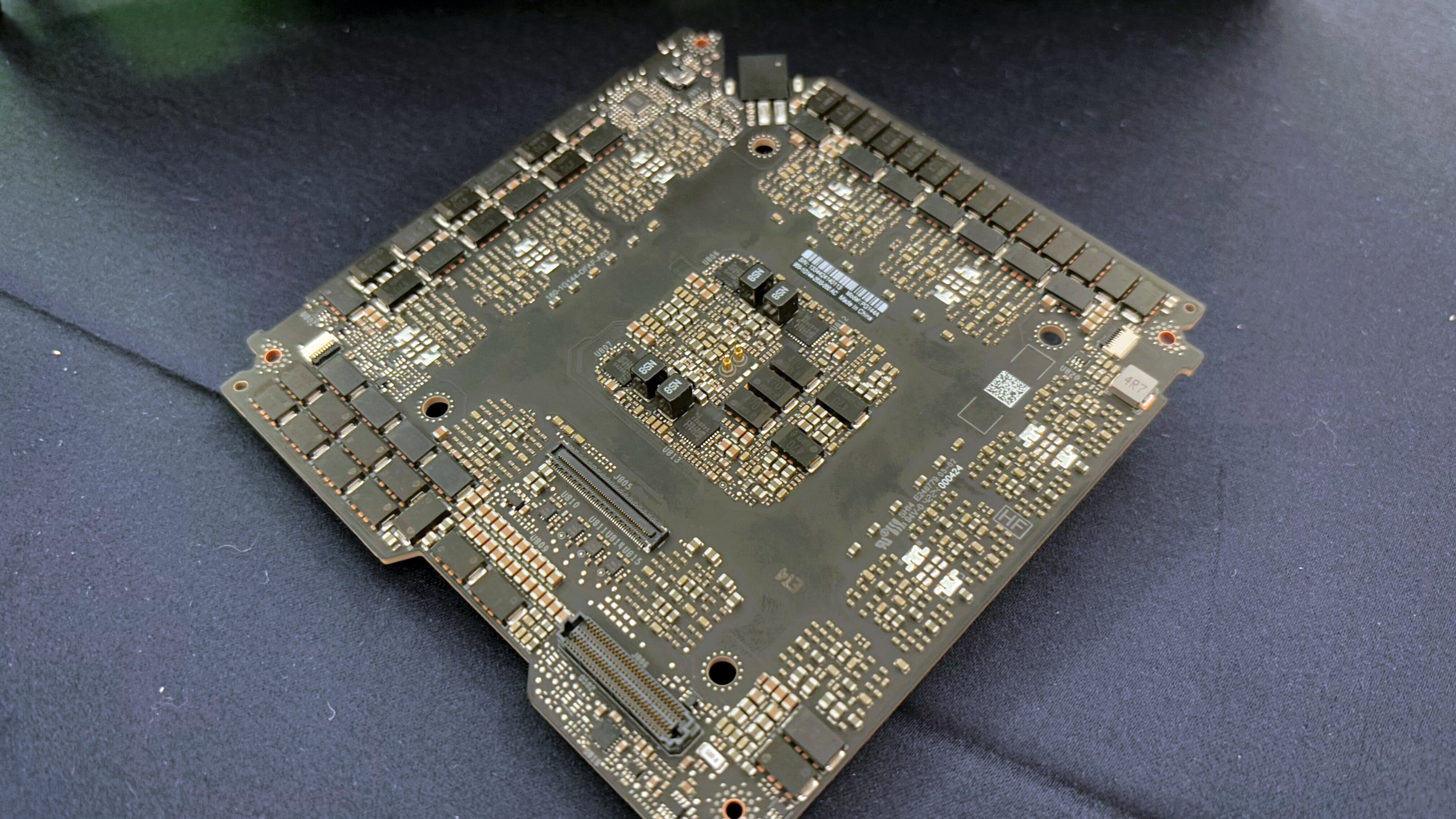

More GeForce RTX 5090 Founders Edition mysteries revealed: backside of the PCB

Mysterious mezzanine connectors pictured.

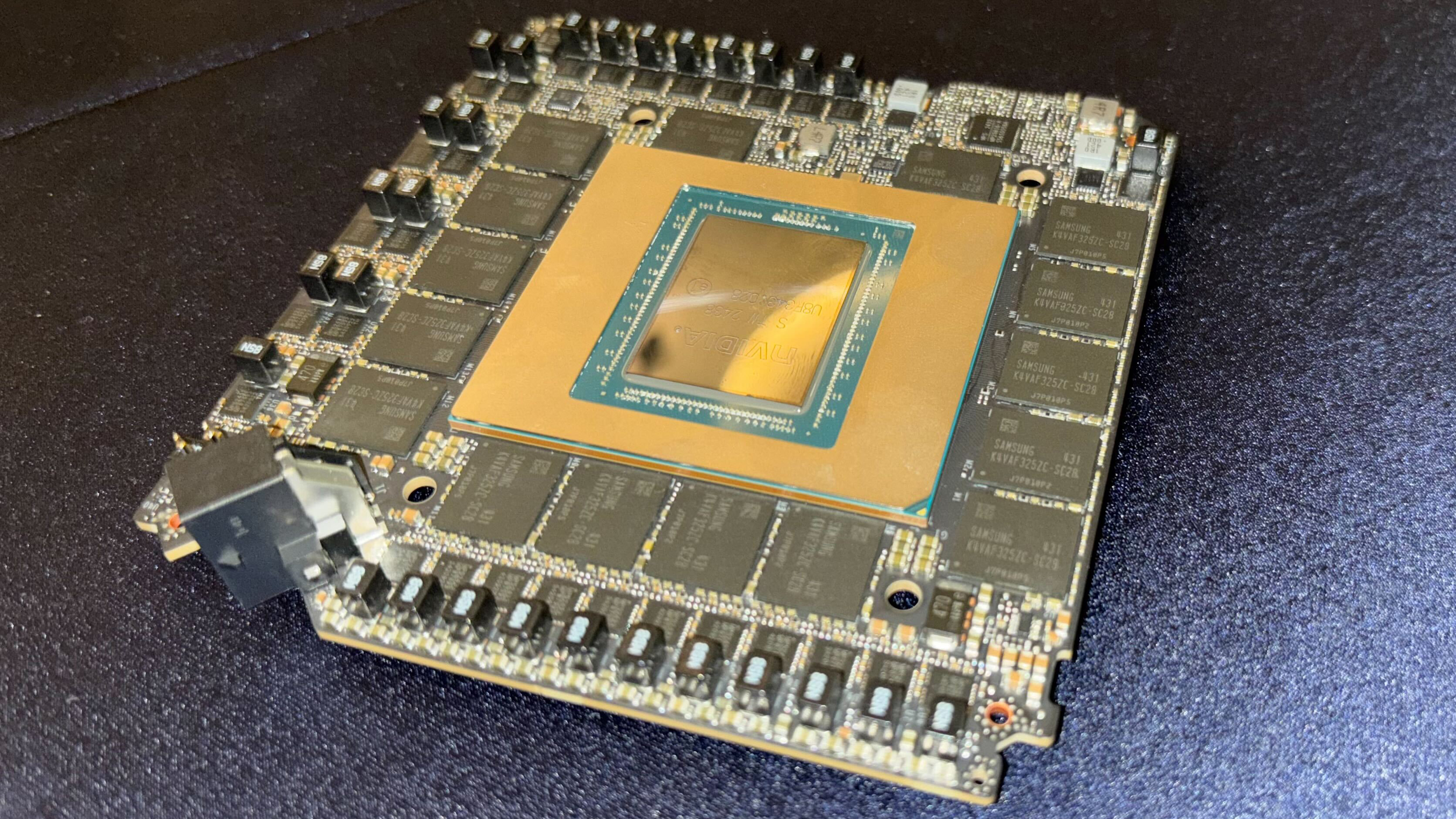

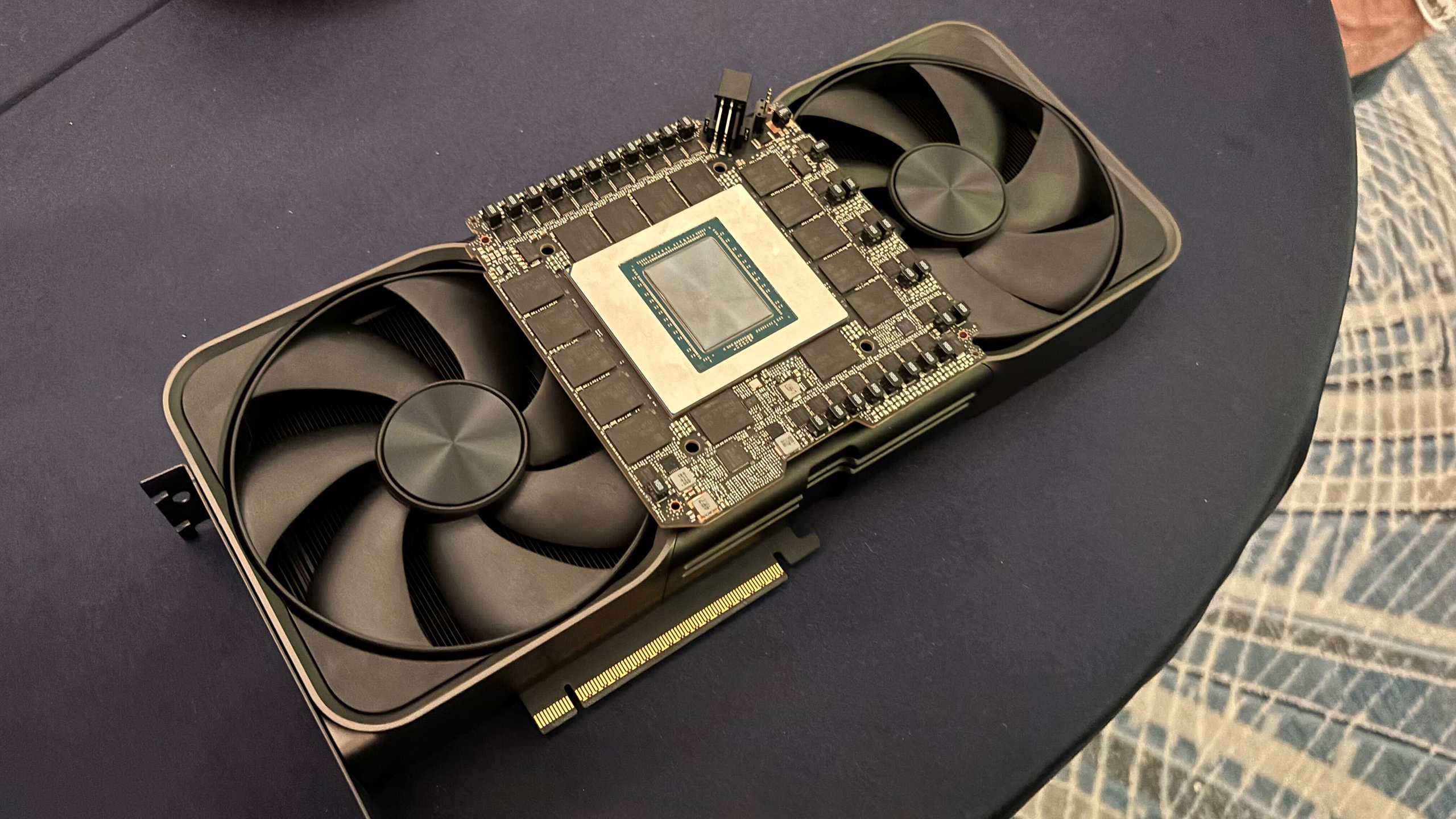

Nvidia's GeForce RTX 5090 Founders Edition graphics board — which promises to be the best graphics card around — uses an unorthodox three-piece printed circuit board (PCB), and the high-density board, which carries the graphics processor, memory, and power supply circuitry, poses many mysteries. Now that we have pictured both the front and back sides of the main GeForce RTX 5090 FE PCB, we can reveal at least some of them.

We already know quite a lot about the front side of the board — which carries a GB202 GPU, 32GB of GDDR7 memory from Samsung (using 16 packages marked as K4VAF3257C-SC28), and a 30-phase voltage regulation module — so check out our coverage from earlier this week. But we have not seen the backside until today.

The backside has four more power delivery phases, which means that Nvidia's GeForce RTX 5090 Founders Edition graphics card uses a rather extraordinary 34-phase VRM. Also, there is a relatively large high‐density board‐to‐board (mezzanine) connector (marked as J806) often used in compact electronics to mate two circuit boards together, and a smaller mezzanine connector marked as J805. In addition, there are two ZIF connectors for fans.

We can only wonder what exactly the J805 and J806 connectors are used for, but common sense tells us they connect the PCBs with a set of display outputs and a PCIe x16 grid. We are unsure which connector transmits standard DisplayPort and HDMI signals or is part of a proprietary high-speed interface connecting to an ASIC, enabling standard DP and HDMI outputs.

Usually, a small PCB — such as the one that carries the GB202 GPU and its memory — allows much more space for airflow and cooling. However, as the main board will need two additional boards to be attached, it remains to be seen how this affects internal airflow. This does not make this particular PCB less impressive, as a tiny board that can supply 575W (and potentially more) of power to the GPU and its memory is certainly an achievement, particularly in the consumer electronics market.

Finally, there are two spring‐loaded contacts (POGO pins) below the GPU that are often used as test or programming contacts, which indicates that we may not be dealing with a final version of the PCB. This is not surprising, as the GPU was made during the 38th week of 2024, which is mid-September.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

edzieba I'd bet on these connecting to FFCs rather than directly to other boards. If they were direct BTBs, then there would be no need to use 1x male and 1x female connector (simplified BoM for populating that board by eliminating an entire component stream), but if using FFCs then having two different gender connectors effectively keys them to only accept the correct flex. Using FFCs also minimises airflow disruption, and allows the sub boards to be freely relocated: likely the entire reason for separating out the different boards from the normal monolithic layout in the first place.Reply -

80251 Wouldn't using FFCs to connect other PCBs introduce more parasitic RLC characteristics to the circuit than having just one larger PCB?Reply -

edzieba Reply

Not necessarily, FFC substrates can be just as well performing as FRC, and sometimes even perform better (nice and homogenous rather than fibrous).80251 said:Wouldn't using FFCs to connect other PCBs introduce more parasitic RLC characteristics to the circuit than having just one larger PCB? -

atomicWAR Reply

Pretty standard fair though your not wrong in the slightest. I'd prefer straight on shots myself even if I get they do it to prevent more accurate speculation about yet/soon to be launched products. Man do they love to make measurements harder to do for folks like us but end of day...we'll still try!!P1nky said:How hard is to to take a photo directly above the product and not an angle? -

tresnugget PCWorld has already looked at the different connectors. J805 connects to a cable that routes around the edge of the frame to a board hosting the display ports and HDMI. J806 connects to the pcie 5.0 x16.Reply