Akasa Reveals Venom IV CPU Heatsink

Akasa is demonstrating a new CPU cooler at Computex 2013.

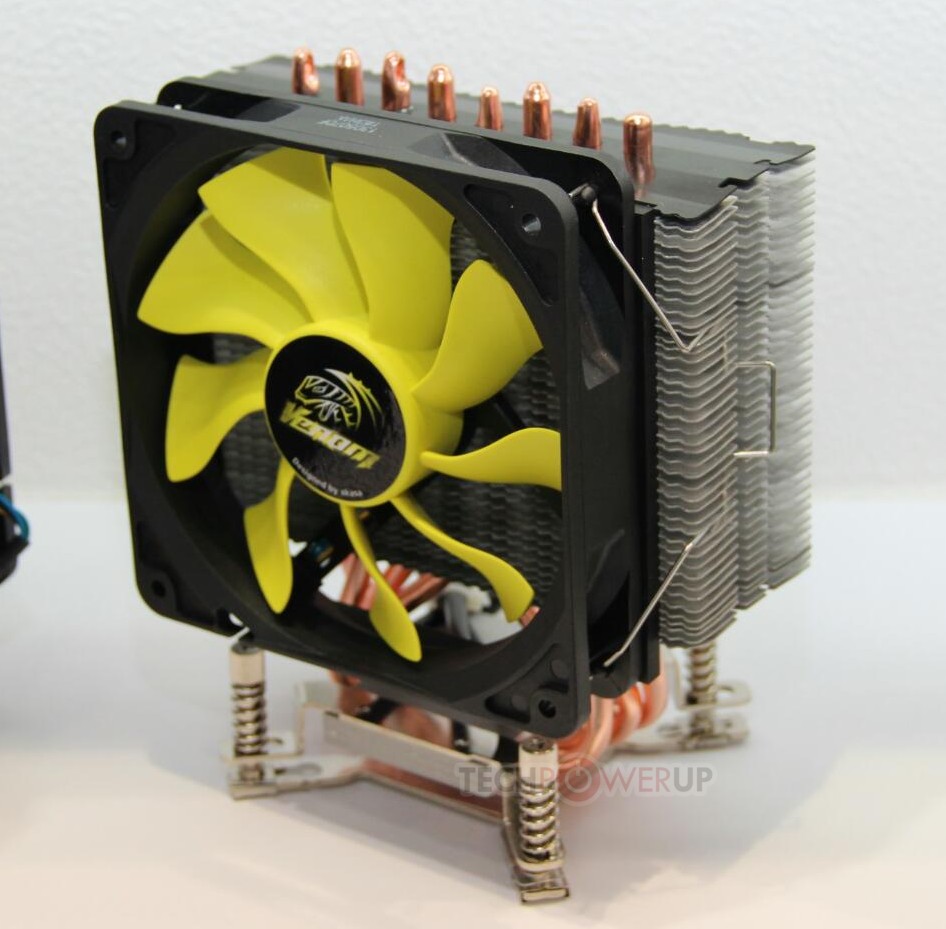

Akasa is showing off a new CPU cooler at Computex, the Venom IV. The cooler itself appears fairly simple, but there is actually more to it than meets the eye. The aluminum fin stack might look a bit messy from up close, but this is actually done on purpose -- the fins are shaped asymmetrically and use planes. This is meant to increase heat dissipation.

The heat gets fed to the aluminum fin stack through a total of four 6 mm thick copper heat pipes. They are U-shaped, and the bottom bend of each heat pipe makes direct contact with the CPU. They are spread out evenly through the aluminum fin stack for better heat distribution.

The Venom IV comes with a 120 mm S-flow fan, which with its particular blade design, should provide up to 30 percent more airflow at any given RPM. The fan is PWM controlled and can spin at speeds ranging from 600 RPM to 1900 RPM, during which it will make up to 28.9 dBA of noise and push 83.63 CFM.

Akasa gave no word on the units' pricing or availability, though it will work on all modern CPU sockets, including LGA 1150.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Niels Broekhuijsen is a Contributing Writer for Tom's Hardware US. He reviews cases, water cooling and pc builds.

-

eklipz330 hard to imagine heatsinks getting any better design... it looks like companies are just swinging blindly, and hit some homers by chance.. do they have engineers to design these or what?Reply

im not criticizing this one particularly, but is putting the heatpipes int he way of the airflow smart? what happens to all that surface area behind those pipes? and why dont more companies put heatsinks above the base plate? why aren't more fins notches to increase surface area? where are the mirror like base surfaces? why haven't any company tried to make one giant heatpipe as the base, and make it split into many to have a flat base and avoid soldering the pipes to a base or having those pesky HDT bases with all those grooves?