Apple to become first customer for Amkor's $2 billion Arizona chip packaging facility

The advanced packaging facility will be in Arizona.

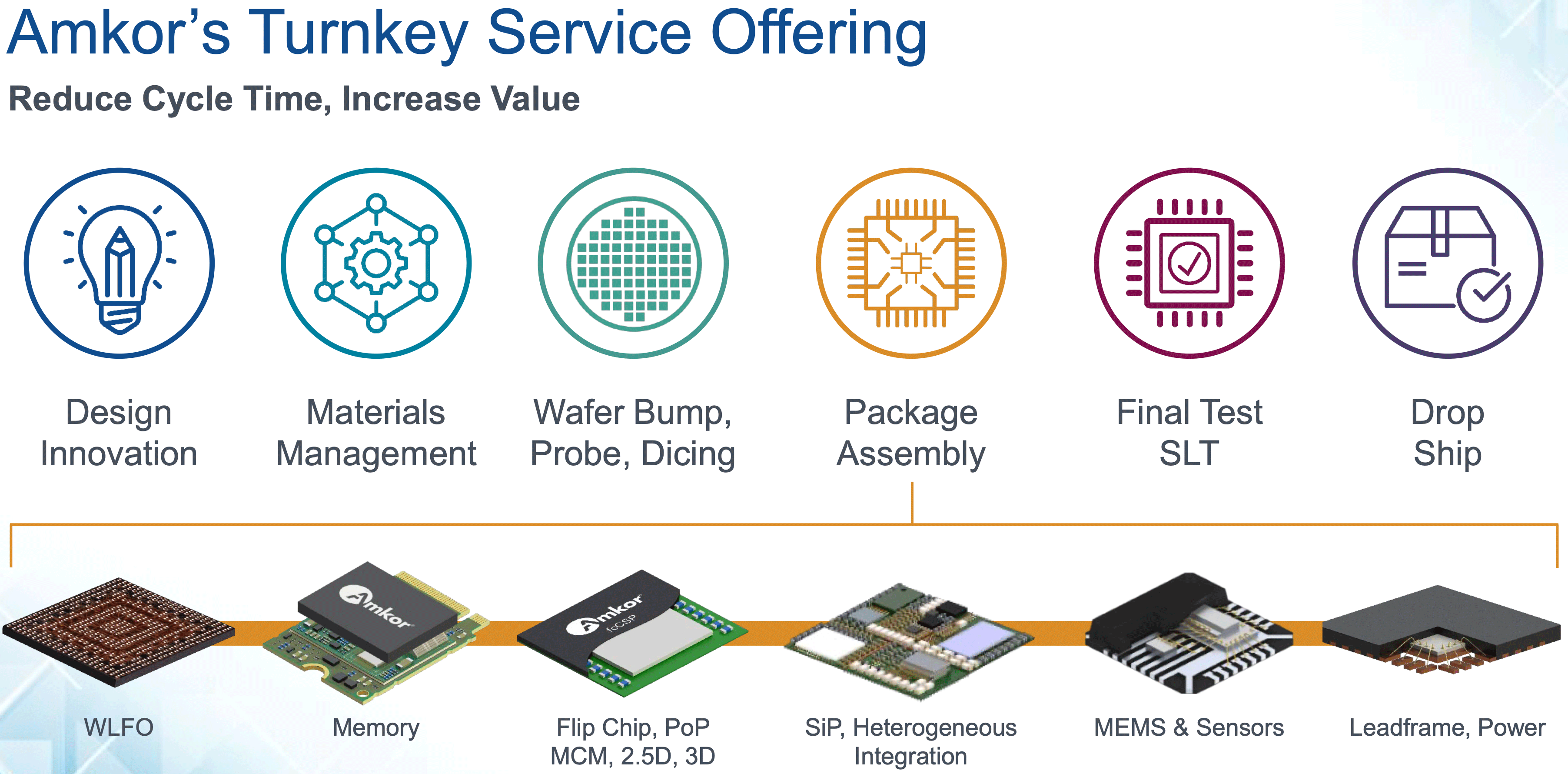

Amkor, a leading OSAT (outsourced semiconductor assembly and test) service provider, on Tuesday announced plans to build an advanced chip packaging facility in the U.S. The company plans to invest around $2 billion in the new facility, which will be located in Arizona and will be used to package chips produced by TSMC at a fab nearby. Apple is set to become the largest customer of the facility.

The upcoming advanced packaging facility near Peoria, Arizona, will feature a massive 55-acre state-of-the-art manufacturing campus with over 500,000 square feet (46,451 square meters) of cleanroom space when fully built and equipped. To put the number into context, the cleanroom space of the Peoria plant will be over two times larger than the cleanroom space of Amkor's advanced chip packaging facility in Vietnam. The initial phase of the Peoria factory, which will use Amkor's leading-edge technologies for advanced packaging and testing of chips for computing, automotive, and communications applications is expected to be operational within two to three years, so in 2025 or 2026.

"Expansion of a US semiconductor supply chain is underway, and as the largest US-headquartered advanced packaging company, we are excited to lead the charge in bolstering America’s advanced packaging capabilities," said Giel Rutten, Amkor’s president and chief executive officer said in a press release.

Amkor said that it had collaborated extensively with Apple to shape the strategic direction and initial manufacturing capacity of the Peoria facility, which implies that the factory is tailored for Apple's needs two or three years down the road. Apple will be the facility's first and largest customer, using it to package and test chips produced at the nearby TSMC Fab 21.

"Apple is committed to help build a new era of advanced manufacturing, right here in the US,” said Jeff Williams, Apple's chief operating officer in a statement. "Apple and Amkor have worked together for more than a decade packaging chips used extensively in all Apple products, and we are thrilled that this partnership will now deliver the largest OSAT advanced packaging facility in the United States."

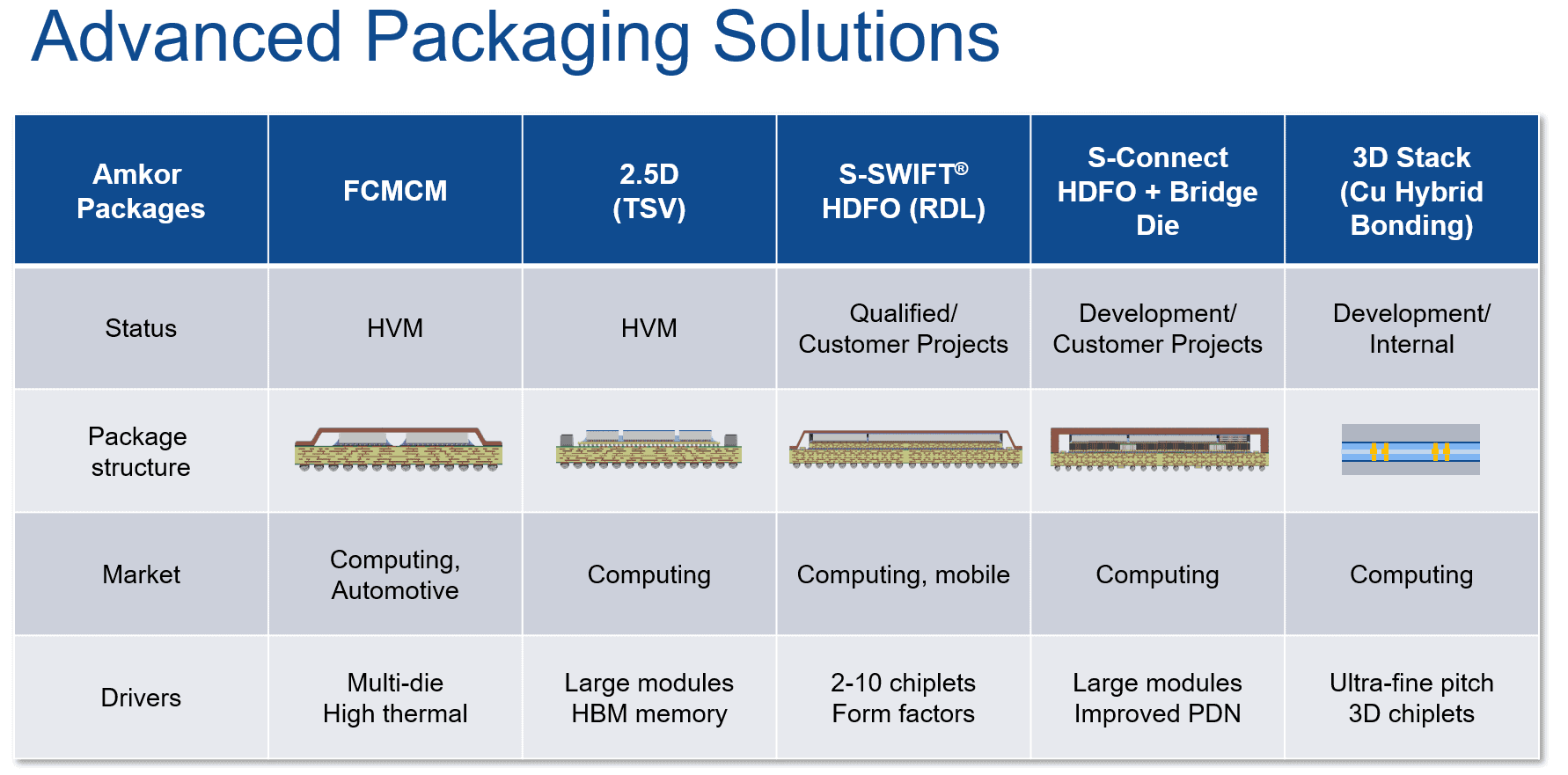

TSMC's Fab 21 phase 1 will make chips using N5, N5P, N4, N4P, and N4X process technologies in late 2025. Meanwhile, TSMC's N3-capable Fab 21 phase 2 is expected to come online in 2026. That said, the plan to use Amkor's test and packaging facility in 2025 – 2026 indicates that Apple will have loads of 3nm and 4nm-class chips or chiplets to package at the time.

"Apple silicon has unlocked new levels of performance for our users, enabling them to do things they could never do before, and we are thrilled that Apple silicon will soon be produced and packaged in Arizona," said Williams.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The project will require investments of around $2 billion and is projected to create approximately 2,000 jobs, significantly contributing to the local economy. $2 billion is a rather massive sum for a chip test and packaging facility. To put the number into context, TSMC is set to spent $2.87 billion on its next advanced packaging facility in Taiwan, which is set to be completed in 2027. Meanwhile, modern packaging technologies require production tools that are used to produce logic chips and are quite expensive. For Amkor, $2 billion is a massive sum as well. Last year the company's total capital expenditures reached $908 million, so the cost of the new facility will be higher than its CapEx budget for two years.

To ensure completion of the project in the United States, Amkor has requested funding from the CHIPS program (advanced chip packaging-oriented program, to be more precise). Amkor's advanced facility is a very good candidate to get funding from the U.S. government as it greatly strengthens American semiconductor supply chain and enables customers of TSMC's Fab 21 in Arizona to use advanced packaging methods without moving their wafers outside of the state.

"Semiconductor companies, foundries, and other supply chain partners understand the need to strategically broaden their geographic footprint," said Rutten. "The announcement of our new advanced packaging and test facility in Arizona is a clear signal of our intent to help our customers ensure resilient supply chains and be a part of a strong American semiconductor ecosystem."

"As one of the first advanced packaging facilities in the U.S., this is a huge step forward to reducing dependence on other countries in the microchip supply chain," said Senator Mark Kelly of. Arizona. "When negotiating the CHIPS and Science Act, one of my top priorities was making sure companies like Amkor had the support needed to develop a resilient supply chain in places like Arizona that are leading the way in bringing microchip manufacturing back to America."

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

rluker5 Maybe Apple will still get chips from Taiwan and have them packaged in Arizona. The process nodes listed seem a little late for Apple. I don't think Apple will keep using the same nodes until 2025-6.Reply -

bit_user It seems like we're headed into an era when most leading CPUs, SoCs, and probably even GPUs will employ some form of advanced packaging.Reply -

thestryker Packaging is rapidly becoming as important as the fabrication nodes themselves and I think a large chunk of the reason is the cost of said nodes. Apple's current big chips have got to cost an absolute ton to manufacture and they're limited in configurations because of it. Advanced packaging should not only allow them to make SoCs for less but also use optimal nodes for each chiplet they decide to make while allowing for more configurations.Reply -

HaninTH My concern is... I hope Amkor doesn't need a lot of fresh water, as Arizona, and the whole southwest, is in a deep drought. I suppose they think it'll be resolved in a few years with good weather, but that's what they've been saying for the least 5 and it's only getting worse.Reply

Are all of these chips factories building in AZ because of it's sparse population density, and hence, won't have to worry about environmental hygiene issues as much?

Where is all the electrical power for these sites coming from as well, as hydro power is waning because of the drought and they killed most of the solar/molten sodium reactor power generators? -

thestryker Reply

It's not terribly seismic, there aren't really extreme weather events aside from heat, and there's very little environmental regulation at the state level.HaninTH said:Are all of these chips factories building in AZ because of it's sparse population density, and hence, won't have to worry about environmental hygiene issues as much?

I doubt they'll need anywhere near as much as a fab would, but the Phoenix area does have regulation on their water supplies so they're generally better off than the rest of the state.HaninTH said:My concern is... I hope Amkor doesn't need a lot of fresh water, as Arizona, and the whole southwest, is in a deep drought. I suppose they think it'll be resolved in a few years with good weather, but that's what they've been saying for the least 5 and it's only getting worse.

In 2022, 99% of Arizona's total electricity net generation was provided from 6 sources: natural gas (42%); nuclear power (29%); coal (12%); solar energy (10%); hydroelectric power (5%): and wind (1%). Biomass, hydroelectric pumped storage, and petroleum, supplied the rest.https://www.eia.gov/state/?sid=AZHaninTH said:Where is all the electrical power for these sites coming from as well, as hydro power is waning because of the drought and they killed most of the solar/molten sodium reactor power generators? -

bit_user Reply

Phoenix recently had a problem with unregulated construction, in unincorporated townships. The water crisis is real and uncertainty looms. It affects not just new businesses, but their ability to attract residents to work at these plants.thestryker said:I doubt they'll need anywhere near as much as a fab would, but the Phoenix area does have regulation on their water supplies so they're generally better off than the rest of the state.