Toshiba Showcases QLC NAND Development Platform At Flash Memory Summit

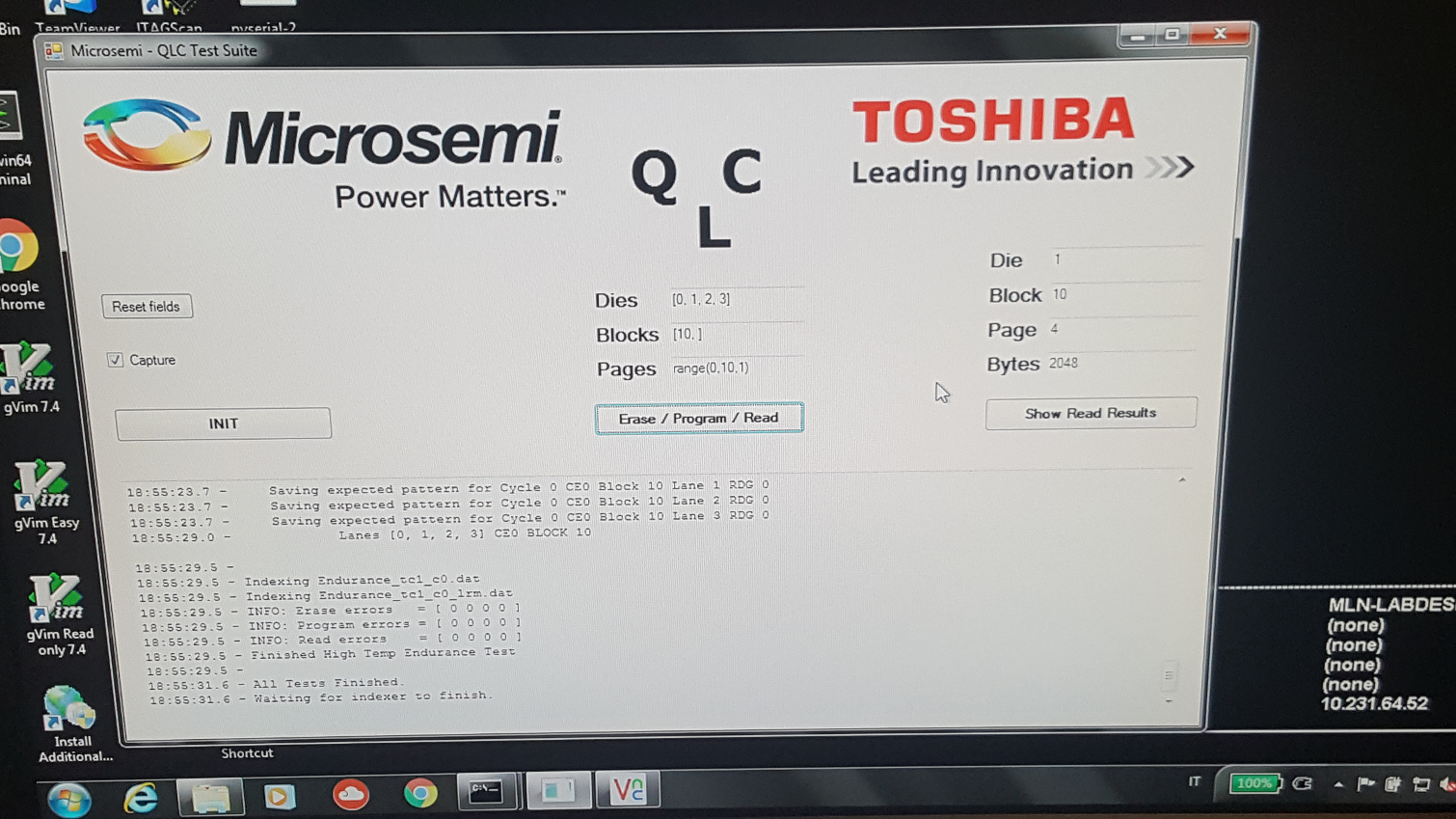

Last month Toshiba announced QLC (4-bit per cell) storage using BiCS 3 technology. We've heard about QLC for around a year now but never expected to see it this soon. At Flash Memory Summit we not only saw QLC, but also saw it running in a development platform.

To truly understand why QLC is an amazing technology you have to understand the way data sits on NAND flash. We all hear that data is just a bunch of 0s and 1s but we never see it like that. In single-level cell NAND the data is either a 0 or a 1, which means the cell literally only holds 1 bit. That happens because the cell can either hold a charge or not hold a charge. Think of this as black and white. It's easy to identify.

Multi-level cell NAND is 2-bits per cell. Granted, the industry never really expected to scale beyond two bits, so the name is a bit misleading now that we have more than two bits in there. What 2-bits really means is four levels of charge. This is where the technology starts to increase in intelligence. It's no longer black and white: The controller has to read four charge levels, so our metaphorical color gradient expands to black, dark gray, light gray, and white. Over time the charge can escape. You can think of this like a black shirt fading as you wash it over the years. Voltage drift is a real problem, so not only does the controller have to see what's there, but it also has to know how it will change over time.

Holding 3-bits in a cell is even more complicated. Now there are eight charge levels, which leaves you with black, six shades of gray, and white. Again the controller has to not only identify what data is present but also to understand how the charge changes over time.

QLC—Quad-Level Cell or 4-bits per cell—doubles the charge measurement levels again. With QLC we have black, fourteen levels of gray, and white. If you've ever seen a TV test pattern grayscale then you can visualize this (we found one that you can see above). There is less distinction between each color and they shift over time.

The unsung hero that will allow QLC to be a viable option for storage will come from NAND flash controller companies. The algorithms will have to become even more advanced than they are today, and they will also need to be able to decode the shifting data faster just to keep pace with modern 3-bit per cell SSDs shipping today.

Over the coming months we'll hear a lot more about QLC as each NAND flash manufacturer outlines plans to leverage the technology to increase storage capacity. We don't think we'll see a consumer QLC SSD until 2019, but the technology is moving fast, so we could be wrong. NAND companies can build four bits in a cell now, but controller manufacturers will have to innovate new error correction techniques to make it usable.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

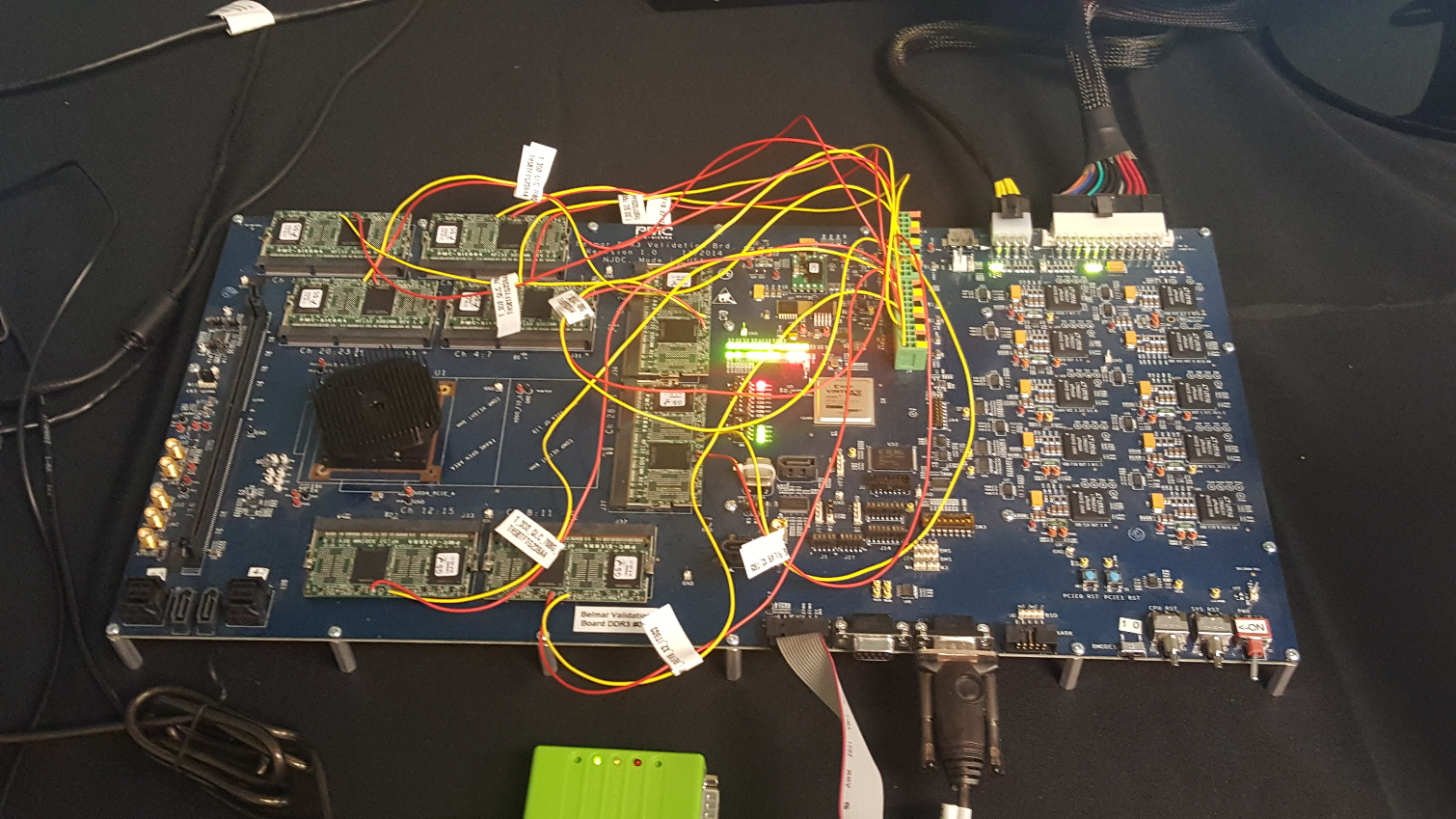

We found Toshiba's first QLC tucked in the back corner of the Microsemi booth. Microsemi designs flash processors used in enterprise products.

Chris Ramseyer was a senior contributing editor for Tom's Hardware. He tested and reviewed consumer storage.

-

2Be_or_Not2Be QLC - great, more storage at the expense of much less durability and less performance. I see the merit of the technical accomplishment, but I don't see any performance jump for the end-user. Which is sad when you see these seemingly advances in storage tech.Reply -

Half the controllers time will be spent correcting all the garbage errors present in every single page. QLC has less than 1000 P/E cycles, SLC over 100 000 P/E cycles.Reply

So what if I have to pay 4x the price, if it's 100x more reliable, and has 4-10x less latency? -

hannibal The marging of error is so slim in there... so easy to corrupt the files, because one "shade" of change shange to something else... Yep very bright future in ahead... and SLC has allready faded out of production MLC if fading. Soon the stop manufacturing TLCs... then we have only QLCs and PLCs... nice...Reply -

derekullo It's not as bad as everyone makes it out to be. (Assuming Toshiba is telling the truth)Reply

http://www.anandtech.com/show/11590/toshiba-768-gb-3d-qlc-nand-flash-memory-1000-p-e-cycles

Don't forget that the larger the drive the longer each P/E cycle takes

A hypothetical 1 terabyte drive @ 3000 p/e cycles would theoretically be able to write the same amount of data as a 3 terabyte drive @ 1000 p/e.

QLC is slower per cell versus ... all the others, but don't forget about the parallelization from 3 terabytes of QLC.

The same arguement was made from the transition from SLC to MLC, and MLC to TLC.

If anything going from SLC to MLC was the biggest jump 100,000 P/E to 10,000 P/E, but we of course welcomed the doubling of capacity with open arms.

With TLC at 3000 P/E and now QLC at 1000 P/E to make it all complete.

Toshiba: We choose to make QLC NAND and do the other things, not because they are easy, but because they are hard; because that goal will serve to hold all of your movies, music, documents and text messages, because that challenge is a highly profitable one that we are willing to accept, one we are unwilling to postpone due to Samsung beating us to the punch in so many other areas, and one we hope to ... ahh ... maybe win. -

grape1829 Toshiba will just be a brand name like Kodak and Polaroid soon... This will be their final achievement in semiconductors as true Toshiba.Reply -

Sakkura Reply20068906 said:QLC - great, more storage at the expense of much less durability and less performance. I see the merit of the technical accomplishment, but I don't see any performance jump for the end-user. Which is sad when you see these seemingly advances in storage tech.

The end user doesn't need a jump in performance, the end user needs a jump in capacity per dollar. Especially with the current short supply of flash memory that has caused SSD prices to increase. QLC will increase the bit output of the fabs, helping to alleviate the supply shortage in the market. That'll tend to drive prices down, even if you stick to SSDs based on MLC or TLC. -

farmeunit I just need more storage. I have a 2TB drive just for my Steam library. Would love to get that only an SSD, but not paying $500-$600 for the luxury.Reply