Let's Take a Trip Inside Budget Power Bars, Part Three

In this third and final part of this series, we take a look at three units from some of the most popular brands in IT-related power products. All of your patience is about to pay off: we're also picking an overall winner.

Tripp-Lite's Y-Wings

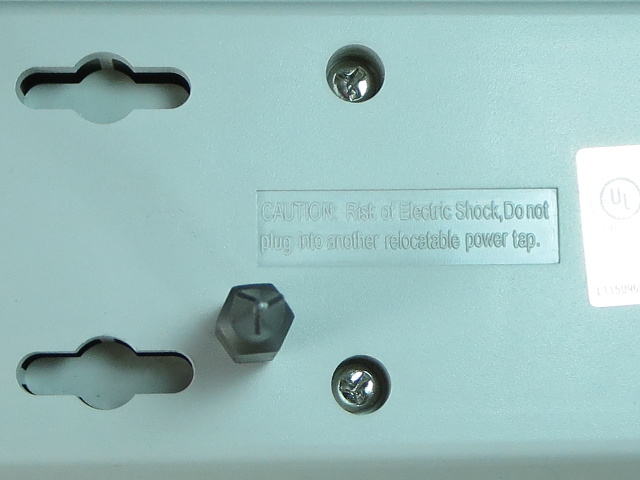

The TLP604 is the only other bar in this round-up to use security screws of some sort (in this case, the tri-wing or Y1 type). We're presented with yet another occasion to justify tool hoarding.

Trip Inside The Tripp-Lite

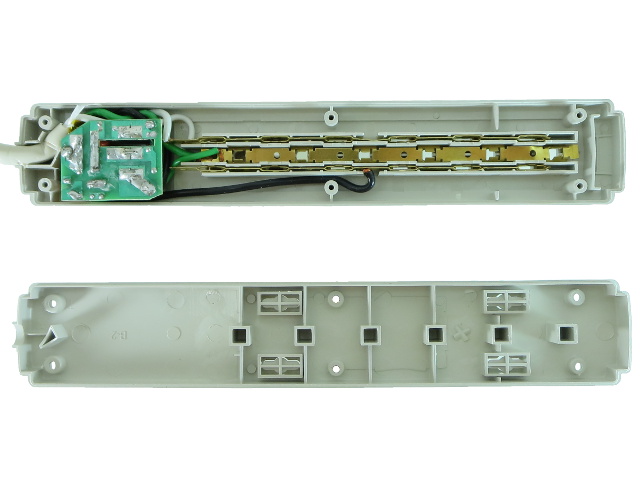

TrippLite's layout is similar to CyberPower's, with the PCB soldered directly on the breaker's terminal. And since this one has a switch illuminator, it has the third (neutral) terminal to power it. For some odd reason, Tripp-Lite decided to bring the live wire half-way down the outlet strip instead of connecting near the tip.

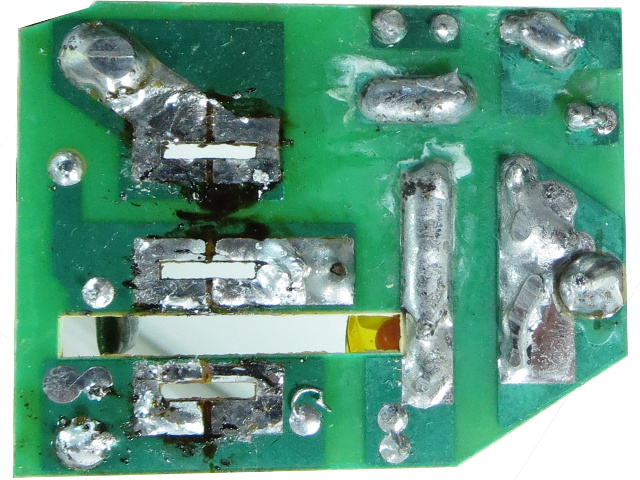

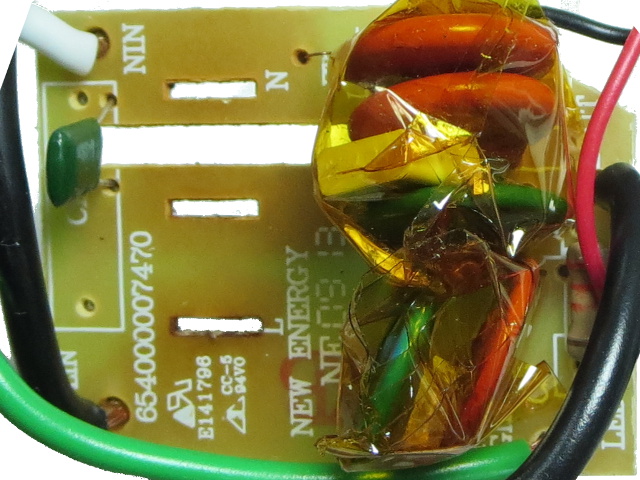

Tripp-Lite's PCB

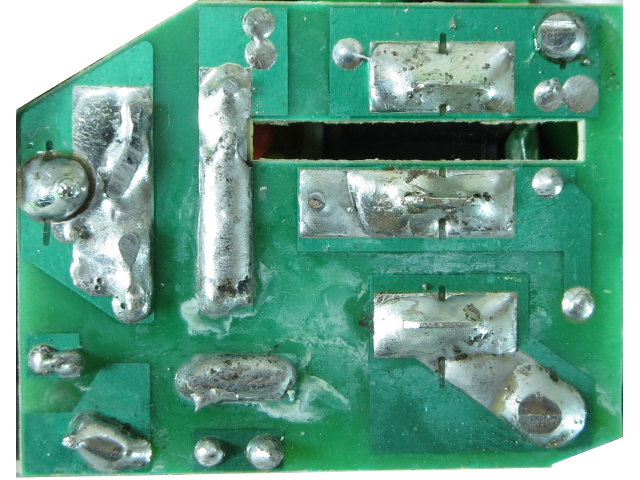

If you like nice and shiny solder jobs on clean PCBs, you might want to avert your eyes. There is a generous quantity of solder flux all over the board, and most leads have blobtastic solder jobs. Fortunately, soldering does not need to look pretty to get the job done.

I am not going to solder-wick this one.

Trippy Spying

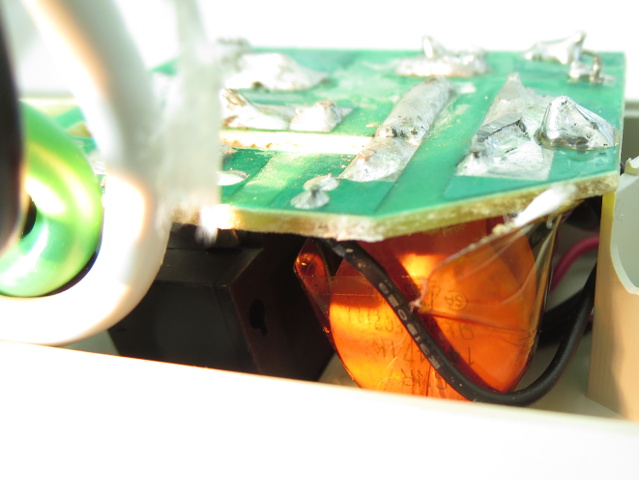

From what I can glean from the sides, the live-neutral protection has two GNR 14D471K MOVs and a third blue MOV further back that I can't identify. The main shut-off fuse is sandwiched between the orange and blue MOVs, so I would hazard a guess that the blue MOV has a lower clamping voltage. I could not read the live-ground and neutral-ground MOVs' models, but they also have one each (as expected).

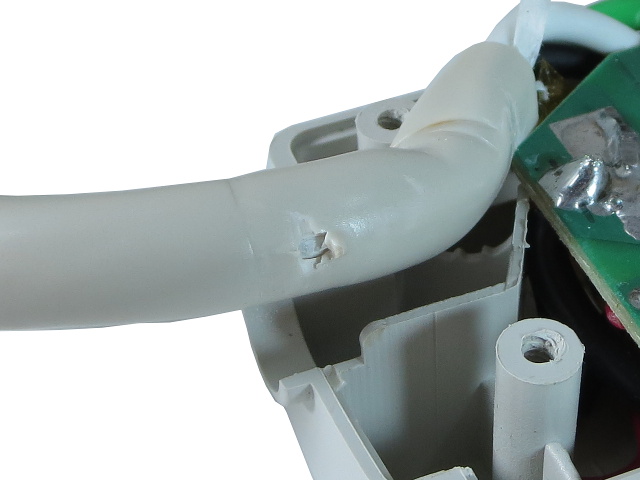

Pinched

Safety codes generally tell people not to use extensions and appliances with damaged power cords. Here, the bar's cable got pinched clean through right at the housing's outer edge when it was assembled. You can see the wires' paper wrap through the hole.

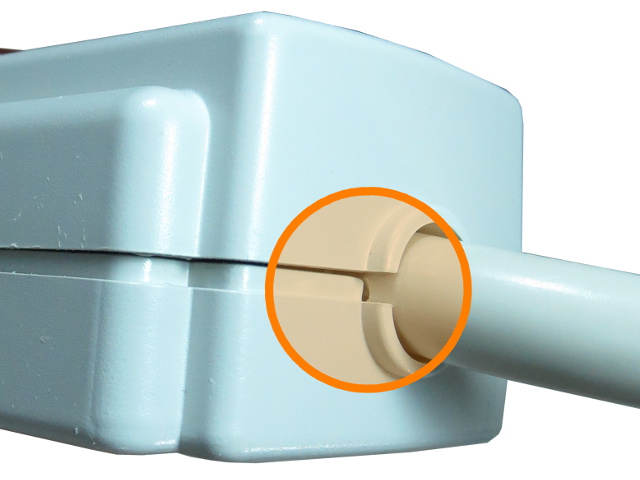

Barely Visible

With the enclosure nearly closed, the nicked cable area is barely visible.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

This is one of those cases when trying to file a warranty claim technically proves that you voided your warranty. When I mailed Tripp-Lite about the issue, I was told the company's engineering department would look into it.

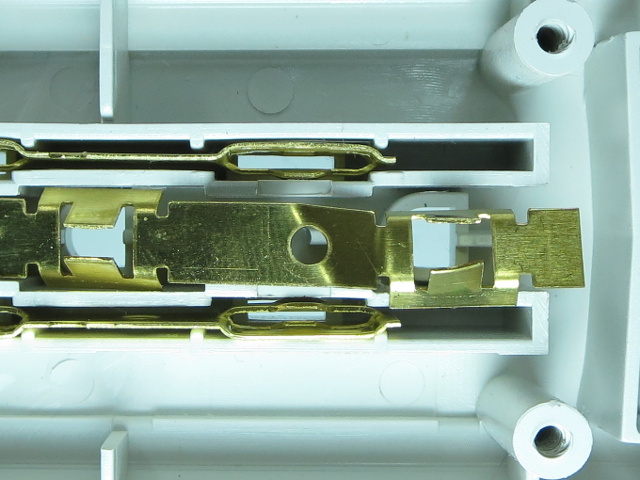

Skewy Trippy

Here is more proof that no manufacturer is immune to slip-ups: the tip of that ground strip has a few extra bends to it. While that may not affect performance, it does complicate keeping the strip in place for (re-)assembly.

The TLP604's power strips are 5.2mm wide by 0.5mm thick, while the ground strip is 3.7mm wide by 0.4mm thick, placing both at the chunkier end of the scale.

On Second Thought...

As I was re-arranging the rest of this article to form a third part, I had a change of heart about desoldering Tripp-Lite's entry. The tabs looked straight, after all.

Indeed, the task turned out much easier than getting into CyberPower's unit since the tab holes were far enough below the PCB to not draw solder in. Liberal use of solder flux also helped.

Tripp-Lite's Components

Here are those components I almost didn't dig out. The live-neutral protection comprises two 14D471K MOVs (orange) and one 14D201K (blue), while the neutral-ground has a lone 14D201K and the live-ground has a single 14D471K. The PCB clearly contains a footprint for a 47-100nF X-rated capacitor. Tripp-Lite decided to go with a tiny 1nF Mylar capacitor instead, so no EMI filtering happens.

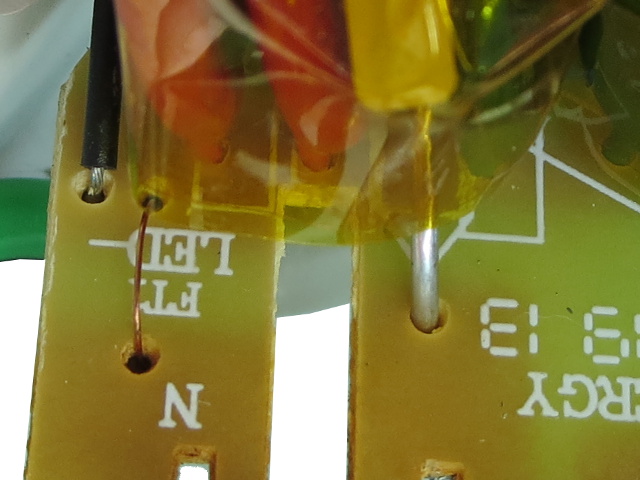

Hanging By A Thread

Do you see that jumper wire above the 'N'? This is the wire that connects the MOVs to the power cord's neutral line. Above and further to the left is the “Protection Working” LED's anode wire. Does anyone else find it ironic that a LED wire, which carries less than 0.02A, is twice as thick as a jumper wire that may need to bear 3000A during a surge?

Obviously, this piece of wire (and an identical one on the ground side) is intended to serve as a fuse. Tripp-Lite must have calculated them to be sufficient for the surges this bar is intended to cope with. The company could have gone even cheaper by simply using a narrow PCB trace and extra separation between copper islands.

-

Amdlova thank you daniel for another bad trip. when i look for those bars i have a bad feeling about what happens inside of it.Reply -

babernet_1 Is it just me? For this and another similar presentation I can only get one picture switch then the rest of the pics are locked, I cannot see them.Reply -

Daniel Sauvageau Reply

Those last three were fairly decent and the Belkin was not too bad either as far as basic surge protection go.15085733 said:thank you daniel for another bad trip. when i look for those bars i have a bad feeling about what happens inside of it.

If you want dangerous everyday stuff, someone asked me to take a look inside their LG microwave yesterday. Complaint: not heating up. Cause of failure: door safety micro-switch rated for only 0.6A at 125V in series with the HV transformer which should draw at least 10A based on the oven's 1100W rating, likely more due to reactive power and crest factor. The connector covers were melted and partially carbonized onto the switch. -

rdc85 Reply15086478 said:Is it just me? For this and another similar presentation I can only get one picture switch then the rest of the pics are locked, I cannot see them.

usually caused by connection problem (lag)..

try refresh and wait a while the pic is loading...

-

hydac8 How about doing a tear down of European power strips ? I'm sure it would be interesting for non US residentsReply -

synphul Doesn't surprise me, seems like as time goes on and tech 'improves' basics get crappier. Most anything electrical anymore is a fright fest, especially compared to older 'outdated' things. I've noticed this with a variety of electrical appliances. Old funky power bars no one gave a second thought about just worked. New ones with all the bells and whistles are melting down.Reply

Who used to worry much over their psu for their pc? So long as it had an appropriate wattage rating, it just worked. Now? Buzzing, popping noises, puffs of smoke, melted sata power wires, you name it. Literal Chernobyl in a box. Countless stories recently of people using electric heat tape to keep their pipes from freezing (since it's winter here in the u.s.) and fires breaking out. Many just from friends of mine alone who have smelled burning and smoke and panicked, shut off their main house power. Fire dept confirmed they did the smart thing since it was burning their home's insulation and about to start a major house fire.

I've personally had 2 electric heaters just within the past couple of months getting so hot that they melt the plugs. To the point the contact spades are literally falling out of them and the plastic insulated plug head is like goo. On a 1500w heater, that's ridiculous (although at least I didn't experience blue sparks or smoke/flames emitting from the front as others have). That's not a 'cheapy' either, it was a $100 DeLonghi. Everything electrical anymore is flat getting scary terrible in build quality and worse than not performing as we'd hoped is becoming a health and fire hazard. -

Daniel Sauvageau Reply

The main problem with that would be the basic fact that european power accessories are not readily available in North America.15092925 said:How about doing a tear down of European power strips ? I'm sure it would be interesting for non US residents

If you want something frightening, I saw a video on youtube a few months ago of someone doing dangerous appliance tear-downs. I do not remember if it was an Euro or Australian bar but it was absolutely horrible: packaging said it had a fuse or breaker but there were none, it said it had surge protection but there was none, same for filtering. It claimed to be heavy-duty but its power cord was copper-plated aluminum thinner than #16. The outlets were strung together using #18 gauge copper-plated aluminum. Wiring insulation started melting with the bar passing merely 8A out of its 16A rating. At 10A, wiring caught on fire. Packaging claimed the product used fire-resistant material but the plastic failed to put itself out after power was removed.15097247 said:Doesn't surprise me, seems like as time goes on and tech 'improves' basics get crappier. Most anything electrical anymore is a fright fest, especially compared to older 'outdated' things.

I think none of the units I had in my three parts tear down come anywhere near that horrible - though I did not do actual load/conductivity or flamability tests.