TSMC to Begin 3nm Chip Production Next Month

3nm chips from TSMC are getting closer.

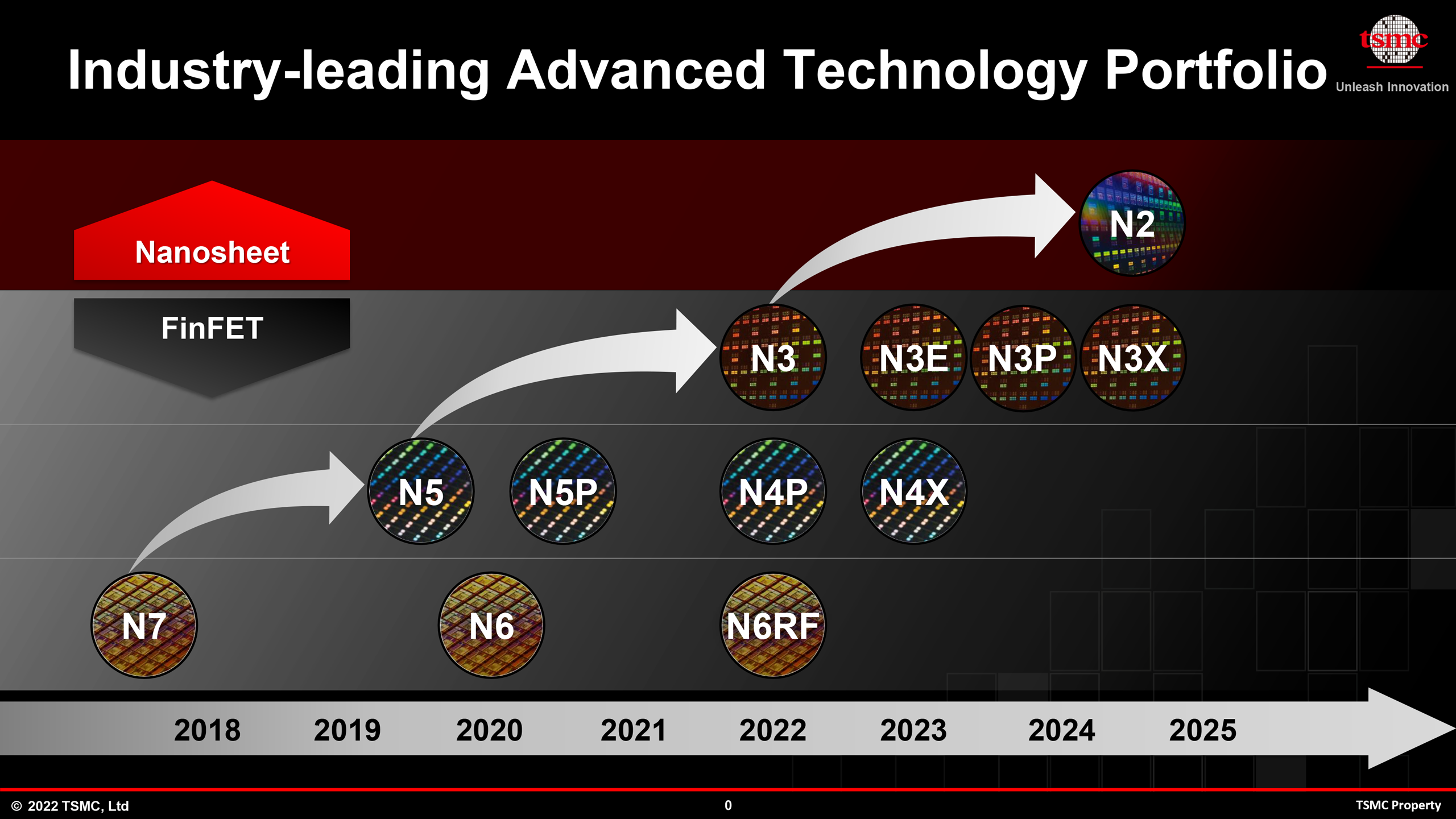

TSMC will begin mass producing chips using its leading-edge N3 (3nm-class) manufacturing process this September, according to a Commercial Times report that cites equipment manufacturers. The contract chipmaker will deliver the first products made using its N3 node to its customers early next year.

Traditionally, TSMC begins its high-volume manufacturing (HVM) of a new node sometime in the March to May timeframe to produce enough chips for Apple's latest iPhones, which typically launch in September. But the development of TSMC's N3 node took longer than usual, which is why Apple's upcoming smartphone chips will use a different node. In contrast, the first 3nm chips from TSMC will reach the HVM milestone only in September, which is a bit later than what TSMC originally promised (a couple of months delay versus typical schedules). Still, the company will meet its goal of starting N3 production in the second half of the year.

| Row 0 - Cell 0 | N3E vs N5 | N3 vs N5 |

| Speed Improvement @ Same Power | +18% | +10% ~ 15% |

| Power Reduction @ Same Speed | -34% | -25% ~ -30% |

| Logic Density | 1.7x | 1.6x |

| HVM Start | Q2/Q3 2023 | H2 2022 |

When compared to the original N5 manufacturing technology, the initial N3 fabrication process is projected to offer a 10% to 15% performance improvement (at the same power and complexity), reduce power consumption by 25% – 30% (at the same speed and transistor count), and increase logic density by around 1.6 times.

This original N3 node has a narrow process window, which means a lower-than-expected yield for some designs. TSMC is developing an N3E node with an improved process window that will feature a slightly lower transistor density. That technology is projected to enter mass production about a year after N3, but there are indications that N3E will reach HVM sooner rather than later. Eventually, TSMC will add N3P, N3S, and N3X nodes to its 3nm family.

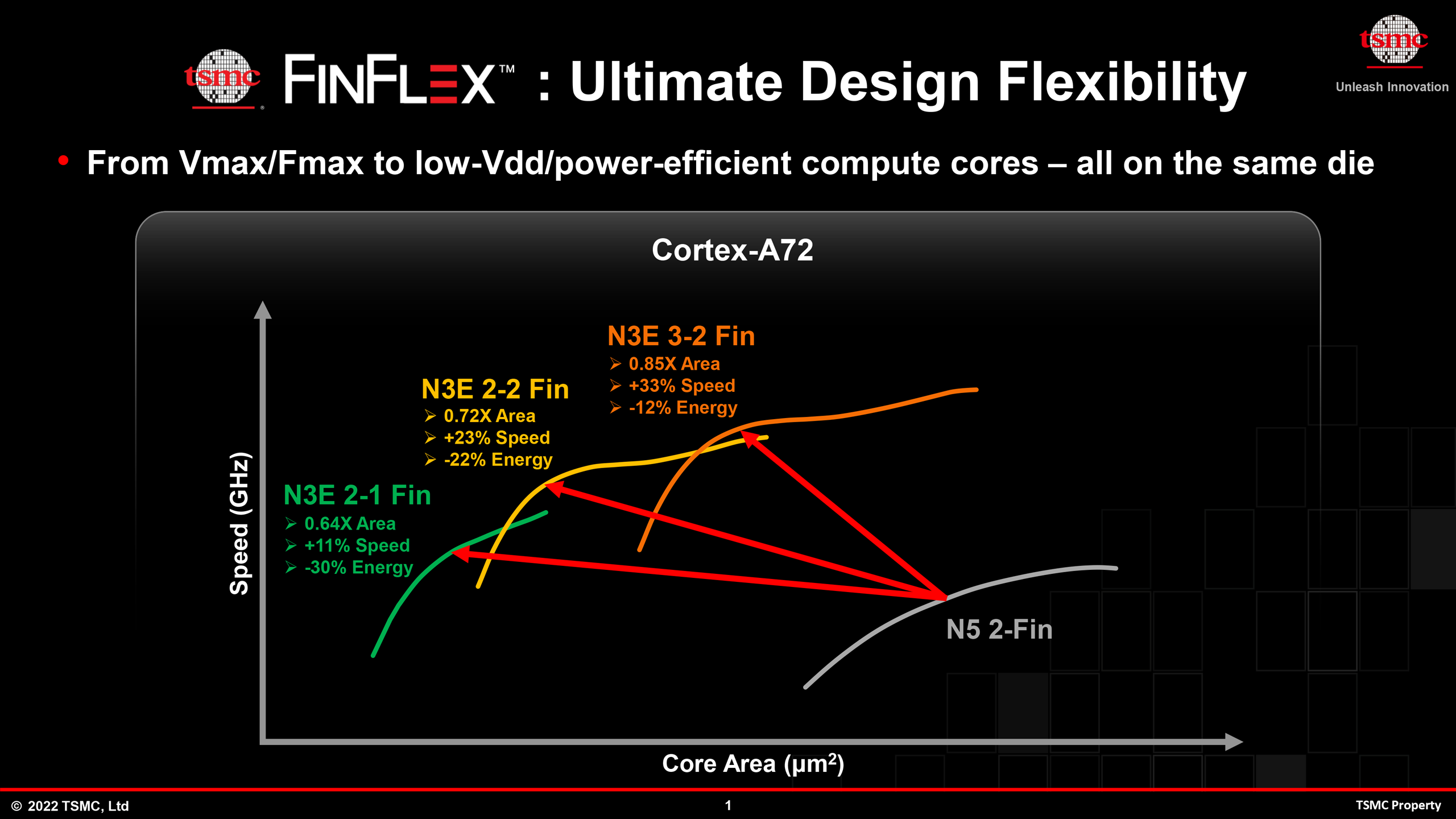

TSMC's FinFlex tech is one of the key features of N3, enabling chip developers to mix and match different kinds of standard cells within one block to accurately optimize performance, power consumption, and area. FinFlex is particularly beneficial for complex things like CPU or GPU cores, so companies like Apple, AMD, Intel, and Nvidia will be able to build better processors and graphics processors for PCs and high-performance computing applications.

Apple is expected to be TSMC's first customer to adopt the N3 fabrication process.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

scottenj Your article says N3E is lower density than N3 (correctly) but your table say N3E is higher density than N3 (incorrectly). Some of the other numbers in the table look wrong to me to but I am not in front of my computer right now to check.Reply -

quadibloc2 I hope that TSMC decides to refuse to label their chips as manufactured in "Chinese Taipei" so that AMD will get a chance to have access to that 3nm capacity, instead of Apple getting it all.Reply -

shady28 Replyquadibloc2 said:I hope that TSMC decides to refuse to label their chips as manufactured in "Chinese Taipei" so that AMD will get a chance to have access to that 3nm capacity, instead of Apple getting it all.

Apple reportedly can't even get enough for its 2023 iPhone, and will need more for upcoming Apple Silicon for Macs. Pretty much all N3 production for the next 12 months will be Apple / Intel.