The International Space Station is getting the first metal 3D printer made for space, designed by Airbus and the ESA

Once proven successful, the stainless steel wire-based printer will be fabricating parts needed for missions on the moon and Mars.

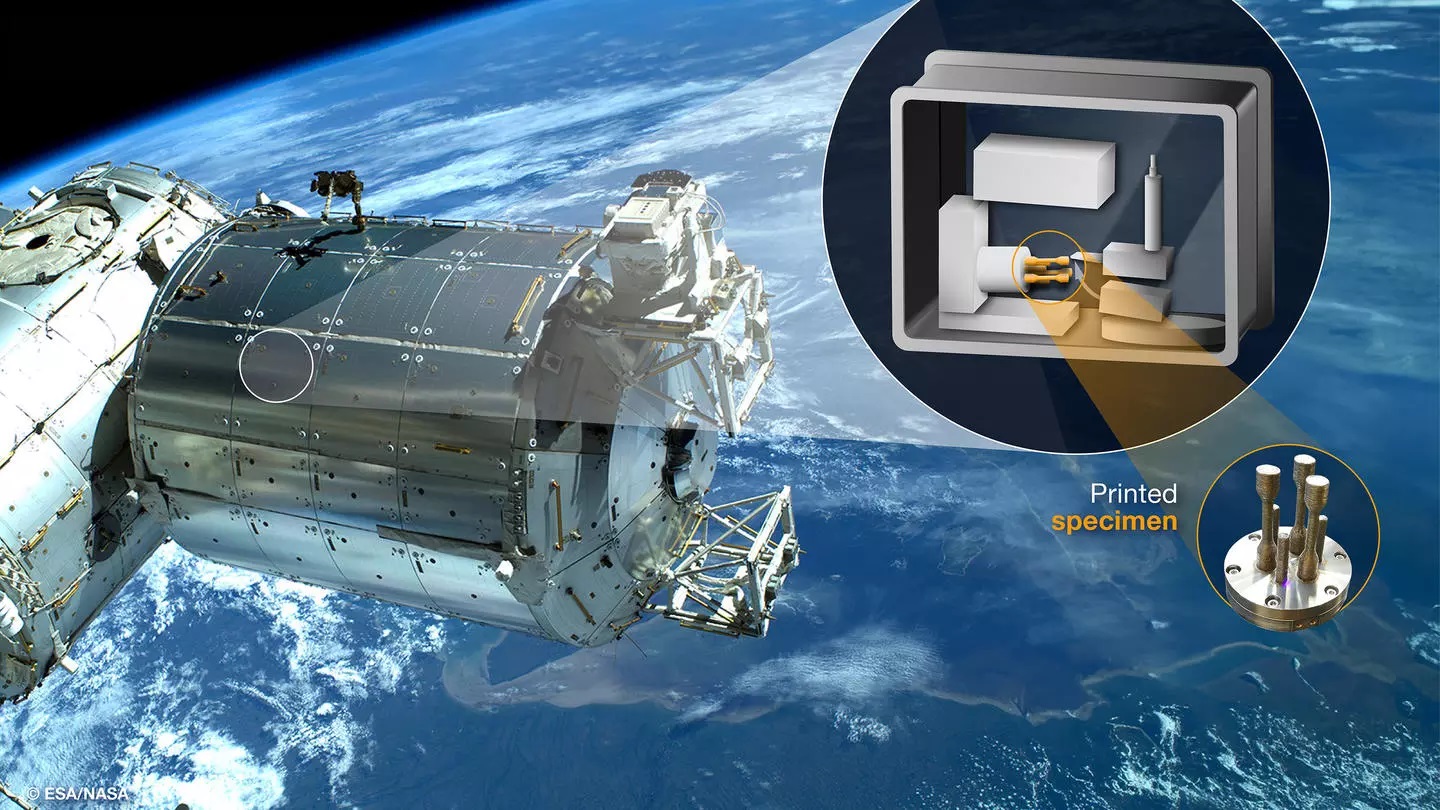

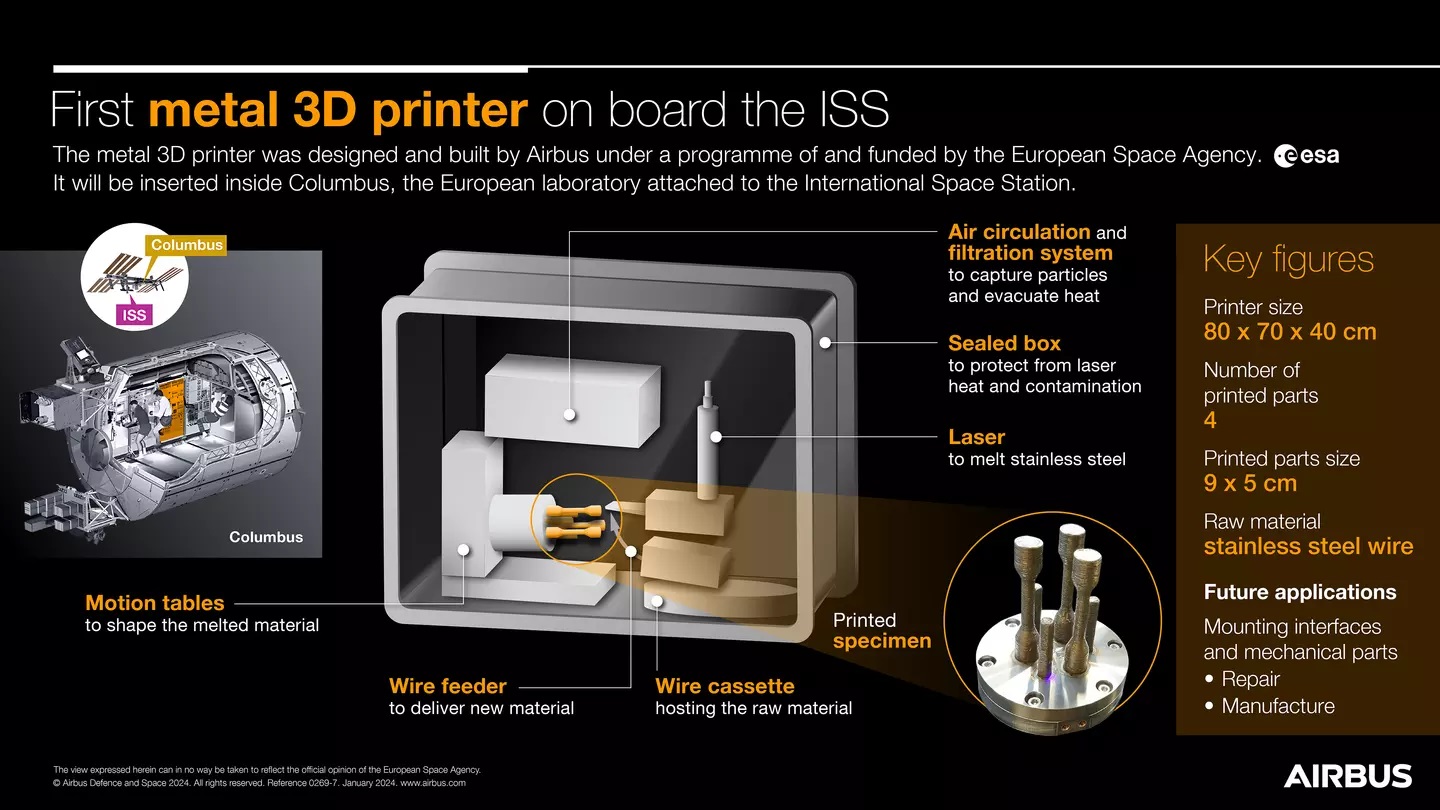

A promising European-made metal 3D printer is on its way to space, to be tested on the International Space Station. The new hardware will be transported via the upcoming Cygnus NG-20 resupply mission, and will use stainless-steel wire which will be heated by a high-powered laser. This is the first metal 3D printer made for space, in collaboration between the European Space Agency and Airbus, and will be used inside 'Columbus' a European Laboratory aboard the ISS.

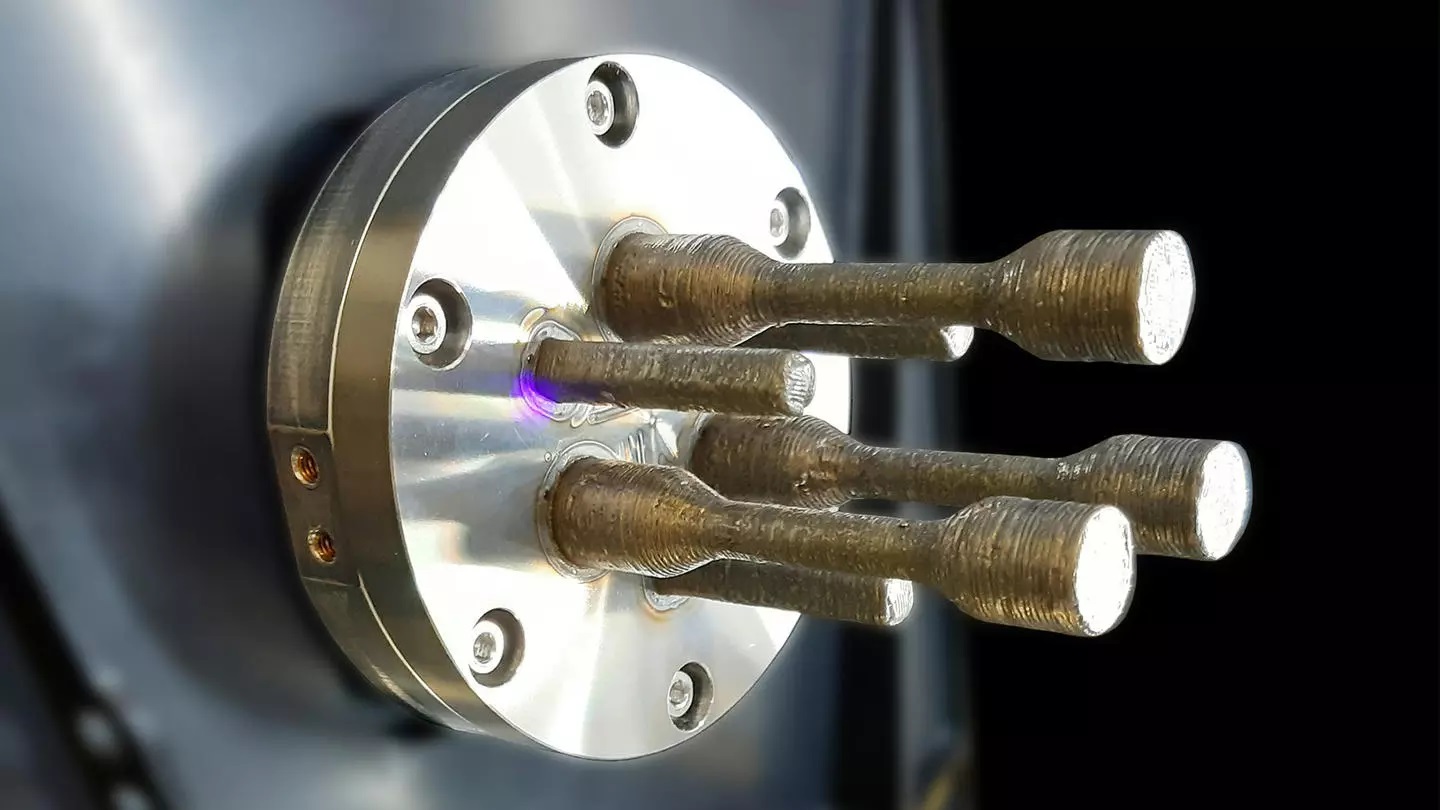

Two printers will be used for this experiment, made by Airbus. One is the engineering model made on Earth, and the 'flight model' to be used on the ISS. The experiment will initially involve printing four samples in space, to be later sent to Earth for analysis. Each part will take around 40 hours to print. These samples will be tested by the ESA and Danish Technical University.

Gwenaëlle Aridon, Airbus Space Assembly lead engineer, said in a post on the company's site the printer “will bring new on-orbit manufacturing capabilities, including the possibility to produce load-bearing structural parts that are more resilient than a plastic equivalent. Astronauts will be able to directly manufacture tools such as wrenches or mounting interfaces that could connect several parts together. The flexibility and rapid availability of 3D printing will greatly improve astronauts’ autonomy.”

The importance of Metal 3D Printing in Space

The International Space Station has been a platform to experiment and implement independent systems to rely less on mission control on Earth and more on on-site data processing and manufacturing for NASA & ESA, in collaboration with a few private companies. With the benefits of such additive manufacturing, future missions on the moon and even on Mars would have the means to design and make new parts. The implication of this is significant, as engineers cpould print anything they need during a mission, from living quarter upgrades to making spare parts. Printing these parts on-site is more efficient than bringing them from Earth, reducing the logistics and potentially saving multiple trips.

3D printers have been used on the ISS extensively for years, but the durability of steel will bring more applications and reliability. That said, there are challenges in printing metal in space as explained by Sébastien Girault, metal 3D printer system engineer at Airbus. He says that to create this prototype on the ISS, it will need to be the size of a washing machine to print parts to a volume of nine centimeters high and five centimeters wide. Safety will also be a key priority as the process involves 1200 degrees Celsius needed for metal printing, compared to 200 degrees used for plastic-based 3D printing. Gravity management and managing fumes & contamination are other important issues. Hence, unlike metal 3D printers that are in the works here, the entire unit will be in a safe-like sealed metal box.

NASA did similar exercises last year using a new alloy called GRX-810, which is made to be durable at high temperatures and very resistant to oxidation.

With space exploration expanding across all space organizations, and involving commercial companies like HPE, Kioxia, SpaceX and Airbus, having such on-site solutions is critical. While this printer's implementation, these experiments onboard the ISS will allow engineers to refine its development through a trial-and-error process. Lessons learned here may also eventually translate into benefits for commercial applications on Earth.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Roshan Ashraf Shaikh has been in the Indian PC hardware community since the early 2000s and has been building PCs, contributing to many Indian tech forums, & blogs. He operated Hardware BBQ for 11 years and wrote news for eTeknix & TweakTown before joining Tom's Hardware team. Besides tech, he is interested in fighting games, movies, anime, and mechanical watches.