Meet Wraith Ripper, A New Cooler For Threadripper 2

AMD's Threadripper 2 announcement has the enthusiast community excited at the prospect of 32 cores and 64 threads coming to the desktop, but you'll need to top the processor with a capable cooler to bring the rumored 250W TDP under control. AMD told us at Computex that the new Threadripper 2 models will come with the Asetek bracket that provides compatibility with leading AIO watercoolers. But the company has also worked with Cooler Master to develop a new air cooler, Wraith Ripper, specifically for the Threadripper's TR4 socket.

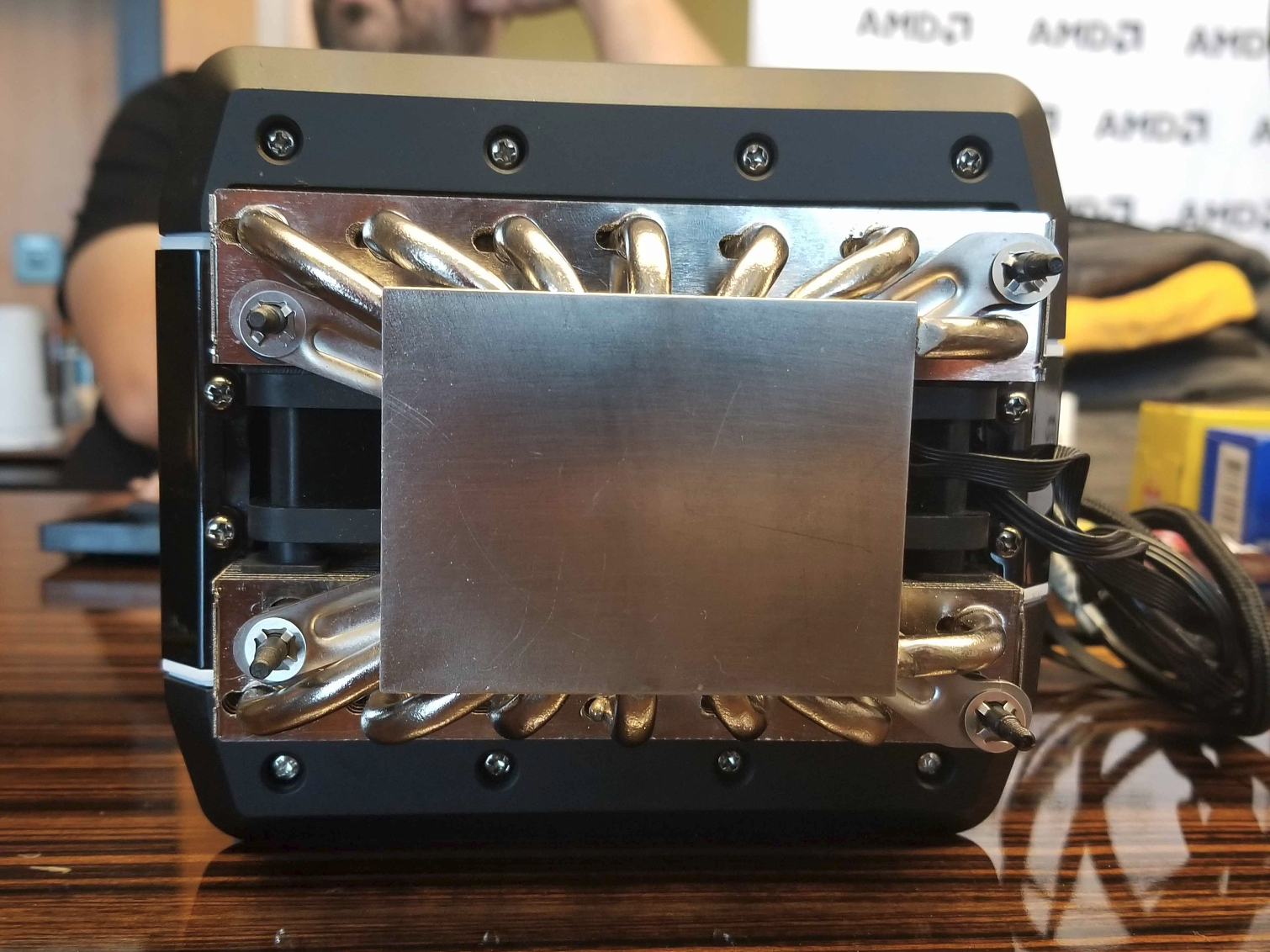

Cooler Master will launch and sell the new air cooler separately. The Wraith Ripper cooler comes resplendent with fully-addressable RGB lighting for the Ryzen Threadripper logo and two LED strips that run down the center of the heatsink.

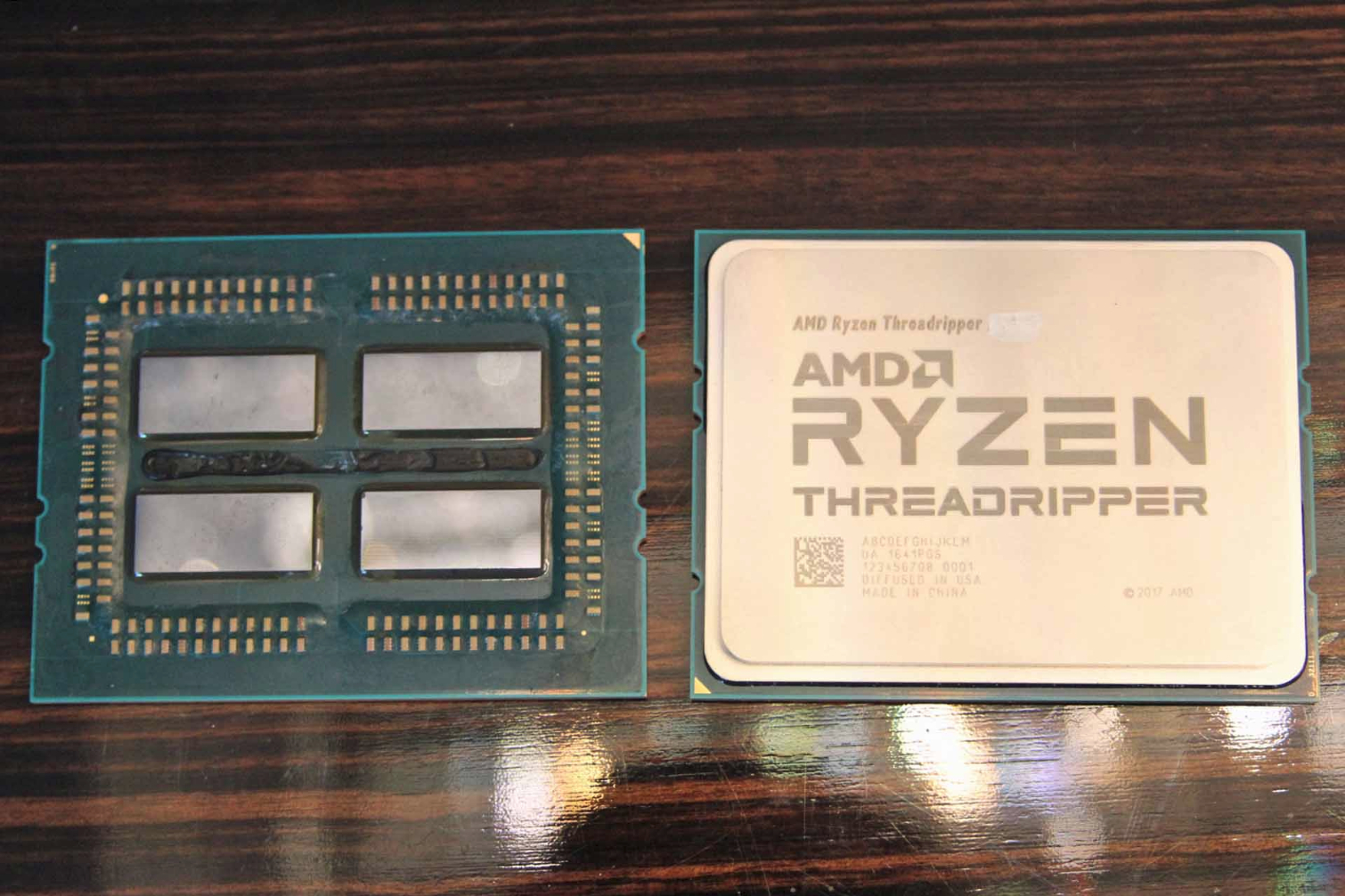

AMD's first-generation Threadripper came with two active die and two inactive 'dummy' die, but the new model comes with four active die. That will require a bit of extra cooling power, but the Wraith Ripper cooler provides full coverage of the large TR4 socket.

Seven copper heatpipes wick heat up into the hefty fin stack while a concealed 120mm fan in the center of the cooler provides airflow at a relatively tame 39dBA. The top of the housing features four Phillips head screw mounts that attach directly to the four threaded fasteners that mount into the TR4 socket, which eases installation. The cooler is quite heavy, as we would expect from a cooler that can dissipate roughly 250W of thermal output.

Neither AMD nor Cooler Master have released more details, such as pricing, but we're sure that information will pop up when the new coolers come to market during the Threadripper 2 launch in Q3 2018.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Paul Alcorn is the Editor-in-Chief for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.