AMD Ryzen 5 2400G Delidded: Solder vs. Thermal Paste vs. Liquid Metal

Test Results & Conclusion

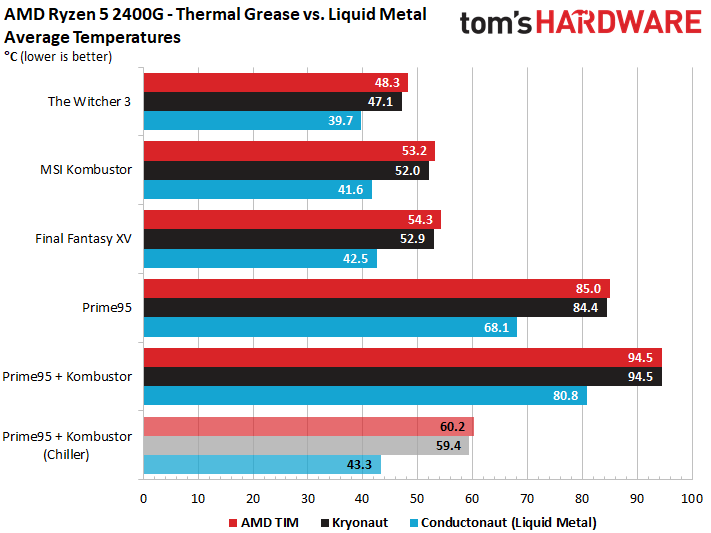

Temperature & Power Consumption

Our thermal data yields a couple of surprises. First, the paste that AMD uses between its die and heat spreader performs better than we believe a lot of enthusiasts were expecting. Second, it'd be hard for anyone to improve on the stock configuration, since the paste is applied so thinly to the heat spreader during production.

Gluing the heat spreader under pressure furthermore ensures an optimal result. When we carefully removed the original layer of thermal paste, we took note of how much AMD used and replicated its effort with our own high-quality stuff. Upon removing the heat spreader a second time, we confirmed that our application looked just about as perfect as AMD's.

Nevertheless, we did not succeed in achieving a noticeable advantage over the original paste's performance. Not even a burn-in over several hours helped to significantly improve our findings. The hotter Ryzen 5 2400G became, the smaller the already tiny difference got. In addition, when we used the boxed cooler, both applications of thermal paste failed to keep AMD's chip from hitting its thermal limit with Prime95 and MSI Kombustor running. Naturally, then, replacing the stock paste with another silicone-based paste is pointless. AMD makes the best of its position by achieving optimal performance within the framework of industrial mass production and pressure to cut costs.

Our modification using liquid metal is another story entirely: it's the best solution, no doubt about it. The temperature differences range from ~9-11°C during gaming. Though, to be honest, the effort required is a little excessive given our results. It's not like thermals were a big issue to begin with, even under overclocked settings. Temperatures are only a limiting factor with stress tests running, and in those cases, the liquid metal does help by up to 17°C.

Liquid metal only makes sense if you're operating within the absolute upper range of this processor's limits. Otherwise it's merely nice to have.

The boxed cooler hardly gets any quieter, either. A rather humble drop of just 135 RPM (at best) during normal operation doesn't significantly reduce the background noise we described in our launch article. Under full load, this benefit shrinks to a 40-50 RPM improvement, which is hardly distinguishable at all.

The conversion would definitely be worthwhile if you replaced the cooler with a quieter version and installed the chip in a small form factor chassis without good airflow. Then, the temperature delta could be the difference between what works and what doesn't. But for everyone else, the time and money won't net an appreciably better outcome.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

We can't really fault AMD here. After all, the competition uses thermal interface material on its highest-end CPUs aimed at enthusiasts. At least for that market, AMD still applies solder.

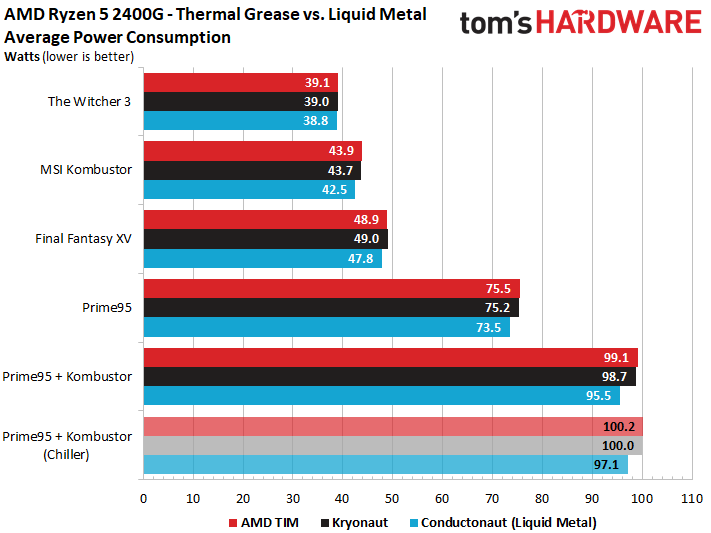

Power consumption comparisons between the two thermal pastes are pretty much identical; measured differences land within a margin of error.

Power consumption doesn't drop unless the temperatures fall significantly first. Even then, a maximum of 3W in an extreme case is not exactly earth-shattering. Perhaps if our sample hadn't throttled, the values would be a bit higher. It is also worth mentioning that, apart from the stress tests, CPU and GPU frequencies change very little. In no case is it possible to achieve a significantly higher clock rate by following our footsteps. Even during our stress test, Ryzen 5 2400G doesn't achieve an average gain of more than 75 MHz with liquid metal.

Summary & Conclusion

Yes, replacing AMD's paste with liquid metal works well, facilitating improved thermal performance compared to a stock Ryzen 5 2400G. It's just too bad that you won't see much of a practical difference. There's not much added value, and AMD's processor is neither faster nor more power-friendly in the end.

The only measurable benefit is lower temperatures. Unfortunately the boxed cooler is not really able to take full advantage of lower temps without changes to its fan profile. Hours of work, notable risks, and minimal benefits just don't balance out. Thus, this modification is only worth considering if you're building a seriously compact PC.

Our findings may give you reason to complain about AMD's cost-cutting or praise the company for its execution. At a financial level, AMD made a reasonable decision. But when it comes to enthusiast mind share, shifting over to thermal paste is bound to raise eyebrows. On the other hand, are gamers buying eSports-ready PCs likely to argue about what's between their dies and heat spreaders?

MORE: Best CPUs

MORE: Intel & AMD Processor Hierarchy

MORE: All CPUs Content

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

AgentLozen You guys ran a delidding article (http://www.tomshardware.com/reviews/kaby-lake-de-lidding-overclocking-test,4970.html) similar to this a while ago for Intel chips. It's focus was measuring the difference between a stock i7 7700k and a delidded one. The article showed how much further the 7700k could overclock when you replaced Intel's TIM. I liked it a lot.Reply

I was hoping this article would similarly show how much further the 2400G would overclock after replacing the TIM. The conclusions that this article reached were interesting. It shows that the TIM AMD uses is pretty good but it was a little anemic otherwise.

edit: changed some wording -

damric AMD has always used paste on APUs. Nothing has "shifted". Even the FM1/2/+ were pasted.Reply -

FormatC Reply

Did you really read the launch review and this one? The barrier for a higher overclock is NOT the temperature. This is an AMD APU and we overclocked it also on the launch review to the stable maximum. And the conclusion said: you get it cooler, but not faster. That's a fact. Intel CPUs are temperature limited, this one not.20721981 said:...

-

BulkZerker @damricReply

AMD used solder for their latest midrange / HEDT chips and that is a very well known fact. -

Nintendork What I want to know is what's the cost of indium solder vs thermal paste per cpu/apu.Reply -

Nintendork We know the answer more or less.Reply

A $7 TIM will probably last you for 10 builds. In a worst case scenario TIM should cost $1 per unit and solder.. $1.5?

Is it really justifiable? I don't think anyone will cry about paying $1-2 more. -

Nintendork @FORMATCReply

The barrier for all current Ryzen is not the cpu or the arch, por temps or power consumption IS THE NODE PROCESS.

It's 14 LOW POWER PERFORMANCE (LPP) which is made to have a high efficiency at low clocks sacrificing a higher wall for base/OC chips, the 12nm LEADING PERFORMANCE (LP) lets you have higher frequencies without sacrificing efficiency.

All Ryzen 2000 cpu's (Non APU) will have around 300Mhz more with the same power consumption) and should easily allow for 4.5Ghz OC~. -

Gillerer Reply20722224 said:@damric

AMD used solder for their latest midrange / HEDT chips and that is a very well known fact.

Damric was talking about APUs - meaning earlier AMD CPUs with integrated graphics - and was comparing these new offerings to them. Ryzen and Ryzen Threadripper definitely don't belong in that product category. -

AgentLozen ReplyFormatC said:Did you really read the launch review and this one? The barrier for a higher overclock is NOT the temperature. This is an AMD APU and we overclocked it also on the launch review to the stable maximum. And the conclusion said: you get it cooler, but not faster. That's a fact. Intel CPUs are temperature limited, this one not.

Thanks for the clarification. I read the review for the Ryzen 2400G, but I guess I missed that detail.

Edit:

I wanted to read more about the overclocking outcomes and limits in the 2400G launch article. What I found instead were optimistic projections about the overclocking capability of that chip. There are lines that read, "Overclocking with AMD's Ryzen Master utility is simple. The execution cores responded readily to our efforts, and the Ryzen 5 2400G floated up to 4 GHz with a 1.4V vCore setting. " and "Specifically, our Ryzen 5 2400G sample overclocked easily.". I guess that's why I was expecting this article to take a different direction.

When I re-read the conclusion of this article I found that "Even during our stress test, Ryzen 5 2400G doesn't achieve an average gain of more than 75 MHz with liquid metal. ". It's disappointing that the 2400G can't go much further than 4.0GHz. -

FormatC @Nintendork:Reply

Solder costs around 5 USD per CPU for the whole process, TIM is significant cheaper, this are only a few Cents. Don't compare the small end-user units and their pharmacy prices with industrial compound, delivered in big cans ;)

I know, that the node process is the reason for this freq wall and that we have no reason to discuss this thing in this review. The sense behind this testing was the question, what it can change (or not). All this crying about TIM and solder... It's simply boring. This is not a high-end CPU with an ultra-high density and a big power draw, it's an APU with a big die and a low power draw. We have no reason to beat AMD for this decision. And I bet: the real target group for this product doesn't even know the difference between TIM and solder. :)