Under The Kimono: Inside Intel's Hidden R&D

Bending Motherboards For Fun

Here’s another shock and vibe machine, similar to the other but with much taller standoffs and arms able to elevate and drop the test board. While the larger machine we saw previously will vibrate at about 130 inches per second, the tall machine varies between 100 to 200 inches per second. The object here is to test how much quick bending a motherboard will take. The tall standoffs actually bend sideways during a shock, thus reducing the pull on the motherboard. Additionally, by changing where the standoffs are, the board will bend differently.

Shock And Awww...

One configuration with the tall shock and vibe instrument involves supporting all four motherboard corners, resulting in what’s called a spherical bend during the shock. Tests are conducted with the motherboard mounted upside-down in an attempt to peel components off of the board. After testing, boards are dyed then vacuumed. Then components are removed and the board is scanned with a special detector. If the detector finds ink traces in the solder at this point, it means there were cracks in the solder before the components were removed.

Throwing Hardware Around

Alongside the tall machine sit two technicians and their analysis systems. In addition to assessing test data, they also make sure that the tests themselves are conducted safely. The machine won’t operate if the cage doors are open. We observed multiple 4.4" drop tests, and before each one could come a call of “readyyy...drop!” Then a loud thud would fill the room. This drop means to simulate the force of a system being kicked under a desk or being slightly dropped.

Simulating FedEx's Horrible Handling

Last in the shock and vibe room, but definitely not least, we have the package drop machine. You might think of this as the UPS or FedEx test. A platform raises a box, then releases and drops the package to its potential doom. The drop distance can vary in six-inch increments from one to six feet. A test set includes dropping the package on all six sides, two corners, and three edges. Intel engineers expect packages under 20 pounds to be dropped 36 inches. A 120-pound server might be dropped 18 inches. Lighter products, such as handheld devices, are prone to being tossed during shipping, and there’s another drop machine rated for up to 3,000 G specifically meant for such devices.

Working In The Dark

Nestled among a sprawl of cubicles sits the rework cage, the place motherboards go for modification and optimization. When we first entered this area, we thought perhaps the staff had taken a long weekend or been laid off en masse. Far from it. It turns out that this is where many of Intel’s CAD designers work, and CAD designers can see their screens more accurately without a lot of ambient lighting. Apparently, marketing staff sometimes refers to these CAD workers as “mushrooms.”

Rebuilding Broken Boards

Think you’re bad with your workbench and solder gun? Intel’s reworkers get the real goods. Within their cage rests nearly all the capabilities of a manufacturing facility, including the ability to do a lead-free overhaul and replacement of major components, such as BGAs and ASICs. It’s not uncommon for a board to emerge from shock and vibe, come up here for reworking, then head straight back for another round of abuse.

Engineers Need Sleep, Too

Some elements of being a geek are universal. There was a time once when reworkers could allegedly be bribed with Mountan Dew. Now that Intel recently made drinks free to employees in the cafeteria, outside staff must find other means of trying to get their jobs ahead in the queue. We counted no less than three candy baskets in the rework cage, and chocolate is supposed to be particularly effective.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Pictured here is one of the many emergency eye wash stations we found throughout the Hawthorn Farms facility. One of our guides joked that it served as the shower for engineers pulling all-nighters. No doubt, the hand-written exit sign above the cage’s only doorway serves as additional help for overtired staffers.

A Little Re-Decoration

What happened to the stodgy, white-collar Intel of the ‘80s? We found little evidence of it at Hawthorn Farms. Instead, the modding spirit seems to have taken hold in more than Intel’s high-end motherboards. Witness the cubicle of validation engineering manager and equine enthusiast Julia Petersen. In addition to receiving eight-week sabbaticals for long-term service (ten if you want to lump in your annual vacation time), it appears that a bit of hazing for sabbatical takers is common at Intel.

...Now We Have To Kill You

Onward to electrical and thermal testing! In this voluminous room, each aisle has its own nickname, such as Intern Alley or Land of VREG. In the foreground, you can see a technician working with a Flir Systems thermal imager, the same sort of camera often sold to the military. Under the camera sits a late beta version of Intel’s new P55 (Ibex Peak) platform. We took many pictures of this board. The engineers were proud to show it off. One noted that we were the first outside of Intel to ever lay eyes on it. However, our press relations and marketing escorts received some cell calls during our shoot, and one politely asked to see our flash card so that the images could be deleted. We pulled the old “oh, my God, what’s...THAT?!” trick and copied the images onto a second card while everyone’s back was turned. But since Intel was exceptionally generous in hosting our visit, we’ll return the favor by not posting the images until the P55's official release. So sad.

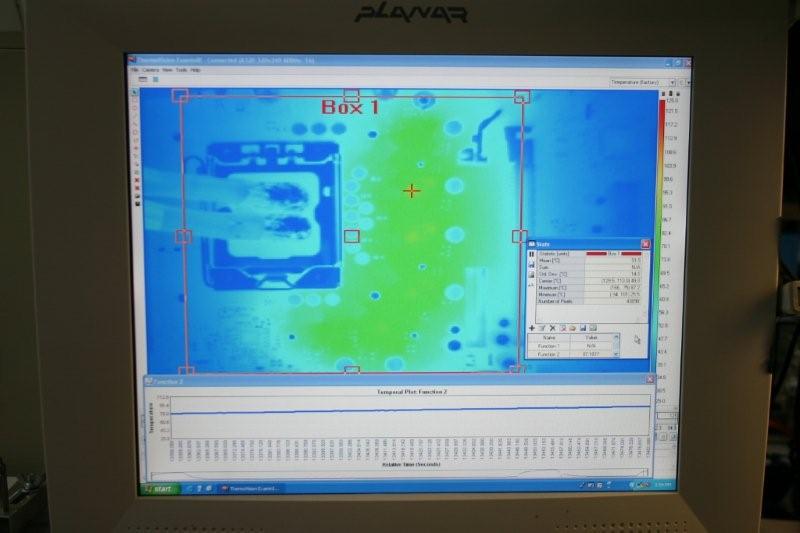

The Truth That's Hard To See

Here’s a better look at what Intel techs see with that thermal imager. Intel’s DX58SO (Smackover) board uses 6-phase voltage regulation, and you can see how the power circuitry is heating up evenly around the CPU socket. Notice that the phase balance is nearly perfect, with no hot spots standing out. This means the board has very even current distribution, enabling you to get more current out of the VR. Intel engineers purposefully push more current into outer phases where the air is cooler to help facilitate this heat balancing.

Some competing X58 boards use 16-phase VR, which looks much more impressive on paper. More is better, right? Not necessarily. Testing in this room reveals that the competitor’s product will show a significant load imbalance, even driving two or three of the phases into “catastrophic thermal conditions.” Intel explains that “catastrophic” can start at about 120̊ C. At this temperature, a thermal runaway condition, like a feedback loop, can set in and start roasting components. Real danger sets in around 150̊ C, at which point the PCB can start to carbonize. If the board standing vertically in its chassis during this situation, elements can desolder and components can actually slide off of the board.

Fortunately, this Smackover is evenly distributed, allowing it to be pushed harder. It’s 6-phase power can handle up to 140A or 200 watts. That competing 16-phase board tops around 130A and 180 watts.

-

randomizer "In this test setup, the chassis gets hit with 25 G and the installed card with 50 G."Reply

Now that's quality control! -

Pei-chen Intel should move on to solid state (Japanese) capacitors. Better parts are better parts even if they are equally reliable in desktop environment.Reply

BTW, that “dark room” looks great. My office is too well lit.

-

enterco They may have good testing environment, but it seems that it's used only for 'select' motherboard/chipset combinations. For example, they don't test Core2 E7xxx CPU's in combination with x965 chipsets. Anyway, x965 boards should be able to use all Core 2 Processors with 1066 MHz.Reply

The conclusion: why bother to test and certify such an old motherboard chipset, as long there are so many testers out there?

-

curnel_D TheCapuletAhh, so this is what Toms got for this article: http://www.tomshardware.com/review ,2138.htmlProbably. Lol. But at least it was worth the cool look into Intel.Reply -

So, if Intel is so great then, what happened with the X38, X48, and X58?Reply

All three performance Intel boards "suck"......X975 was a great motherboard, however it has been very average since.....Has Intel ever thought to use a "solid capacitor" motherboard for the Extreme tine of boards? What gives with the Intel board? Anyway they need an enthusist level bios such as Gigabyte, Evga, Asus, or Dfi anyway.....Greatest Cpu and Chipset combination around, however the MOBO's suck wind.......Mr. Bad Kat......... -

Area51 ReplyThey may have good testing environment, but it seems that it's used only for 'select' motherboard/chipset combinations. For example, they don't test Core2 E7xxx CPU's in combination with x965 chipsets. Anyway, x965 boards should be able to use all Core 2 Processors with 1066 MHz.

The conclusion: why bother to test and certify such an old motherboard chipset, as long there are so many testers out there?

You sir are an idiot. -

enterco I believe you are wrong. There are few facts:Reply

1. Intel claims that their boards, specifically DG965OT can be used with 'Core 2 Processors with 1066 MHz FSB' (check this link)

2. Intel has made the Core2 E5xxx and Core2 E7xxx processors with lower FSB than E8xxx series, and these CPU's FSB are 1066, and 800 MHz, but their statement is that 45nm CPUs are compatible with 3x series chipset and later. Perhaps, a good reason to make these variants of Wolfdale is to make them available for older chipsets. But that's true only for other vendors' boards.

3. Intel's CPU compatibility tool claims that Core2 E7xxx (1066 MHz) cannot be used with DG965OT motherboard. This can be checked here.

4. Intel's support specialists from the agree that 'this combination is not tested'

5. Since I've asked them any details, Intel didn't update their DG965OT product specification page, and they did not include any statement regarding Wolfdale series Core2duo processors

Now, how can anyone explain that a motherboard which can be used with 'Core2 processors with 1066 MHz' cannot be used with Wolfdale-derived Core2s? The only answer I found is: they don't have enough resources to waste TESTING a combination whch seems to be valid; or they are interested in selling only the new motherboards, so a customer won't upgrade only the CPU.

Best regards, -

anonymous user enterco.Reply

Is your motherboard tested to work with every DDR3 memory vendor, every SATA HDD model, every PCI-e Video card? - NO -

As long as Motherboard and components meet common electrical specifications - they should work fine.

Functional testing usually covers some common components as a sanity check, but never every possible combination (that would be a waste of resources).

As long as motherboard and CPU meet common spec (and CPU is supported by BIOS) the combination should work, even if it is "untested"

In the end, that is the whole purpose of having electrical specificion for components.