Let's Take a Trip Inside Low-Cost Power Bars, Part One

Inside The Noma

I know these power bars look awfully similar overall, but this one appears to be identical to Electro's, right down to injection-molding hole placement. They do have different outer bottom molds though. Noma employs bilingual warnings, while the EL543 only has English. Moreover, the Noma lacks a 10m/30' warning. The more obvious differences include cord length, colors and surge suppression energy ratings.

What do UL listings have to say about that? When I picked up both bars to check listings, it turned out both the Noma and Electro power bars actually had the same UL file number: E302504. After taking another look at the rear covers, both also sport the same molded FL-25S model number on the UL listing. The sticker does show different design numbers for the two bars, however.

This begs the following question: if the two bars are similar enough to share practically the same molds, base model number and UL listing, where does Noma's bar gets its 312J surge rating instead of the Electro's 90J rating? Time to take a second look at those MOVs.

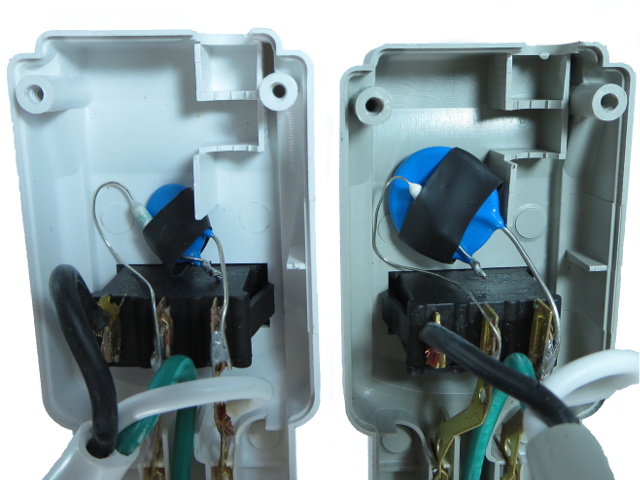

Duel Of The Twins: Electro Vs. Noma

A side-by-side look at the MOVs inside those two bars makes the difference fairly obvious: after pushing the cables and heat-shrink aside, the Electro variant reveals a small Ceramate GNR-14D201K MOV with 70J rating and 115°C thermal fuse, while the Noma was hiding a Hongzhi HEL-20D201K MOV with 160J rating and 102°C thermal fuse. The Noma's MOV can handle over twice as much surge energy as the Electro, but 160J is only half the 312J claim on Noma's packaging.

While this may look like false advertising at first, you need to keep in mind that 10 meters thing I mentioned earlier: during a 3000A surge, the building wiring and power cord will actually dissipate nearly as much energy as the MOVs themselves due to resistive losses, and this does double the effective rating.

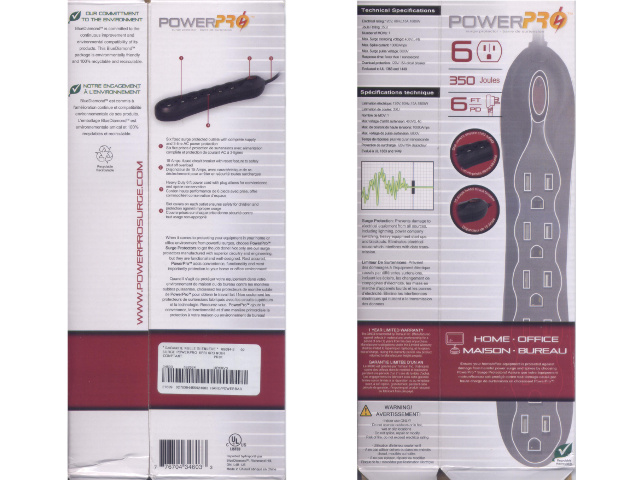

Our Fourth Contestant: BlueDiamond's PowerPro

This is the funkiest-looking bar in the first round, which I picked up from the nearest computer store as its cheapest unit in stock. This one also happens to be one of the two most expensive units overall. The key distinguishing feature is child-proof outlet shutters: it is the only unit in this round-up to have those. Its rear cover features UL's holographic sticker and the usual warnings molded in the recessed area.

Diamond's Packaging

With the amount of marketing fluff on this packaging, you might expect good things out of it. When you actually read the copy, though, expectations drop considerably. The amount of text makes it look like the bar has many features, but most of them are stuff that any remotely decent power bar should have, such as a three-wire power cord. Some of the wording seems to imply surge protection across all wires, but the specification area clearly indicates only one MOV is actually in there.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The company should have spent more space marketing what is unique about the bar instead of drumming up basic features.

Cleaving The Diamond

Out of my four locally-bought power bars, this is the only one featuring security screws. Ever had friends or family ask why you own so many odd-looking bits they have never seen a use for? This is one of those occasions when you get to tell them, “See? I am using them now.”

In the background, you can read the indoor-only and do not plug into other power bars warnings.

Cut Diamond

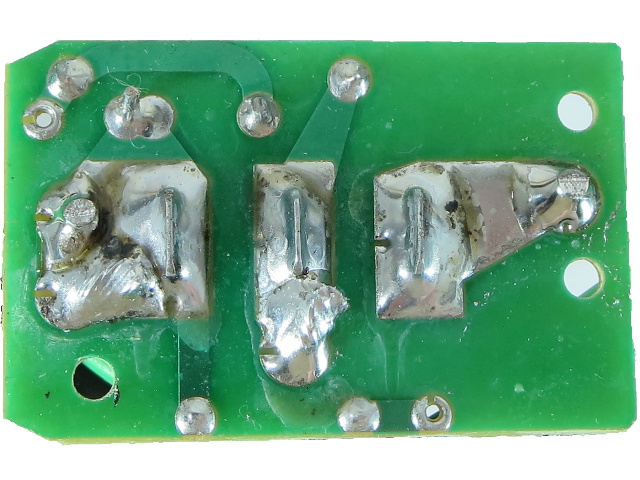

This is also the only unit of this round that actually has a PCB inside to host the breaker-switch-indicator unit, the MOV and thermal fuse. Since the MOV's markings are flat against the switch, the only writing I can see is GNR and 01K, which is enough to conclude it must be a GNR 20D201K. Wires are attached to their respective strips using solder, and the ground strips are the same story as before except they are flipped upside-down and secured to the body for easier assembly by melting down plastic pins.

Diamond's PCB

One thing that Diamond will not get accused of is being a Scrooge with the amount of solder it put on the board, though the company could have held back a little on the solder flux if it didn't intend to clean it. With this much contamination on the PCB, creepage (the effective clearance after accounting for contamination) could become an issue.

I am expecting most major-brand power bars to use isolation slots to eliminate surface contamination as a potential issue by removing the surface altogether.

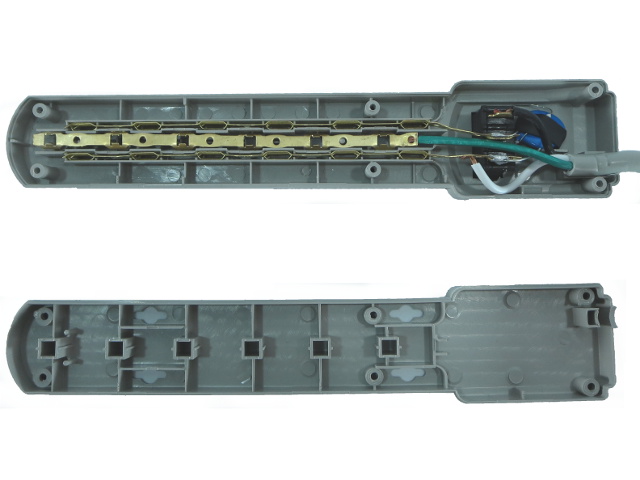

Diamond Strips

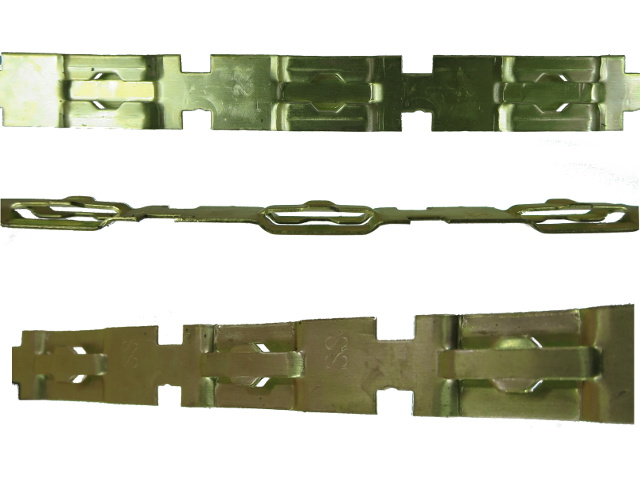

The live and neutral strips have a slightly different stamping pattern with “wings” on the middle part and subtle ribbing on the other two. The power and neutral strips are beefy at 0.6mm thick and 9.5mm wide, but the necked-down areas are only 4.8mm wide, which is still much better than the three other units so far. Its ground strip is approximately 3mm wide at its narrowest by 0.4mm thick, which is par for the course.

Child's Play

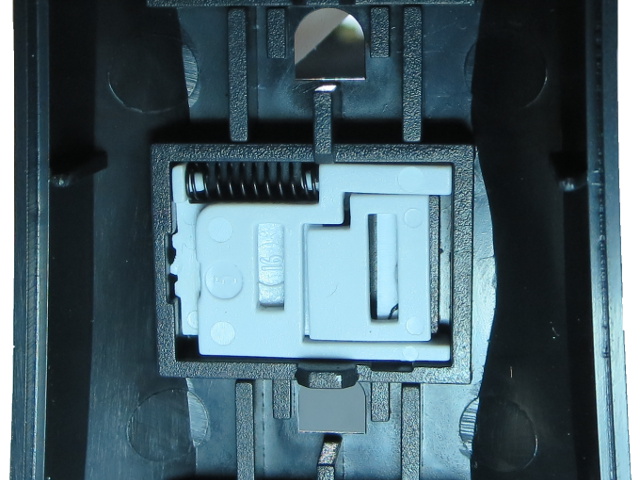

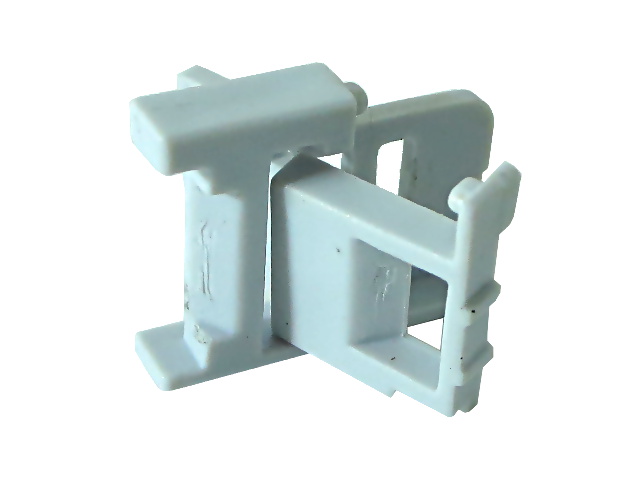

The childproofing mechanism consists of two interlocking plastic tabs and a small recall spring. For plug prongs to get through, each blade needs to push against the corresponding wedge-shaped slot to move its cross-linked shutter out of the other blade's way, making it very difficult to insert anything in the outlet by accident. If this is not clear to you, the next slide shows how the two shutters come together from a different angle which might help.

Hitting A Snag

One disadvantage with those shutters is that unless you hit them at just the right angle with smooth-tipped plugs, chances are that the plug's tips will dig into the plastic and slowly gouge it out. Those scratches and gouges make future insertions rougher, wear will accelerate with use and they will eventually break off.

This shutter has only been exercised twice with the bar's own plug. The left part already carries two noticeable marks and the right part's wedge looks slightly pitted near the middle.

-

qlum This article makes me wonder how well my own no brand power bars fare but I don't have the expertise to know what to look for when opening them and they probably look failry different from the US ones as well, at least they do on the outside. We use the german plugs here and also 230v is probably making a difference as well.Reply -

srap @qlum: I believe Tom's has a german branch, maybe we should ask them to do the same with europlugs.Reply -

Shin-san There has been several things I bought from Sunbeam, and I'll never buy from that company again (Sunbeam, Oster, Jarden, and Holmes). Their stuff simply doesn't last.Reply -

hp79 This article format really sucks. I click on "see more" just to see few more words.Reply

The article however is informative. Thanks for the write up. -

CaedenV @HP79Reply

Ya, the team that run's Tom's website really REALY sucks, the commenting section in IE sometimes doesn't show up, sometimes it shows up but you cannot do quotes, and sometimes you hit submit and it just gets lost in space. Clicking on a picture on any other website on the internet will take you to a larger or better quality picture, but on tom's the linked picture is often smaller/worse than the picture in the article. These kinds of picture+text articles are by far the worst though, offering minimal readability combined with smallish pictures. And we will not even get into how broken the Tom's charts are... it is just sad. And using Tom's without some sort of ad-blocking is an absolute nightmare! Tom's is the reason I use ad-blocking extensions in all of my browsers because it became such a hassle so early on.

But the content on Toms is often golden, and the data is both accurate and well explained. Not to mention that the community is amazing. It is more than worth putting up with a broken web page when the content is so good. -

Niccodemure Thank again. I am really looking forward to the name brands and hope they include Monster, PSaudio, Panamax, thurman, APC,Reply -

Flying-Q In the UK most power bars are unprotected, but there is a limit to the number of outlets you can expand from a single wall socket and most houses have been uprated to full RCCDs in the consumer unit supplying a ring main. Sadly, many people do not know of the 'max-4-expansions-per-socket' rule and 6-socket bars without protection are available to buy at hardware stores and supermarkets. That said, every UK plug must have a built-in wire fuse with 13A rating, or 5A or 1A depending upon the equipment.Reply -

Daniel Sauvageau Reply

This roundup was for sub-$15 power bars - all nine of them.14656840 said:Thank again. I am really looking forward to the name brands and hope they include Monster, PSaudio, Panamax, thurman, APC,

The goal was to show how much (or little) of a difference there is between inexpensive power bars with surge suppression ratings of some sort.