How to Prevent 3D Printer Filament From Tangling

How filament tangling occurs and how to avoid it

3D printer filament tangling is where the material becomes twisted, disrupting its flow during 3D printing. It occurs for various reasons, like uneven tension on the filament spool or even the presence of objects near the printer, causing it to snag as it unwinds. However, the main cause is when the filament locks on another layer, and the extruder cannot pull it through. Also, improper storage of the filament can result in tangles.

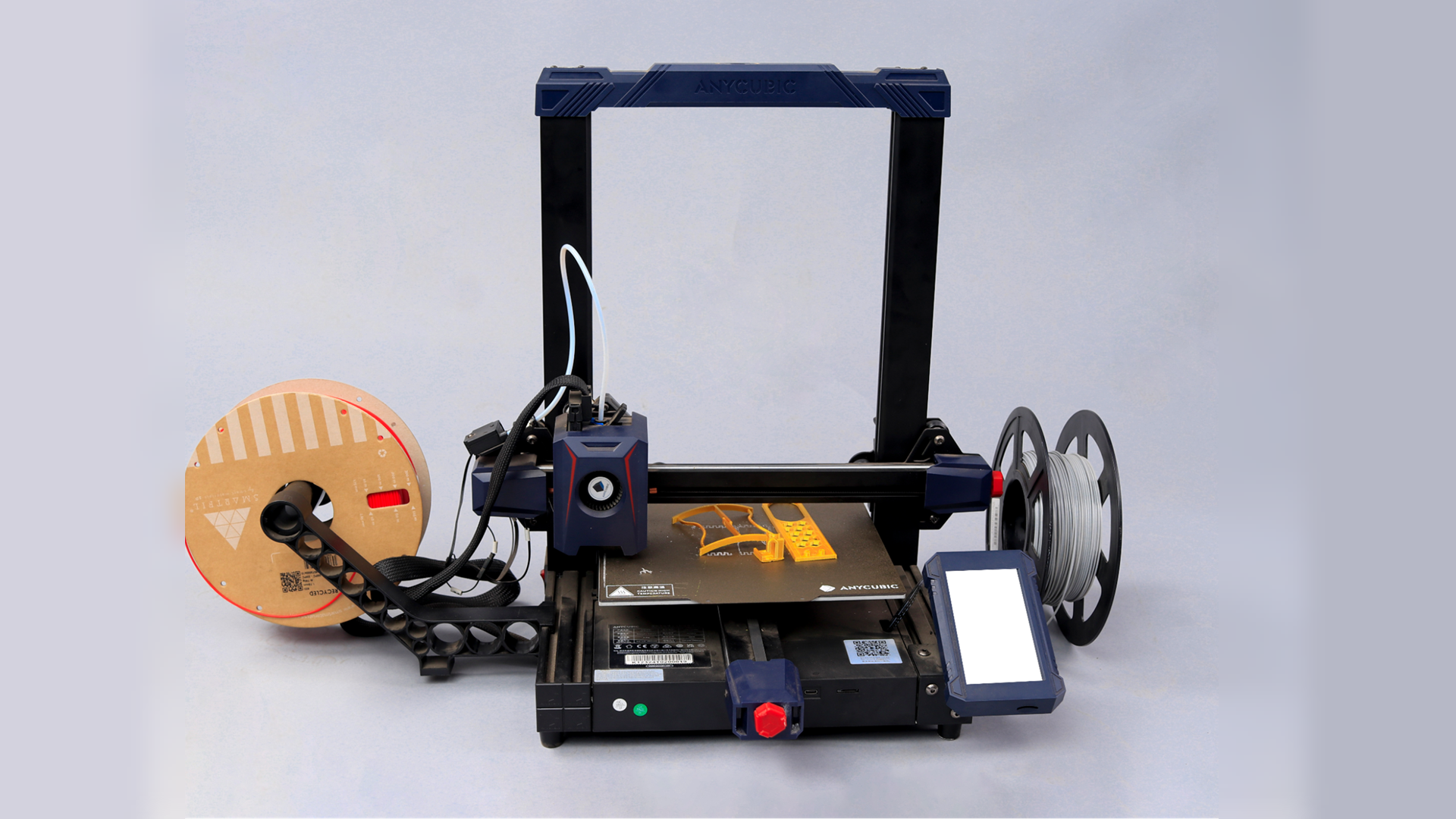

When this problem occurs, the 3D printer struggles to feed the filament evenly into the extruder, leading to print failure. Even if you have one of the best 3D printers and the filament spool is not set correctly, tangling will still occur. Thankfully, there are things you can do to prevent it from happening, as we have discussed below.

1. Use Filament Clips

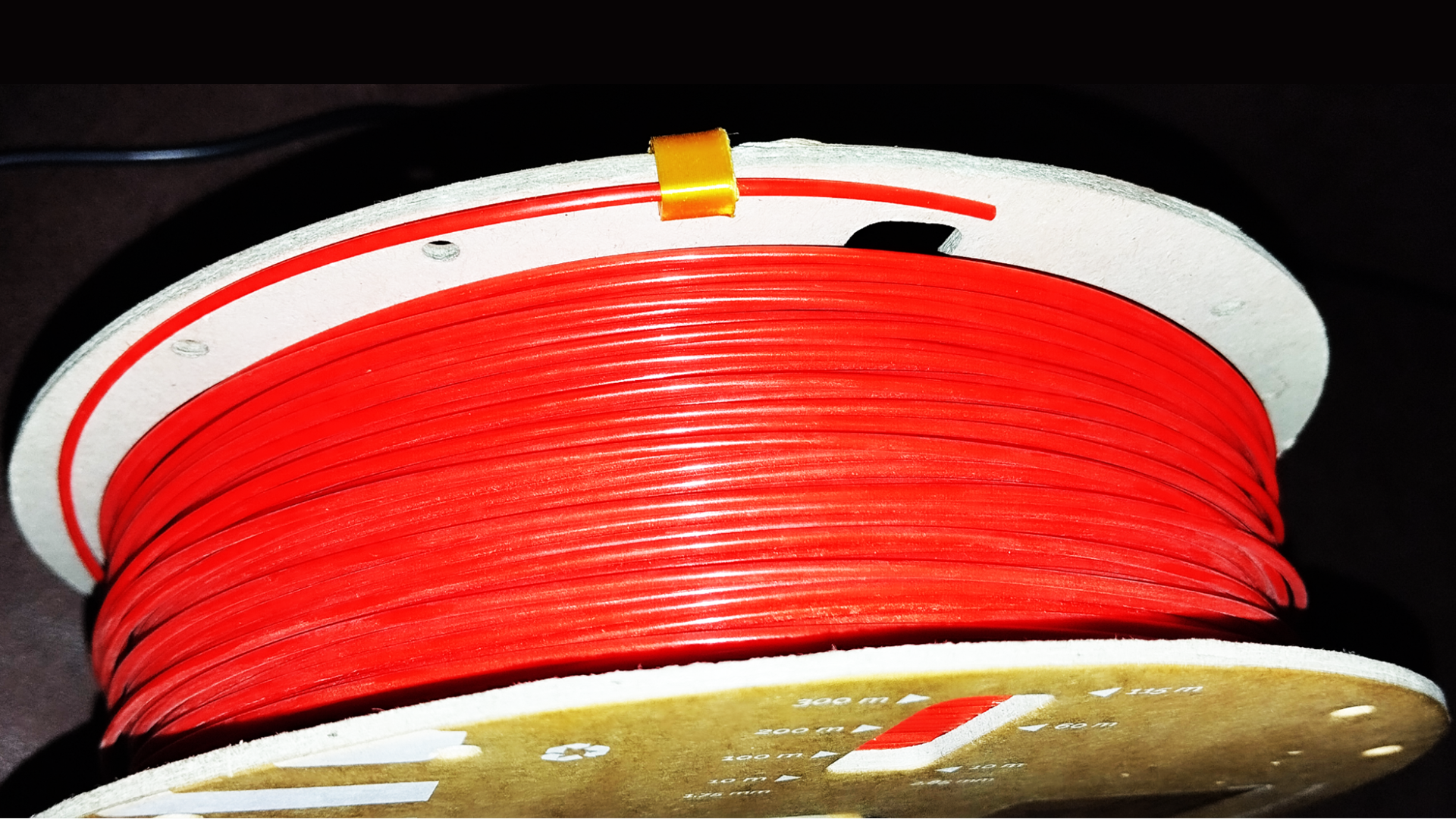

You can use clips to fasten the loose ends of the filament to the spool when not in use to prevent unraveling, which could result in tangles. The clips are usually small plastic or metal and usually come with other 3D printer accessories. You can use it to hold the clip to the side of the filament spool, as shown above. Additionally, you can also use them to hold the rolls of the filament on the top surface, as shown below.

You can also find many 3D models of the files on various websites and download and 3D print. A good example is the 1.75mm filament clip that you can find on Thingiverse. There is also an Anti-tangle filament clip designed by Robeena Shephered.

This is also great, but you must use 3D printing supports when printing them. As you remove the supports, do it gently, as the parts are delicate.

Once you have your clips, you start by locating the ends of the spool and then securing it. Ensure that it’s secured but not too tightened. If you don’t have the clips, you can manually wind the loose end around the spool a few times, then secure it with tape or a rubber band to provide an additional layer.

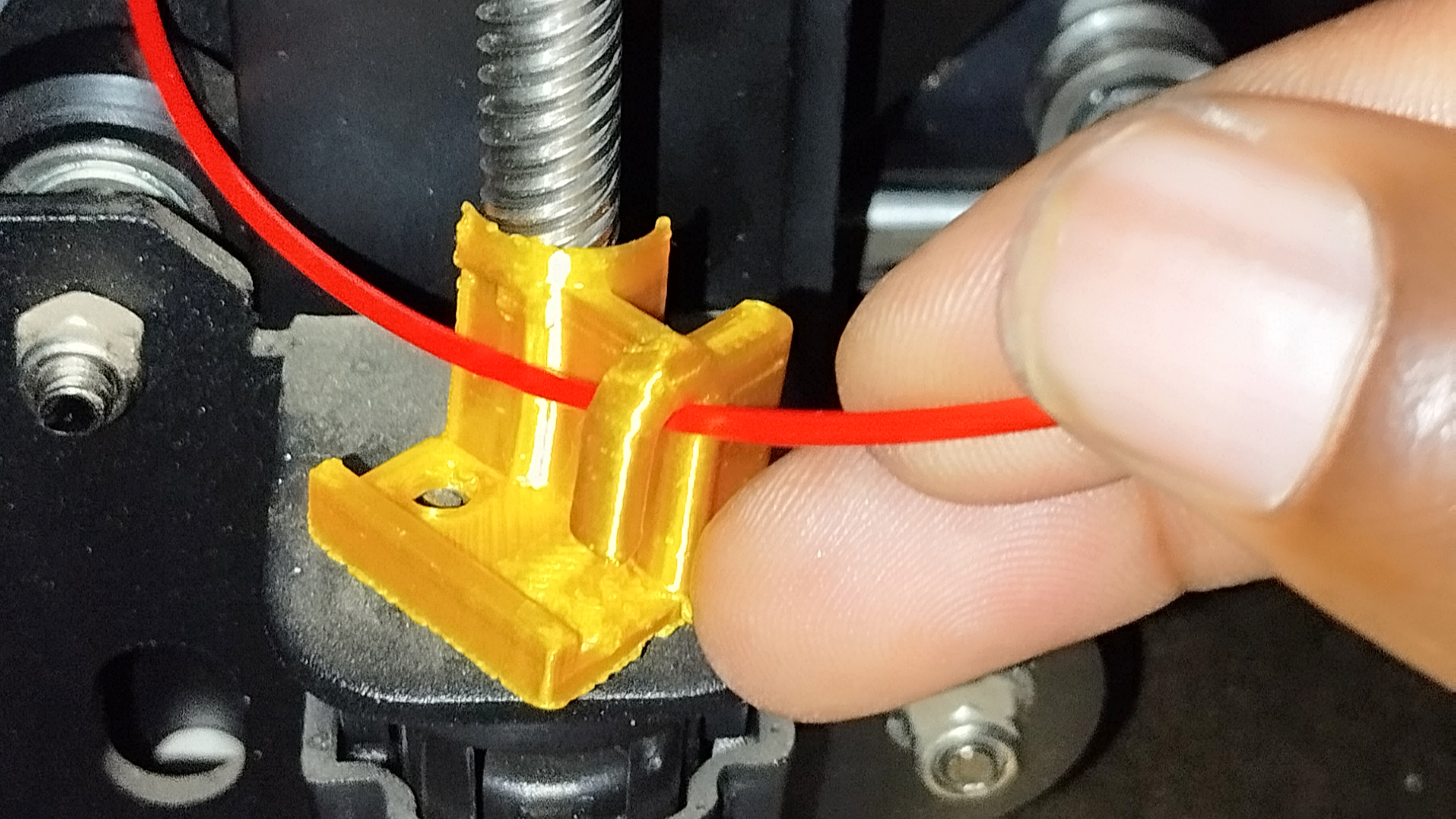

2. Use a Filament Guide

As the name suggests, a filament guide guides the filament from the spool to the extruder to minimize the risks of twists. Depending on the design of the filament guide, you can attach it directly either by clipping it onto the edge or by threading through the center hole of the spool.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

In others, you can attach them to the 3D printer itself, like the Ender 3 filament guide that you can download and 3D print. There are also other versions that you can mount on the extruder like the Ender 3 filament guide easy install.

In addition to helping prevent filament tangles, the guide can also help reduce friction and resistance as the filament moves from the spool to the extruder, ensuring that the quality of the filament is maintained.

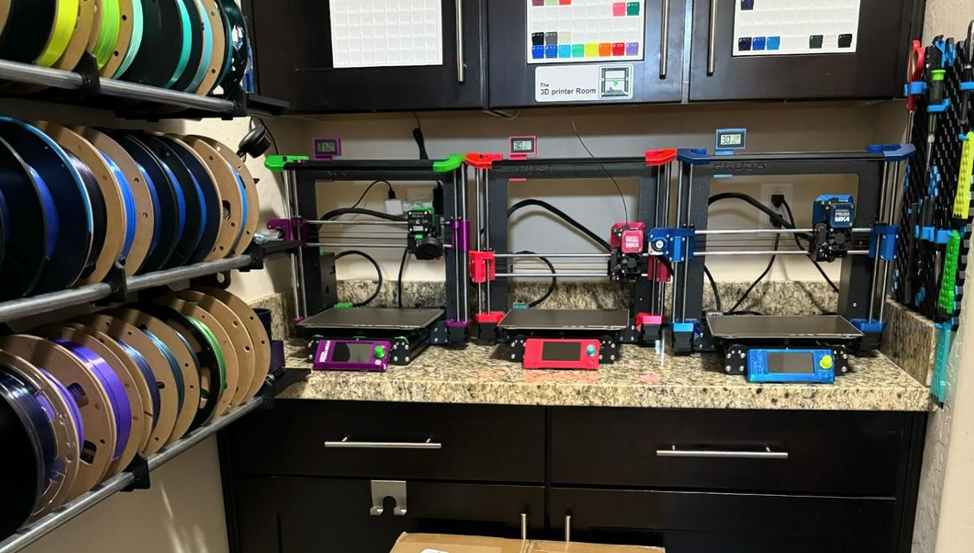

3. Maintain a Tidy Workspace

Stray objects or obstructions in your workspace can interfere with the flow of the filament from the spool to the extruder. So you have to ensure that you work in a clean environment and that there are no foreign objects around, which the filament can snag or catch along the way, leading to tangling. You also have to ensure that your filament doesn’t come into contact with moisture and sunlight, as changes in humidity and temperature can increase the chances of tangling.

In addition to ensuring that you work in a clean environment, you should monitor the filament frequently and ensure it’s feeding smoothly into the extruder without any issues. If you notice any problem, you stop and fix it. Regular maintenance, such as cleaning the filament path and ensuring all moving parts are properly working as expected, can also help prevent the problem.

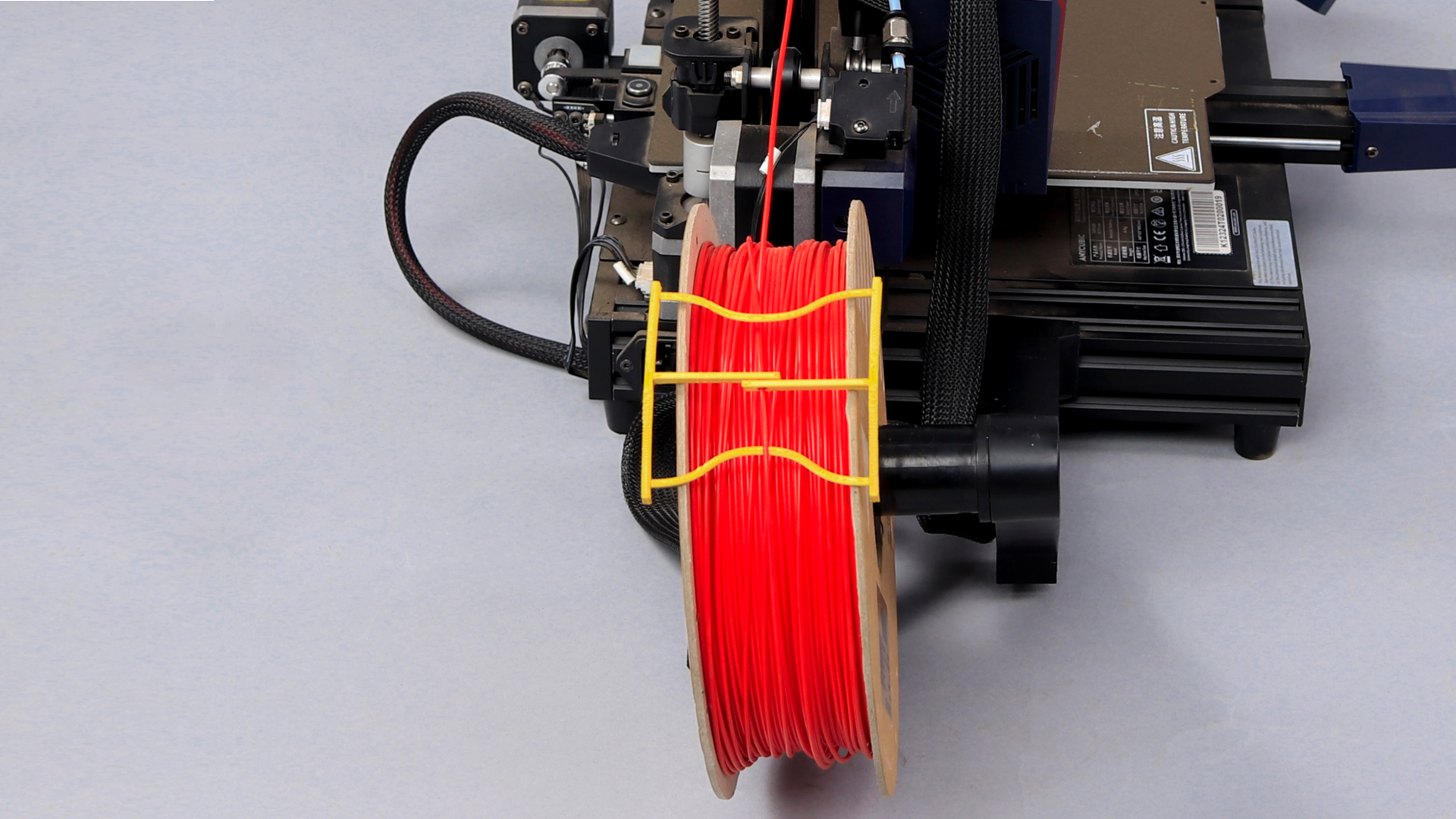

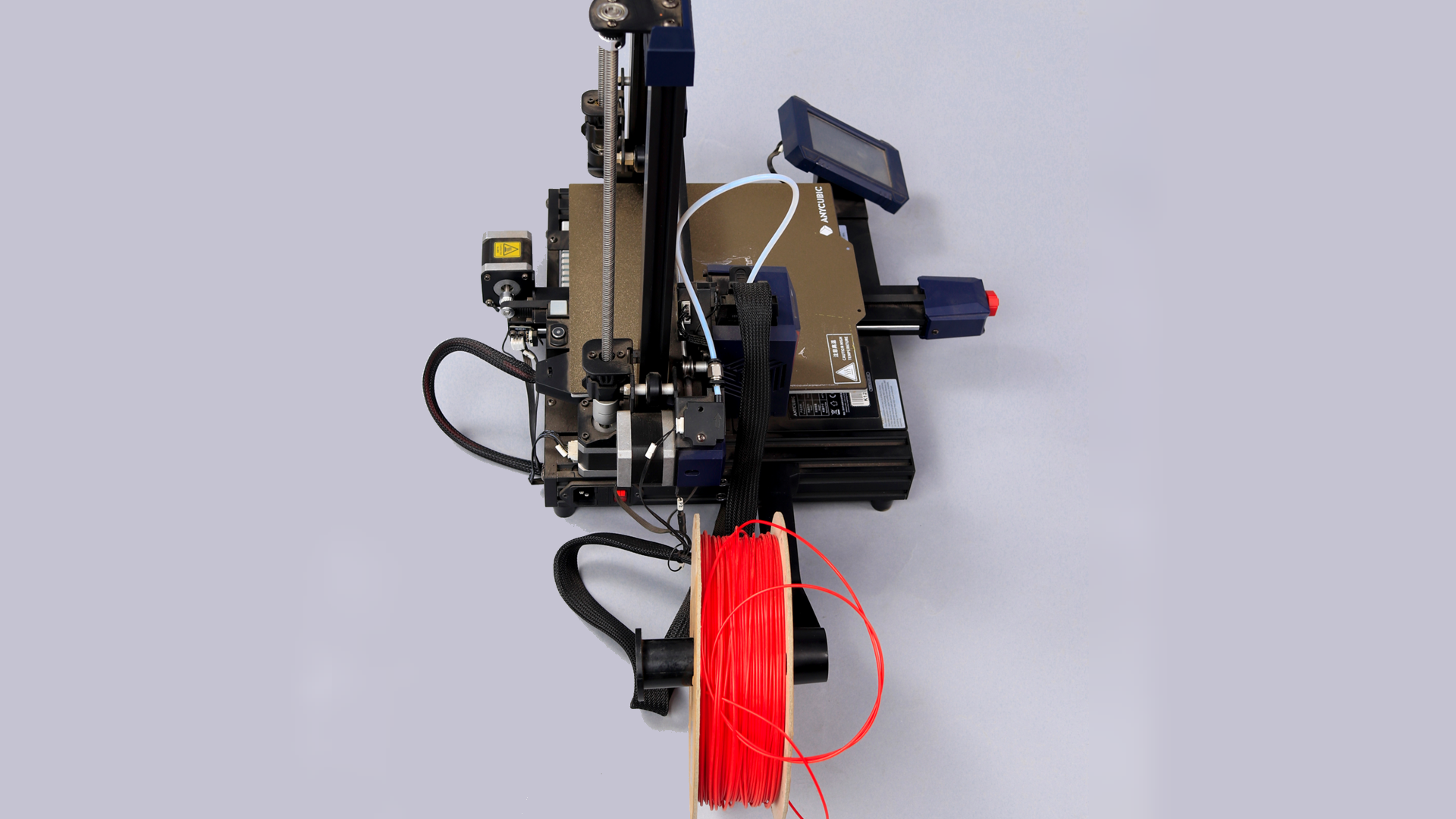

4. Properly Mount the Filament Spool

Properly securing and correctly positioning the spool ensures that the filament unwinds smoothly without disruptions. The spool must not spin too loosely to minimize the risk of wobbling, which can cause the filament to twist as it feeds into the extruder, preventing the chance of tangling.

Additionally, you have to check on the orientation of the filament spool to ensure that it rotates freely without obstructions so that the winding pattern of the filament is consistent and uniform.

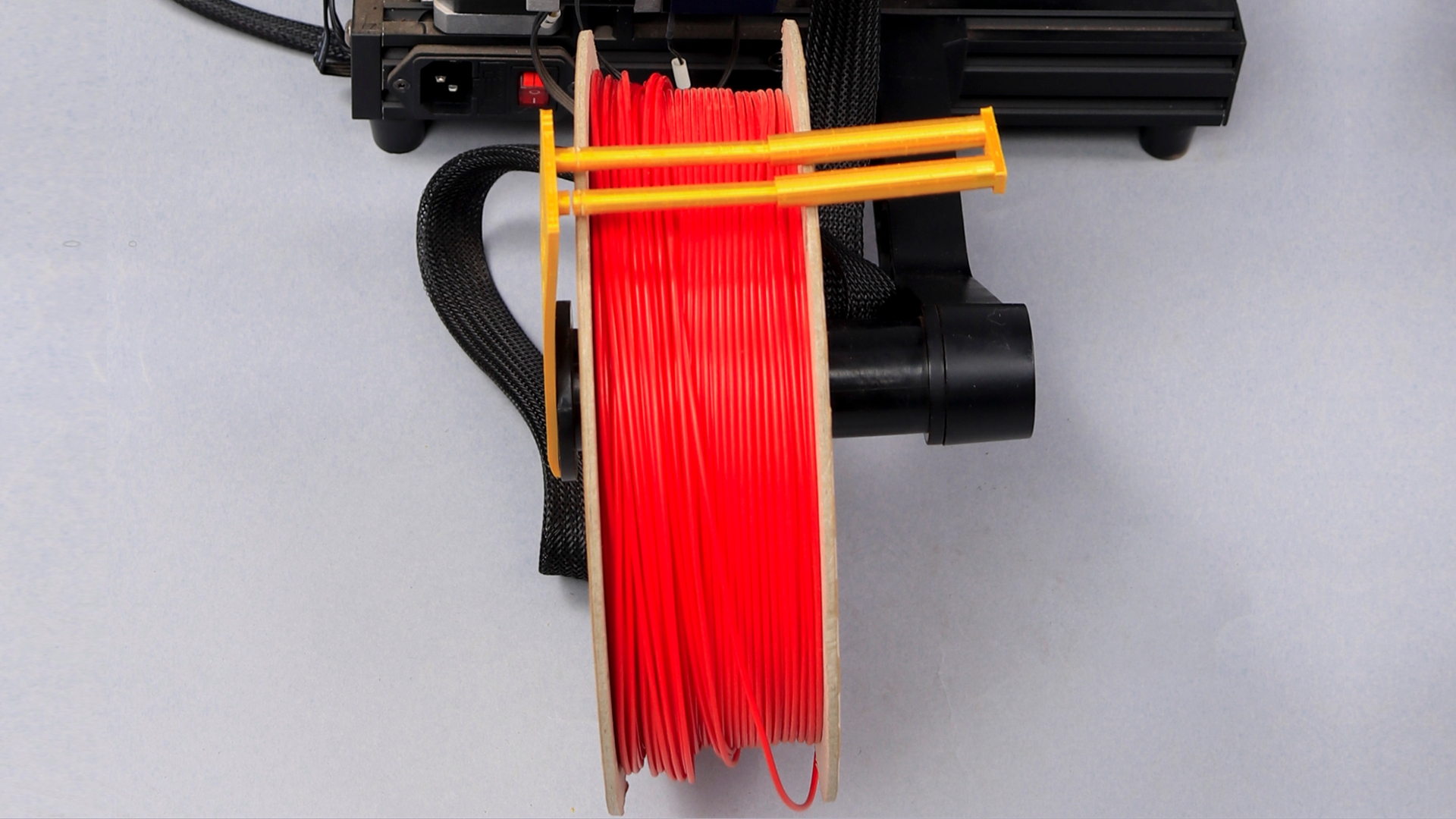

5. Use Filament Tensioner

This is another accessory you can download and 3D print to hold your filament in place and ensure it doesn’t jump out of the spool when spinning. It holds the filament in place by adding pressure to the spool, and you can adjust the amount of pressure applied by sliding the bar further away or closer to the spool holder using the elongated hole where it attaches.

I like the adjustable filament tensioner created by SpicyLimes, which you can find on Printables.

It comes in two files: the spool anti-unravel bracket arm and the spool anti-unravel bracket base. Depending on the 3D printer you are using, you might encounter a snug fit when sliding, and to prevent this, you can scale the arm extension in your slicer.

How to Untangle Filament

If your filament has tangled, it’s not the end; there are steps that you can take to rectify the situation. First, you need to pause your print and inspect the extent of the tangle. If the filament is loosely tangled, you can gently rotate the spool in the opposite direction of the tangle to loosen it. You should avoid pulling, as it can worsen the tangle and potentially break the filament.

If the tangle is more severe, it is necessary to remove the filament from the spool entirely, lay it on a flat surface, and untangle the knots using your fingers. After untangling it, carefully rewind it back onto the spool.

Once the filament is untangled, carefully rewind it onto the spool, ensuring that it is wound neatly and evenly to prevent future tangling, then reposition the spool back, ready for your next print job.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

Sammy Ekaran is a freelancer writer for Tom's Hardware. He specializes in writing about 3D printing tutorials and guides. You can find more of his work on various publications, including Makeuseof, All3dp, and 3Dsourced.