Broken Nvidia RTX 3090 rises from the grave – 'death by liquid metal' wasn't permanent

North West Repair fixes card after thermal material seeped under the GPU and two GDDR6X chips.

North West Repair has ably demonstrated that "death by liquid metal" isn't necessarily permanent. After analyzing and diagnosing a deceased Nvidia GeForce RTX 3090, the repair tech demonstrated dexterous GPU and VRAM chip removal, cleaning, reballing, replacement, and testing. Except for one of the VRAM chips requiring its solder balls to be reflowed a second time, the repair went without a hitch, and his customer must have been happy to get back a fully working (and still potent in 2024) GeForce RTX 3090.

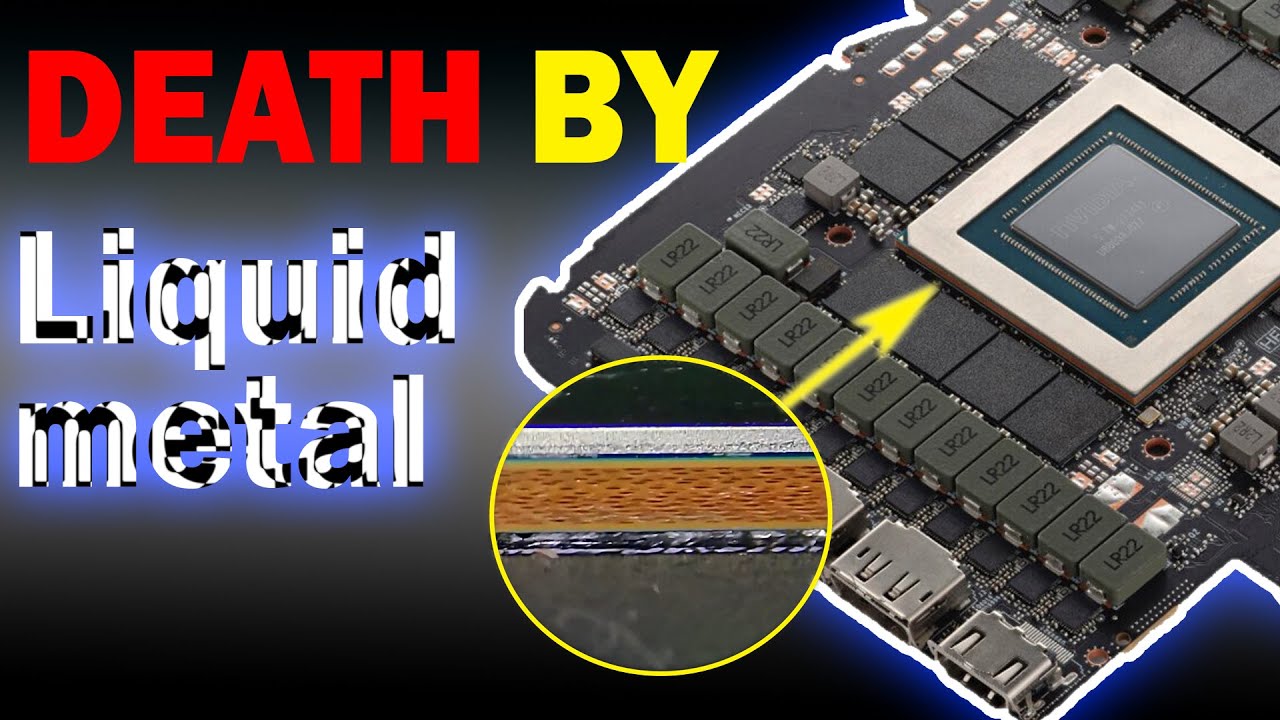

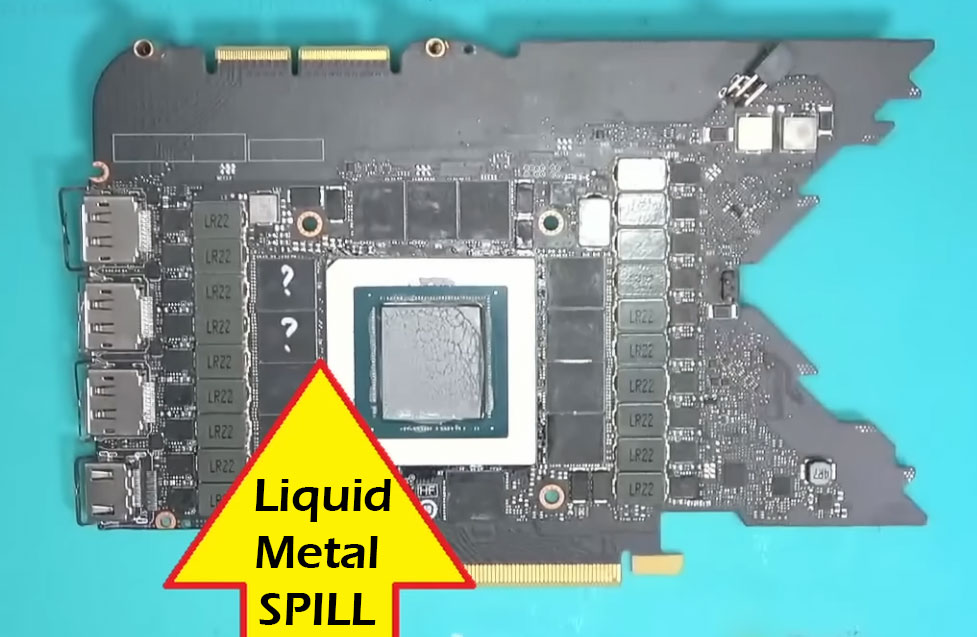

Liquid metal thermal interface material (TIM) is notoriously tricky to handle, with commercial applications using specially designed application tools and barriers to stop it escaping from where it's needed. Asus, for example, is known to use solder mask on nearby conductive surfaces and a tiny barrier sponge just 0.1mm tall around processor sockets. Unlike the long-established oxide thermal pastes, liquid metal conducts electricity, so if it seeps out it can cause all sorts of electrical havoc (usually short circuits). This seems to be exactly what has happened to the RTX 3090 in the North West Repair video.

In the video, repairer Tony explains that he received an Nvidia Founders Edition GeForce RTX 3090 "after an unsuccessful liquid metal application." He seems to be wary of such cases, recommending good-quality thermal paste instead. The first job is to check the graphics card isn't completely dead, and to assess the spread of the liquid metal. It is 'known' to be under the GPU – but did it get into any other nooks and crannies?

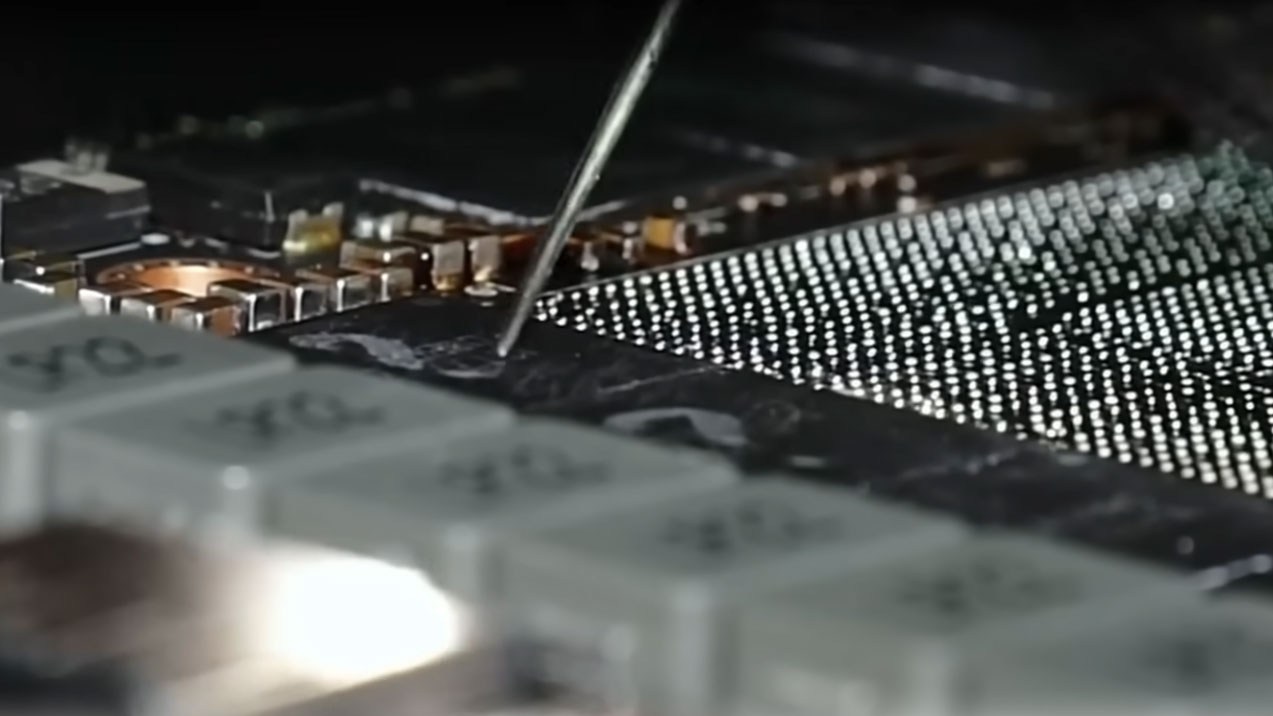

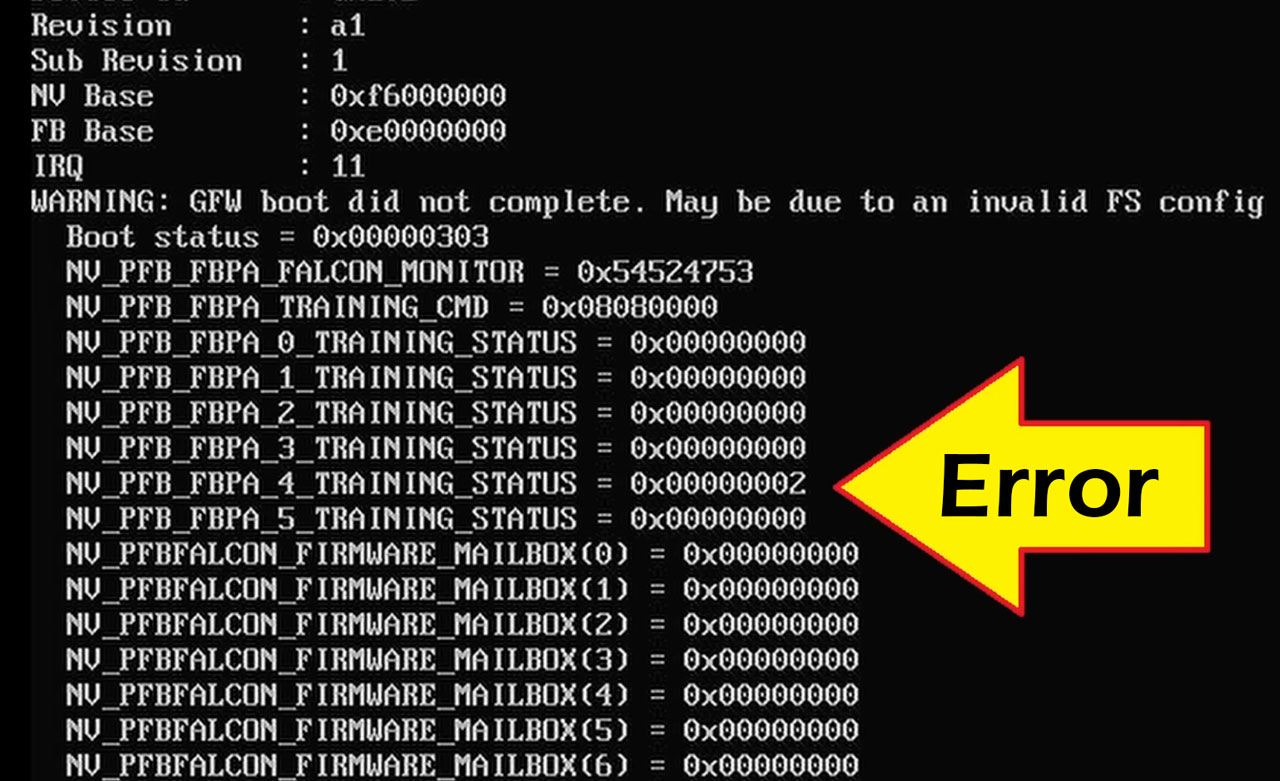

A multimeter confirmed that most circuits were OK, but the card wouldn't output any video signal. The next step, connecting the card to run tests on its memory banks, revealed that two GDDR6X chips were causing errors. Knowing liquid metal got under the core, it was suspected that it went under from the upper-left side, affecting the two marked memory chips.

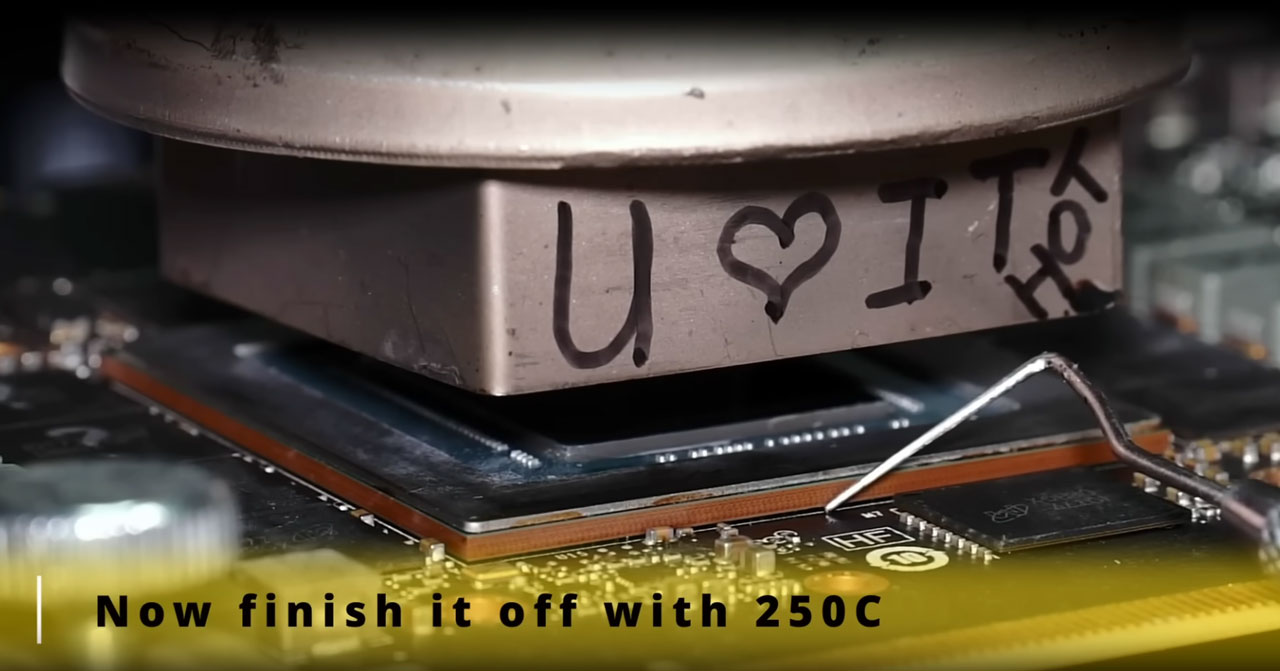

Tony then got to work, using specialized equipment to evenly heat the GPU and memory chips to around 250 degrees Celsius. This allowed the spill-affected components to be removed. Next, the cleanup process began, and North West Repair noted an unusual coating on the freshly exposed PCB area that had to be cleaned with adhesive remover.

The next segment of the video shows the GPU and two VRAM chips getting cleaned and solder re-balled, which is a tricky specialized task. Tony makes this look easy though. After the successful component re-ball, the components were soldered back to the graphics card PCB for testing. As we mentioned in the intro, one of the memory chips precipitated an error in the text phase, so the problematic chip got a fresh squirt of flux and was reheated to the solder melting point, for an operation called a reflow.

After a last spell of cleaning, using an ultrasonic bath to remove old dried-up flux residue, the GeForce RTX 3090 card was ready for testing again and passed all Tony's heat, stress, and benchmark testing. It was a happy ending for a card that easily could have been tossed in the trash after the owner's very expensive mistake.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

Sluggotg Good Job Tony! I stay away from the Electrically Conductive Thermal material. I could certainly successfully use it, but I just don't want the hassle anymore. I get decent performance from other TIM.Reply

It is nice that someone got their card fixed.