Paper PCBs Heralded as the Future of Disposable Electronics

Definitely not suitable for 600W video cards.

Electronics has a big waste problem, often referred to as eWaste. However, a recent study into Integrated Papertronic Techniques may provide a path away from the toxic eWaste dystopia. The study looks closely at the potential of using paper in disposable electronics, beginning with paper-printed circuit boards (PCBs). Futurist Faisal Khan reckons the study, published by researchers from the State University of New York at Binghamton, shows single-use paper PCBs are the future of disposable electronics.

Paper is a highly affordable, accessible, flexible, and sustainable material, which is thus a strong candidate for environmentally friendly PCB designs. Current PCBs are made of an environmentally unfriendly blend of glass fibers, resins and metal wiring. In the drive to combat eWaste we must consider how to both increase recycling rates of electronic devices and produce more single-use electronics using appropriate biodegradable materials.

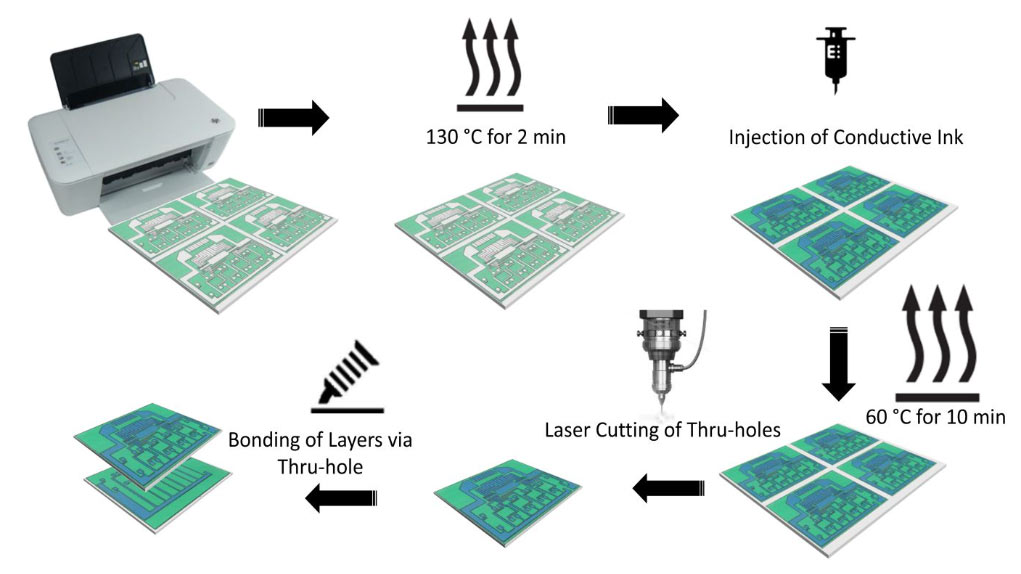

A diagram accompanying the paper provides an overview of the paper PCB creation process. In brief, the steps are as follows: wax pattern printing, paper ink infusion, and screen printing of functional elements, laser cutting of through holes, and adding conductive traces. The aforementioned inks use a mix of conductive and semi-conductive formulas, capable of forming resistors, capacitors and transistors. The printed ‘wires’ and components are said to be as flexible as the paper they are deposited on.

We have already hinted that paper PCBs are not intended for paper motherboards or paper graphics cards. Instead, it is envisioned that disposable paper PCBs will be used in wireless sensor networks and the Internet of Disposable Things (IoDT). Such devices are currently used to evaluate human health, monitor environmental conditions, in logistics and shipment tracking solutions, for food and grocery monitoring systems, and in military surveillance or delivery systems. It should be noted that paper PCB-based devices will need additional packaging care, due to their susceptibility to humidity impacting active use- and shelf-life. Water damage is already a problem for traditional electronics, but it could be extremely messy where paper PCBs are concerned.

For environmentally friendly recycling, the used paper PCBs and electronics could be dissolved and filtered for recyclable elements, or efficiently incinerated with carbon capture.

The researchers managed to eschew the use of traditional electronic components made out of difficult-to-recycle materials. Specifically, the researchers say they can currently create all-paper tunable resistors (20 Ω to 285 kΩ), supercapacitors (∼3.29 mF), and electrolyte-gated field-effect transistors.

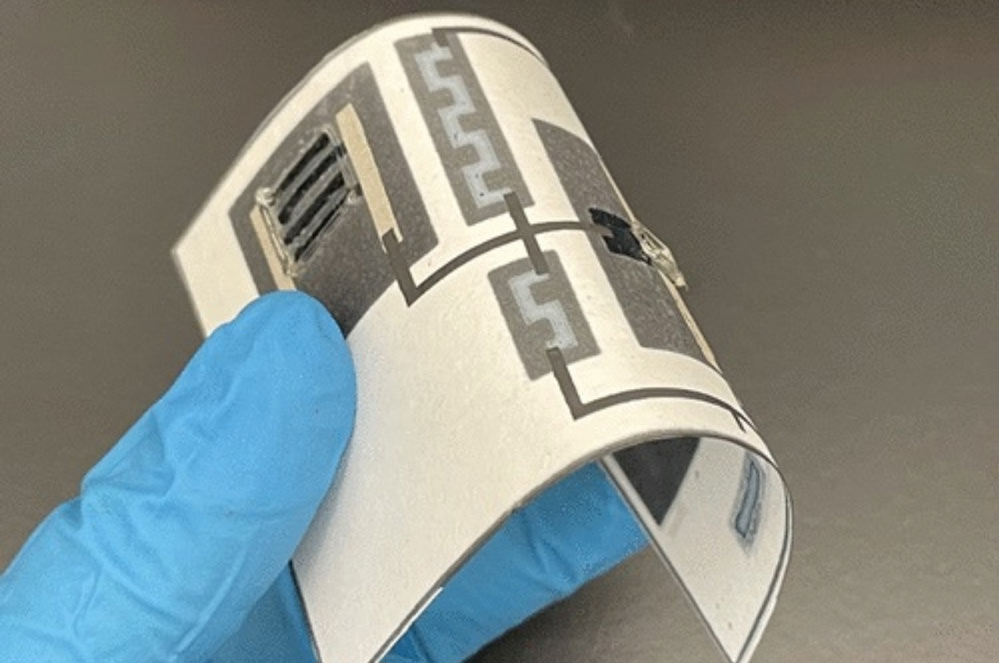

Paper PCB images in the article show a simple amplifier circuit, which was successfully tested during the study of paper PCBs.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

TechieTwo This sounds a lot like the theory of the paperless office that was suppose to occur some twenty plus years ago but never did.Reply -

Amdlova This is the future, for now we have poo connectors, recycle power supply when you use twenty times.Reply

The green world likes e-waste -

InvalidError "Internet of Disposable Things."Reply

Yup, that pretty much sums up all cloud-powered hardware IMO - instantaneously turns into garbage the instant you either lose internet connectivity, the vendor scraps support or decides to charge for it where it used to be free. -

bigdragon Interesting technology. I could see this being used for RFID in particular. I wonder how far they can push this medium.Reply

I predict Samsung will be the first one to put these paper PCBs in their products. They're well known for making products designed to fail -- from monitors with heat-sensitive components above major sources of heat to major appliances with parts designed to experience galvanic corrosion. Using paper could empower them to precisely time the failure happening just after the extended warranty expires. -

TheScrubofNick Mercedes tried some biodegradable wire harnesses earlier. As expected, they degraded during their regular life causing a ton of problems. I can't see this ending any other way.Reply