Gigabyte's pressurized thermal pads lower SSD temperatures in M.2 slots by up to 12C

Two small springs can solve a big problem.

Gigabyte has added pressurized thermal pads to M.2 slots for SSDs on its latest Aorus Stealth Ice motherboards (via Uniko's Hardware) to maximize heat dissipation of high-end SSDs. The motherboard maker claims that its pressurized thermal pad may reduce SSD temperature by 12 degrees Celsius, though it admits that the effect depends on multiple factors.

Thermals often constrain the performance of high-end SSDs in an M.2 form-factor, as both the controller and memory packages tend to heat up under high loads. Most high-end drives come with a pre-installed heat spreader, and many high-end motherboards come with their thermal solutions for SSDs. However, these thermal solutions are mainly designed to cool down the controller and the upper side of the drives, whereas backplates are tailored for single-sided or double-sided drives. Apparently, Gigabyte has found a flexible solution. Literally.

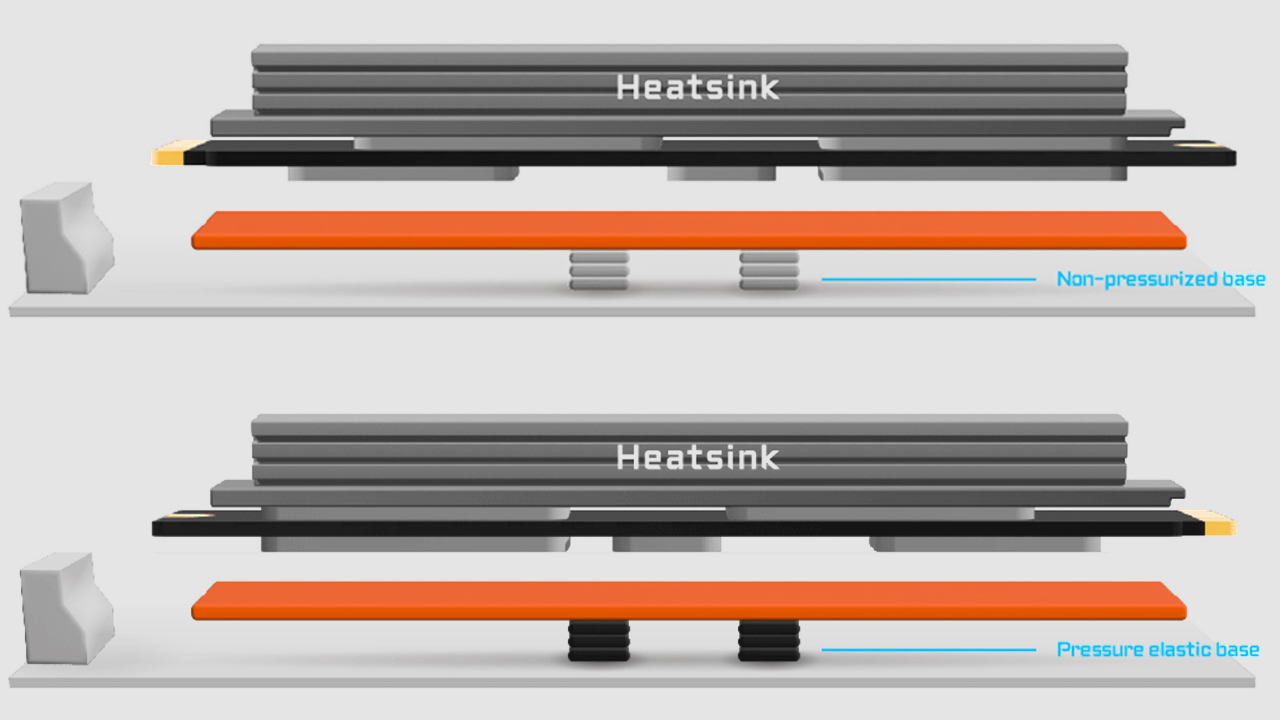

Gigabyte’s EZ-Flex solution, introduced on its B850 Aorus Stealth Ice motherboard, addresses these shortcomings by combining pressurized thermal pads with a spring-loaded, flexible backplate. This setup adapts to the thickness of both single- and double-sided M.2 SSDs, maintaining uniform pressure and ensuring better thermal contact on both sides of the drive. As a result, SSD temperatures can be reduced by up to 12°C, helping to prevent thermal throttling and sustain high performance during intensive workloads.

Gigabyte’s EZ-Flex design not only improves thermal performance and enhances compatibility with both single- and double-sided SSDs, but it also ensures more consistent mechanical pressure for better stability and reduces the risk of installation errors due to its adaptive fit. As a bonus, such a design could reduce SSD bending after prolonged usage. In addition, lowering temperatures helps extend the lifespan of SSD components. It minimizes performance throttling under sustained workloads, making it especially beneficial for users handling large data transfers or demanding applications.

It remains to be seen whether EZ-Flex will now be a part of all Gigabyte’s motherboards, or will only be featured on premium solutions. Considering that the B850 is not a premium platform, EZ-Flex will likely be a widespread feature on Gigabyte mainboards. After all, just two springs are not expensive, right?

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

Notton This sounds like a great idea. It simplifies applying a heatsink to an SSD and you'll get great contact without the use of 2 or 3 different pad thicknesses.Reply

The worst type of SSD to mount a heatsink to is clam shell with differing heights between NAND, DRAM, and controller. A further icing on top are tall SMD caps on both sides that you don't want to short. -

Amdlova That gigabyte graphics with the thermal melt down is the first gigabyte attempt for this new tech.Reply

With some heat and pressure you will get the perfect fit lol -

Findecanor It is "12° C", not "12C".Reply

On Mac, you can type Option + 0 (zero).

On Linux, with a non-English keymap, the symbol is often available on a similar combo: Alt Gr + 0.

On French, German/Austrian/Swiss and Italian layout, it is available right on a key, but sometimes with Shift.

Otherwise, I'd recommend installing/enabling support for the very versatile Compose key, Then type Compose o o -

bit_user Reply

If you're talking about a heatsink that doesn't directly attach to the SSD, sure. I guess you're counting on the spring pressure, over time, to mold the pad so it conforms to the chips better? I wonder if most thermal pads would flow very much, even when hot? I'm not sure they would, because some people depend on them to provide electrical insulation between the components and heatsink, but if the material got too soft and flowy when hot, they would no longer offer such protection.Notton said:This sounds like a great idea. It simplifies applying a heatsink to an SSD and you'll get great contact without the use of 2 or 3 different pad thicknesses.

How important is it to cool those surface-mount components? If you can cool the NAND & controller enough, then it seems to me that the caps and whatever else will do fine, just dumping their heat to the PCB. I think the NAND is far and away the most heat-sensitive component on there.Notton said:The worst type of SSD to mount a heatsink to is clam shell with differing heights between NAND, DRAM, and controller. A further icing on top are tall SMD caps on both sides that you don't want to short.

Furthermore, consumer SSDs are only made to be stressed for a limited proportion of the time. So, unless you know otherwise, I wouldn't be too concerned about the other components on those drives. -

bit_user Reply

Yeah, I don't bother with the degree mark in forum posts. But, it'd be a different matter, were I writing an article. And in the headline no less!Findecanor said:It is "12° C", not "12C". -

Notton Reply

You can squish thermal pads to conform to whatever you mount it to.bit_user said:If you're talking about a heatsink that doesn't directly attach to the SSD, sure. I guess you're counting on the spring pressure, over time, to mold the pad so it conforms to the chips better? I wonder if most thermal pads would flow very much, even when hot? I'm not sure they would, because some people depend on them to provide electrical insulation between the components and heatsink, but if the material got too soft and flowy when hot, they would no longer offer such protection.

How important is it to cool those surface-mount components? If you can cool the NAND & controller enough, then it seems to me that the caps and whatever else will do fine, just dumping their heat to the PCB. I think the NAND is far and away the most heat-sensitive component on there.

Furthermore, consumer SSDs are only made to be stressed for a limited proportion of the time. So, unless you know otherwise, I wouldn't be too concerned about the other components on those drives.

Mobos and GPUs use it on VRM.

However, unlike Mobos and GPUs with custom VRM heatsinks mounted through the board with spring loaded screws, SSD heatsinks don't have that luxury.

Instead you get this wonderful selection of hack-job mounting methods including heat non-resistant rubber bands, metal clips that might short on SMDs mounted on the backside of the SSD, or kapton tape.

No, you don't need to cool SMDs, but they do get in the way. The worst are SMDs mounted to the backside, as that will conclude use of any metal clips or sandwich style heatsinks. If you mount it bare, it shorts, if you use a pad thick enough to negate shorts, then the clips don't fit because the SSD becomes too thick.

When it comes to the Kapton tape or rubbur bands, they simply do not have enough physical force to squish the pads to conform to all chips.

And rubber bands are the worst.

For example, the MP34 is one of the worst offenders when it comes different chip heights, not helped by tall SMDs mounted to both sides.

https://cdn.mos.cms.futurecdn.net/HpA7o5obStoJR6o5d7sZAB-970-80.jpg.webpDoes the MP34 absolutely need a heatsink? no.

Do hotter SSDs have the same problem? yes.

Oh, and SSD PCBs are very flexible. Sometimes helpful, sometimes not when the PCB bends.

also refer to this vid I8Z09nU554Q -

bit_user Reply

I thought of this comment last night. The memory of it came to haunt me, like a bad dream.Notton said:The worst type of SSD to mount a heatsink to is clam shell with differing heights between NAND, DRAM, and controller. A further icing on top are tall SMD caps on both sides that you don't want to short.

A couple years ago, I had the "brilliant" idea to buy an enterprise SSD, because they should be extra reliable, right? Only problem is that, even then, they were getting almost impossible to find in M.2 format. But, I found one (Samsung PM9A3).

It was 110 mm long, though. That made finding a heatsink much more difficult, and you pretty much need a heatsink, because they idle way hotter than a consumer drive. So, unless your chassis is designed to channel continuous airflow over it (like they tend to do in servers), you'd better put that thing in a heatsink.

The worst part is that it's double-sided. Double the fun!

: D

Anyway, I decided I could get away with measuring and cutting out only 4 segments of thermal pad (Arctic TP-3, 0.5 mm), but two were non-rectangular. For the tallest surface-mount components, I just put a little piece of kapton tape on the heatsink, itself, so they wouln't short against it. Then, I dabbed some thermal compound on what I'd guess are probably power-loss capacitors (in which case they probably didn't need it) that had no exposed metal on top and what's probably an inductor.

I ran some thermal compound (some old Arctic MX-4 I had lying around; trying to use up, now that I'm using MX-6 on CPUs) along the inside edge of the bottom plate, where it connects to the top part. By then, it was late and I decided to wait to see whether I smashed my "SSD sandwich" too hard or messed it up in some other way.

After this experience, I've got to say I don't relish the prospect of a repeat. Fortunately, the other M.2 drives I have are basically flat (no tall surface-mount components) and single-sided. So, if I even decide to put one of those in a heatsink, a simple application of one 0.5 mm thermal pad on each side should do it.

Here's the heatsink:

https://www.ebay.com/itm/155880372217

I wish they'd made at least the bottom part out of copper. It's quite thin and I'm not confident it's sufficient to conduct enough heat up to the top part. We'll see. BTW, this cooler was literally the only 110 mm option that completely covered the bottom side. I really had no better option.

The cooler I used has slotted screw holes, so that it can accommodate varying degrees of thickness. I could've used another 0.5 mm on each side and it still would've fit together. I put thermal pad over only the controller, DRAM, NAND, and everything else that was approximately the same height. No double-stacking or using different heights of thermal pad (although I had some 1.0 mm stuff, if I'd wanted to go that route).Notton said:No, you don't need to cool SMDs, but they do get in the way. The worst are SMDs mounted to the backside, as that will conclude use of any metal clips or sandwich style heatsinks. If you mount it bare, it shorts, if you use a pad thick enough to negate shorts, then the clips don't fit because the SSD becomes too thick.

That's not what kapton tape is for. It's a quick & easy way to make a surface non-conductive (i.e. so that the SMDs won't short against the surface, if they touch it). It's rather annoying, and took me a few tries, to get it positioned correctly. I recommend sticking it to the side of a knife tip, when applying it, rather than holding with your fingers.Notton said:When it comes to the Kapton tape or rubbur bands, they simply do not have enough physical force to squish the pads to conform to all chips.

And rubber bands are the worst.

Rubber bands are a definite no. They dry out, lose all elasticity, and disintegrate. Heat will only accelerate this process.