Asus AMD Ryzen 9 7945HX3D Laptop Processor Liquid Metal Mitigations Revealed

Solder mask or a similar non-conductive barrier has been meticulously applied to the APU.

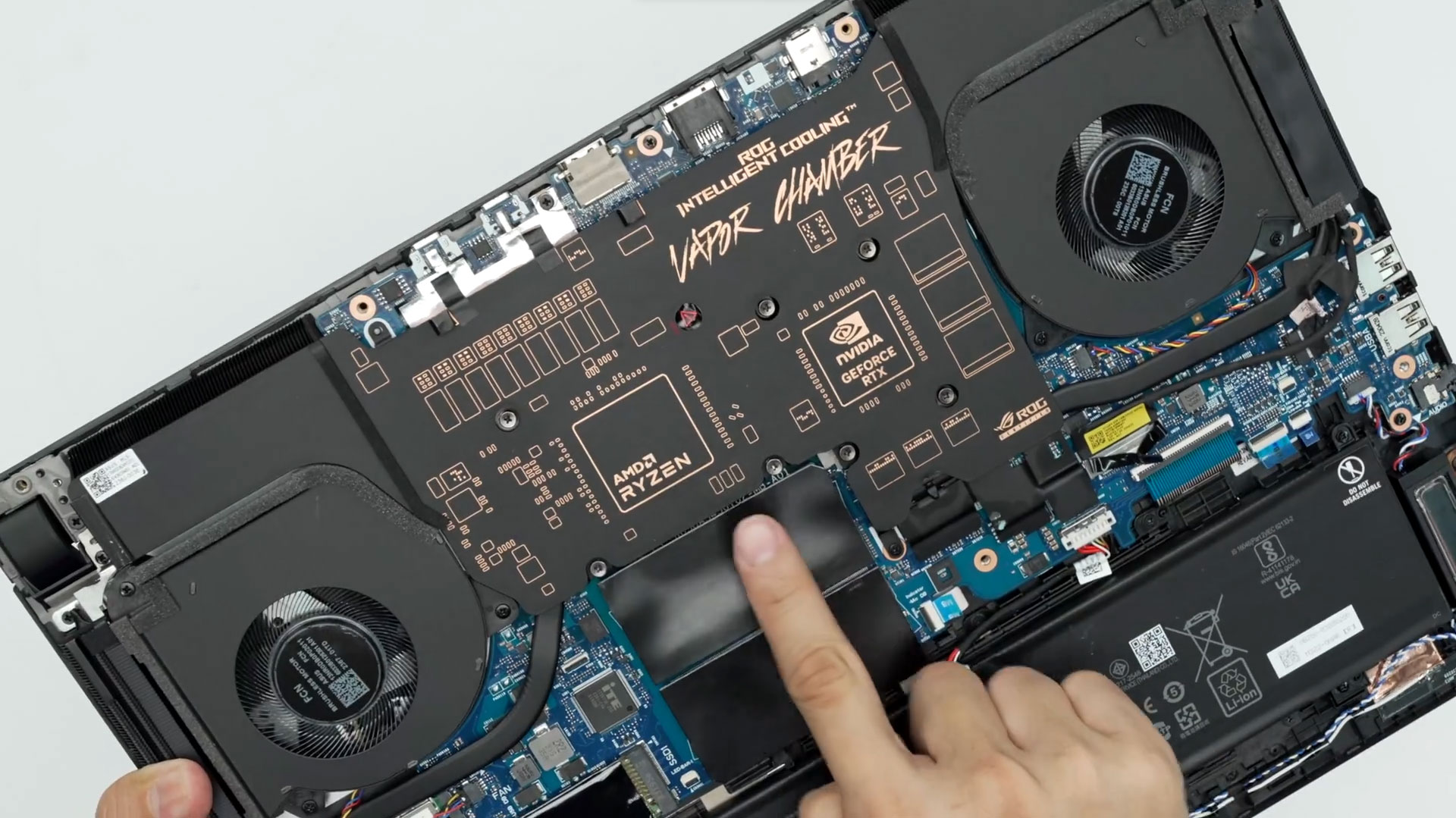

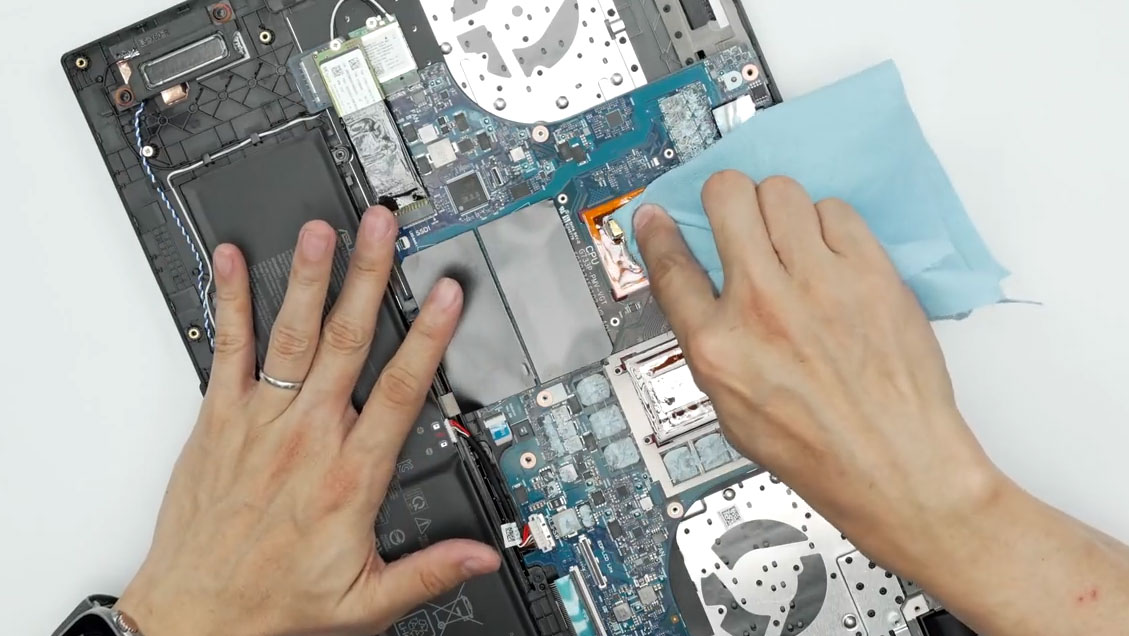

A Chinese TechTuber has revealed how Asus has managed to cool the powerful new AMD Ryzen 9 7945HX3D for laptops, as well as the GeForce RTX 4090 Laptop GPU. Bilibili user Ordinary Uncle Tony disassembled his Asus ROG Strix Scar to quite a daring degree to reveal the AMD APU as shown above and below (h/t HXL).

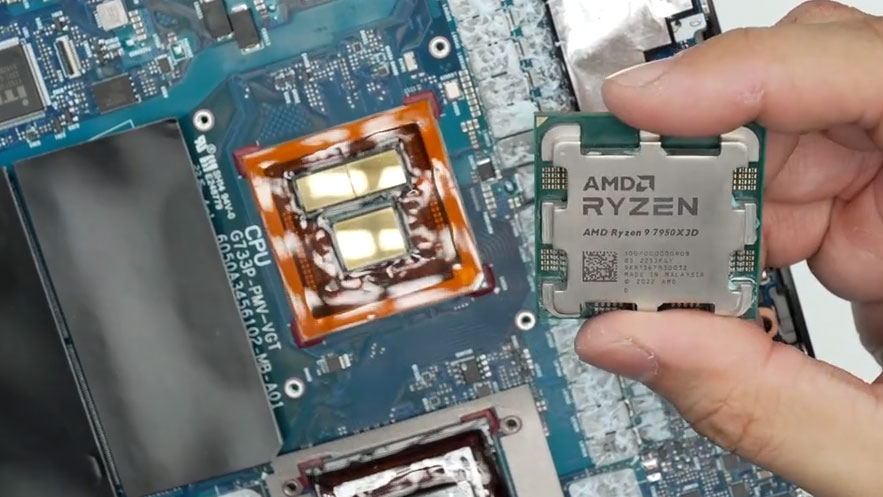

What you see is AMD’s powerful X3D enhanced mobile APU — without an IHS, of course — with its multiple dies visible. Solder mask, or a similar non-conductive barrier like a lacquer or epoxy resin, has been meticulously applied to the protect the processor circuitry surrounding the dies from the damage which might occur from stray drips and drops of (electrically conductive) liquid metal.

PC enthusiasts will be aware that liquid metal is coveted for its great thermal properties when used as a TIM (Thermal Interface Material), but it has some particular drawbacks.

On desktop processors with liquid metal TIM, the application placement and maintenance of the metallic goo is still tricky, but it can be constrained more simply with a uniformly shaped barrier, stopping it from flowing to areas it should not be.

Asus has been applying liquid metal to high-end laptop processors for several generations now. Before its first commercial laptop use in 2019, Asus says it took two years to experiment with production line application of the conductive but messy liquid. Asus “added a tiny barrier sponge just 0.1mm tall around the CPU socket, safeguarding against any accidental seepage.” This spongy method seems to have become redundant with the X3D mobile processor.

If it applied liquid metal to the AMD Ryzen 9 7945HX3D, it would have been first time Asus has had to cope with the complications of a multi-tile processor. With the exposed dies and electronic components on a mobile chip like the Ryzen 9 7945HX3D, some more complicated TIM wrangling would be called for.

We see that the red solder mask (or similar lacquer coating) is one effective method of mitigating the presence of potentially hazardous room-temperature liquid metallic material. Solder mask is a simple, non-conductive durable barrier that has been used in electronics applications for decades. We wonder if it too is being applied by robots on the production line. Anyway, this application seems to have only been done to protect the X3D APU from liquid metal contamination from the GPU. It looks like the AMD APU contacts with the large vapor chamber cooler via a thermal pad.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

In our review of the Asus ROG Strix Scar 17 X3D, we noted the massive cooler and vapor chamber for the CPU and GPU. The hottest area of the system was recorded 56.6 degrees Celsius (133.88 F) on its underside. However, the thermal imagery indicated that the cooling was effective in taking the heat away from the processors and expelling most of it out the back. No evidence of thermal throttling was observed in the demanding benchmark runs.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

Kamen Rider Blade We'll find out soon enough how long that Liquid Metal Solder masks holds up in the "Long Term" with in-field usage by real people.Reply -

ryankm Reply

It works I used it. It dose lose some of it's thermal conductivity over time, but is 10 times better than typical thermal paste so this negligible. It is like solder and there is a burn in process. This just means you cant knowck the cooler or whatever because it will break the solder. I myself switched to indium foil pads. It is about the same as liquid metal except is non toxic and easy to clean up and doesnt break down either. Way easier to just put and indium pad on than go through the careful process of applying liquid metal.Kamen Rider Blade said:We'll find out soon enough how long that Liquid Metal Solder masks holds up in the "Long Term" with in-field usage by real people. -

edzieba ReplySolder mask, or a similar non-conductive barrier like a lacquer or epoxy resin

The term you're looking for is 'Conformal Coating'. That's what is applied to a populated PCB assembly to protect it from external chemicals (be it water, corrosive gases, corrosive compounds like 'liquid metal' pastes*, etc). Solder mask is applied to the bare PCB prior to population.

* Liquid Metal TIM is an eutectic Gallium alloy. Gallium is well known for its propensity to infiltrate other metals, and Gallium also attacks Silicon. The backside of a die is normally protected by a layer of Nickel with a thin Gold coating (the Nickel wets to the solder TIM well, the Gold protects the Nickel from oxidisation as Nickel oxides do not wet the solder), but against attack by Gallium only the Gold coating is doing any good, the underlying Nickel is vulnerable to attack just like the Silicon die.

My concern for X3D chips specifically (and any other chips incorporating TSVs) is whether they retain the same sort of sealed backside coating or not. If the exposed TSVs of a die that has not been populated with a cache die on top - or if a stacked cache die exposes an uncoated edge around the periphery - cannot be coated with conductive metal due to the exposed TSVs, then those dies would be vulnerable to accelerated attack by Gallium. -

secrertqwerty10 That's not a conformal coating or anything like that. It's a Kapton tape layer, which they've been using on pretty much all of their AMD CPU's with liquid metal. In the corner there's a bit of silver of the exposed frame, indicating that this is not a conformal coating or solder mask. There is indeed a small amount of foam bordering the edges of the exposed dies on the underside of the Kapton, and the small SMD's have a coating on them, but the reddish stuff is just their usual Kapton layer.Reply

TL;DR they've been doing it exactly this way for a while now. Nothing new has been shown. -

edzieba Reply

It's definitely not Kapton tape. Kapton tape does not conform to component Z-height as this substance does, even thin polyimide films are far too rigid to do that (and are thermosets, so will not soften with heating).secrertqwerty10 said:That's not a conformal coating or anything like that. It's a Kapton tape layer, which they've been using on pretty much all of their AMD CPU's with liquid metal. In the corner there's a bit of silver of the exposed frame, indicating that this is not a conformal coating or solder mask. There is indeed a small amount of foam bordering the edges of the exposed dies on the underside of the Kapton, and the small SMD's have a coating on them, but the reddish stuff is just their usual Kapton layer.

TL;DR they've been doing it exactly this way for a while now. Nothing new has been shown.