Samsung Showcases 10nm Wafer At Open House

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Samsung Semiconductor Inc. (SSI) opened its doors to an open house at the Bentley Reserve in San Francisco last week to offer an overview of the subsidiary's activities past, present and future, replete with demos and cutting edge 10nm wafers.

The chip-making side of the Korean giant said it had posted revenue of $196 billion in 2014 and employs over 307,000 people.

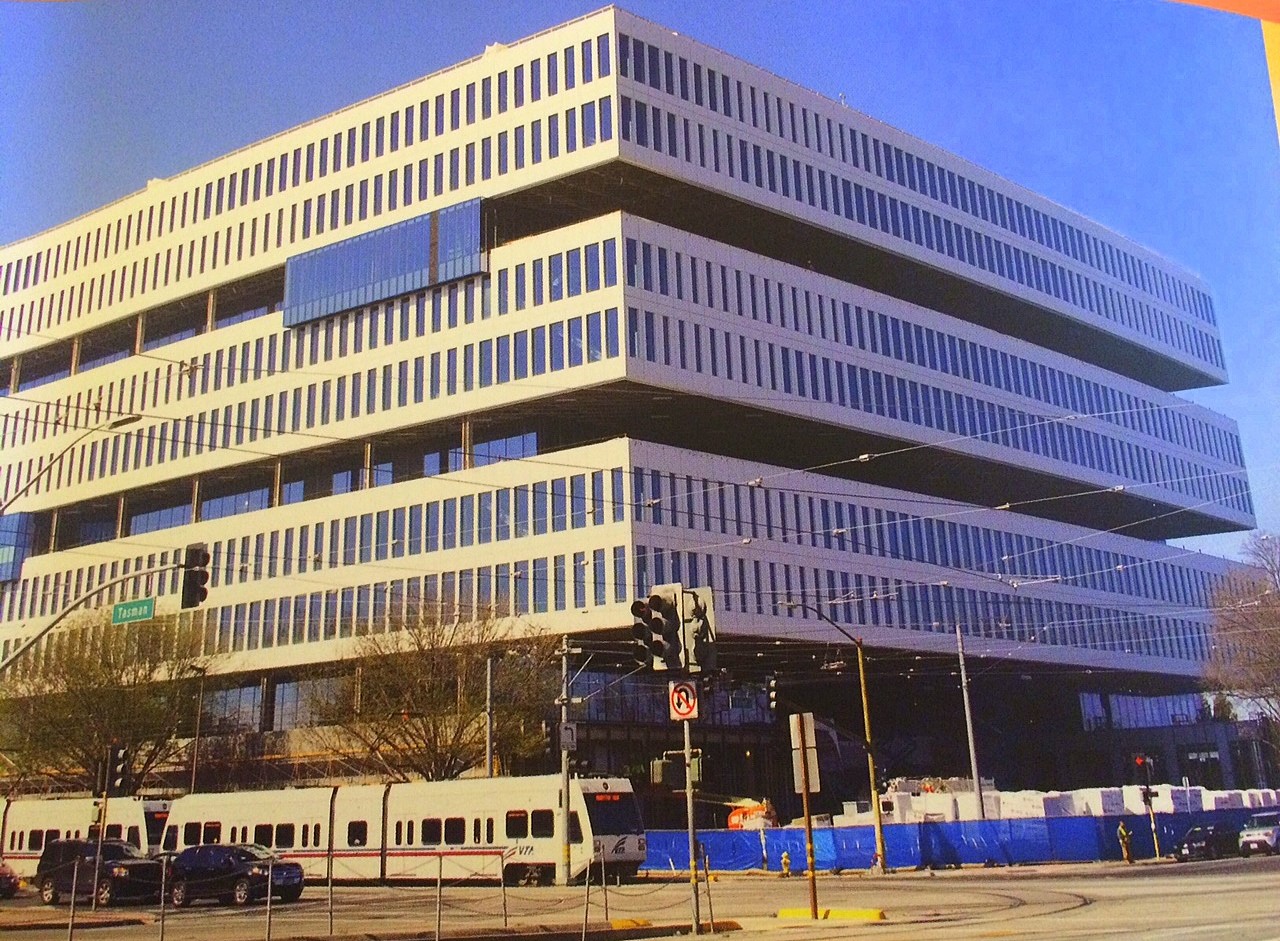

Indeed, such is the subsidiary's growth that it's building a new 1.1 million square foot R&D and sales headquarters in San Jose, CA, with the architectural design looking rather chip-like in and of itself.

The R&D expansion in Silicon Valley, which includes labs dedicated to memory, display, semiconductor, advanced image research and modems, will help keep SSI closer to its customers, said the firm.

SSI told press it was committed to developing "innovative open system architectures" and pushing performance on all of its memory products in SSDs, IoT devices and data centers, while simultaneously undertaking advanced research into materials and device technologies for ever more advanced wafer processes. On the display side, the firm is working on next-generation LCD and OLED displays, while on the imaging side, SSI is still grinding away at building out advanced CMOS sensors and machine learning-based algorithms for visual recognition.

Bob Brennan, senior vice president of memory solutions at SSI, noted that his team was actively looking two to five years ahead and putting big bets on tiered memory, while Mike Williams, vice president of memory product planning at the company, said his team was focused on the transitions from LP3 to LP4 technology happening in this year's flagship phones and the transition of LP2 to LP3 for mainstream phones. Williams also cited the ever increasing importance of Universal Flash (UFS) as a game changer in mobile storage. Both DRAM and NAND would continue to scale for a "long time," said the company executives.

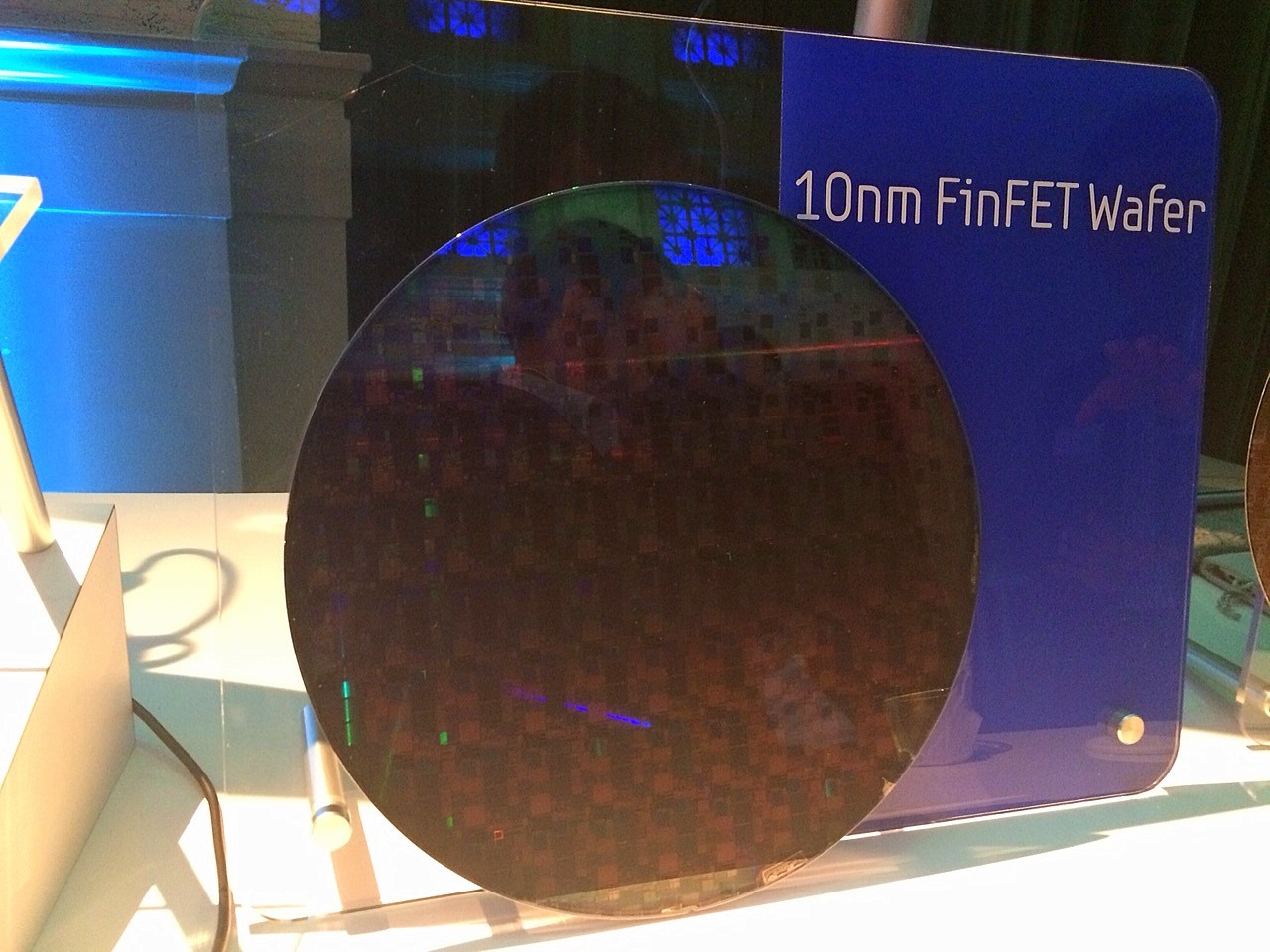

On the foundry side of the equation, SSI seemed especially bullish and even showcased a 10nm wafer, while offering demos of products already on the market boasting the current 14nm SoCs. Hong Hao, SSI's SVP of Foundry, said the company was already in mass production on its 14nm chips, with the Galaxy 6 phone already sporting 14nm silicon. Two of Samsung's own fabs are already in full production, with SSI partner GlobalFoundries also helping to take on some of the load.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

SSI said its 14nm SoCs had "clear differentiation" from other firms' offerings, noting a marked increase in power efficiency and accelerated performance levels. Hao also cited vastly improved Power/Performance/Area (PPA) capabilities and time to market advantages, calling each "a game changer."

The next generation 10nm would also have a "very significant impact on the foundry industry" and would be the firm's third generation of FinFET transistors, said Hao.

Meanwhile, Brent Kirby, SSI's director of System LSI, talked up his division's product as "one of the best image sensors on the market today." And Curtis Sasaki, VP of Ecosystem Development, proudly showed off the ARTIK developer platform, which he said would likely have impact on many things including the drone and autonomous driving space.

"This is not vaporware," he emphasized. "We already have developers hacking away at it."

Follow us @tomshardware, on Facebook and on Google+.

-

chicofehr I'm sure it's just low power wafers. It's much harder to get high power wafers which is why samsung seems to be ahead of Intel. I'm sure Intel already had 10nm low power already but it it's not useful to them for their parts.Reply -

Amdlova for us 10nm its like a dream maybe 256gb SSD for 100usReply

but for intel new shine processors 350us for a silicon chip! no way! -

jasonkaler Intel's tri-gate tech beats finfet tech so there!Reply

The best news is job creation - that's what we really need, not smaller finfets! -

therealduckofdeath ReplyThis after TSMC announced that they are working with 10nm.

The minor difference here is, Samsung showing an actual production sample. -

whassup ReplyThis after TSMC announced that they are working with 10nm.

I can see you sentiments with TSMC....

-

aviconus I love how all the idiots are comparing Samsung's mobile chips to Intel's PC chips. It's like comparing vodka to water. I'm curious if they used Si or SiGe for this wafer, and what the yield % is.Reply -

Coolio Tools It is indeed comical reading all the arrogant Intelismell (...er is that StinkEmUp) fans blowing their snot nosed stacks over Samsung being the first legitimate Intel Killer on the rise. Fact: Samsung is 2nd only to Intel right now in Revenue from processor fabrication alone. They already hold the crown as the #1 Memory Maker on the Planet!Reply

Do realize this all you brain dead Un-Intel...ligent Intel Super Fans. Samsung as a whole is magnitudes bigger than all of Intel. They spend far more on both R&D and CAPEX now than both TSMC and Intel combined in their whole entire semiconductor business end to end. The first ARM chip tested at 10nm was run by Samsung in late 2013...... look it up? Now they are not only testing whole SoC processors fabricated at 10nm they are at the beginning stages of full ramp up, in order to begin production by next year ahead of Intel not even close to producing a comparable SoC Low Power All in One Processor to compare it to.

Fact; Exynos 7420 and better..... are now slated to be the ARM SoC processor of Choice to go into several HPC Cluster Super Computers. Which on it's own CPU cores only, is turning in benchmarking scores comparable to this generation of i5 processor chips. Add in the fact that these are HMP core processors with HSA heterogeneous Computing API's to turn all the on die GPU's into CPU's and no doubt they'd come close to beating i7's alone. If this is what you fools are relying on.... in thinking that x86 will be first to top Exaflop barrier.... you're all DEAD WRONG!

The power required to run all the Insmell StingEmUp chips needed would require a dedicated Power Plant and the really intelligent people in the industry already see ARM beating out x86 chips in reaching truly sustainable, energy efficient Exaflop computation at far lower cost sooner!!! ;-P ......you can search EU's Mont Blanc HPC Super Computer Project to find out just how much more energy efficient, equivalent Flops Production of ARM HMP HSA SoC architecture really is! :D

Let's see how well ARM Big/Little HMP HSA SoC Processors fabricated at Samsung's 10nm FinFet process do against anything Intel has by next year in flops production per watt!!!.... And by 2017 Samsung will indeed move ahead of both TSMC on Volume and Intel on Revenue to take #1 in those two categories away from both of them!!! ......and above all it's Samsung with fatter pockets than both of them put together and willing to spend it too! ......and don't forget, Samsung pays their own C&T Division to build not only that state of the art building in Silicon Valley above, but to build every one of their own state of the Art foundries and already have superior Litho technology to Intel's too. Plus.... planning on spending more on one new foundry than what neither Intel or TSMC could afford right now!