Technician warns against copper modding GPUs, fixes RTX 3080 with component damage

Copper cooling can drastically improve VRAM temperatures but its electrical conductivity risks the life of the ICs.

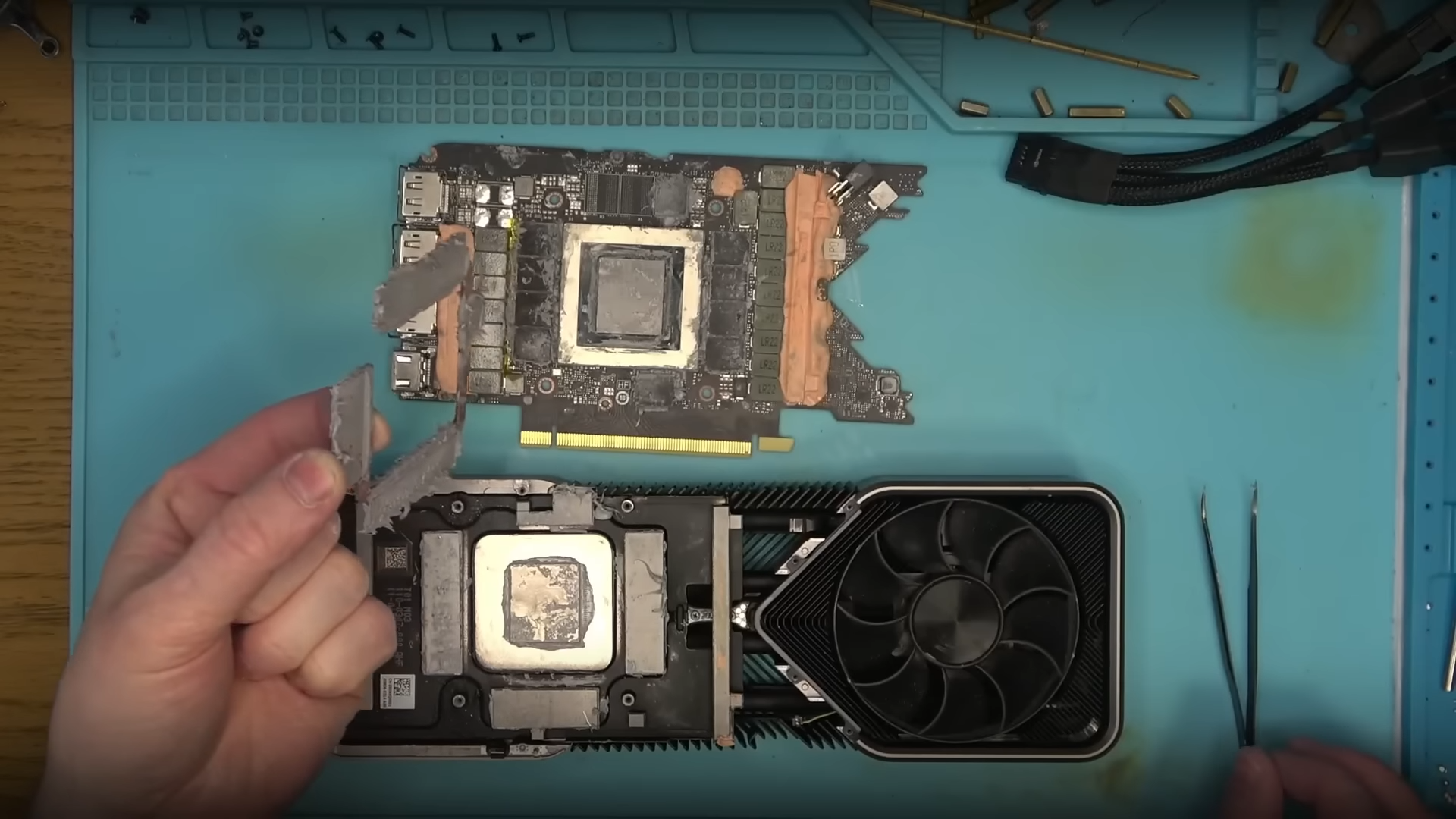

Repair technician "northwestrepair" on YouTube reveals the dangers of using copper memory cooling mods on GPUs. In a RTX 3080 repair video, the technician shows the damage done by a user who modded his founder's edition RTX 3080 with a copper mod. Extensive damage to the GPU's 1.8V rail, memory voltage, and other sub-systems was evident.

Copper modding, in this context, is a cooling upgrade for graphics card VRAM that can significantly improve memory temperatures. The mod involves replacing the stock memory thermal pads with a copper cooling plate (or copper shims) that sit between the memory ICs and the GPU heatsink. Thermal paste is then used to bridge the small remaining gaps.

While this mod can massively improve temperatures, northwestrepair reveals that copper mods can impose significant danger to the system components surrounding the GPU. Any component near the memory ICs is vulnerable to damage, as a result of copper's electrically conductive properties.

That is exactly what happened to the RTX 3080 northwestrepair fixed. Despite the original owner's attempts to protect the surrounding VRMs with Kapton tape, the GPU suffered immense damage making the GPU completely unusable.

The repair technician discovered a variety of issues with the GPU including a short in the memory power delivery system, and several knocked-out capacitors and components affecting the 1.8V rail, 5V VCC, and other systems. Other damage was also discovered including cuts to some of the traces near the PCIe finger, as a result of bad handling of the card which the technician also had to repair.

However, the most problematic issues were related to the GPU die and some of the memory ICs. The technician suspected thermal paste might have made its way underneath the GPU core and/or memory ICs. After reballing (reinstalling) and cleaning the GPU core and two memory ICs that failed memory testing, the card finally posted and passed a FurMark stress test. Confirming that thermal paste or some foreign debris was interfering with the memory and/or GPU core.

Northwestrepair noted that memory temperatures during the FurMark stress test were perfectly acceptable (after he swapped out the wrong pads with the right-sized counterparts), with the GDDR6X memory temps hovering in the high 70s negating any need for modding the cooler.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Copper shim and copper plate modding gained popularity a few years ago, when GDDR6X first debuted on the RTX 30 series and when crypto mining was still profitable on GPUs. These two factors created a massive overheating problem on many RTX 30 series GPUs, with several GPU models running upwards of 110C on the memory, while mining causing thermal throttling. This problem was especially troublesome on the RTX 3090 (not the 3090 Ti), with half of its 12 GDDR6X modules being on the back of the PCB, RTX 3080 Ti Founders Edition, and RTX 3080 Founders Edition.

Using copper mods drastically helped reduce temperatures on these problematic cards ranging from a 25C to a whopping 46C reduction in VRAM temps depending on the copper mod implementation and card model. However, it was only truly beneficial on mining cards, as games rarely caused these GPUs to thermal throttle.

Aaron Klotz is a contributing writer for Tom’s Hardware, covering news related to computer hardware such as CPUs, and graphics cards.

-

bit_user So, basically, the only problem with copper shims is when they're not sufficiently electrically isolated from other components? That, and the leakage of thermal compound (could this be the so-called PTM or Phase-Change material? or just some low-viscosity grease?) were responsible for basically all of the damage?Reply

Plus, from that still frame, it looks like the copper was almost like a foil that the user pushed down onto the components.

I wish graphics card makers would do a better job to keep memory and VRM components cool, as it comes from the factory, but I get that costs money. Graphics card margins are slim, and competition among them is pretty fierce.

Anyway, what I find most surprising about this account is that a tech skilled enough to do this work can actually make money doing such involved repairs. Maybe they can't, which is why they tried to get some supplementary income (or free advertising) from posting the vid. I'm quite amazed they got it working again. Such techs are like magicians to me. -

thestryker Reply

What you're seeing on the card is whatever janky material was used to replace thermal pads the copper mod plate is in his hand. There was a lot messed up with this card beyond just the shoddy plate installation.bit_user said:Plus, from that still frame, it looks like the copper was almost like a foil that the user pushed down onto the components. -

CelicaGT Reply

You've never watched northwestrepair before? I've watched a bit of this stuff and he makes it look easy (as many things can be with the proper tools and most importantly, experience). Mind you, this card was a train wreck so consider that they post the worst case scenarios on the channel. I expect most repairs are mundane stuff like HDMI socket replacement etc. Still, watched a few of their vids over the years and a good time was had by all.bit_user said:So, basically, the only problem with copper shims is when they're not sufficiently electrically isolated from other components? That, and the leakage of thermal compound (could this be the so-called PTM or Phase-Change material? or just some low-viscosity grease?) were responsible for basically all of the damage?

Plus, from that still frame, it looks like the copper was almost like a foil that the user pushed down onto the components.

I wish graphics card makers would do a better job to keep memory and VRM components cool, as it comes from the factory, but I get that costs money. Graphics card margins are slim, and competition among them is pretty fierce.

Anyway, what I find most surprising about this account is that a tech skilled enough to do this work can actually make money doing such involved repairs. Maybe they can't, which is why they tried to get some supplementary income (or free advertising) from posting the vid. I'm quite amazed they got it working again. Such techs are like magicians to me.

(Edit: Spelling. Somehow AI autocorrect makes it worse...) -

zcomputerwiz It wasn't even the copper mod that was the issue with this GPU.Reply

It was missing plenty of passive components that were knocked off the back of the board and had physical trace damage, not to mention the thermal paste underneath the VRAM and core that necessitated a reball. -

Stomx Reply

This is because poor NVIDIA can not even eat, all the time thinking about their users. And its Jensen Huang honestly believes that "...the more you buy the more you save"bit_user said:Graphics card margins are slim, and competition among them is pretty fierce. -

MtFkr Replybit_user said:So, basically, the only problem with copper shims is when they're not sufficiently electrically isolated from other components? That, and the leakage of thermal compound (could this be the so-called PTM or Phase-Change material? or just some low-viscosity grease?) were responsible for basically all of the damage?

It's thermal paste, not PTM pads, if you watch the full video. The owner had a sloppy job applying the paste and perhaps overfill it to the point some of the paste went under the memory and core solder.

Not to mention it's only the beginning since later in the video, he found many missing components ripped out from the board and few deep scratches. -

Gaidax The biggest problem with the mods like this is people.Reply

If you don't know what you're doing - don't mod your card. -

P.Amini ReplyOther damage was also discovered including cuts to some of the traces near the PCIe finger, as a result of bad handling of the card which the technician also had to repair.

DON'T TRY THIS AT HOME! If you have no freaking clue what you are doing. -

gamerk316 Reply

If doing any type of IC work, techs like this one are a godsend. Where I work we have *one* guy capable of this, and he's on the wrong side of 65, and we're terrified of the day he finally retires.bit_user said:Anyway, what I find most surprising about this account is that a tech skilled enough to do this work can actually make money doing such involved repairs. Maybe they can't, which is why they tried to get some supplementary income (or free advertising) from posting the vid. I'm quite amazed they got it working again. Such techs are like magicians to me. -

bit_user Reply

After I nearly killed my original Playstation, installing a mod chip in it, I had a tech at my job install a mod chip for my DVD player. It was a rather more complex affair and his work was masterful. He's the type of guy who'd do rework on boards - not just repairs. He must be retired, by now.gamerk316 said:If doing any type of IC work, techs like this one are a godsend. Where I work we have *one* guy capable of this, and he's on the wrong side of 65, and we're terrified of the day he finally retires.