Generative Design and 3D Metal Printing Enhance CPU Cooling Performance

'22% Better CPU Cooling'

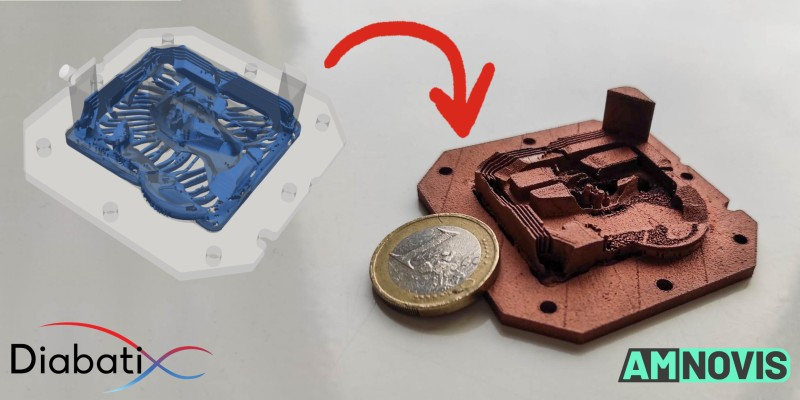

PC cooling design seems to have been stationary for years, with only minor tweaks to the same tried and trusted designs emerging. Thus a heatsink design from, say, 10 years ago may be indistinguishable from a new one. However, a Belgian thermal engineering software firm called Diabatix wants to change the status quo, and has recently found a synergistic partner, Amnovis, a manufacturer which specializes in copper 3D printing. Some early fruits of this partnership were recently shared in a webinar, and they are good. It is claimed that the new collaboratively designed and produced heatsinks deliver “22% better CPU cooling.”

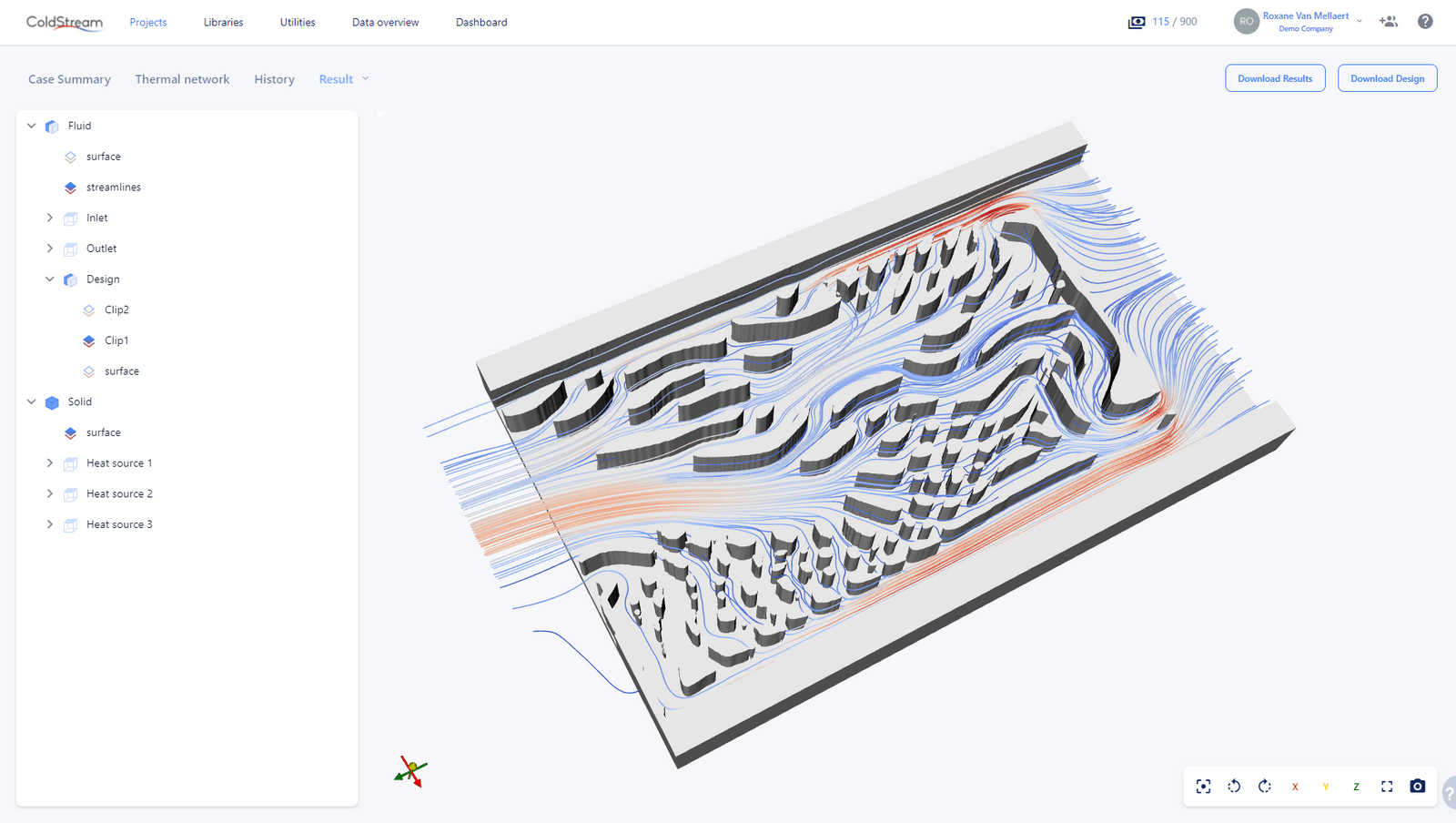

Diabatix’s signature software product is an application called ColdStream. A cloud-native platform that supports the entire cooling design process, “from thermal analysis to thermal design.” From an electronics product profile ColdStream can predict temperatures, automatically indicate the correct size and shape of standard heatsink. ColdStream can go further and generate an optimal custom heatsink based on the science of computational fluid dynamics (CFD), the application of AI, and knowledge of 250+ thermal materials. The generative designs are typically organic looking, and nothing like a traditional heatsink which feature a regular symmetrical array of fins or pins.

It is all well and good having these optimized designs, but what about manufacturing? Most people will be aware that for short run production, which is popular for a specialized design, 3D printing is a great asset. For thermal conductivity, copper remains an optimal choice when weighing up price / cooling performance. Amnovis recognized this strength, and is already established in the copper 3D printing business. Now it has added Diabatix ColdStream designs to its portfolio.

The signature offering of Amnovis is to use its proprietary copper powders and a patented production method to deliver “unprecedented thermal, electrical and mechanical properties for complex-shaped heat and electrical conduction components.” Copper products as thin as 200 microns and with gaps as fine as 250 microns are within the capabilities of Amnovis’ patented processes.

The collaborative 3D Printed custom heatsink, designed by Diabatix and produced by Amnovis, is currently undergoing independent performance validation by the University of Leuven, Belgium. Test figures are expected to become available in Spring next year. Meanwhile, those looking for greater technical depth regarding this partnership, and to check out a simulation based comparison of a generative design vs a reference design heatsink, can check out the webinar and / or download a whitepaper available from the Diabatix website.

If you are a Raspberry Pi aficionado, you might also be interested to read about Diabatix’s application its tech to making an optimal Pi heatsink.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

InvalidError Imagine the fun you are going to have attempting to unclog an AI-generated "organic" water block with tons of tiny inaccessible cavities. Better make sure you run plain coolant with the necessary anti-corrosion, anti-bacterial, with algicide and whatever else may be necessary to prevent any clumps from forming over time.Reply

Simple fins may not be the absolute optimal cooling option but at least inspection and maintenance are simple. -

bit_user Reply

Is this sort of maintenance typical, for water blocks?InvalidError said:Imagine the fun you are going to have attempting to unclog an AI-generated "organic" water block with tons of tiny inaccessible cavities.

Even with a more conventional design, the formation of biofilms or other buildup would hurt performance. Therefore, you'd probably always want to do that.InvalidError said:Better make sure you run plain coolant with the necessary anti-corrosion, anti-bacterial, with algicide and whatever else may be necessary to prevent any clumps from forming over time. -

InvalidError Reply

If you watch some YT vids from liquid-cooling fanatics like Jayz, people put all sorts of crazy stuff in their clear tubing loops for visual effects. Dyes, color-shifting additives, UV dyes and other similar crap has a tendency to form clumps in corners and anywhere where there isn't enough turbulent flow to prevent accumulation. If you turn off loops with such stuff in them for several days, you may have issues with sediment sticking everywhere.bit_user said:Is this sort of maintenance typical, for water blocks?

Pearlescent coolant looks kind of cool, except you are almost guaranteed to have clumping issues if you turn off your PC for more than a day.

I don't do liquid cooling since I don't want to have to deal with any of that extra crap. I slap a dumb 212+/EVO on my CPU and then forget about it. -

RichardtST Stupid question.... why are we running water instead of a nice light oil, like sewing-machine oil or something? Thin and light like water, but doesn't evaporate? Wouldn't that make more sense than something as corrosive as water? And surely no one uses tap water, right? What's so wrong with radiator fluid?Reply

Love the generative/iterative designs. Basically it figures out by itself how to maximize flow and surface contact while minimizing resistance. Keep those little molecules accelerating in all directions to break up that boundary layer! -

InvalidError Reply

Two words: specific heat.RichardtST said:Stupid question.... why are we running water instead of a nice light oil, like sewing-machine oil or something?

Water: 4.17 J/gram

Oil: 0.5 J/gram on average

So if you ran an oil-cooling loop, you'd need 8X as much oil flow for the same coolant temperature rise. Also, most oils have higher viscosity than water, which means the pump would need to work even harder to maintain that 8X flow.

If oil was a great coolant, combustion engines wouldn't need a whole separate radiator circuit for cooling including the added complexity of the engine block and head coolant jacket, they'd just rely on oil flow everywhere. -

RichardtST ReplyInvalidError said:Two words: specific heat.

Water: 4.17 J/gram

Oil: 0.5 J/gram on average

So if you ran an oil-cooling loop, you'd need 8X as much oil flow for the same coolant temperature rise. Also, most oils have higher viscosity than water, which means the pump would need to work even harder to maintain that 8X flow.

If oil was a great coolant, combustion engines wouldn't need a whole separate radiator circuit for cooling including the added complexity of the engine block and head coolant jacket, they'd just rely on oil flow everywhere.

Cool. Thanks! -

bit_user My other thought was that oil is messy and flammable.Reply

FWIW, some turbo-chargers are oil-cooled. Not sure why. Maybe the issue with water-cooling them is they're too hot?InvalidError said:If oil was a great coolant, combustion engines wouldn't need a whole separate radiator circuit for cooling including the added complexity of the engine block and head coolant jacket, they'd just rely on oil flow everywhere.

I expect you could add a constraint to the design that limits the minimum gap.InvalidError said:Simple fins may not be the absolute optimal cooling option but at least inspection and maintenance are simple. -

USAFRet Reply

Stupid high RPM.bit_user said:FWIW, some turbo-chargers are oil-cooled. Not sure why. Maybe the issue with water-cooling them is they're too hot?

And is that cooled, or lubricated? -

bit_user Reply

Looks like it's essential for both cooling & lubrication.USAFRet said:And is that cooled, or lubricated?

https://www.counterman.com/turbo-cooling-the-real-reason-turbochargers-are-back/https://www.garrettmotion.com/racing-and-performance/choosing-a-turbocharger/water-cooling-for-your-turbo/The second link implies water-cooling is very much the exception. -

InvalidError Reply

Some? The only thing that really requires cooling in those are the bearings which also require oil flow for lubrication and cleaning exhaust that makes it past bearing shields. Not sure how you'd cool bearings with anything other than an appropriate lubricant.bit_user said:FWIW, some turbo-chargers are oil-cooled. Not sure why. Maybe the issue with water-cooling them is they're too hot?