TeamGroup Launches Vapor Chamber Cooler for M.2 SSDs

Another exotic cooler for M.2 SSDs.

Modern SSDs use very sophisticated controllers that generate a lot of heat and therefore require advanced cooling so they don't damage the 3D NAND memory chips with precious data. TeamGroup is certainly among the SSD makers that aren't afraid of experimenting with cooling systems for its SSDs, which is why it was among the first to ship an M.2 drive with a factory-built liquid cooler. Now, the company is the first to offer a vapor chamber-based cooler for M.2 SSDs.

Vapor chamber cooling systems rely on the phase transition principle and work the same way as heat pipes. Like heat pipes, vapor chambers are filled with a volatile liquid that boils and turns into vapor very quickly and thus transfers the heat to a colder location, where it rapidly condenses and returns to a hot spot to become vapor again. Vapor chambers are particularly good for cooling down very hot chips that nowadays can have a temperature of 100°C or higher.

In most cases, mainstream SSDs don't get that hot under typical loads, but if you want to ensure the best possible performance and not use exotic methods like liquid cooling, vapor chambers, and heat pipes are the way to go. Meanwhile, vapor chambers are more compact than liquid cooling systems or heat pipes.

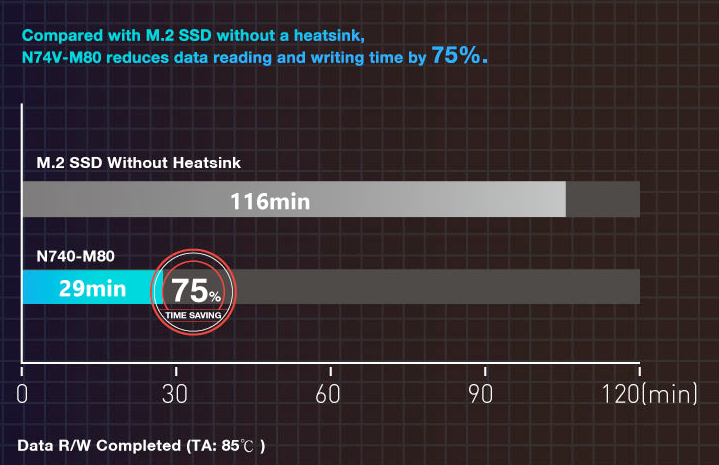

TeamGroup's first SSDs to adopt vapor chamber-based cooling belong to its N74V-M80 family aimed at industrial-grade applications that must survive extreme temperatures between -40°C (-40°F) and 85°C (185°F). The drives are based on 3D TLC NAND and an undisclosed controller compliant with the NVMe 1.3 specification and a PCIe 3.0 x4 host interface. As for performance, Team Group rates its N74V-M80 for up to 3,400 MB/s sequential read speed and up to 2,500 MB/s sequential write speed. The drives will be available in 128GB, 256GB, and 512GB capacities.

Using a vapor chamber-based cooling system for its industrial-grade M.2 SSDs enabled TeamGroup to make those coolers very compact yet very efficient, according to the company. Better cooling guarantees predictable performance under high loads, which results in high performance for the actual devices that use those drives.

For now, TeamGroup is only using vapor chamber coolers for its industrial-grade drives, but we would expect the company to eventually use similar cooling systems for enthusiast-grade SSDs. In the end, drives with a PCIe 5.0 and PCIe 6.0 interface as well as next-generation 3D QLC NAND promise to generate even more heat than today's best SSDs with a PCIe 4.0 x4 interface.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.