Nvidia reportedly selects Intel Foundry Services for GPU packaging production — could produce over 300,000 H100 GPUs per month

But which GPUs?

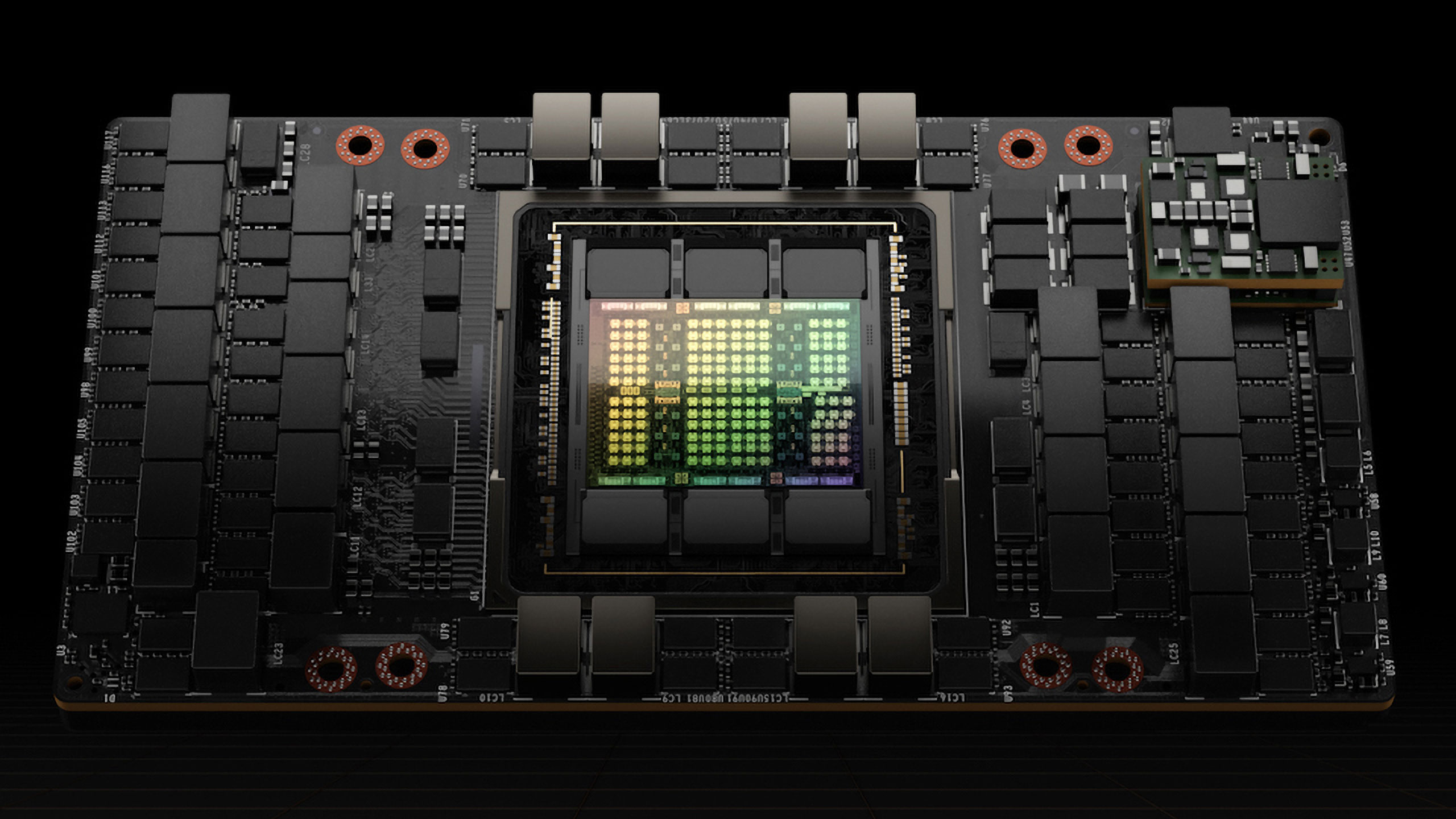

TSMC admitted in mid-2023 that demand for its chip-on-wafer-on-substrate (CoWoS) has exceeded its production capacity, and the company vowed to double capacity by the end of 2024. But while TSMC is building up its CoWoS capabilities, Nvidia would like to ship as many of its high-demand AI processors as possible — which is why it's tapping Intel to use its advanced packaging technology (in addition to TSMC's), according to a report from money.UDN.com, citing industrial sources. As with all unconfirmed reports, we'll have to take this with a grain of salt until the companies involved comment. The deal is purportedly for 5,000 wafers per month, and according to quick back-of-the-napkin math, that would equate to 300,000 of Nvidia's H100 chips (assuming perfect yield and that the contract is for H100) per month.

TSMC is projected to remain the main supplier, providing around 90% of Nvidia's advanced packaging capacity. But starting from Q2, Nvidia is also poised to use Intel's capacity for at least some of its products, the report claims. If this information is accurate, adding Intel's capacities will let Nvidia produce more GPUs for AI and HPC workloads, satisfying demand for its existing products quicker. There is a catch, however.

All of Nvidia's current and previous generation products, such as the A100, A800, A30, H100, H800, H200, and GH200 rely on TSMC's CoWoS-S packaging process, which relies on a silicon interposer. The closest advanced packaging technology that Intel has is called Foveros, which also relies on an interposer, albeit a different one (CoWoS-S presumably uses a 65nm interposer, and Foveros uses a 22FFL interposer).

To use Intel's Foveros, Nvidia will need to validate the technology and then qualify actual products, which will likely have slightly different characteristics (because interposers are made on different process technologies and have different bump pitches) than those packaged by TSMC, so the company's partners will probably also need to qualify them before deployment. If this is the case, it will be interesting to see whether Nvidia outsources only select products to Intel, or all of them.

Intel is expected to join Nvidia's supply chain in the second quarter, producing about 5,000 Foveros wafers monthly (if the report is accurate). This is quite a significant number for Nvidia alone. To put this into context, TSMC could produce as many as 8,000 CoWoS wafers per month as of mid-2023 (which is when Nvidia consumed the lion's share of this capacity) and aimed to increase the output to 11,000 by the end of 2023 and then to around 20,000 by the end of 2024. If Nvidia gets an additional 5,000 advanced packaging wafers per month, this will give it a significant edge over rivals.

Outsourcing some of its advanced packaging to Intel Foundry Service can be seen as a strategic move for Nvidia to diversify its supply chain. As an added bonus, by employing IFS's packaging capacities, Nvidia will also ensure that these capacities cannot used by rivals — allowing Nvidia to solidify its position in the market.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

ezst036 ReplyAdmin said:But which GPUs?

H100 GPUs? Perhaps it was a different person asking than the one who wrote the headline. -

einheriar So I assume nvidia has found a new way to price gauge the world AND sell AI chips illegally to the country of CCP.Reply -

JTWrenn This is a very big deal for Intel. I feel like they are positioning to gobble up a lot of the foundry business especially as China beats it's drum about Taiwan. I wonder how all the political pressures will play out for ASML tech because of that. Could Intel get first dibs on things simply because there is less chance of tech that would be headed to Taiwan could into China's hands? Either way seems like Intel betting on foundries is the right call, as we need more and more of it, and we need it spread out as much as possible.Reply -

L0rdrobot Nobody in their right mind is going to bring their fabless designs to Intel, a competitor. Coupled with endless propaganda from Intel, they have never produced even a 10nm chip.Reply

Further, and I am most assuredly not being rude, but the recent election in Taiwan was a solid victory for the Mainland. To understand Taiwan, what they would like is to reduce the anxiety between the Mainland and Taiwan. You strike me as an American Hawk and you have never been to Taiwan or China. The John and Joan Wayne approach is not palatable to the Chinese culture.

Recent elections the present President won more than 1/3 of the vote but not even a simple majority. The other two candidates were more friendly to the Mainland. The new President does not control the legislature. The strength is moving away from the DDP and it is younger voters propelling the changes. The Mainland is gaining power. The Mainland is the economic driver of the Taiwan economy.

Since Trump and now Biden, the chief complaint about Taiwan has been the silly notion that the US is DEPENDENT on TSMC for chips. One US General said the US would bomb TSMC rather than let China take it. Can you imagine how that remark resonated with the residents of Taiwan?

Taiwan has seen this erosion in the past with the US. Giving Taiwan weapons only invites China hostility. But what else does the US provide. Very little and with Biden's Chip Act which is a laughable government boondoggle, the US Government is hatching a plan with Intel to build Fab plants in UNION Labour controlled Ohio. The idea is to use Automative Labour to build chips. The cost estimates so far indicate that would result in a 50% increase in chip prices. That's assuming that Intel can actually build narrow gated chips. So far they have not show any aptitude fo that. Further, chip fab is manpower intensive. I do not even think the US labour force can do this kind of work. History is on my side in that regard.

This crazy Nancy Kerrigan Style kneecapping foreign policy of the United States is not going to prevail against China. In fact it has already failed.

As I have pointed out many times the narrow gated semis are a mere 5% of the market. 14 nm or under. China can make 7nm now and likely 5nm this year. However China has been focused on the 95% of the market and is now 60 to 70% self-sufficient. All this as a result of the American stupid idea that division of labour is a national security risk. Semiconductors evolved as a global division of labour enterprise. But the Murican first crowd thought that was too Global for them. So the Chips Act was a gambit to try to delay China so the US could catch up.

Even the CEO of ASML admits that China will have its own Litho narrow gated devices in a few years and will then be a hefty competitor to ASML.

The entire semiconductor business in the US is 2.3% of the US GDP. And shrinking 3% a year. By comparison the US Chemical industry is 25% of the US GDP and is expected to shrink 60% in the next five years. But where is Biden placing his chips? On fab. Makes no sense at all. BTW the Global Chemical Industry is moving to China. At present China has roughly a 60% market share and growing rapidly.

The business model for chips is wretched. A developer puts all their money in one chip that may or may not sell. When the US Gov blocks sales, they effectively destroy the semiconductor company that made the chip. Chips have a shelf life of bananas in a broken refrigerator car in Needles California. China doesn't want the NVIDIA disabled chips. NIVIDIA loses billions. There is not one semiconductor company that supports Biden's blockage of Chip sales to China, other than Intel that missed the entire handheld revolution and suddenly is eying FAB. And mark my words, they failed previously and this push will fail too.

I could tell you for example that China leads the US in 34 of 40 leading edge core technologies. And in the remaining 6, is just a hairs-breath behind. In China education is paramount. They are turning out more PhD by far than the US and Britain and Europe combined. In the US, 65% of all college enrolls are women, 35% men. That is a total reversal from the 1970s. Women are not filling the gap in the sciences. Nobody is thinking much about this in the Government or the long term consequences.

In terms of paper's published in AI, Biochemistry, China stands toe to toe with the US in virtually all scientific arenas and is leading in most. Ion impellers are used in chip fab and China has ion engines on its space station and makes ion impellers. The US doesn't have this or dozens of other technologies. But we always have to listen to the John Wayners claim that "Chiner Stole that technology from Murica." China has real 5g and now 6g, the US has neither. In fact, Intel failed in 5g spectacularly.

As my final remark: The individuals that kneecapped Nancy Kerrigan, did not become Olympic champions. To become an Olympic champion, one must compete. The US seems to have abandoned that idea in favour of kneecapping... This kneecapping has given China all the incentive it needs to become self-sufficient. You should have been selling them chips instead of turning them into a giant competitor. -

cyrusfox Looks like Nvidia is looking at ramping max capacity to claim all the market share it can.Reply

The H100 class GPUs packaging tech could likely be simplified, the GPU core is surrounded by 6 HBM clusters with only 5 in use, the 6th serving as redundant backup/structural support. They are connected currently through the silicon interposer

Why does it need a silicon interposer? Was this the best tech TSMC had on hand? Intel has other options or if required I am sure they could match TSMC interposer(Input out routing, to a given bump pitch and pitch pad), Foveros could pattern 65nm interposers through its 22FFL process, not exactly cheap though, why not move it to EMIB or any bridge tech should satisfy as long as the latency is the same or better.

I would bet Nvidia is going to create a whole new class of GPU. Why force it to be identical to a current product? As Intel packaging offerings differ from TSMC(smaller bump pitch), Why wouldn't Nvidia utilize and improve their product based off the advantages here and charge a premium for it? All that matters is MLPERF LLM benchmarks for this class of cards. "The more you buy the more you save ":) -

TerryLaze Reply

So 95% of the market is at larger than 14nm but nobody will use intel because they are on 10nm ??????????L0rdrobot said:Nobody in their right mind is going to bring their fabless designs to Intel, a competitor. Coupled with endless propaganda from Intel, they have never produced even a 10nm chip.

As I have pointed out many times the narrow gated semis are a mere 5% of the market. 14 nm or under. China can make 7nm now and likely 5nm this year. However China has been focused on the 95% of the market and is now 60 to 70% self-sufficient. -

cyrusfox Reply

Intel has been mass producing on 10nm for the last 5 years (Ice lake released Sept 2019 for mobile). Since then, Tigerlake, alder lake, raptor and its refreshes are all 10nm by by old naming convention, probably 10nm+++.L0rdrobot said:Nobody in their right mind is going to bring their fabless designs to Intel, a competitor. Coupled with endless propaganda from Intel, they have never produced even a 10nm chip.

https://www.anandtech.com/show/16823/intel-accelerated-offensive-process-roadmap-updates-to-10nm-7nm-4nm-3nm-20a-18a-packaging-foundry-emib-foverosMeteor lake is sub 10nm... and was release December 2023. Gelsingers whole reason for proposing 5 nodes in 4 years to catch back up to TSMC.

Electronics is very Asia dependent, Covid revealed some of the inherent weakness of concentrating all supply to a single location. (when supply chains broke down, we ran out of chips fast...) Intel has been successful at pushing this issue to get subsidies to build fabs outside of Asia. I view it as a benefit to have competition at the bleeding edge of semi conductor fabrication, hopefully Samsung decides to join the fray eventually... -

SirErr Reply

how many H100 chip can be produced per wafer?ezst036 said:H100 GPUs? Perhaps it was a different person asking than the one who wrote the headline. -

TJ Hooker Reply

Do you have a source for this? Is it 5% market share based on revenue, numbers of chips sold, total die area of chips sold, or what?L0rdrobot said:As I have pointed out many times the narrow gated semis are a mere 5% of the market. 14 nm or under. China can make 7nm now and likely 5nm this year. -

scottslayer Reply

I swear I see a wall of text like this on every tech site like clockwork from new accounts.L0rdrobot said:Nobody in their right mind is going to bring their fabless designs to Intel, a competitor.

blah blah blah blah blah blah