Monster PowerCenter HT 800G Tear-Down

One-Way

You can add Monster to the list of vendors that likes using security screws of some sort. In this case, it uses “non-reversible” flat-head screws. These were surprisingly easy to reverse out, though. I simply sharpened my flat-head screwdriver's tip, applied pressure to make it bite into the screws and kept it from slipping.

First Peek

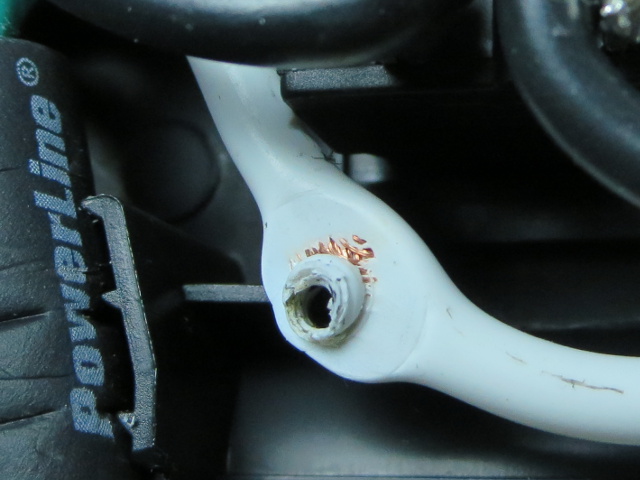

It looks like quality Chinese manufacturing strikes again. As soon as I started prying the top cover off the bottom, I was greeted by the sight of a suspicious hole through the white neutral wire. Whoever put the cover on this unit did not bother ensuring all wires were safely tucked out of harm's way, put the screw right through it and crushed the insulation in the process.

This is one of those occasions where uncovering manufacturing defects and potential safety hazards (like a compromised wire and an enclosure screw connected to mains power) requires breaking the warranty.

A (Much) Closer Look

This is a bottom-side view of the wire. As the screw bore through the insulation, it pulled it into the screw hole, ripping it off and leaving exposed copper. Had the screw been maybe a millimeter closer to the middle of the wire, it might have cut it in two.

When I called Monster's customer support and explained what I found, they offered a replacement even though I technically voided the warranty. But because shipping for warranty replacement was at my expense, I decided to have it replaced as defective by Best Buy instead.

The Replacement

In my replacement unit, wire routing at the cable's entry point is different. Instead of going around the housing edge and breaker switch to the left, it scurries to the right then directly under the main PCB, far away from any screws.

Some Prying Required

The cover's top half popped off fairly easily with only a few snaps holding it down, but the bottom end required extra leverage and patience for some reason. I got the prying started with an expired credit card and, once I had enough room, I upgraded to a bamboo chopstick.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

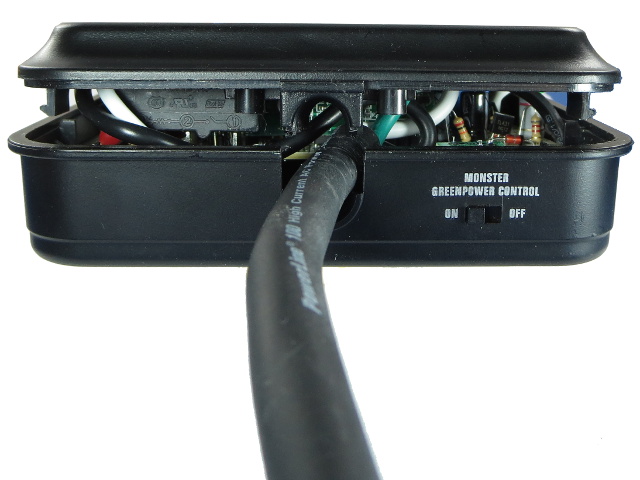

The Fun Begins

The only thing left in the way of separating the top and bottom shells is the GreenPower switch fastened to the bottom half by two tiny screws and the cable connector glued to the PCB. Everything else is fastened to the top cover where the outlets are. In my replacement unit, the glue glob is on the wire, seemingly acting as strain-relief at the connector.

There is some amount of lint or other particles stuck on solder flux near the mid-right solder joint on both the original and replacement units.

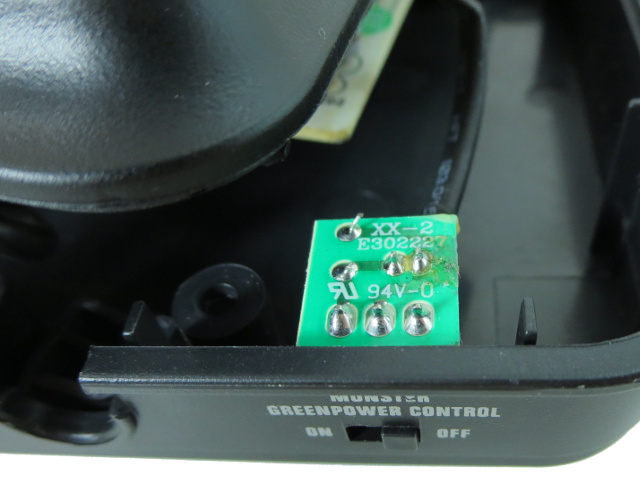

The Dinky Switch

PCBs do not get much simpler than this: one switch, one resistor and one connector. I am a little surprised that Monster did not simply put the resistor on the main PCB and soldered the wires directly on the switch.

Since there is no electrical isolation between mains and the control circuitry connected to this switch, safety regulations require the use of extra isolation. Here, it takes the shape of an interposed plastic cap between the user and the switch's body.

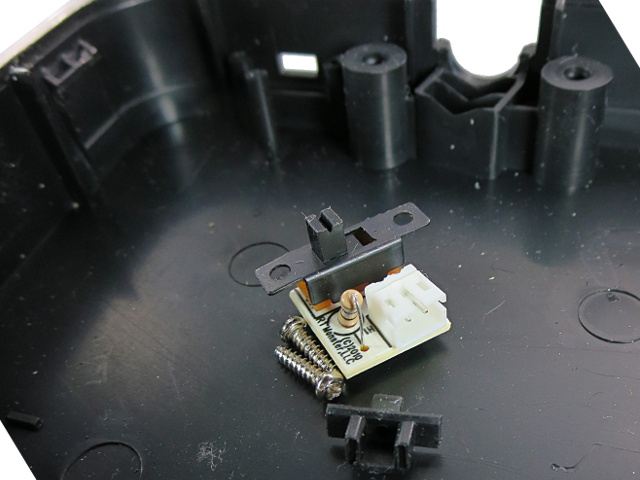

Pressing Matter

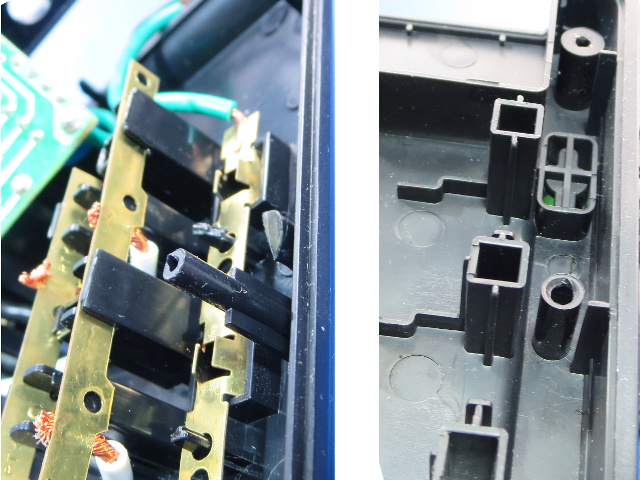

This looks familiar: those of you who have seen my inexpensive power strip round-up may remember the Dynamark “bonus” unit, where I mentioned press-fitted studs but did not actually put pictures of what I meant. Here is a chance to make up for that.

The top cover studs on the left go in the bottom cover holes on the right. No glue, no barbs or anything fancy. The only thing holding the two parts is tight tolerance between them generating enough pressure and friction to make extraction difficult. I am surprised these things did not break. There is one on each side, likely intended to keep the shell together between the time where the two halves are combined and when screws get put in.

Fully Exposed

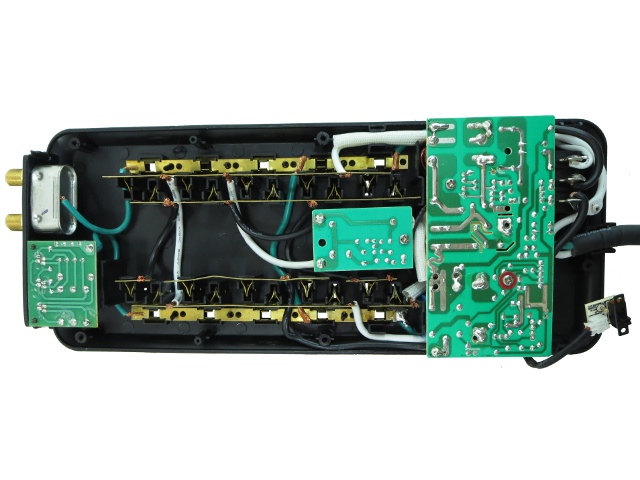

With the last impediment removed, we get a full view of the PCB's back side. From the left, we see the coax and phone surge protection, the outlet connection strips, a small PCB whose function is unclear from this angle, the rather busy main PCB, the breaker switch, power cord and finally, the tiny GreenPower switch PCB.

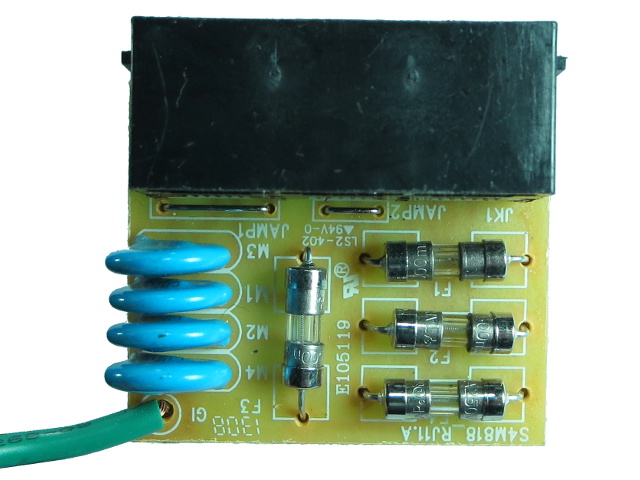

Phone Protection

The HT800G ships with a four-conductor phone cord and contains a matching two-circuit surge protector comprised of CNR10D241K MOVs and fuses.

-

bit_user I long ago replaced my Monster Power A/V surge protection / power filtering product with a Panamax unit, which were peerless at the time. It would be nice to know how their quality rates, these days.Reply

Oh, and thanks for yet another excellent teardown. -

toddybody Not trying to be negative...but Tom's is really confusing me lately;Reply

Continued Power Strip Teardowns (admittedly boring, though technically interesting) juxtaposed against some goofy op eds (yes Im talking about you, Mr. Used Macbook)...with a considerable lag in reporting tech news behind it's peers (i.e., GTX 970 VRAM-Gate, recent AMD 3xx tweets).

Tom's, you ARE an AWESOME site because of your attention to:

PC Component Reviews (though a topical review of Apple Products wouldn't offend master race folks either)

Manufacturer Q&A Articles

System Builders and Benchmarks!

...anyhoo, please dont loose the spark that makes you a special site.

PS: How about a refreshed customer water loop guide?

-

bit_user Reply

Why not complain about this in the comments on those Op Eds and the late news articles, then?15254691 said:Not trying to be negative...but Tom's is really confusing me lately;

Continued Power Strip Teardowns (admittedly boring, though technically interesting) juxtaposed against some goofy op eds (yes Im talking about you, Mr. Used Macbook)...with a considerable lag in reporting tech news behind it's peers (i.e., GTX 970 VRAM-Gate, recent AMD 3xx tweets).

Or, better yet, perhaps the site feedback forum (might actually get some results):

http://www.tomshardware.com/forum/forum-9.html

-

Steelwing Now show us a tear-down of a professional level surge protector that doesn't use MOVs (is a non-sacrificial protector) but cancels the surges in another manner.Reply

I want to see something from SurgeX, Zero Surge, or Brick Wall. -

Daniel Sauvageau Reply

Send an email to SurgeX and try convincing them to contact me and send me a review sample. At $200 and up, those fancy units are far too expensive to tear down at my own expense.15255097 said:Now show us a tear-down of a professional level surge protector that doesn't use MOVs (is a non-sacrificial protector) but cancels the surges in another manner.

I want to see something from SurgeX, Zero Surge, or Brick Wall.

If I did receive one, I would also feel compelled to try giving its protection some sort of work-out to prove a few points based on what I read in their patents during a long argument with other forum posters about SurgeX many months ago.

(Hmm, looks like THG ate my signature and won't let me set it again.) -

babernet_1 I really hate these new horizontal windows. They usually don't work for me. I have Google Chrome and a cable modemReply -

Daniel Sauvageau Reply

Then you might be happy to read that my next tear-down won't be a power strip... and my next two stories after that might not be either, now that I have enough basic test equipment to start building my own and dig into more intricate stuff - THG has lent me an oscilloscope last month and the Eyeball + DFT power factor slides in this story were my first of likely many future uses of it in a story... a hint of on of the things I might end up using it for at least until I get a more convenient method of obtaining the same measurements.15254691 said:Not trying to be negative...but Tom's is really confusing me lately;

Continued Power Strip Teardowns (admittedly boring, though technically interesting) juxtaposed against some goofy op eds

I started doing power strips because it was something simple sparked by an unexpected failure that got more interest than expected from readers. The wild manufacturing quality variability helped keep things entertaining so I will probably continue doing them whenever I get something potentially different enough to turn into a story - you never know where the next shocking revelation will come from until you look and it jumps into your face!

-

tsumeone I personally love these teardowns. Goes to show you that money is not always quality, but sometimes it can be. I'd personally love to see a teardown of one of those highly regarded metal Tripp-Lite units, the ISOBAR Ultra ones. I wonder just how much quality is actually in those, but I don't want to bust mine open.Reply -

06yfz450ridr i have a few panamax pdus that we pulled from a job literally 20+ of them. I use one for my tv equipment and a panamax ups for my pc stuff.Reply

I could donate a pdu to disassemble if you would like here is the model #m4315-pro -

Daniel Sauvageau Reply

That would certainly be much appreciated.15258021 said:i have a few panamax pdus that we pulled from a job literally 20+ of them. I use one for my tv equipment and a panamax ups for my pc stuff.

I could donate a pdu to disassemble if you would like here is the model #m4315-pro