Arctic uses a fan to cool another fan — S12038-4K 120mm fan adds an extra fan in its center to cool its central shaft

I heard you like fans, so I put a fan in your fan so you can fan while you fan.

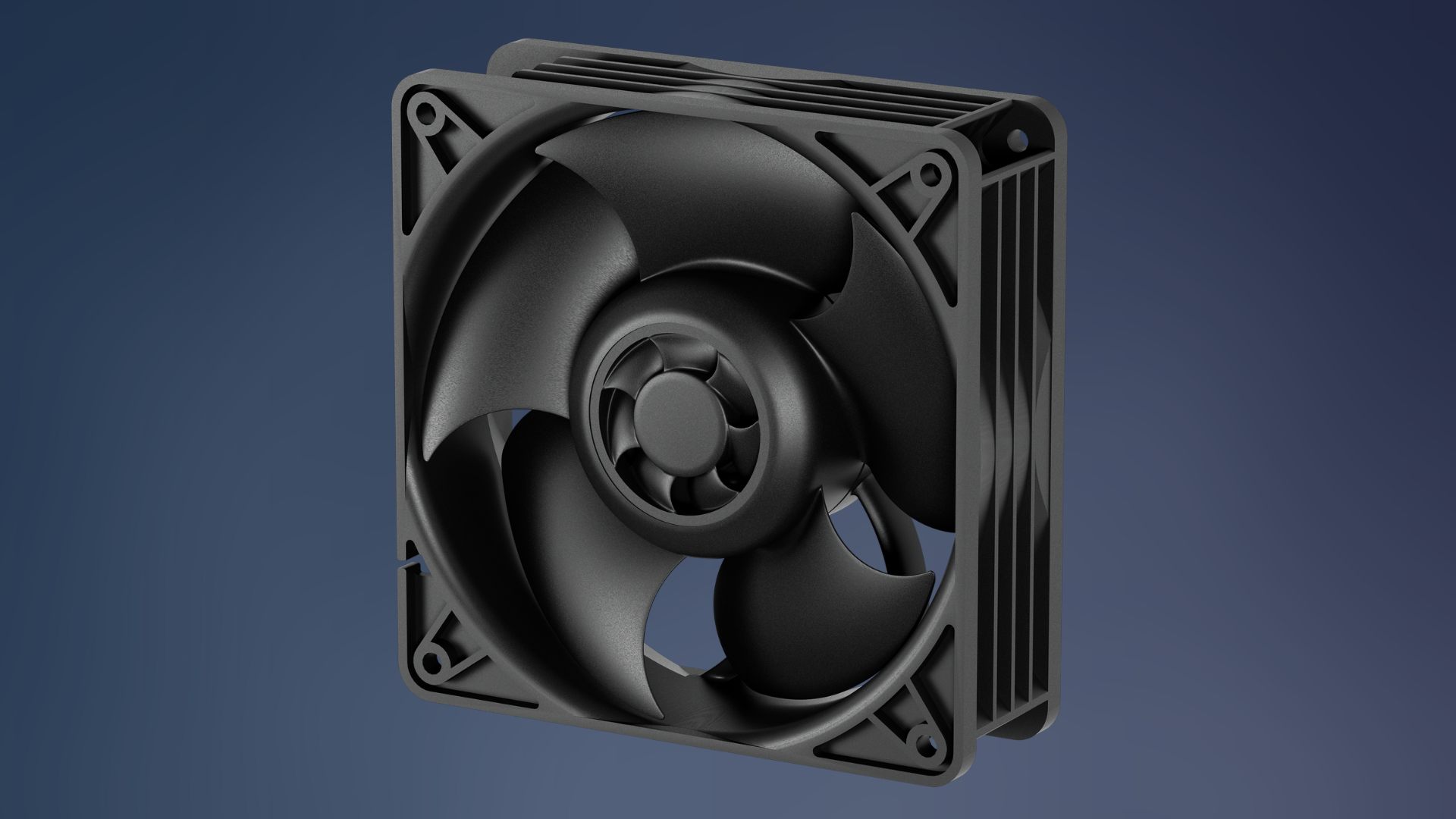

Arctic has released a new cooling fan archetype for server use, the S12038-4K and -8K. The fan is instantly visually unique thanks to its seven bonus fan blades in its direct center, creating a fan-within-a-fan effect. The fan offers class-leading static pressure, though Arctic seems reticent to advertise its new standout.

The S12038's spec sheet is rather impressive on several fronts. Its advertised power consumption at max load, 3.96W, is 12% lower than the next closest server-grade competitor. It generates an insane 11.45 mmH₂O of static pressure, around 3X-6X greater than Arctic's stable of standard case fans. This high static pressure and airflow level is near the best in class for server hardware. As the name implies, the S12038 can be had in flavors of 4,000 or 8,000 maximum RPM.

The fan achieves this power using a dual ball bearing design, with two ball bearings turning the fan, rather than the standard fluid dynamic bearing style. The extra fan blades in the center of the impeller serve to cool the shaft, providing a motor temperature of 5-10 degrees Celsius lower than that of Arctic's press materials (Arctic's press materials disagree on this number). Arctic claims this additional shaft cooling helps double the fan's effective lifespan. It also includes a dust cover sticker for the central fans to protect the fan in highly dusty environments, though why anyone would choose to cover up the majesty of the bonus fan blades is beyond me.

Those interested in using the fan for extra style points in a non-server PC setting should take special consideration before picking the S12038-4K. The fan is 38mm tall, 11mm taller than standard PC cooling fans. It also lacks rubber pads for quieter mounting, as the fan will generate higher noise and vibrations no matter what. As a server fan, this is not optimized for silent operation like most consumer PC fans today.

Arctic seems surprisingly disinterested in advertising its new fan, even though it represents a step up in performance in its class. The company deletes or ignores Arctic subreddit posts, press releases are difficult to find, and very few outlets have reported on the fan's real-world performance. Those interested in using the extreme high-pressure fan in 3U+ servers or workstations can find it for $14.99 from Amazon.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Sunny Grimm is a contributing writer for Tom's Hardware. He has been building and breaking computers since 2017, serving as the resident youngster at Tom's. From APUs to RGB, Sunny has a handle on all the latest tech news.

-

Kamen Rider Blade I think the next step in "Case Fan" tech evolution is to go back to look atReply

TMD (Tip Magnetic Drive) and implement it in the best possible form.

Benefits:

1) You narrow the center Dead zone down to a 5mm diameter which is "Good Enough".

2) With Magnetic Bearings, the hub of the fan can literally float on a cushion of air/oil

3) You move the EM Coil Windings to the 4x outter edges, ergo spreading the heat load.

4) Your fan design will always have a closed outter wheel edge, so you get rid of tip vortices inherently by closing the fan blade tip edges.

5) You have a Larger Surface Area for air to move through with "Less Obstruction"

6) AlphaCool has proven that you can "De-Couple" the fan components from the frame components of the fans and get better noise characteristics, the next step is to open things up and use the metal housing as "HeatSinks" for the EM Coil Windings at the edges. to help with cooling. -

Zenthar For the curious, about how loud those are, Tom had a news about the 8K variant with some videos.Reply -

80251 Nice fan for a cheap price. Longevity is an important fan performance metric in a data center. Power is too and this fan seems to have a too good power draw metric: 3.96 watts for a 4000RPM, 120x38mm fan.Reply

It's weird how Arctic have distanced themselves from their own fan design.

Here's a review from Amazon:

'It also didn't help that Arctic refused to answer questions on their reddit sub about these fans.'

Bizarre. -

Notton Reply

No, it ain't.Kamen Rider Blade said:I think the next step in "Case Fan" tech evolution is to go back to look at

TMD (Tip Magnetic Drive) and implement it in the best possible form.

This is basic math, like Gr.7 levels

10.5cm fan blade w/ 1cm hub (diameter)

area of fan blades: 86.59cm² - 3.14cm² = 83.45cm²

11.5cm fan blade w/ 2cm hub (diameter)

area of fan blades: 103.87cm² - 12.57cm² = 91.3cm²

And that doesn't even get into the highly technical aspects of fan blade design. The gist of it is, bigger and slower is better than smaller and faster, even with a slight loss of static pressure. The only reason to go small and fast is because of size constraints.

It's better to change the fan thickness and geometry. -

80251 @Kamen Rider BladeReply

How efficient were those TMD fans? Did they produce similar or better CFM/static pressure than traditional radial axial fans of the same size? -

Kamen Rider Blade Reply

I don't disagree with you on those points, "Bigger & Slower" = Less Noise.Notton said:And that doesn't even get into the highly technical aspects of fan blade design. The gist of it is, bigger and slower is better than smaller and faster, even with a slight loss of static pressure. The only reason to go small and fast is because of size constraints.

But I'm applying the TMD design principle to fans of ALL sizes.

Ranging from 4 cm to 20 cm in Case Fan sizes.

I concur, but 25 mm remains the most popular thickness, I to want "THICC" fans for certain specific applications.Notton said:

It's better to change the fan thickness and geometry.

They made 1x model, it was 70 mm (Why, 70?, I have no idea as to why that was the first design size to be chosen).80251 said:@Kamen Rider Blade

How efficient were those TMD fans? Did they produce similar or better CFM/static pressure than traditional radial axial fans of the same size?

They cranked it up to 5800 RPM as the upper limit.

http://www.dansdata.com/tmdfan.htm

So while it was "Noisy", it wasn't as bad as other fans in that RPM range. -

80251 @Kamen Rider BladeReply

That article you cited points out some of the downsides associated w/TMD fans. For one thing, the outer impeller ring has to be supported while it spins. On a 70mm fan thin struts might work, but on larger fans this might not work (i.e. because the fan blades are larger and heavier) so you would need some sort of bearing race to support the outer impeller ring, which adds more friction -- especially considering the linear velocity with which this outer impeller ring bearing race would have to rotate -- and the fact you would have to more than two ball bearings to support it. Maybe a Sunon maglev type solution could be adapted for this though.

I hope some industrial fan manufacturer somewhere is working on next-gen TMD fans or maybe even some drone manufacturers.