Enthusiast Develops First Low-Profile Raspberry Pi 4 Cooler With Direct-Contact Heatpipes

George Godinez, experienced maker and computer engineering student, released a low profile heatsink with a direct-touch heatpipe for the Raspberry Pi 4 this week. Since the Pi 4 released in June, it's overheating issues have become more apparent. Godinez told us he was tired of not finding decent heatsinks for the Pi 4 that could accommodate HATs, so he decided to create his own from scratch.

Raspberry Pi 4 Heatsink Specs

| Supported Pi Model | Raspberry Pi 4 |

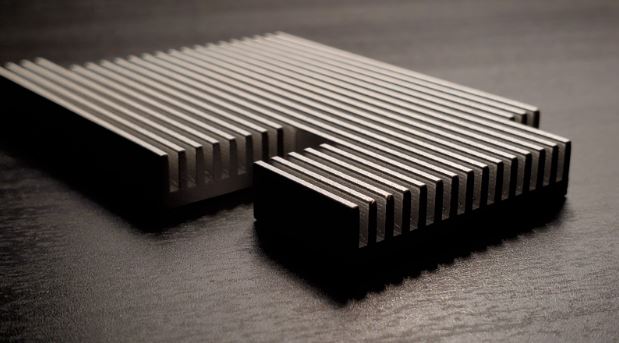

| Dimensions | 62 x 44 x 7mm |

| Material | 6063 Aluminum |

| Fin Size | 1mm |

| Fin Spacing | 1mm |

| Heat Pipe Size | 7.7mm x 1.5mm |

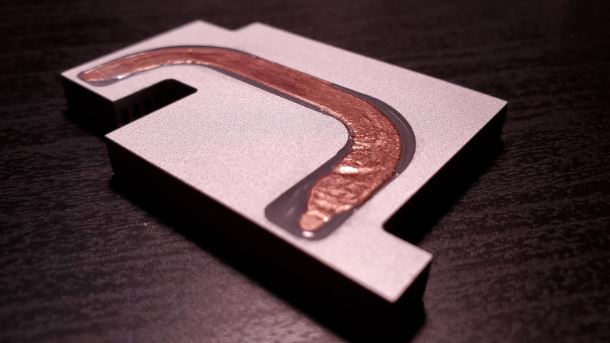

George used 6063 aluminum for the heatsink material. The heat pipe is encased in thermally conductive resin with the bottom exposed to make contact with the Raspberry Pi. He designed it to make sure everything that generates heat makes contact with the heatsink.

This heatsink measures in at 62 x 44 x 7mm, allowing it to accommodate most HATs for the Pi 4. Future editions may include support for a fan, but the first run is mainly designed for passive cooling.

Godinez first announced the heatsink on Reddit in September. Godinez stated he would sell the first batch of heatsinks on his online store known as Red Shiba. When the site is live, he plans to post the official benchmark results and sell them for $25.00 (€22.86) each.

This may not be the only project we see from Godinez. He hinted he might have plans for new projects involving other single board computers (SBCs).

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Ash Hill is a contributing writer for Tom's Hardware with a wealth of experience in the hobby electronics, 3D printing and PCs. She manages the Pi projects of the month and much of our daily Raspberry Pi reporting while also finding the best coupons and deals on all tech.

-

Giroro Putting everything in contact with the heatpipe isn't really ideal. Heat pipes are intended to transfer heat on one end of the pipe to the other, and they work because they are full of liquid.Reply

You want everything hot on one side of the heat pipe (evaporator) and the heat sink on the other side (condenser).

Is it better with the heat pipe than without it? I don't know, probably - unless the heat load saturates the heatsink and the cpu ends up cooking everything (which I doubt would happen)... But I have a feeling it mostly won't be effective enough to be worth the effort of adding the heatpipe at all. Although as far as I remember all the chips are different heights with the CPU being tallest, so cooling the CPU by itself is most likely what people end up doing - and effectively what would happen if the CPU gets direct contact and those chips are contacting through thick cheap barely-thermally-conductive blue silicone pads.

If I were to be designing this to cool only the CPU, I would put the conductive resin at either end of the heat pipe, but a thermal insulator between the heatsink and heatpipe directly above the CPU- this would help the heatpipe to function properly.

As-is, it would be cheaper and most likely just as effective to embed a chunks of copper into the heatsink above each chip (which would also solve the issue of different chip heights) - or just make the whole thing out of copper.

A lot of pi heatsinks do have heat transfer problems, but I think part of that is because people keep selling them with thermally-insulating doublestick tape. -

justin.m.beauvais Reply

Well, the CPU is going to be the hottest component by far. Nothing else is going to heat up like the CPU will. The heatpipe in this case looks more like a heat spreader, in order to distribute the heat over as much of the aluminum cooling surface as possible. The heatpipe is going to heat up and transfer heat down its length and the aluminum is going to draw that away with its large thermal mass. This cooler might not be perfect, but it will definitely keep the Pi from overheating, probably even without any active cooling.Giroro said:Putting everything in contact with the heatpipe isn't really ideal. Heat pipes are intended to transfer heat on one end of the pipe to the other, and they work because they are full of liquid.

You want everything hot on one side of the heat pipe (evaporator) and the heat sink on the other side (condenser).

Is it better with the heat pipe than without it? I don't know, probably - unless the heat load saturates the heatsink and the cpu ends up cooking everything (which I doubt would happen)... But I have a feeling it mostly won't be effective enough to be worth the effort of adding the heatpipe at all. Although as far as I remember all the chips are different heights with the CPU being tallest, so cooling the CPU by itself is most likely what people end up doing - and effectively what would happen if the CPU gets direct contact and those chips are contacting through thick cheap barely-thermally-conductive blue silicone pads.

If I were to be designing this to cool only the CPU, I would put the conductive resin at either end of the heat pipe, but a thermal insulator between the heatsink and heatpipe directly above the CPU- this would help the heatpipe to function properly.

As-is, it would be cheaper and most likely just as effective to embed a chunks of copper into the heatsink above each chip (which would also solve the issue of different chip heights) - or just make the whole thing out of copper.

A lot of pi heatsinks do have heat transfer problems, but I think part of that is because people keep selling them with thermally-insulating doublestick tape. -

bit_user Reply

No, I don't believe so. A heatpipe is basically a specialized vapor chamber, and those have no real requirement on shape. The only requirement is for the "cold" parts to remain cold enough for the fluid to re-condense.Giroro said:Putting everything in contact with the heatpipe isn't really ideal. Heat pipes are intended to transfer heat on one end of the pipe to the other, and they work because they are full of liquid.

Also, heat pipes are not "full of liquid". All that's required is that you have enough active fluid for some to remain liquid within the pipe's operational parameters.

They can include shims for the other chips, if so. Although that's less efficient (i.e. no longer direct-touch), the CPU is certainly what produces the most heat.Giroro said:as far as I remember all the chips are different heights with the CPU being tallest,

I think you need to spend more time reading about heatpipes and less time posting.Giroro said:If I were to be designing this to cool only the CPU, I would put the conductive resin at either end of the heat pipe, but a thermal insulator between the heatsink and heatpipe directly above the CPU- this would help the heatpipe to function properly.

You don't want a "chunk" of copper. What you want is to efficiently move heat into to the fins. You don't do that with a "chunk" of anything. And heat pipes are massively more efficient than solid copper, which is why they're so popular.Giroro said:it would be cheaper and most likely just as effective to embed a chunks of copper into the heatsink above each chip

Copper is also rather expensive. I'm not sure that would be within budget.Giroro said:just make the whole thing out of copper. -

bit_user I just wonder if this would work better with cross-cut fins. Particularly with a hat on top, it seems like the linear fins could tend to trap hot air up against the hat.Reply

That said, I'm sympathetic to cost constraints. A lot of people will be unwilling to use a heat sink that's near or equal to the cost of the Pi. -

CooliPi Heatpipes aren't necessary. HATs on top of the heatsink block airflow.Reply

I've designed a different solution in mid July. Unfortunately, many hardware sites' editors are busy with new mainstream hardware and don't have time to review it. What a pity.

No ads - google my name. -

CooliPi ReplyGiroro said:Putting everything in contact with the heatpipe isn't really ideal. Heat pipes are intended to transfer heat on one end of the pipe to the other, and they work because they are full of liquid.

You want everything hot on one side of the heat pipe (evaporator) and the heat sink on the other side (condenser).

Is it better with the heat pipe than without it? I don't know, probably - unless the heat load saturates the heatsink and the cpu ends up cooking everything (which I doubt would happen)... But I have a feeling it mostly won't be effective enough to be worth the effort of adding the heatpipe at all. Although as far as I remember all the chips are different heights with the CPU being tallest, so cooling the CPU by itself is most likely what people end up doing - and effectively what would happen if the CPU gets direct contact and those chips are contacting through thick cheap barely-thermally-conductive blue silicone pads.

If I were to be designing this to cool only the CPU, I would put the conductive resin at either end of the heat pipe, but a thermal insulator between the heatsink and heatpipe directly above the CPU- this would help the heatpipe to function properly.

As-is, it would be cheaper and most likely just as effective to embed a chunks of copper into the heatsink above each chip (which would also solve the issue of different chip heights) - or just make the whole thing out of copper.

A lot of pi heatsinks do have heat transfer problems, but I think part of that is because people keep selling them with thermally-insulating doublestick tape.

Heatpipes can thansfer heat from one end to the other with low delta temperature. But the Pi isn't limited by too much power in one hotspot. It's limited mainly by size of the heatsink for passive cooling.

Copper and heatpipes may help with a 100W hotspot. Large area alone helps with 8W. No need to transfer a few watts a few centimeters unless you are height limited. And after an installation of a HAT on top of the heatsink, all the effort with copper and hetapipes becomes nil.

I don't agree on the last idea - many of the Pi heatsinks have a problem that they're too small for the 8W load! Or are blocked behind something, thus voiding its proper function.

Some I've seen are way way too small - just a joke. Some others are a bit bigger, but covered with fans blowing nowhere. Or with fans blowing towards each other. Or blowing through a 1mm wide hole. One another has horizontal fine fins . They must be vertical. And not so fine, because that blocks airflow.

Forced cooling is a different playground. Small fans die in a half a year. Really "good" investment... But finely spaced fins can start to work with enough airflow. -

syadnom This is a flat out bad design. Heatpipes transfer data from end to end to take heat away to a cooler spot. This puts the primary heat source directly in the middle of the pipe, so it's completely useless. This likely behaves worse the just having the heatsink.Reply

Further, this is pushing heat from the hot CPU to other lower watt devices so will likely make the overall system less stable.

Much simpler and more effective would be a substantially larger heatsink with taller pin-fins. I understand that the desire to have a heatsink compatible with hats was the initial goal so along those lines, the heatpipe should wrap around the side to a large heatsink on the back side. The low profile heatsink on the front can be for the devices on the front, then the end of the heatpipe should be right on the CPU. -

CooliPi Replysyadnom said:This is a flat out bad design. Heatpipes transfer data from end to end to take heat away to a cooler spot. This puts the primary heat source directly in the middle of the pipe, so it's completely useless. This likely behaves worse the just having the heatsink.

Further, this is pushing heat from the hot CPU to other lower watt devices so will likely make the overall system less stable.

Much simpler and more effective would be a substantially larger heatsink with taller pin-fins. I understand that the desire to have a heatsink compatible with hats was the initial goal so along those lines, the heatpipe should wrap around the side to a large heatsink on the back side. The low profile heatsink on the front can be for the devices on the front, then the end of the heatpipe should be right on the CPU.

We can get max temp delta at about 23degC with 4 core linpack load, no video output. Stock RPI4B with no case throttles at 3rd and 4th core load.

And yes, it's larger and it can host HATS without blocking airflow ;-)

CooliPi -

Giroro Reply

If the intention is to move heat from the 'bottom' to the 'top' of the heat pipe like a vapor chamber, then it will be better to use a vapor chamber. The capillaries in a heat pipe will interfere with that action.bit_user said:No, I don't believe so. A heatpipe is basically a specialized vapor chamber, and those have no real requirement on shape.

bit_user said:The only requirement is for the "cold" parts to remain cold enough for the fluid to re-condense.

That's exactly my point. This is why it's bad design to put load across the entire heat pipe: It prevents "cold" parts from existing.

If the CPU saturates the heat sink at a higher temperature than the other chips -which seems likely, then putting other chips in contact with it will heat them up instead of cool them.bit_user said:They can include shims for the other chips, if so. Although that's less efficient (i.e. no longer direct-touch), the CPU is certainly what produces the most heat.

No need to be rudebit_user said:I think you need to spend more time reading about heatpipes and less time posting.

Well the thesis of my argument is that using a heat pipe in this arrangement isn't going to transfer heat over such a small area and small load any more efficiently than plain copper. Heat pipes are massively more effective than solid copper when designed so the fluid flows properly. This one isn't designed to work as effectively as it should. I think it is adding very little, if anything to the effectiveness of the heat sink compared to solid copper. Depending on the resin holding it in there, it might not even be more effective than direct contact to the aluminum heat sinkbit_user said:You don't want a "chunk" of copper. What you want is to efficiently move heat into to the fins. You don't do that with a "chunk" of anything. And heat pipes are massively more efficient than solid copper, which is why they're so popular.

bit_user said:Copper is also rather expensive. I'm not sure that would be within budget.

Heat pipes cost a lot more than the copper that they are made of. All the extra steps to inlay it into the heatsink also adds cost that wouldn't be necessary with a solid copper heatsink. -

Giroro ReplyCooliPi said:I don't agree on the last idea - many of the Pi heatsinks have a problem that they're too small for the 8W load! Or are blocked behind something, thus voiding its proper function.

I specifically mean the pimoroni heatsink which is one of the more commonly reviewed ones

https://www.tomshardware.com/reviews/pimoroni-fan-shim-heatsink-raspberry-pi-4,6219.html

Thermal images from Tom's and others always show the surface of the heatsink as much cooler than the CPU when it's thermal throttling, with the temperature evenly distributed throughout the heatsink. This suggests there is a heat transfer problem between the CPU and heatsink.

And as Tom's pointed out that heatsink (and almost every Pi heatsink I've seen) it ships with 3M Double Coated Tissue Tape 9448A which is a "thermal tape" in the sense that it will stay sticky at high temps but is not an effective thermal conductor. 3M dosn't even list it's thermal conductivity on the spec sheet, because its not intended for that use.

But hey, I could be totally wrong, most people have never gone shopping for thermally conductive tape before, and I've never found a review where they test that heatsink with better tape.