Tom's Teardown: SilverStone UC01 USB Power Adapter

Time To Impro-Vise

How do you crack a welded seam without obliterating everything underneath? By carefully applying and cycling pressure along the seam, hoping that it yields somewhere.

Here, I used a pair of screwdrivers to focus my clamp's pressure on top of the seam. But the seam turned out stronger than my improvised vise. A bench vise (which I don’t have) would have been a more appropriate tool for this job.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

Mini-Vise

After my first idea failed, I rummaged through my toolbox and dredged up a mini clamp-vise wide enough to comfortably fit the adapter. After a minute or two of adjusting the clamp and cycling pressure at different spots around the enclosure, one of the seemingly seamless edges popped apart.

From there, I worked the seam around the enclosure with the vise some more, re-opened the parted seam, wedged a flat screwdriver in there, used it as a lever, and was rewarded with a loud crack accompanied by my vise going slack.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

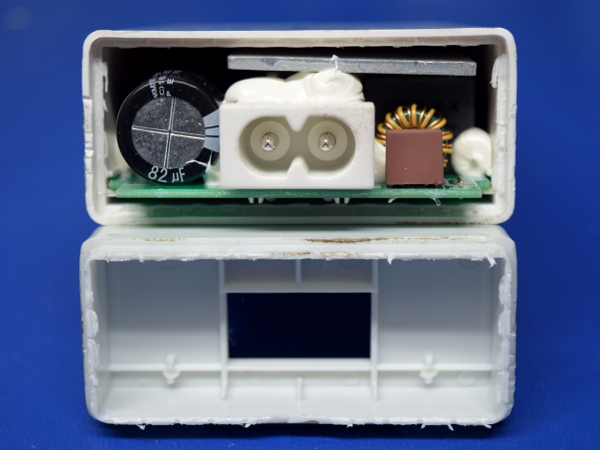

First Peek

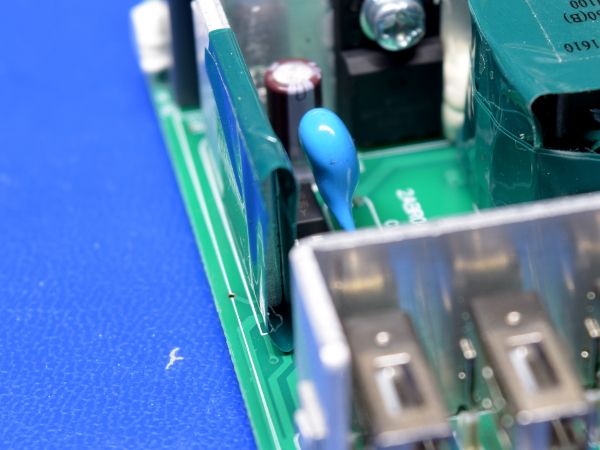

Here we are with the seam cracked apart. Welding along the top and bottom sides appears to have happened mainly on the inner ridge, while the thin sides are welded mostly along the outer edge (more so on the left than the right). This explains why the narrow sides had little to no visible seam.

Although some effort was made to secure the power cord connector using Silastic or an equivalent, soldering it directly to the board could still be a durability concern due to mechanical stress on solder joints every time the cord gets plugged/unplugged or tugged.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

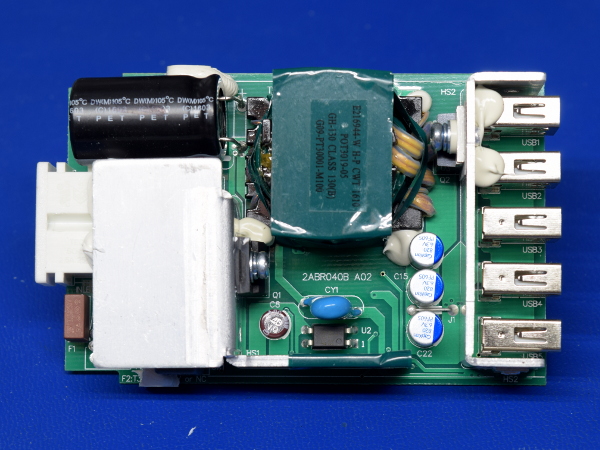

PCB Top

The board area is dominated by the primary side switching transistor’s heat sink, the flyback transformer, the output rectifier’s heat sink, five ports, and the primary side’s bulk storage capacitor.

Based on the characteristic green tape and CWT marking on the transformer, I’ll hazard a guess that this unit was designed and manufactured by Channel Well Technology.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

Different Volume Classes

What's the difference in transformer size between an unsafe 1A adapter that can barely deliver 600mA and a presumably safer adapter capable of delivering 8A? The UC01’s transformer alone is about as big as the entire generic 1A adapter, enclosure included. The transformer E-core dimensions themselves are nearly twice as long, twice as thick, and three times as wide. I’d eyeball the volume difference in the ballpark of 12x. Even its 82µF input capacitor would be too big to fit in the A1265’s shell!

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

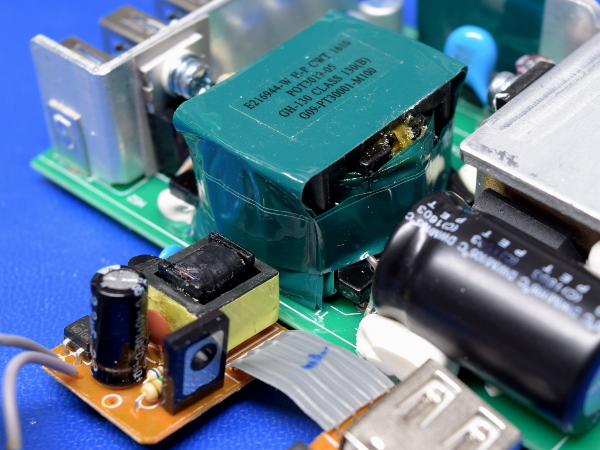

Doing It Right On The Primary

All transformer conductors going to the two primary-side windings are sleeved between their respective pins on the coil form and (hopefully) wherever they go within the transformer, as they should be. This looks promising for the 5kV isolation withstand test.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

Not Taking Chances On The Secondary Either

All conductors from the coil form’s secondary-side pins to what appears to be two windings on the secondary are also sleeved for safety. CWT’s green tape is much thicker than what was used in the fake A1265, and the gloss I see between tape layers seems to indicate that winding layers may have been lacquered. You can see some of that sheen above the top-most wire where it comes out of the E-core. To minimize wiring losses, the high-current output winding is composed of four wires. There is also an unexpected additional secondary winding with thinner-gauge wires visible at the bottom.

Everything within reason appears to have been done to make this design safe. I will be disappointed if the transformer fails to survive the isolation withstand test.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

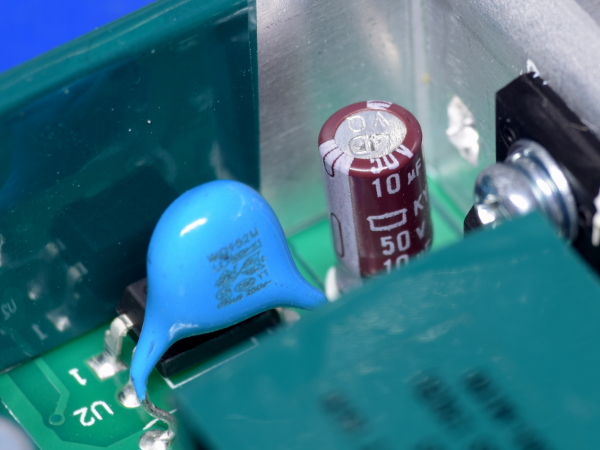

Proper Caps

What do we have here? It appears to be a real 1.5nF Y1-class (that’s 8kV pulse rating) capacitor that should have no trouble surviving my 5kV withstand test next to a 50V, 10µF Chemi-Con KY-series for the primary side’s auxiliary supply. Though it's far from being the greatest electrolytic capacitor at 1.5Ω of ESR, this cap should still be more than good enough for a rail that does little more than power the PWM controller.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

Tape-Out

With the primary-side heat sink extending well into the low-voltage output area, accommodations in the form of at least two layers of tape over-hanging the heat sink by about four millimeters had to be made to ensure that sparks wouldn't jump from the heat sink to traces passing under it.

Is this encroachment really necessary? I doubt the additional ~15mm of tape-covered sheet metal contributes much to cooling inside a practically airtight plastic housing.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters

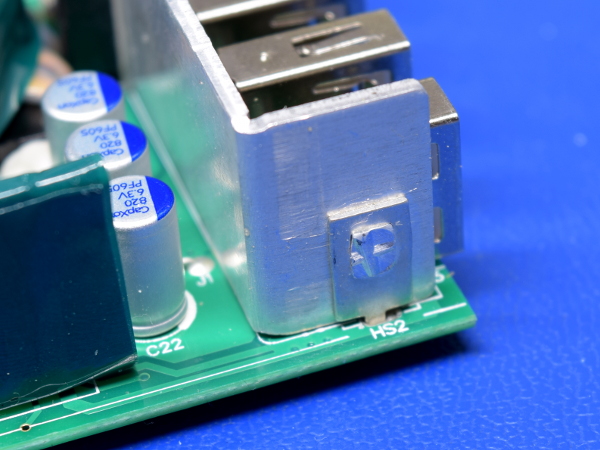

Staked-Out

As is quite common in power supplies, large heat sinks have extra stake-down points to help secure them and relieve stress from component pins. Next to this sink, a trio of 820µF, 6.3V CapXon PF-series polymer capacitors provide the bulk of the UC01’s output filtering. At 9mΩ of ESR apiece, ripple performance should be quite good, despite the lack of an output filter inductor.

MORE: APC BN650M1-CA UPS Tear-Down

MORE: CyberPower EC350G Tear-Down

MORE: How (And Why) We Test USB Power Adapters