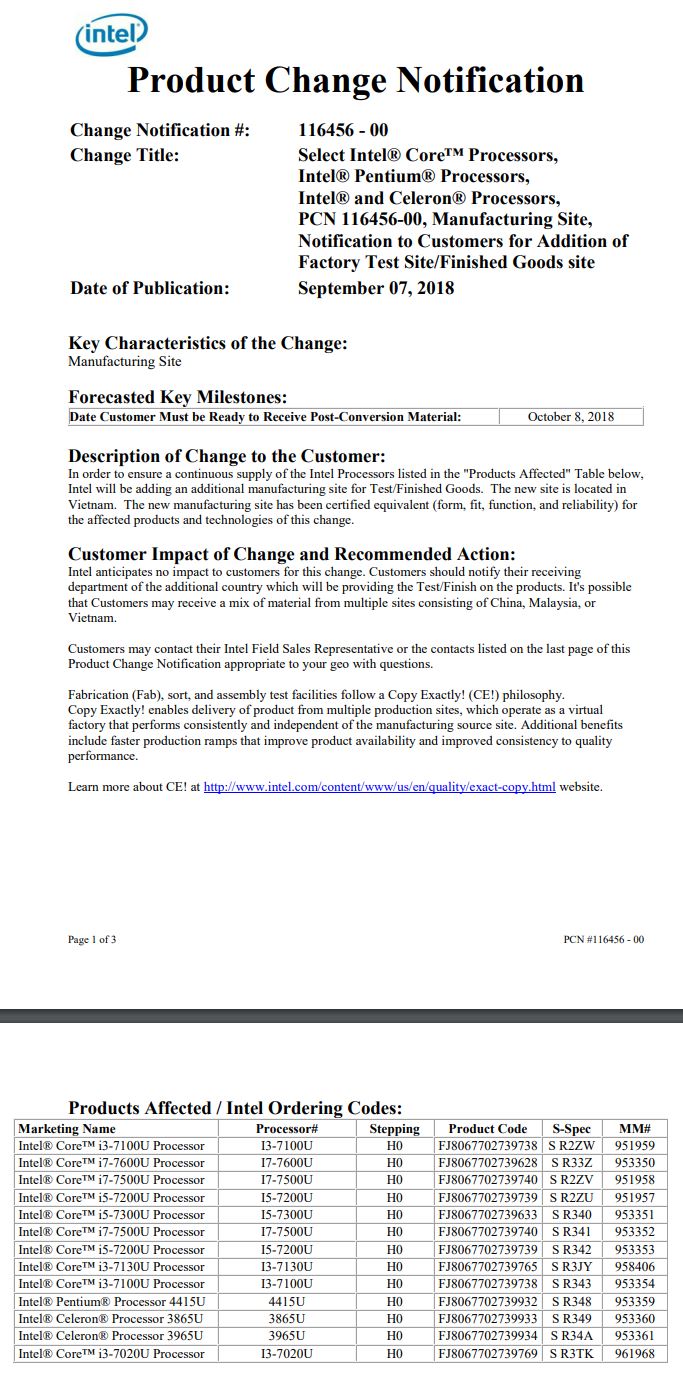

Intel's document (click to expand) outlines the move of some 14nm product testing to a facility in Vietnam under its Copy Exactly! program. This program assures that all production, testing, and methodologies used in Intel's various facilities aligns perfectly, thus speeding up the time to production and ensuring product quality is consistent across manufacturing sites.

Intel will test finished goods in the facility to assure supply of many seventh-gen processors (listed in the image), but it also suggests that testing capacity, and not necessarily just wafer production, is part of the bottleneck.

As we've covered in detail, Intel has several new 14nm products ramping simultaneously, such as Cascade Lake and Coffee Lake Refresh processors, and perhaps most importantly, the XMM 7560 modems that are used in the new line of iPhones. The sheer volume of modems is daunting. Apple ships ~50 million iPhones a quarter, and while all of those won't feature Intel's modems, a large number will.

These new modems are small, as outlined in iFixit's iPhone XS and XS Max teardown that it posted today, so these chips consume very little real estate on wafers. Consequently, Intel can pack a tremendous number of chips per wafer, which means modem production would only consume a few production lines.

But more chips per wafer equate to more time and steps required to cut the chips out of the wafers in a process called wafer dicing. The number of these tiny chips could also present a challenge for testing facilities, as each chip has to undergo rigorous test processes. These same concepts would apply to chipsets, which are also small yet still consume time in packaging and test facilities. That could be yet another impetus for Intel to manufacture the H310C chipset on the 22nm process.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Recent reports suggest Intel's biggest challenges may lie in testing capacity, and offloading some testing, even for older seventh-gen processors built on 14nm, could help alleviate some of the strain. A recent report from CRN reinforces the impact, which Intel purportedly outlined during a presentation to its partners:

The company also attributed the shortage to additional factory and assembly test capacity required for higher-end 14nm processors from the latest families of Core client and Xeon products that are seeing fast adoption from customers, said the source, who spoke on the condition of anonymity because the person wasn't authorized to speak publicly about the matter.

The impact of Intel's production limitations is also having a tangible impact on the broader PC market: Recent reports from industry analysts predict that the shortage could reduce PC sales five to seven percent, and it is also having the knock-on effect of reducing demand for other PC components, and thus sending prices plunging for both DRAM and NAND.

In fact, during its earnings call yesterday, Micron CEO Sanjay Mehrotra attributed some of the DRAM and NAND company's future performance to the ongoing shortage (via Seeking Alpha):

In our fiscal first quarter, we see some impact to our client compute customers, due to a shortage of CPUs.

And in the following question and answer session, Mehrotra indicated that the shortage could last beyond Q1 of next year:

And I would just add that the CPU shortages, we expect it to be short-term; it’s possible that it goes beyond Q1 as well.

All signs point to challenging times ahead for both Intel and the industry, and although Intel is obviously taking steps to address the production capacity issues, the industry may suffer well into 2019.

Paul Alcorn is the Editor-in-Chief for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.

-

anghellic so basically the shortage will last at a minimum 6 months till you get that facility up and running unless it already isReply -

chimonow Maybe they should cut down on the number of chipsets they have? AMD has 3 and that is enough. Z390 is a complete waste of resources and brings almost nothing to the table.Reply -

fffrederik Prices aren't plunging for dram, I doubt this shortage will be felt much. Probably 60% of people are fine with amd and some prefer it.Reply -

mlee 2500 Reply21341578 said:Maybe they should cut down on the number of chipsets they have? AMD has 3 and that is enough. Z390 is a complete waste of resources and brings almost nothing to the table.

Yeah, but for all you know it was an iterative development that cost them almost no investment to roll out but allows them to sell more chipsets. In fact I would bet on it.

-

DavidC1 ReplyThese new modems are small, as outlined in iFixit's iPhone XS and XS Max teardown that it posted today

How do you figure? It's the biggest chip in the picture. The last generation 7460 had a die size of 70mm2.

Intel's average die size shipped is only 100mm2. Even if the 7560 is only 50mm2, lets say with 140 million units sold, that's going to increase Intel's wafer requirements 30% overnight as the previous generation was using TSMC's process!

-

emv Couple questions:Reply

1) I think Intel told people they were making 100% of Apples Modems... so 50M might be the number. DO you know tht Qualcomm has some business on Xs Modems?

2) Intel has been shipping from Vietnam and most products are qualified. I think this is more formal decision on something that has been possible. do you think test facility is the limiter on 14nm? -

eye4bear Unless I missed something in this article, which to me almost comes across as an Intel infomercial, it fails to say who caused this, self inflicted?, problem in the first place. It is not like this is Intel's first day at the rodeo. What if AMD's chips had not turned out to be as good as they are and more PCs were still being built with Intel chips. This problem would be even worse than it is. Finally, to be clear, my personal home computer is an intel i5, so I am not a AMD fanboy.Reply -

bit_user Reply

Their 10 nm production has taking unreasonably long to bring online. They planned around having that capacity available, when deciding how much 14 nm production they would be running.21347645 said:Unless I missed something in this article, which to me almost comes across as an Intel infomercial, it fails to say who caused this, self inflicted?, problem in the first place. It is not like this is Intel's first day at the rodeo.

Combine that with a strong economy and Intel's first meaningfully faster CPUs in a while (i.e. 6-core Coffee Lake and upcoming 8-cores - both of which are *bigger dies* = fewer per wafer) and I think you have a recipe for something like this.

P.S. if AMD's chips had been weaker, I'd bet Intel would not be bringing 8-core chips to the desktop, right now.