RTX 4090 failures from ripped pads made worse by poor packaging

Solder pads are often ripped off the PCB when cards suffer impacts.

Too many flagship graphics cards are suffering unnecessary irreparable damage, reckons NorthWestRepair. The TechTuber, who specializes in graphics card repairs, has published a new short that bemoans a rash of Nvidia GeForce RTX 4090 failures due to poor shipping and improper mounting practices. Remember, these flagship cards can cost $2,000 or more, but some choose to save nickels and dimes by skimping on packaging or support. That’s a false economy.

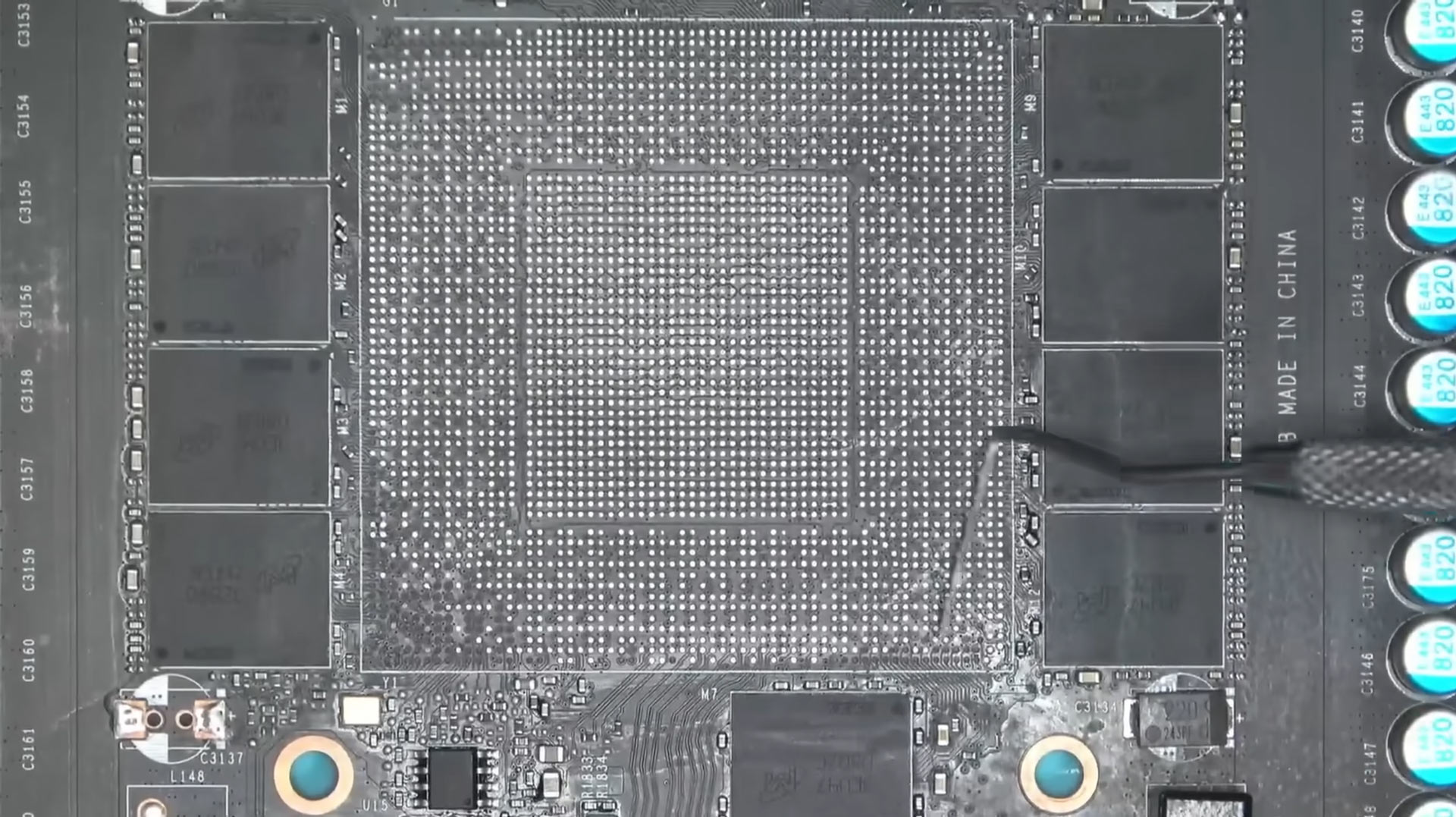

In the linked short, Tony from NorthWestRepair begins by showing a quartet of bare RTX 4090 PCBs all laid out next to each other. He explains that they all suffered the same fate: ripped pads on or around the GPU socket.

Tony concludes that the practically irreparable damage resulted from the card, or system housing the card, being damaged in transit. Another common cause of damage that looks like this is when weighty GPUs are installed without proper support. We guess sudden impacts, where improperly packed parcels are roughly handled, deliver the most catastrophic damage. Ripped pads like those shown could be the result of the shearing force between the PCB and cooler during an impact. However, Tony has seen this same kind of damage from cards installed without GPU supports when they were needed.

Proper packaging and GPU support are such minor expenses. Considering that an RTX 4090 costs around $2,000, this damage verges on a tragedy.

At the end of the short video, Tony shows off another RTX 4090 that has just arrived at his repair store. The box looks like it is the correct size, but apparently, it contained such scant packaging that the graphics card inside was “tumbling in the box.” Soon after he unpacked the card, apparent impact damage was seen on the twisted metal fan shroud. Tony hasn’t checked this GPU yet but was pretty confident it would also suffer from ripped pads on the PCB.

“Please package your GPUs properly using at least 2-inches of foam, or bubble wrap, all the way around it,” pleaded NorthWestRepair at the end of the video short. He went on to explain that when sending components for repair they should be “tightly packed inside the box so it does not tumble.”

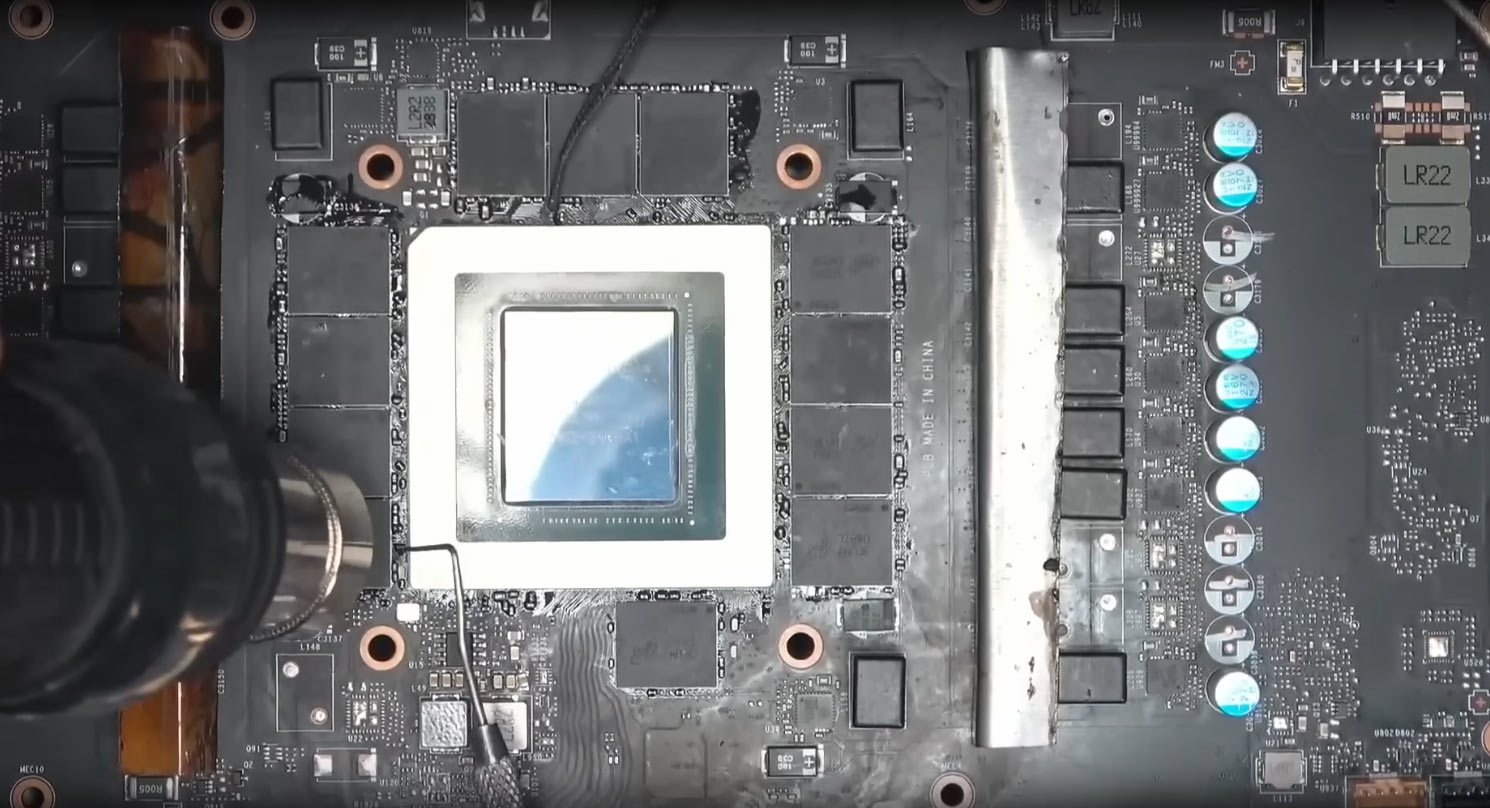

An MSI sample repaired using a donor PCB

The above video short was released just ahead of a full feature video from NorthWestRepair, which told the tale of why 50% of all 4090 will end up in the trash. After his initial investigation of the MSI on the repair bench, Tony decided to lift the GPU core. He found “a ton of ripped pads,” meaning the GPU would be categorized as a ‘no fix.’ Fixing these is considered impractical, as it would take “a week or two” to do, with any fix also being prone to failure.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

If you watch this second video, the second half of it documents Tony’s attempt to salvage the working components from the MSI and add them to a donor board that doesn’t have the solder pads problem. However, the donor board has its own issues, with evidence that little care was taken when stripping it.

This was quite an involved task for Tony’s skills, but as you will see, experience and patience paid off. The combination of the two non-working RTX 4090s resulted in a working model of one of the best graphics cards. Subsequent stress testing revealed that this one-good from two-bad graphics card salvage job was a resounding success.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

MacZ24 These graphics cards are becoming so huge and heavy that soon you will be pluging your motherboard on your graphics card.Reply

This seems like a leitmotiv : maximum powa at all cost. Even when it ends up damaging the hardware itself... -

zorgan.roman It's sad to look at NVIDIA's policies and practices, how they treat the competition. And what's even sadder is that such a good GPU silicon is invalidated by NVIDIA's terrifying design of the 4090 RTX, including a pointless power connector. Again, the evidence shows that these cards have another weakness. For NVIDIA's management, the end user has become a cash cow to their billions in profits, which they are now pushing into the development and production of AI for large corporate companies.Reply -

spoidz I have finally switched my own and all my relatives PCs that I maintain to Cube-horizontal cases - Thermaltake Level 20 XT for mine and Core V21 Micro-ATX (4) for them.Reply

Much easier to work in and vertical for all the GFX cards,

I guess I might have to add supports in the future but at least there is no immediate sag from horizontal cards. -

Eximo Reply

I want this. Instead of having an enormous GPU eat up all your expansion slots, why not a GPU that you put the motherboard on top of.MacZ24 said:These graphics cards are becoming so huge and heavy that soon you will be pluging your motherboard on your graphics card.

Riser cables get us most of the way, but often still mean a larger than normal case.

They have been putting power connectors on the back of the motherboard, I don't see why that first x16 slot can't be done that way. which gets rid of having to bend a riser from the front to the back in lots of small form factor layouts.

Only downside is being unable to see your GPU. But then I also liked some of the modular desktop design concepts with GPU and CPU modules. Even Intel's attempt was almost it with the NUC on a PCIe board and simple right angle PCB to connect the CPU board to the GPU board. -

thisisaname Reply

Or your graphic card will be more like the motherboard and everything plugs into it. Can already get a graphics card with an sdd card slot.MacZ24 said:These graphics cards are becoming so huge and heavy that soon you will be pluging your motherboard on your graphics card.

This seems like a leitmotiv : maximum powa at all cost. Even when it ends up damaging the hardware itself... -

BillyBuerger Reply

I had an idea recently where instead of the PCIe x16 slot being on top of the board with the GPU sticking up and needing support, the PCIe slot could be edge mounted on the bottom of a mITX or uATX. Then the GPU would essentially "extend" the motherboard and then be mounted to the case with standoffs. I'm doing something like that using an extension cable. Also means you can do tower coolers on the GPU similar to the CPU. And the whole back end of the card would have room for 3x 8-pin power connectors or just a single 20-24-pin molex connector like the motherboard except all 12V (plus sense pins but somehow motherboards survive without those???) This would all be new standards and crap so It'll likely never happen. But it seems like a much cleaner way to do it. Essentially two motherboards, half CPU and half GPU that have an interface between them and you can swap either half for upgrades.Eximo said:I want this. Instead of having an enormous GPU eat up all your expansion slots, why not a GPU that you put the motherboard on top of.

Riser cables get us most of the way, but often still mean a larger than normal case.

They have been putting power connectors on the back of the motherboard, I don't see why that first x16 slot can't be done that way. which gets rid of having to bend a riser from the front to the back in lots of small form factor layouts.

Only downside is being unable to see your GPU. But then I also liked some of the modular desktop design concepts with GPU and CPU modules. Even Intel's attempt was almost it with the NUC on a PCIe board and simple right angle PCB to connect the CPU board to the GPU board. -

Eximo That would make for a very 'tall' solution. Not too different from what a riser cable will get you now as you say.Reply

I've kind of wanted to push for reducing most expansion cards to half height with the GPU behind the motherboard as in most SFF cases. Or having a vertical mount for GPUs so that you can still have some expansion cards. Right now you just have to go ATX or more so that a few slots poke out past the GPU.

Seems silly to lose out on the x16 slot with a riser cable on Mini ITX. Could be another x16 on the front face for something else. But the problem with pretty much any other solution is the riser cable or the GPU being in the way of further expansion slots.

But if case and motherboard makers are willing to do backside connectors, someone should take the next step. -

Notton If the x16 slot was placed on the back of the mobo with a 90d downwards angle, you can then route the riser cable around all the slots in-between. If done correctly, it wouldn't need extra tall standoffs, as the bulky connector part would fit inside the CPU backside cutout.Reply

The GPU should get its own suspension. Use some silicone blocks or something. Alternatively, if the various GPU makers could figure out a universal mounting bracket, that would be nice.

Similar to how engine blocks get mounted to car frames. -

Conor Stewart The article isn't very clear about who's fault it is. Initially I thought it meant the manufacturers were not packaging the cards well, but then I thought why aren't people just RMAing them. It seems what it really means is people sending the GPUs in for repair but aren't packaging them well and at that point it is the users own fault. If people are that careless with their stuff when it is well known how roughly packages are treated then that is completely their fault.Reply

Surely I can't be the only one that keeps the boxes for things like my GPU? If I ever need to transport it anywhere (like when moving down to uni and back) it comes out of the PC and straight into it's original box with all the foam that's designed to keep it safe, mostly because of the size of GPUs now, having that in the PC when it is in the back of a van is just asking for something to break, it's a lot of mass to be flexing up and down. -

A Stoner Hard to believe that is a professional who is using a carpet as a background and in fact drags the latest to be saved video card across that carpet.Reply