Plastic Processors for Less Than a Penny Apiece

Researchers design cheap plastic processor that could usher in the age of truly ubiquitous electronics

If you've been following statistics about the Internet of Things (IoT), which is growing by billions of devices every year, the numbers are pretty mind-boggling. But the truth is that expensive silicon chips are actually holding this rampant growth back.

But now researchers have designed a new plastic processor, which they estimate will be able to be mass-produced for less than a penny. That's right — the new Flexicore chips could kick-start a world in which everything — from bandages to bananas — could have a chip, according to a report by IEEE Spectrum.

The chip designs we currently use — even for the most basic microcontrollers — are too complex to be mass-produced in plastic: You surely won't see a plastic processor on our list of best CPUs for gaming. This is the main issue these designs face, according to researchers at the University of Illinois Urbana-Champaign and flexible-electronics manufacturer PragmatIC Semiconductor — that existing chip designs are too complex for production on plastic with acceptable yields.

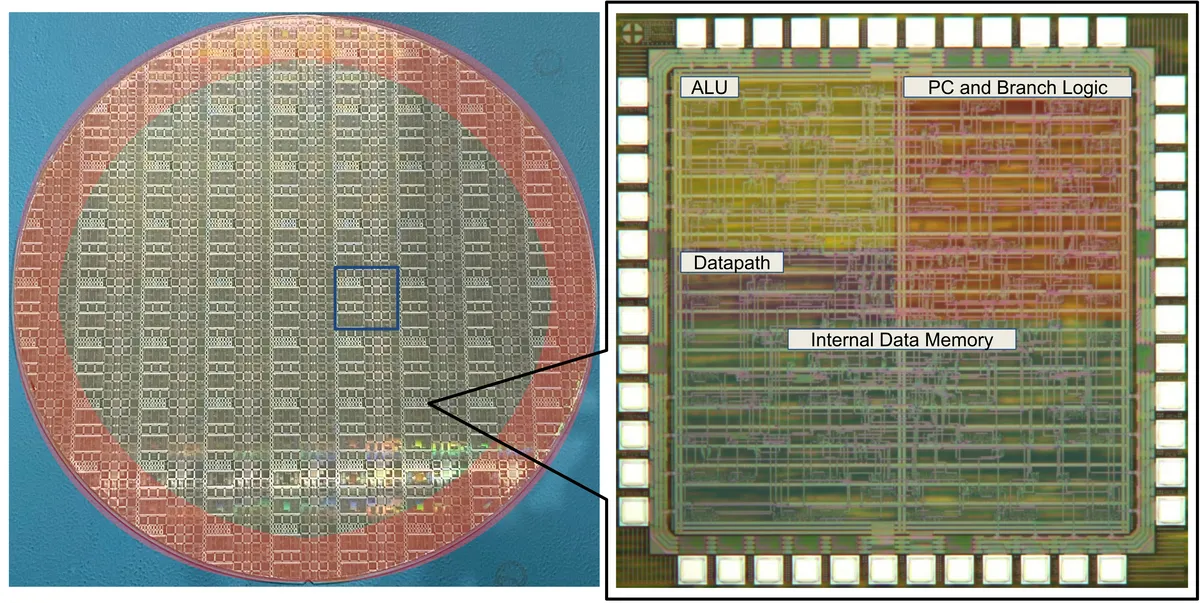

Last year Arm and PragmatIC announced the development of the PlasticArm prototype, which implemented the Arm M0 processor design incorporating >56,000 semiconductor devices for a flexible and cheap microchip. This latest research suggests that a completely new architectural approach was needed to achieve usable yields and a sub-penny chip.

To address the peculiarities of plastic chip design, the University of Illinois team built the new Flexicore processor design from scratch. Because yields dive when processor gate count rise, they decided to make a minimal design that reduced the gate count and used 4-bit and 8-bit logic instead of 16-bit or 32-bit alternatives. Flexicore memory architecture and its instruction set were optimized for fewer components and less complexity. The researchers also designed logic that re-uses parts (and so, has fewer transistors). Last but not least, the processor was designed so that it executes an instruction in a single clock cycle.

For chip manufacture, the research team used flexible thin-film semiconductor indium gallium zinc oxide (IGZO) technology. Readers will be familiar with IZGO for its use in monitor panel manufacturing. It is a reliable and established technology and films can be flexed into curves with a radius of millimeters with no ill-effects.

A sample 4-bit FlexiCore processor is 5.6mm square and contains 2,104 semiconductor devices, similar to a classic Intel 4004 CPU. Remember — earlier we mentioned the PlasticArm prototype using the Arm M0 architecture — the Flexicore uses less than 4% as many semiconductor devices. Manufacturing yields were over 80% and the researchers reckon a Flexicore chip would cost under a penny to produce. Yields with 8-bit designs weren't good enough to break the one-penny barrier at this time.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

There is still work to be done, and the researchers have already tried optimizing the Flexicore design for different processes and target workloads with some success. It will be interesting to read about how flexing chips affects performance and how durable these things are.

With this sub-penny plastic processor, and the move of flexible electronics from niche to mainstream, we may be seeing the dawn of truly ubiquitous electronics. The above research is going to be presented at the International Symposium on Computer Architecture later this month, so we should learn more about it and further development plans soon.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

artk2219 Super neat, it should allow for some great tracking metrics on all sorts of things, you could drive tons of sensors for just about anything. Of course there are some huge tracking implications, but frankly those currently exist anyway with a regular mobile phone. Now how can we mod them to run classic games :LOL:.Reply -

Neilbob I hope it's never more than niche, because making use of even more plastic seems like a great idea.Reply

I went all eco there for a moment. -

hotaru.hino Reply

But what's the alternative? Semiconductor IC manufacturing isn't exactly environmentally friendly either. And plastic will be used anyway for the chip carrier.Neilbob said:I hope it's never more than niche, because making use of even more plastic seems like a great idea.

I went all eco there for a moment. -

TheOtherOne As long as these can be produced with "proper" recycling methods, not the complete BS that most of the countries have now, it's a great idea!Reply -

edzieba Compare and contrast the "3 cent micro": more expensive than the projected price, but available today at retail, and orders of magnitude more capable in performance (and with more compatibility than rewriting your software for a 4-bit system).Reply

Packaging would also be a problem: this design seems to be targeted at fabbing an array of identical chips to be diced and packaged like silicon-substrate ICs are. That kills the flexibility advantage of the plastic substrate unless you develop a brand new flexible packaging methodology, as well as bonding a flexible package to a flexible substrate without introducing failure points (more difficult than it sounds). On the flipside, if you fab the entire circuit (not just the IC, but sensors and passives too) on a monolithic piece of plastic you have a entirely flexible device, but you are now effectively fabbing a chip of several hundred to several thousand of square mm 'die' area, and your cost advantage vanishes out the window again. -

LuxZg Replyedzieba said:Compare and contrast the "3 cent micro": more expensive than the projected price, but available today at retail

My first thought was - how much would such 4-bit processor cost on silicon? I mean sure, 1c is cheap, but it is also very limited design.

Does anyone have projected prices for IDK, 10nm? I found some data saying that 1.2 trillion are on that "wafer chip" at 7nm and 8.5 inch size, but wafer is almost 12 inch. Well chip is probably square so that's about right. And price per wafer is 9k something, so let's say it was 12.000$ after all the waves of peice increases. So multiply that with 5000 transistors that this flexi chip claims and you end up with 0.00005 $ price. That's way cheaper than a cent. Other view would be that silicon chip with 1 million transistors would be 1 cent on TSMC 7nm, and Pentium Pro of 1995 had 5.5 million and ran at 200MHz.

Now, I'd rather pay 5-6 cents for x86 chip like Pentium Pro that can probably run at 4-5 GHz then this Flexi thing. If we ran Windows 95 on these chips (at 200MHz), imagine how it would run something like Debian at 4GHz.

Now I want a 5 cent Pentium ;D -

Alvar "Miles" Udell Instead of thinking about new products, think about all the existing products which could be made more environmentally friendly, especially if these were made out of biodegradable plastic. Drug tests, pregnancy tests, things which are already using traditional silicon chips, require very little processing power, and are disposed of after one use.Reply -

Kamen Rider Blade How much useful computing will you get out of 4-bit or 8-bit micro controllers?Reply

I thought the most useful modern micro controllers would have at least 16-bit's, but going backwards to 4-bit or 8-bit?

Is that necessary or useful? Or are they making e-waste by making so many cheapo controllers with limited processing capability. -

criticaloftom Perhaps before we make a banana sticker that can use our temperature to tell us our mood, current blood sugar level & radio our metrics back to base to recommend other purchases; we should step back and think about how far into our lives we want technology to encroach for no good or valid cause.Reply -

Reply

Seconded. But I sure would like the blood sugar testing. My fingers have been ruined by poking 10-20 times a day for 40 yrscriticaloftom said:Perhaps before we make a banana sticker that can use our temperature to tell us our mood, current blood sugar level & radio our metrics back to base to recommend other purchases; we should step back and think about how far into our lives we want technology to encroach for no good or valid cause.

if you don’t check often you can’t achieve 5-6 A1C levels like me