Micron Unveils 1β (1-beta) DRAM Process Node, LPDDR5X-8500 Memory

The final frontier for non-EUV DRAM fabrication tech

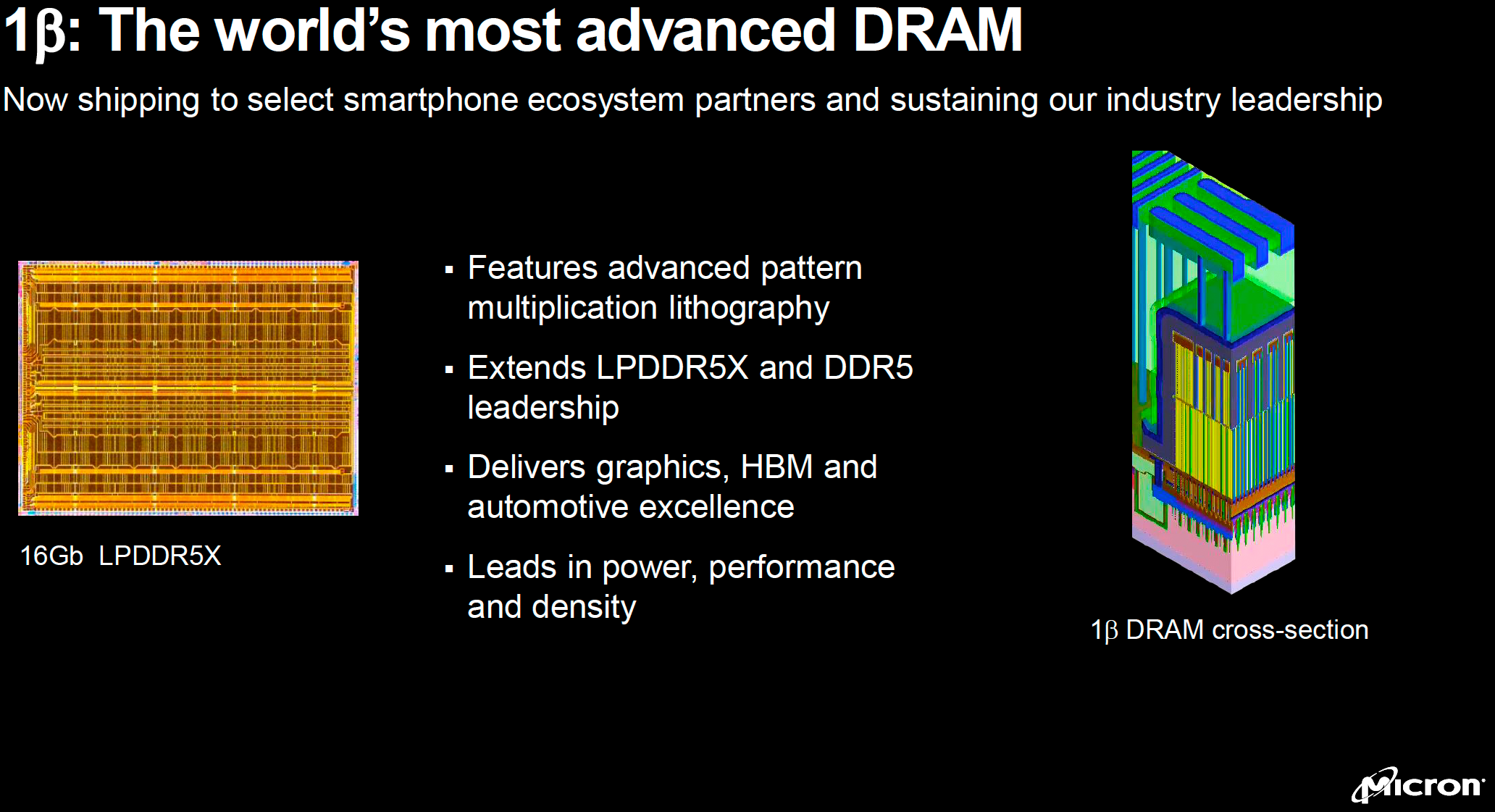

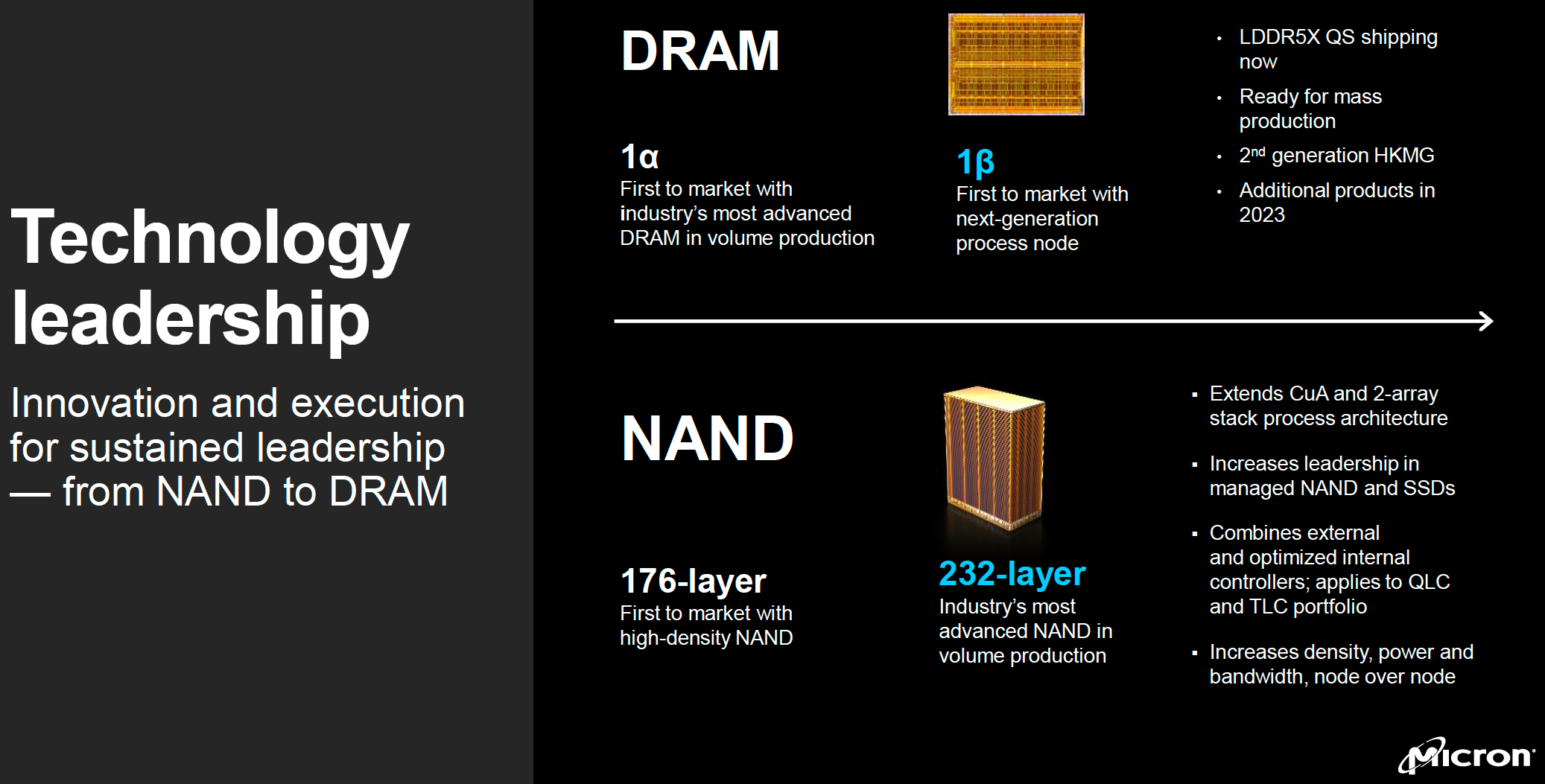

Micron on Tuesday announced its next generation 1β (1-beta) fabrication technology for DRAM (dynamic random access memory). The new node will enable Micron to cut down costs of its DRAM while also increasing their power efficiency and performance. 1β (1-beta) will be the company's last DRAM production process that will rely on deep ultraviolet (DUV) lithography and will not use extreme ultraviolet (EUV) tools.

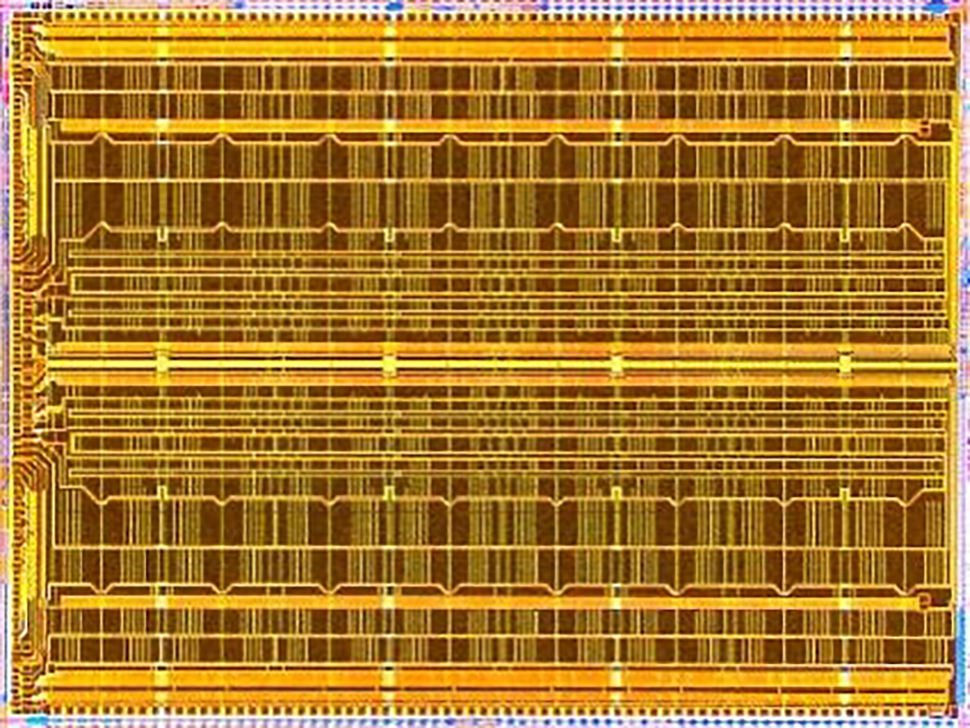

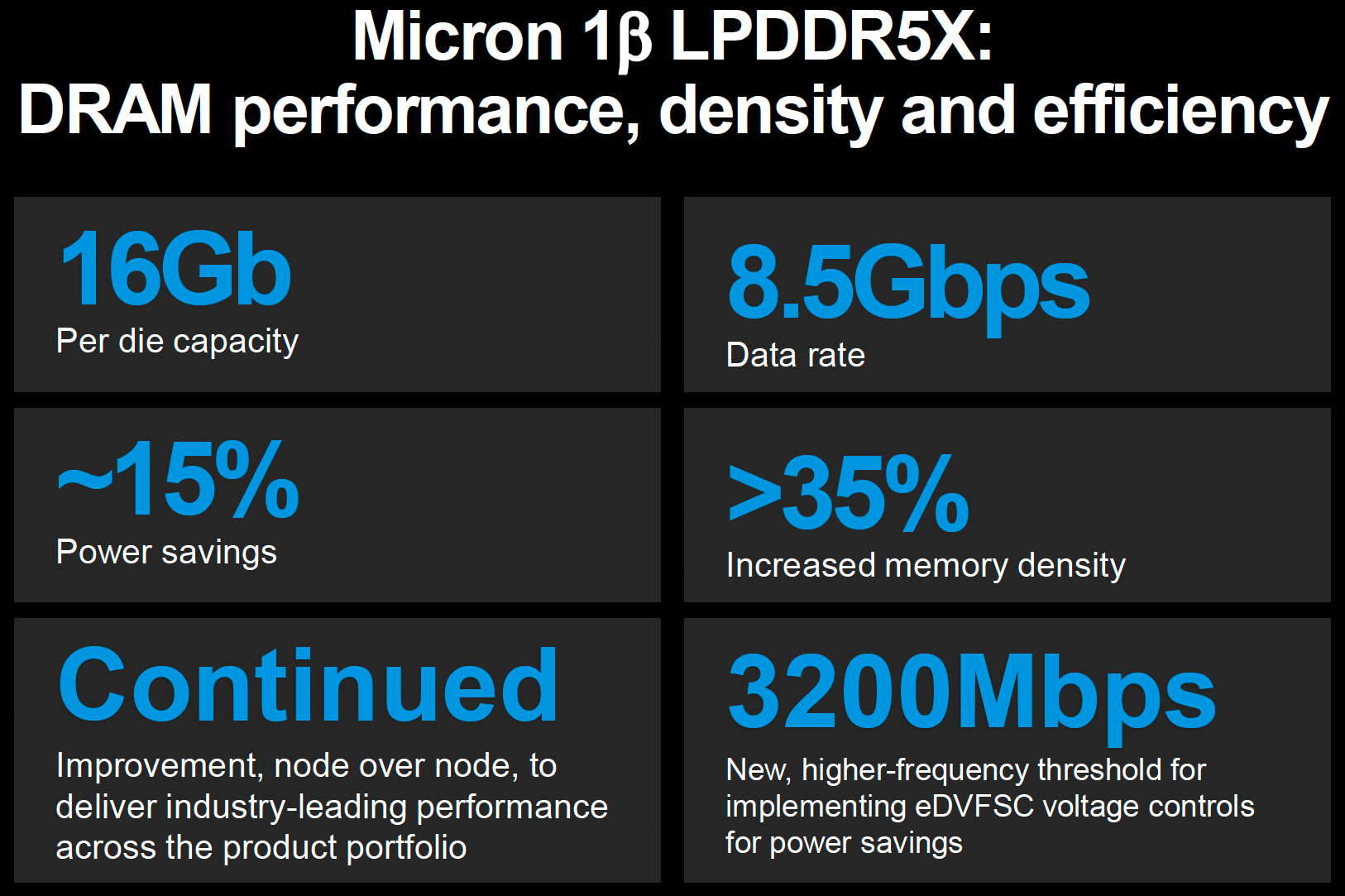

Micron's 1β fabrication process uses the company's 2nd generation high-K metal gate (HKMG) and is said to increase bit density of a 16Gb memory die by 35% as well as to improve power efficiency by 15% when compared to a similar DRAM device made on the company's 1α node. The new manufacturing technology will be particularly useful for high-capacity DDR5 and LPDDR5X chips for mobile, server, and desktop applications.

Unlike its Samsung and SK Hynix rivals, Micron currently does not use EUV tools and therefore has to rely on various multi-patterning techniques to keep making DRAM cells smaller.

"We drove innovation from all fields, including cutting edge pattern multiplication techniques," said Thy Tran, vice president of DRAM process integration at Micron. "1β also comes with new processes, materials, and advanced equipment to advance our memory cell integration so that we can shrink the memory cell array. […] To maximize all the technology benefits and our design innovations, we are also aggressively scaling both the memory cell height in terms of size and also the rest of the circuitry in the die to save space and bring you the smallest die possible for a given density while optimizing for power and performance improvements."

The first product that Micron will make using its leading-edge node will be 16Gb LPDDR5X-8500 memory, but eventually the company will start using the node for other products. The 16Gb LPDDR5X chip is said to offer enhanced dynamic voltage and frequency scaling extensions core (eDVFSC) voltage control techniques for power savings.

LPDDR5X memory was designed not only for mobile applications like tablets and smartphones, but also to improve performance of various bandwidth-hungry applications like PC-class system-on-chips as well as artificial intelligence (AI) accelerators.

Micron's 16Gb LPDDR5X-8500 memory as well as its 1β fabrication process are ready for mass production, according to Micron. At present the company is shipping samples of its LPDDR5X-8500 DRAMs to interested parties and will initiate mass production of these ICs once they pass qualification procedures.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.