World's first chip-based 3D printer is smaller than a coin — benefits from having no moving parts

Imagine misplacing your house keys and then pulling out a 3D printer from your pocket to make new ones.

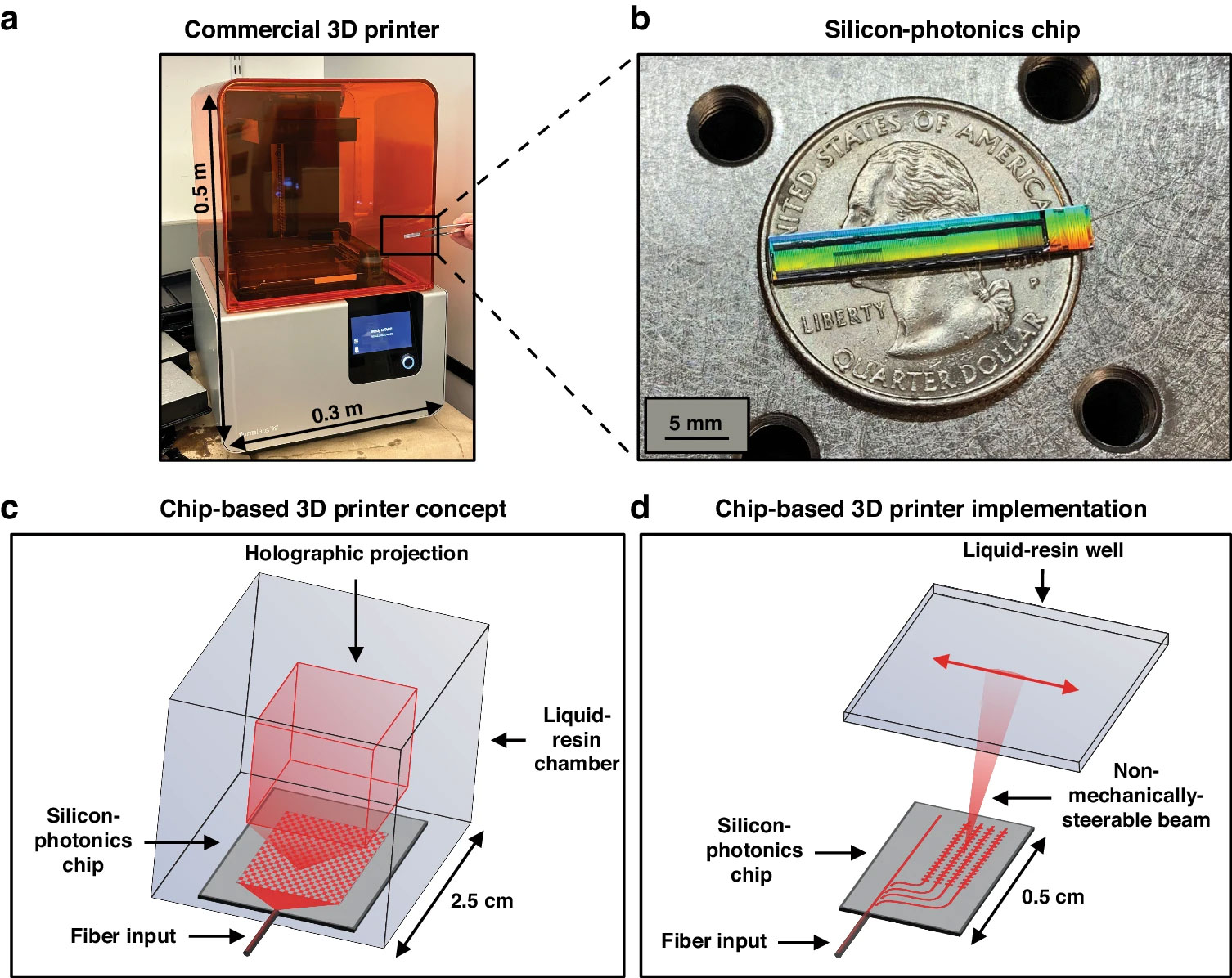

3D printing has made manufacturing more affordable, especially for low-volume production. However, 3D printers are often huge and heavy devices that need a stable platform to work properly — until now. MIT News reports that its researchers have worked closely with a team from the University of Texas at Austin to create a prototype 3D printer that is smaller than a coin.

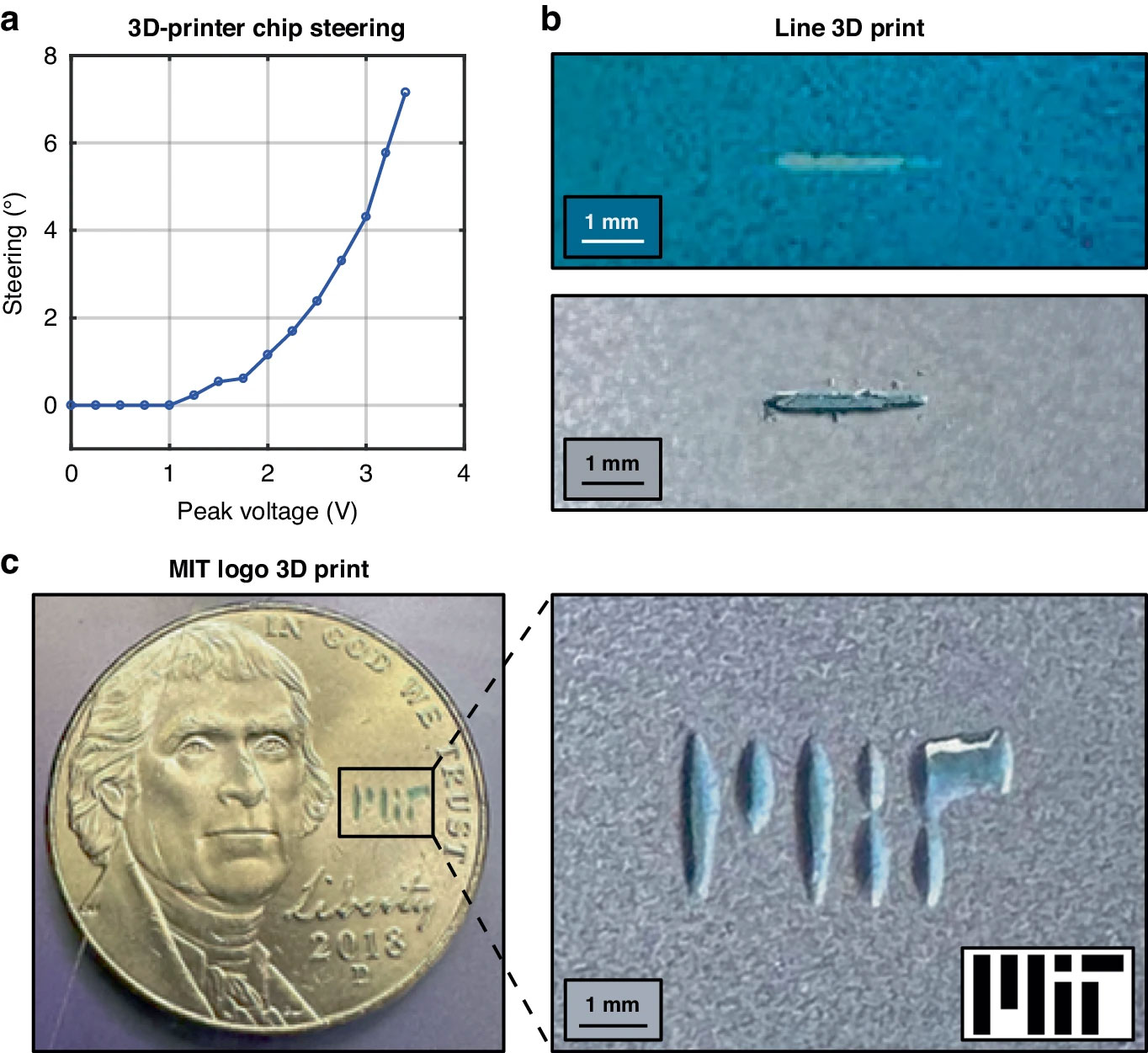

This photonic chip focuses its beam into a resin well that rapidly cures when it’s hit by a particular wavelength of light emitted from the chip. The palm-sized 3D printer also saves space by eschewing moving parts — instead of using arms and motors to change the beam’s focal point, the prototype uses tiny optical antennas to move it around and create the desired shape.

If the team is successful in turning this concept into a viable product, it could change the face of instant manufacturing. The portability and speed of this palm-sized printer could allow anyone — engineers, doctors, or even first responders — to create solutions on the fly without needing to lug around a big and heavy device.

For example, an orthopedic surgeon could bring a 3D scanner into the operating theater and scan a patient’s broken bones. From there, they could bring in a biomedical engineer to craft a custom bone implant to help fractures heal and then print it with the portable 3D printer using a biomedical resin.

Alternatively, this small 3D printer would be much easier to bring on the Artemis moon exploration program, especially as it is lighter and more compact than other alternatives. It could then be useful for creating tools that the crew will need on the fly.

These are just some of the exciting possibilities that this 3D printing concept brings to the table. According to MIT Professor Jelena Notaros, “This system is completely rethinking what a 3D printer is. It is no longer a big box sitting on a bench in a lab creating objects, but something that is handheld and portable. It is exciting to think about the new applications that could come out of this and how the field of 3D printing could change.”

3D printing has quickly changed over the years since it was first introduced. Today, we are getting metal 3D printers in the International Space Station that can print tools and parts needed for moon and Mars missions, as well as cheap $77 AliExpress 3D printers that let you start making your own builds at a fraction of the cost. We’ve even seen affordable new 3D printers that are large enough to print a small child. If this project makes it to retail, then, soon enough, we’ll have a 3D printer you can fit in your pocket.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Jowi Morales is a tech enthusiast with years of experience working in the industry. He’s been writing with several tech publications since 2021, where he’s been interested in tech hardware and consumer electronics.

-

nightbird321 Imagine not having keys to a house you don't live in... beginning of the end of physical locks?Reply -

hotaru251 Reply

If a criminal wants in your house doors lock is the least of your worries as they can easily just bust a window.nightbird321 said:Imagine not having keys to a house you don't live in... beginning of the end of physical locks?

Most digital doorlocks are poorly done you might as well have a cheap physical lock & save some $. -

vinay2070 Reply

Big problem in western countries, doors windows are all glass. Less of an issue in Asian countries and India though. Everything is concrete, only way is to break a lock or the wooden door as even the windows have thick grills. Forget thieves even wild animals can just walk in through the glass.hotaru251 said:If a criminal wants in your house doors lock is the least of your worries as they can easily just bust a window.

Most digital doorlocks are poorly done you might as well have a cheap physical lock & save some $. -

adunlucas Reply

He meant the house os buit in concrete. In most south América countries houses are built with bricks and cement. Windows are iron or wood (hardwood, not softwood), or maybe glass but with iron bars. Is not uncommon houses being invades even trough the ceiling when possível, só house buit with drywall are note common. O myself live in a house with 15cm walls built with bricks and cement, the Doors and Windows are iron. And i live in a safe neighbourhood. It's because is a common and cheap material.jkflipflop98 said:Concrete windows, eh? I'd like to see that. -

Air2004 Reply

https://images.app.goo.gl/ReBgXWzsomxCSGyq7jkflipflop98 said:Concrete windows, eh? I'd like to see that. -

ivan_vy "We’ve even seen affordable new 3D printers that are large enough to print a small child."Reply

child and child-size things are not the same thing. -

HWOC I've learned a lot from this news article, and from this thread of comments. I didn't know you could "3D scan broken bones in an operating theatre, I thought you'd need an x-ray or CT machine for that.Reply

Also I didn't know you can make windows out of concrete, iron or wood.

No one is talking about the need to wash and cure resin prints after they are actually printed, does this miniature printer somehow not need those steps, or has it been ignored for convenience? The news headline is a lot less impressive if you need extra bits in addition to the coin-sized printer itself, like a resin vat, means of washing and curing etc. But I guess you could use water-washable resin and let it cure in sunlight. -

Evildead_666 This picture on a coin also doesnt seem to show the steerable tiny light source either.Reply

It also looks like it can only print tiny things....

Im having a hard time visualizing the whole 'printer'

This just looks like the printable material....