Mechanical Switch Spec Ranges and Those Pesky Plus and Minus Signs

What does ± mean in mechanical switch specs?

So you’ve finally decided to build your own mechanical keyboard and are looking for the perfect mechanical switch for your discerning fingers. Or maybe you’re after a pre-built keyboard and perusing the switch options available. The specs sheet seems simple enough: It includes a measurement for the switch’s total travel, another for its pre-travel distance and one for how much force is needed for the switch to actuate. But what’s this? A “±” symbol that you haven’t encountered since your days in math class. Suddenly, you realize that your switch’s pre-travel isn’t simply 2.2mm but rather a range of values of “2.2 ± 0.6mm.”

While many in the industry, from keyboard enthusiasts to keyboard and switch makers and partners, simplify switch specs to a specific number, if you look closely, you’ll see that many switch specs are actually written to cover a range of measurements.

Take the Cherry MX Blue switch. If you know switches well, you might think you know that MX Blues have exactly 4mm total travel with 2.2mm of pre-travel and 60g of force to actuate. However, Cherry’s official datasheet for MX Blues [PDF] tells a more detailed story.

The sheet points to the switch having a pre-travel distance of “2.2 ± 0.6mm.” That literally means that the switch may travel anywhere from 1.6-2.8mm before actuating. And yet, most would tell you, and expect, for a MX Blue switch to actuate at 2.2mm — no more, no less.

It doesn’t just stop at pre-travel. Continuing with our MX Blue example, the spec sheet says it requires 50 ± 15 centinewtons (cN) of force to actuate. That’s anywhere from 35-65 cN of force. And when it comes to the full travel distance, Cherry MX Blue’s spec is “4 - 0.5mm.” This time the range is tighter — 4-4.5mm — but still notable.

Of course, Cherry isn’t the only player here. You can find these off-putting “±” symbols across switch makers’ spec sheets. For example, Kailh x NovelKeys Box Cream switches are specced for 3.7-4.3mm travel, 1.5-2.5mm pre-travel and 35-55 grams (g) of force to actuate.

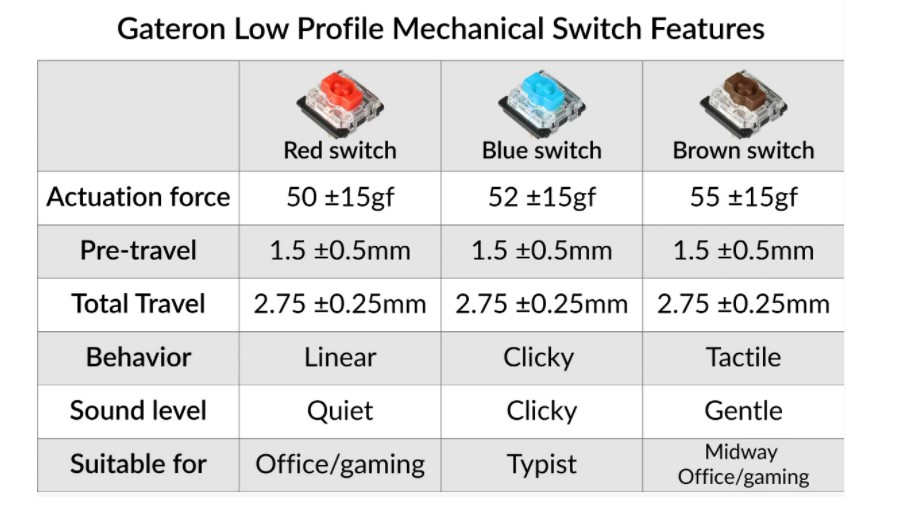

And this isn’t something that only enthusiasts snooping into the depths of datasheet PDFs will find. Even someone shopping for a pre-built keyboard may find switches with spec tolerances, as they’re called. For example, the product page for the Keychron K3 displays the ± symbol prominently when describing the low-profile Gatreron switches offered.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Having tolerance in mechanical switch specs gives switch makers wiggle room in the very exact performance of their tiny keyboard component. And when we say very exact, we mean it; these are minute differences we’re talking about.

“Namely, every switch manufacturer will try to make their switch to the exact spec as much as possible. But they cannot guarantee that all the switches they made have exactly the same force and travel distance, so they put a safe range on every spec of their spec,” Paul Tan, Keychron COO, told Tom’s Hardware.

But given that spec sheets typically provide hard figures (imagine if a CPU said it had 2 ± CPU cores!), this can be confusing to see, even for a keyboard enthusiast.

“The average consumer is going to look at this and be really confused, and it probably honestly, for the average consumer, will not affect their purchase at all,” keyboard modder Alexander “Alexotos” Medeot told Tom’s Hardware. “This is for someone who's really in depth and looking for something very specific. I'd say even past your enthusiast.”

It might seem like switch makers are reluctant to commit to a certain spec; however, Michael Sicker, owner of NovelKeys, which sells and makes its own keyboards and switches, said that the tolerances are more the need of switch manufacturers, rather than switch brands like itself and Cherry.

Sickler also attributed the need for tolerances to cost and time.

“When you start really honing in on the tolerances of these switches, it will cost a lot more for the molds to be made as you are getting into ranges that would probably be considered NASA-level tolerances,” Sickler told Tom’s Hardware.

If you’re big on transparency and properly set expectations, you may be slightly irked right now. To go back to the MX Blue example, if we were to take its specs sheet literally, that’d mean a bag of MX Blue switches could have some samples with 1.6mm pre-travel, 3.5mm and 35g of force, with others having respective specs of 2.8mm, 4mm and 65g and anything in between. When what you probably want is 2mm, 4mm and 50g.

One of the biggest tolerances we’ve seen is for the Cherry MX Silent Blacks, which can have an actuation force of 60 ± 20cN [PDF], allowing for a potential range of 40-80cN. The good news is that when you buy a pack of MX Silent Blacks, what you’ll most likely get are switches with the exact spec, 60cN of force. If not, the difference will likely be so small that even a switch fanatic wouldn’t notice.

Alexotos has built over 350 keyboards and owns more than 70. He says that when it comes to specs like pre-travel, travel and actuation force, any variances among the same switch are so little that the vast majority of people would not be able to tell. He noted that the tolerance for Cherry MX Blues is “quite a big variance” but said he has never personally noticed it.

“Unless you're sitting there meticulously testing every single switch. It'd be very hard to discern the difference between a lot of these things …,” Alexotos said. “Again, I think for the average consumer, those spec sheets are listed there just in case someone measures something, but it's not something I've ever, ever noticed or had to worry about personally.”

NovelKeys’ Sickler agreed.

“The ranges that switches actually end up being are almost all the time imperceivable to most people, especially when you are typing fast,” he said.

According to Keychron’s Tan, despite switch tolerances, finding a switch where you actually encounter samples with measurements across the full range of extremes listed in the specs sheet is rare.

“We are not sure when the industry is going to change their spec sheet, but the switch usually doesn't have this kind of range,” Tan said.

In fact, there may be more important things to worry about when it comes to variances among the same switch type. Alexotos noted variances in things like stem wobble, possibly due from the mold used, as being more common than discrepancies in travel and actuation force.

Sickler, meanwhile, pointed to batches of springs showing the most variances but noted that this won’t really affect the typing experience.

“I have mostly seen only variances of about 5g, and it’s pretty much imperceivable, especially when typing,” he said.

So should you worry about getting a bunch of the same switch with dramatically different feels? Probably not. Pros, like Alexotos, don’t.

“I’d look at 2.2[mm] and read 2.2[mm],” he said. “I know there's a variance, but the variance comes with literally … everything: the plastic, the stem, nicks and stuff in the plastic. Tons of things can vary in a switch, but I'll take it as what the vendor lists.”

Scharon Harding has over a decade of experience reporting on technology with a special affinity for gaming peripherals (especially monitors), laptops, and virtual reality. Previously, she covered business technology, including hardware, software, cyber security, cloud, and other IT happenings, at Channelnomics, with bylines at CRN UK.