A peek into the future of 3D printing: Rapid + TCT 2025 in Detroit

Discovering (not so) new technology at North America’s biggest Additive Manufacturing event.

Detroit’s RAPID + TCT was a huge Additive Manufacturing event with over 400 exhibitors from all facets of the 3D printing industry showing off new machines and technological breakthroughs for both the media and potential buyers. Though most companies displaying wares were on the industrial side, there was still plenty to see for those of us focused on the consumer market. Prusa, Bambu Lab, Elegoo, Creality, FLSun, and Phrozen were all there to show off their latest models. We also saw handheld scanners from Creality and RevoPoint, as well as lasers and plenty of filament.

The show was simultaneously overwhelming and slightly disappointing. There were no surprises unveiled, at least not for me, as all the new consumer-grade printers were either something I knew was coming or had already spent time on my workbench.

On the industrial side, we checked out HP, who sponsored custom car designers Blazin Rodz and their “Doughboy”, a restored and highly modified 1970 Chevy Chevelle. The team used HP’s Multi Jet Fusion technology to produce over 75 custom parts.

Probably the coolest industrial printer we saw in action was Rapid Liquid Print’s Levity, a gravity free 3D printer that injects super soft materials like 50A silicone into a reusable tub of gel. After resting for a few hours, the finished prints are scooped out and rinsed in ordinary water. The new technology is capable of making custom gaskets, shoes, comfy liners for prosthetics and more, all without waste.

Prusa Research shows off the CORE One, MK4S with MMU3 and XL

We sat down with Josef Prusa, CEO and Founder of Prusa Research, for a quick chat about the CORE One and his expansion into the American market. In 2022, his company acquired Delaware-based Printed Solid, a filament manufacturer that also sold spare parts for 3D printers. Prusa Research has since expanded the company’s filament production and added a Prusa print farm to manufacture MK4S.

“I’m very excited we’re getting a lot of orders in, manufacturing is ramping up, and we’re hiring more people,” Prusa said. “We’re making 200 MK4S a month at Printed Solid, which is very few in the grand scheme of things, but we want to solve everything before we scale up.” He added that in the near future, all MK4S and CORE One printers for the US market will be made at Printed Solid.

Printed Solid’s machines are currently labeled as “Assembled in the USA” even with the local print farm. “There are some marks we have to hit. It’s hard. We’re working to meet that goal,” Prusa said of getting the coveted “Made in the USA” certification. Though Prusa Research has sought to bring much of its printer manufacturing in-house at Prague, it’s another thing entirely to duplicate the setup in the United States. Prusa said he aims to become the biggest manufacturer of 3D printers in America.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

When I asked if the CORE One would be getting its own MMU system, I was told that it was coming very soon, most likely by this summer. The printer’s firmware is being tuned to use the current MMU3 rather than devise a new color unit. The biggest hurdle seems to be figuring out if they will put it in an “AMS” style box like the competition or keep it strung out to the side as it currently sits with the MK4. Members of the team agreed that the company had issues with previous incarnations of the multimaterial system, and though the MMU3 still looks like a science project, it's the best color system on the market.

For full disclosure, Prusa Research was kind enough to sponsor my travel to Detroit and arrange interviews with their team.

Creality Reveals New K2 sizes, a scanner and laser

Creality was the only company to show off something I hadn’t expected, and no, it's not a rumored H2D clone. The company had two new Core XY printers: A K2 Combo and a K2 Pro Combo. The printers are not yet released and did not have prices. The K2 Combo has a 260 x 260 x 260mm build volume, while the K2 Pro Combo has 300 x 300 x 300mm build volume. This will no doubt disappoint Creality fans who were hoping the K2 Plus, with it’s 350 x 350 x 350mm build volume, was the mid-size printer and were waiting for a “max”.

Creality instead gave center stage to its new handheld scanner, the Raptor, which comes in Pro and X models as well. The scanners currently range from $1,499 to $4,599, have incredible accuracy, and can scan items up to 12 feet or more. They can scan black and metal objects without sprays and should be a huge improvement over the now-discontinued Scan Lizard, which we reviewed in 2022. The Raptor Pro arrived at our workshop shortly before Rapid and will soon undergo testing.

They also had their new Creality Hi on display, an affordable 260 x 260 x 300mm bed slinger with a four spool CFS multicolor unit. It’s currently on sale for $519 and can handle up to four Creality Filament Systems. Our test unit was lost in shipping, but I’ll be sure to let know how it stacks up in a review later this year.

Creality also had a Falcon A1 Pro “smart” laser on display, which is a fully enclosed dual 20w diode and 2w IR laser that can engrave nearly any material. I look forward to reviewing this unit shortly.

Creality shared their booth with sister company Piocreat, which now handles the HALOT resin line as well as their large industrial FDM machines. The HALOT-X1 has put a twist on resin by introducing a fixed build plate and a lifting vat for the resin. This is to reduce vibrations for even smoother prints. We’re unboxing this one soon and report back to you in a few weeks!

Elegoo presents the Jupiter 2, Centauri Carbon and OrangeStorm Giga

Elegoo’s newest offering was the Jupiter 2, the company's largest resin printer to date, with a whopping 14-inch LCD screen and 16K resolution. It has a build volume of 302 x 162 x 300mm, which is bigger than most FDM machines. It has swinging doors instead of a lift-off lid, which promises to be much easier to use. It will be available sometime in the 3rd quarter, and the price is yet to be determined.

However, Elegoo disappointed us by not following through on a social media campaign proclaiming “something big is coming” with a black draped teaser image. Naturally, Elegoo fans looked at the bumpy shape and surmised the wildly popular Centauri Carbon was getting a multicolor addition. When I arrived at the booth, I was greeted with a nervous giggle and shown their new “big” resin. The 800 x 800 x 1000mm OrangeStorm Gigawas also on display.

Looks like color will have to wait.

Bambu Lab shows off the H2D, new filament and STEM Kits

I didn’t expect anything new at Bambu Lab, as the company had just launched its premium flagship, the H2D. This show may be the closest many people will get to the controversial Laser + 3D printing “personal manufacturing hub” as the pre-tariff stock sold out in minutes. Post tariff, the machine is $500 to $900 more expensive, depending on the model. The website is currently advertising an April 22 availability date, but it's unknown how many printers will be set aside for US customers.

A much more affordable offering was the Cyberbrick, currently available on Kickstarter. Once the Kickstarter is over, parts will be sold on Bambu Lab’s Maker’s Supply. Reminiscent of Lego’s Mindstorm kits, Cyberbricks are reusable electronic modules that are combined with 3D printed parts to create RC cars. A basic kit includes parts for the remote and one vehicle, with files available online. Bambu Lab invites the community to come up with custom models for the kit and share them with others on MakerWorld.

Also on display is their new, very soft, TPU 85A and TPU 90A, which comes in six colors, including two gradients. The filament is being shown off in 3D printed shoes on the H2D.

FormLabs: Hammer Time

FormLabs was a major player at Rapid + TCT, and somehow the only company that convinced the venue they could safely demonstrate resin printing, which really says a lot. A company rep was doing live demos of the FormLabs 4 and showing off their new industrial-sized FormLabs 4L, which is currently under review.

They had an array of materials on display, most notably, BioMed Durable, which is a transparent and shatter resistant material used for implants and surgical guides. They invited YouTuber Joel Telling to compete with visitors in a hammering contest, where they used a 3D printed BioMed hammer and common wood nails.

Also on display was their new Creator Resin, designed for hobbyists who want FormLabs quality without paying FormLabs industrial prices. The resin is designed to run in ordinary LCD and DLP printers and is currently on sale for $35 a KG.

GreenGate 3D: Now Recycling Nylon

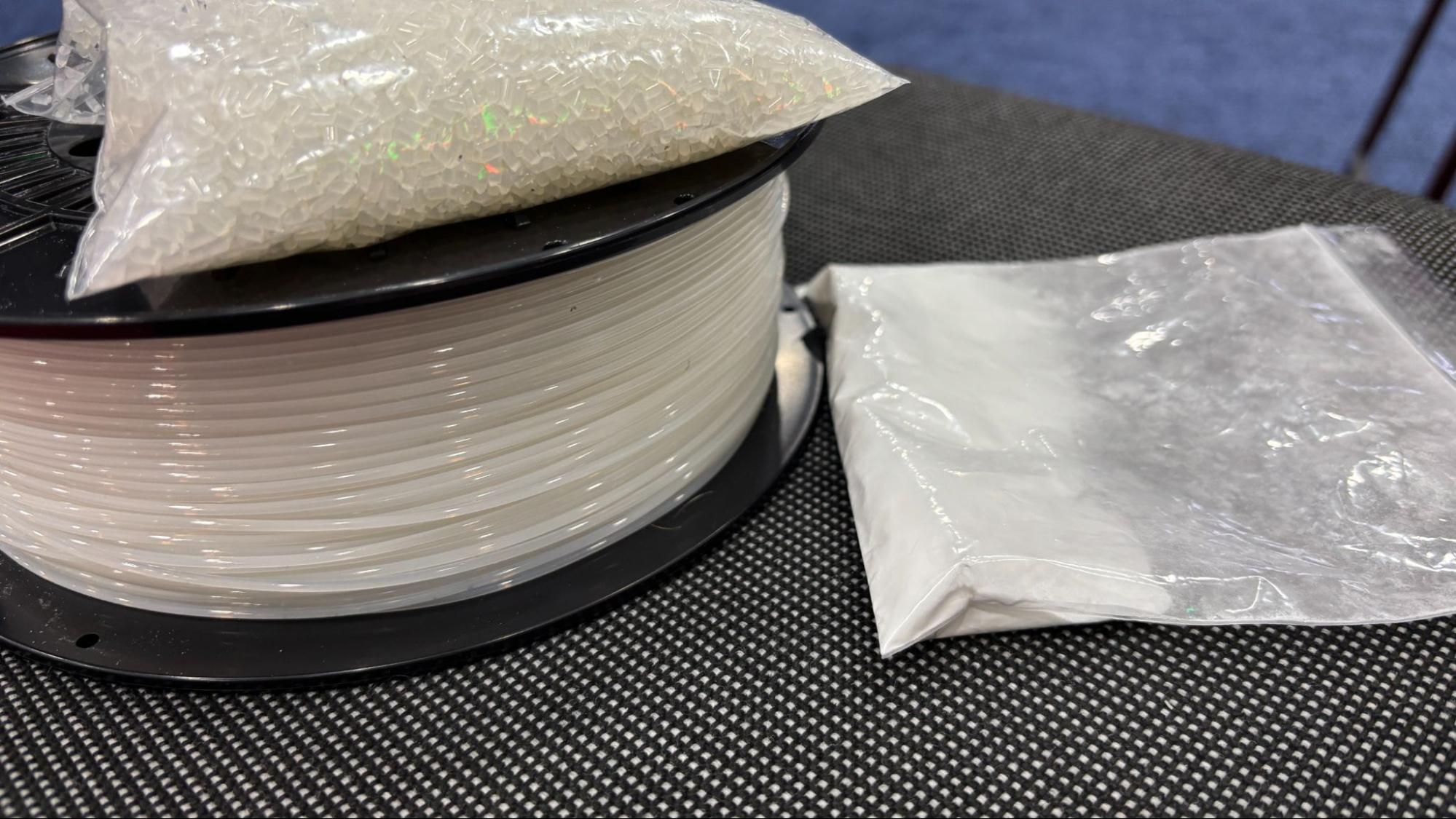

GreenGate3D, known for their recycled PETG filament, gave me a scoop: they are in the midst of recycling nylon. The owner, Rich Silberfeld, was excited to show his first ever spool of recycled Nylon 12 material. GreenGate found another (undisclosed) additive manufacturer that uses nylon power in SLS printers but didn’t have a good way to recycle their material. GreenGate will take the powdered nylon leftover from the manufacturer, sift out any impurities, compound it into pellets, and extrude it onto a spool. The new filament is still in the prototyping phase but is expected to sell for $40 a half kilogram. We’ll be sure to test some as soon as it’s ready!

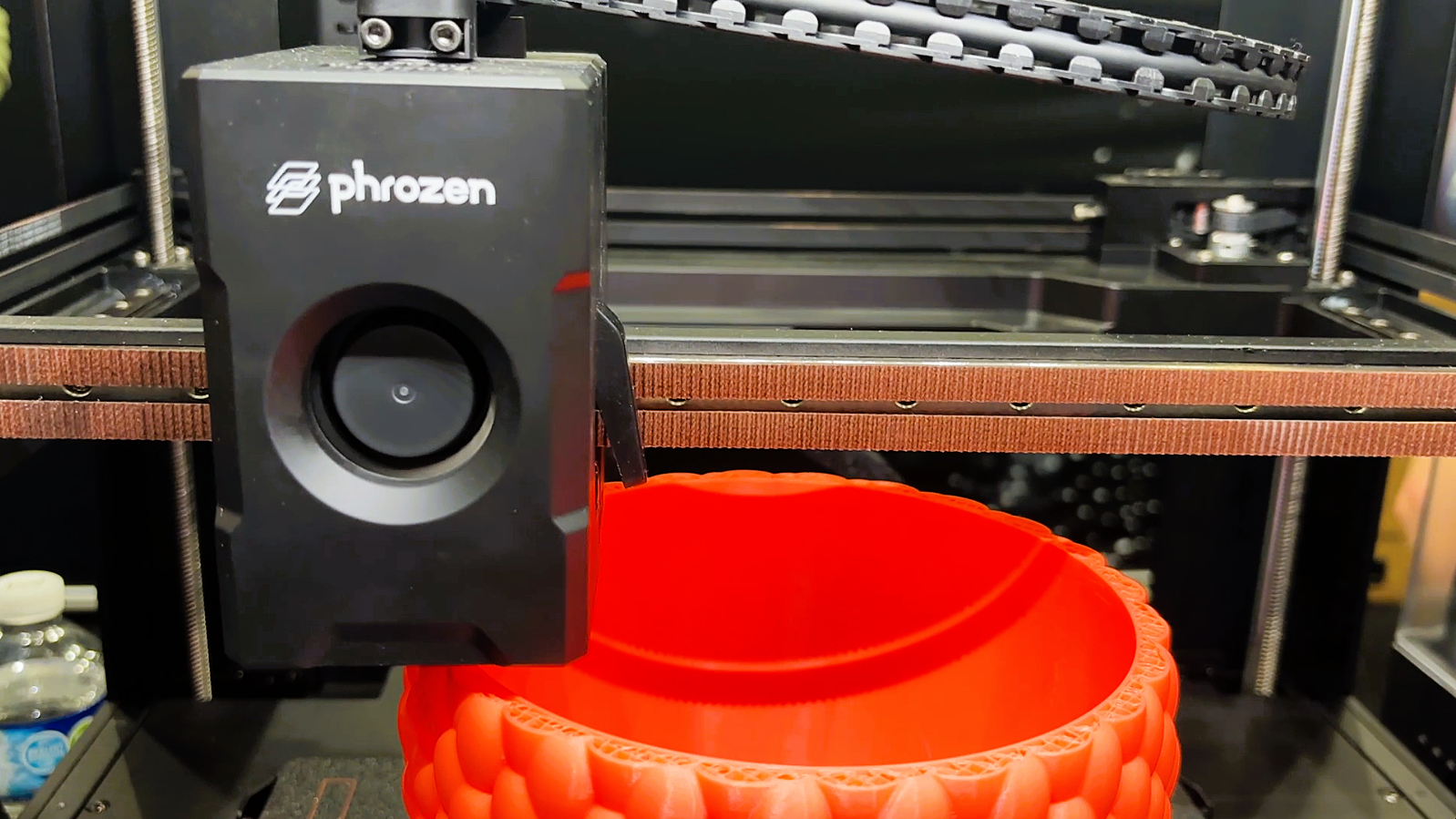

Phrozen: Still holding for Arco

Phrozen had a smaller booth to show off a couple resin machines, and the long awaited Arco. The company is well known for quality resin printers like the Sonic Mega 8KS, but I only had eyes for the Arco. It’s the company's first FDM machine, a CORE XY with a heavy bottom and flying gantry, with promised speeds up to 600mm/s and a four-color material box. Phrozen launched the Kickstarter early in 2024, gathering $1,408,493 in funding from over 1400 backers, with original plans to deliver machines in July 2024.

The four-slot multicolor unit was on display but not running. I was reassured that it would be ready very soon and that Kickstarter units are nearly ready for release.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.