Samsung inks $16.5 billion Tesla AI chip deal — Elon Musk says Samsung will produce new A16 chips: 'The strategic importance of this is hard to overstate'

A huge win for Samsung

In an unexpected turn of events, Samsung announced on Monday it had inked a $16.5 billion foundry deal with an unnamed partner, confirmed to be Tesla by Elon Musk, who says the company will produce its next-generation A16 chip. The deal represents a major win for Samsung Foundry, which has been lagging behind TSMC for a while. In addition, the deal is big news for Samsung's fab in Taylor, Texas, where the system-on-chips (SoCs) will be produced.

A major contract

The deal will run through December 31, 2033, and involve production of the Tesla AI6 (formerly HW6) processor, which is used to manage and self-drive Tesla cars, at Samsung's upcoming semiconductor production facility in Taylor. The AI6 processor is projected to ship towards the end of the decade and replace the company's next-gen AI5 processor, which is expected to enter mass production in 2026.

"Samsung's giant new Texas fab will be dedicated to making Tesla's next-generation AI6 chip," Elon Musk wrote in an X post. "The strategic importance of this is hard to overstate. Samsung currently makes AI4. TSMC will make AI5, which just finished design, initially in Taiwan and then Arizona."

Interestingly, Samsung allowed Tesla specialists to 'assist in maximizing manufacturing efficiency,' according to Elon Musk, though he did not disclose how experts in car production can assist in making chips. "This is a critical point, as I will walk the line personally to accelerate the pace of progress. And the fab is conveniently located not far from my house," Musk added.

Samsung used to produce Tesla's HW3 (AI3) processor using its 14nm-class fabrication process and is currently producing the company's HW4 (AI4) SoC using its 7nm-class (7LPP?) manufacturing technology. TSMC will be in charge of production Tesla's AI5 (HW5) processor, though it is unclear whether the world's No. 1 foundry will use its N3A process technology (expected to be qualified and ready by late 2025 and ready for production in Taiwan, so a likely scenario for Tesla), or more conservative N4A or N5A process technologies (which are already available at TSMC's Fab 21 in Arizona).

Neither Tesla nor Samsung Foundry disclosed details about the upcoming AI6 project, but considering the fact that Tesla tends to update its main SoCs every three to four years and the AI5 processor is expected to land in Tesla cars sometime in 2027, one can expect AI6 to arrive in 2029 at the earliest.

A 2nm-class SoC in 2029?

A source with knowledge of the situation told FNnews that Tesla demanded a production yield in the range between 60% and 70%, and Samsung is aligning its plans to meet that target. Mass production and delivery are expected to begin around 2028, approximately three years from now, so Samsung has plenty of time to fix the defect density of its fabrication process intended for AI6.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current projections indicate that equipment installation at the Taylor fab in Texas will start in the first half of next year, followed by test production and Tesla's evaluation in the second half of 2027. In preparation, Samsung has also reassigned semiconductor division staff from headquarters to the Taylor site, according to the FNnews report. Keep in mind that this is unofficial information, though.

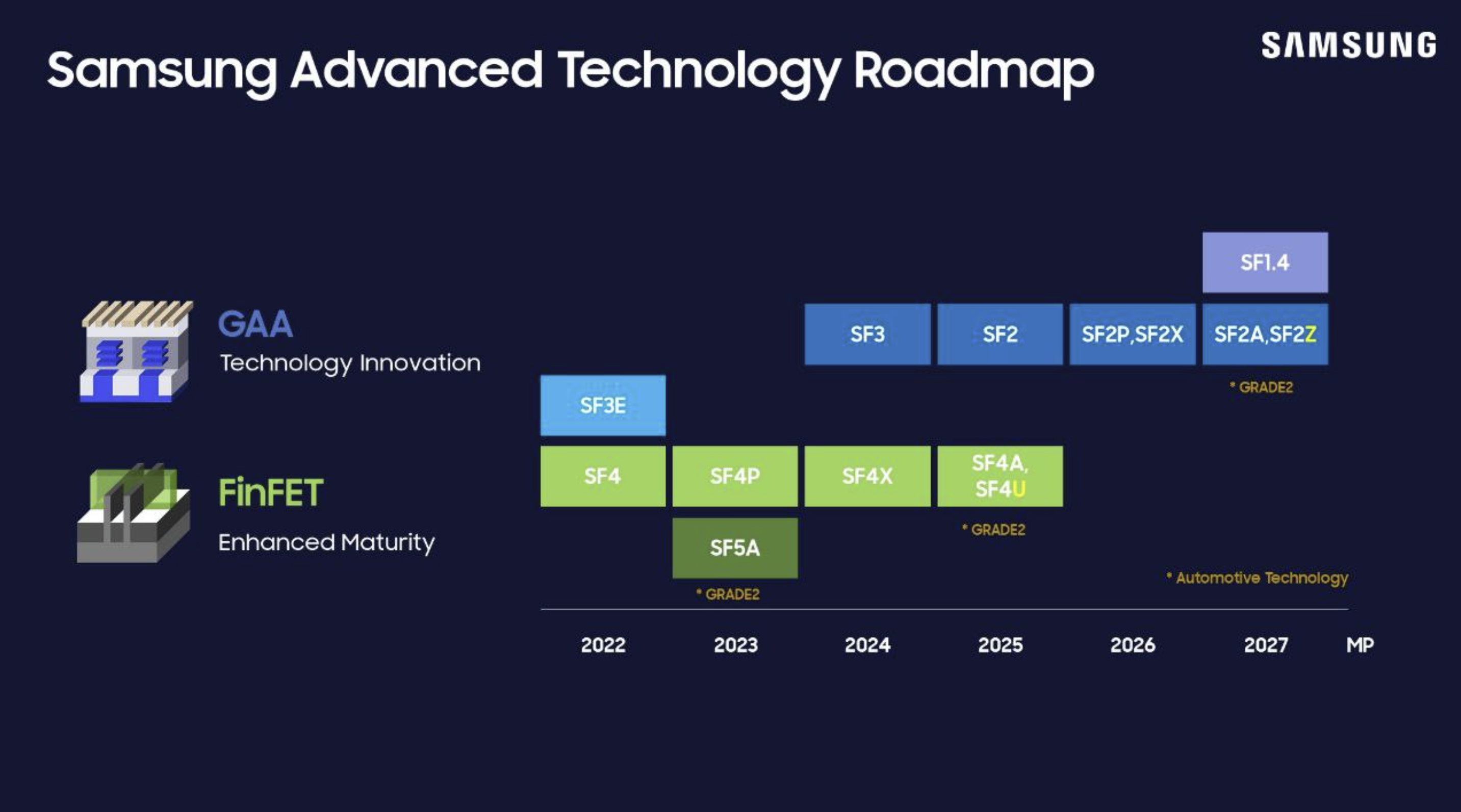

The fab in Texas is said to be capable of making chips on Samsung's SF4, SF3, and SF2 (formerly SF3P) process technologies. It is also likely capable of making chips in the automotive-grade 2 SF2A fabrication process, though it is unknown whether this node will be used to build Tesla's AI6 SoC.

In general, signing a $16.5 billion deal with Tesla is a big deal for Samsung Foundry, which is a major testament that the company can produce chips reliable enough for a major automaker. The contract is also crucial for Samsung's fab in Taylor, Texas, as it gets a major customer. While Tesla's volumes are not as high as those of consumer electronics companies (the company sold 1.79 million vehicles last year), we are talking about fairly high-end processors here, so it definitely is an important contract.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

Notton Interesting, so they chose Samsung over Intel Foundries?Reply

Isn't Samsung famous for failing at <5nm nodes, being unable to find customers outside of crypto ASICs, and also an underperforming and overheating Exynos?

Well, at least they shouldn't have to worry about overheating with a car sized device. -

bit_user Reply

Uh oh. I hope he doesn't DOGE it up. That's the last thing Samsung needs, right now.Elon Musk said:Samsung agreed to allow Tesla to assist in maximizing manufacturing efficiency,

This is a critical point, as I will walk the line personally to accelerate the pace of progress. And the fab is conveniently located not far from my house.

I was going to say it's a shame Intel didn't get this deal, but now I'm not so sure. -

bit_user Reply

Given that it's going in an electric car, efficiency is definitely important. Poor efficiency means a heavier and more expensive thermal solution, possibly wasting even more power on active cooling. All of the energy used to power and cool the electronics also means reduced range.Notton said:Well, at least they shouldn't have to worry about overheating with a car sized device. -

Notton Reply

Well, at least you don't have to worry about the range shortening in Winter because it doubles as a cabin heater.bit_user said:Given that it's going in an electric car, efficiency is definitely important. Poor efficiency means a heavier and more expensive thermal solution, possibly wasting even more power on active cooling. All of the energy used to power and cool the electronics also means reduced range. -

bit_user Reply

Depends on where it's located and exactly how it's cooled. I wouldn't assume the waste heat goes into the cabin, but you might be right.Notton said:Well, at least you don't have to worry about the range shortening in Winter because it doubles as a cabin heater. -

Eximo Some quick math for you.Reply

Let's say a 30W TDP.

Give the vehicle a nice 300 mile range with the lower end battery of 72kWh. (310 miles/500km, really) This gives the nominal Wh/Mile at 240W/per mile. (Typical Model 3 long range)

At 50 miles per hour we can run for 6 hours. That would put our chip power costs at 180Wh. Or a shocking loss of 3/4 of a mile, or just over a kilometer.

A slight breeze or running the headlights would be worse.

It all adds up, but I wouldn't worry too much about it. -

bit_user Reply

You're going to drive a car using basically a 30 W GPU? I'd say more like 300 W, at least. Then, you need enough power to cool the thing on a hot day. So, probably at least another 25W for fans, because a giant radiator would add weight and that hurts efficiency.Eximo said:Let's say a 30W TDP.

Nvidia's AGX Thor chip, which is supposedly shipping this year, can do 500 TFLOPS of fp16, which is slightly more than a RTX 5090. Furthermore, they support a NVLink-type interconnect which enables you to use a pair. So, we're definitely talking about power consumption well into the hundreds of Watts, possibly up to about a kW (for a pair).

https://en.wikipedia.org/wiki/Nvidia_Drive#Blackwell_based -

Eximo Granted, that was more for the typical onboard computer. Tesla claims that the chip in the Cybertruck uses 72W, and the total system for FSD uses about 300W. I assume that means all the cameras as well. Though those would be running all the time anyway.Reply

Still, that would take 7.5 miles off the range of a Model 3, for the Cybertruck, it would be more of an impact because the efficiency is worse. But the battery is bigger. Just add a little battery capacity to the design, increase efficiencies here and there and you would be none the wiser.

Though, having been in some of these cars with FSD, they also drive very conservatively and probably make up the difference between it and a human driver. Honestly, people make too much of range limitations. It only matters when there aren't sufficient charging stations, and generally, I have not found any issues getting between charging stations when traveling. And this was before my car could use Tesla chargers. 95% of the time you are charging at home. And 99% of the time traveling to places you have been before and know roughly how much charge you need to get there and back. -

thisisaname Reply

Neither Tesla nor Samsung Foundry disclosed details about the upcoming AI6 project, but considering the fact that Tesla tends to update its main SoCs every three to four years and the AI5 processor is expected to land in Tesla cars sometime in 2027, one can expect AI6 to arrive in 2029 at the earliest.

I would think 2030 at the earliest.