Bloody B188 8 Light Strike Keyboard Review

Why you can trust Tom's Hardware

Teardown

We found that tearing down the bloody B188 was remarkably easy compared to many other keyboards (such as those from Corsair, Logitech, and Zalman). You simply remove the fourteen screws at the back as well as the extra one under the model sticker (which detaches and reattaches with no damage, smudging or loss of stickiness), and you’re in.

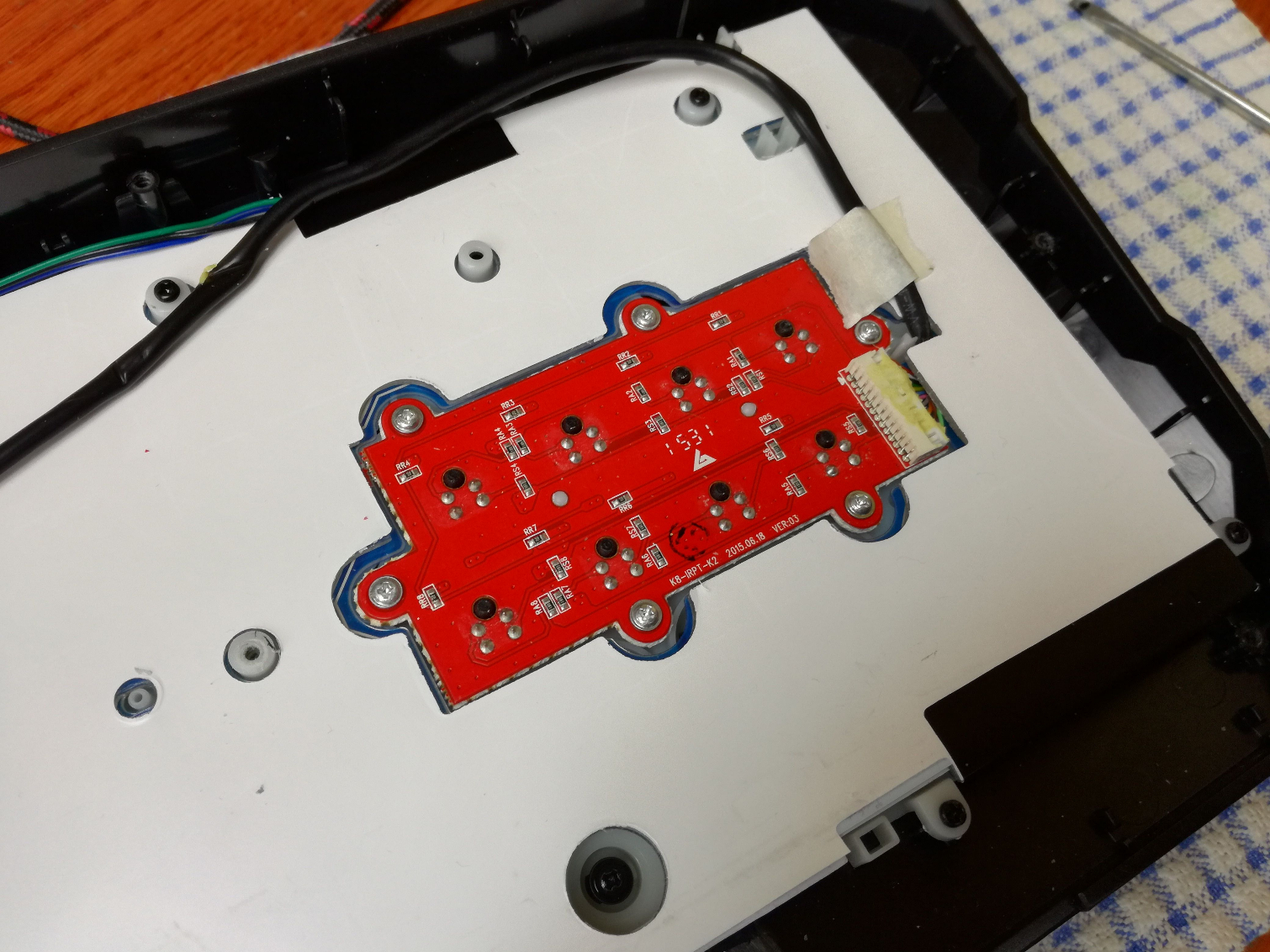

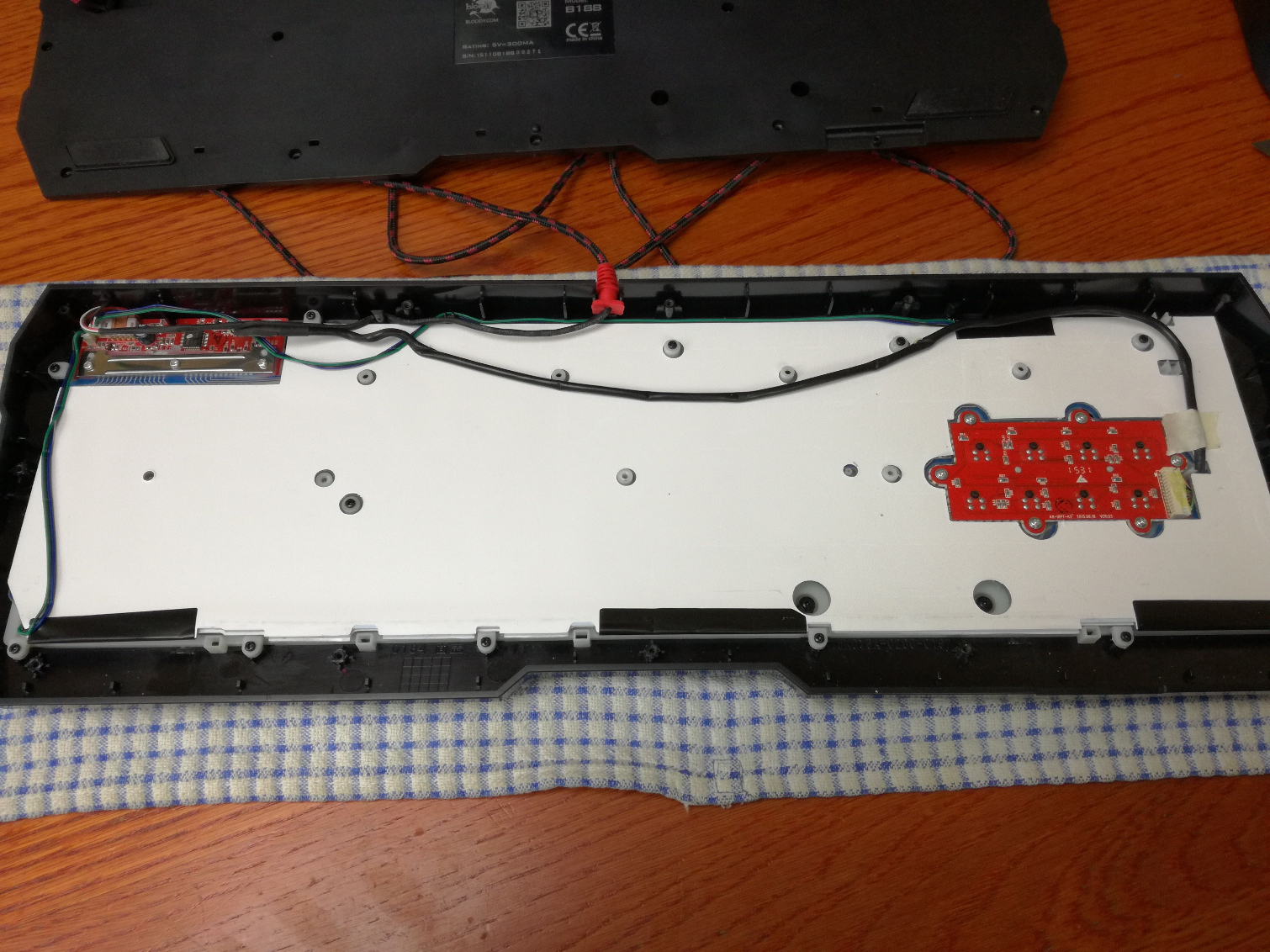

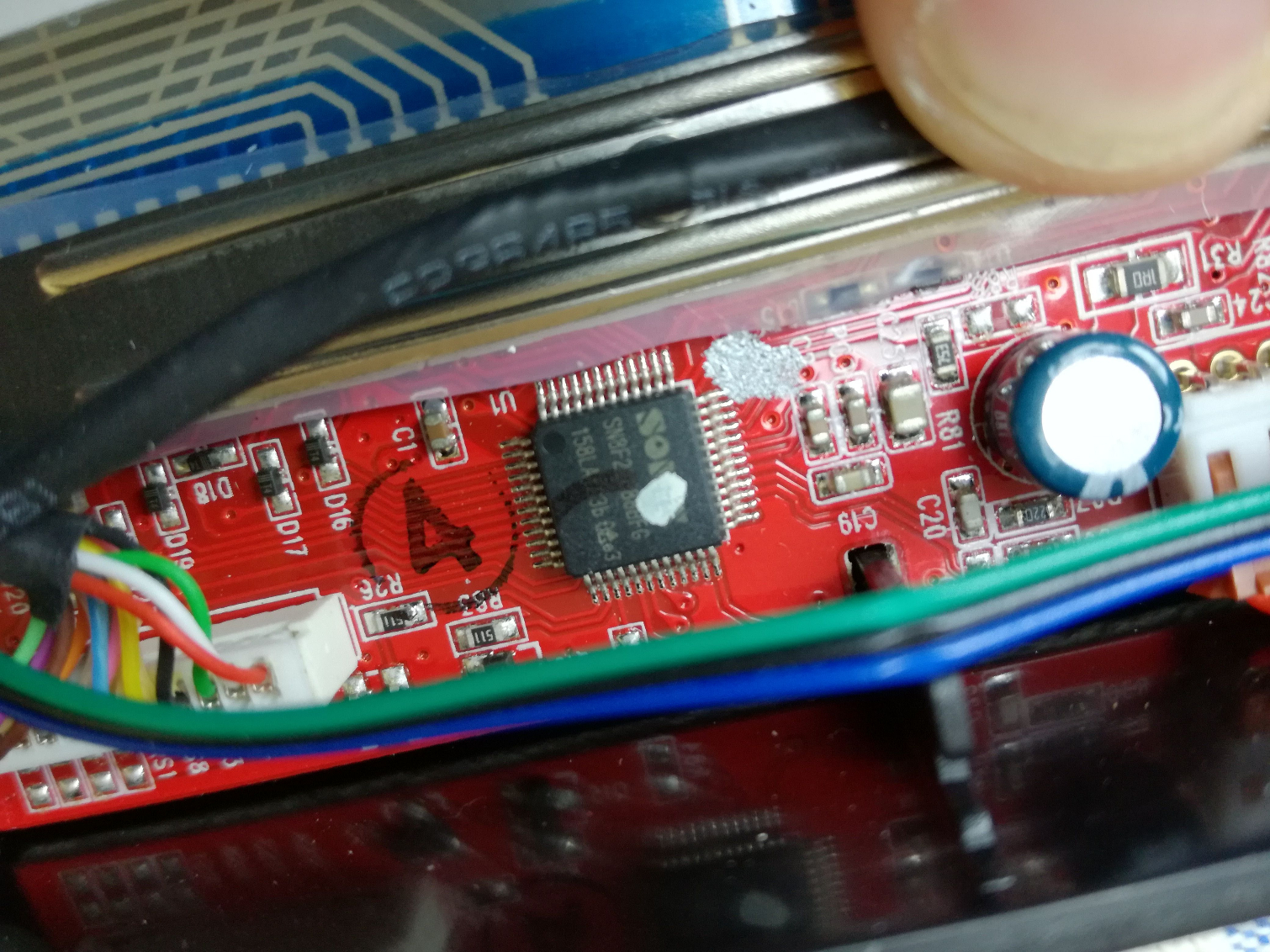

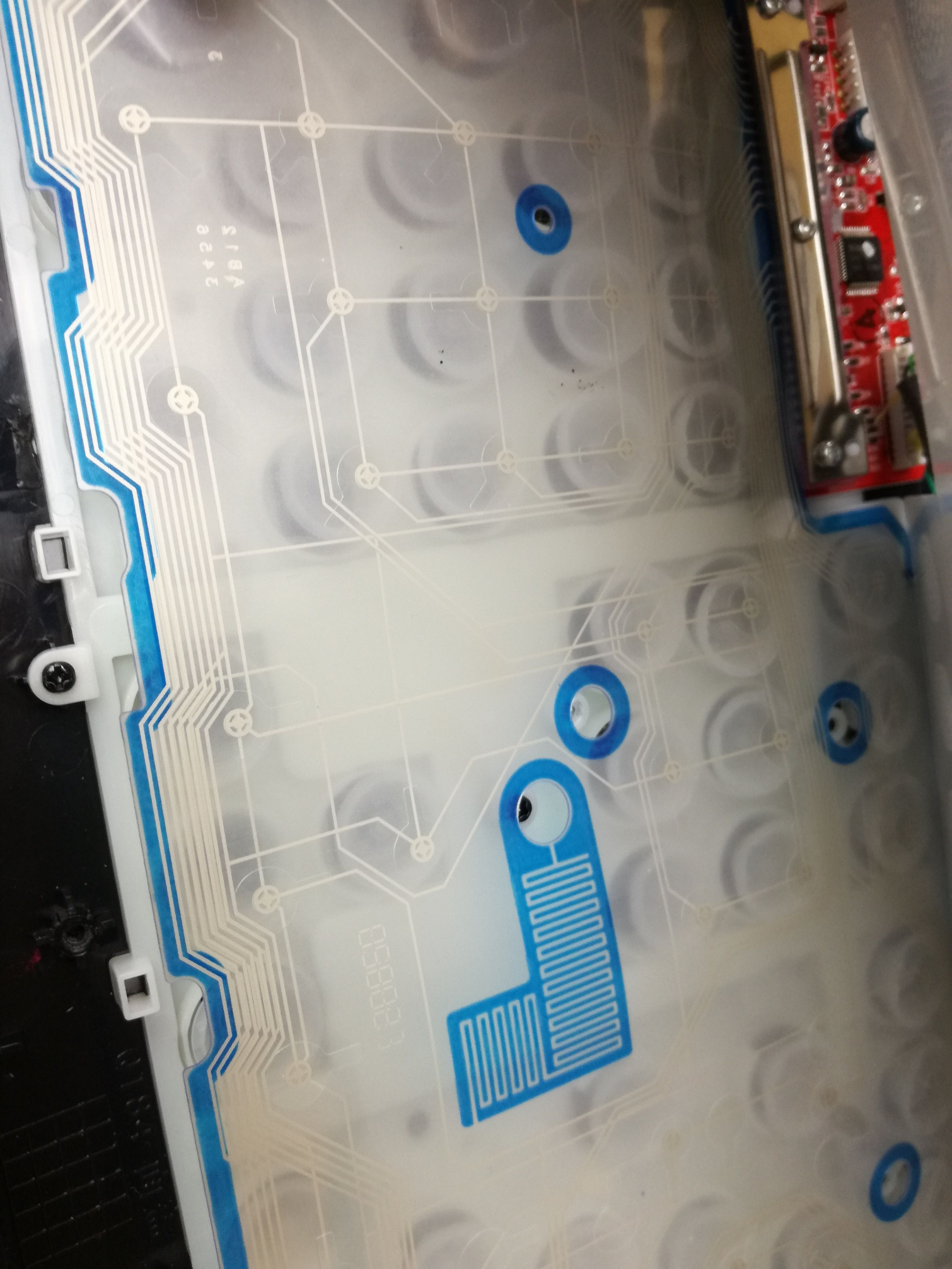

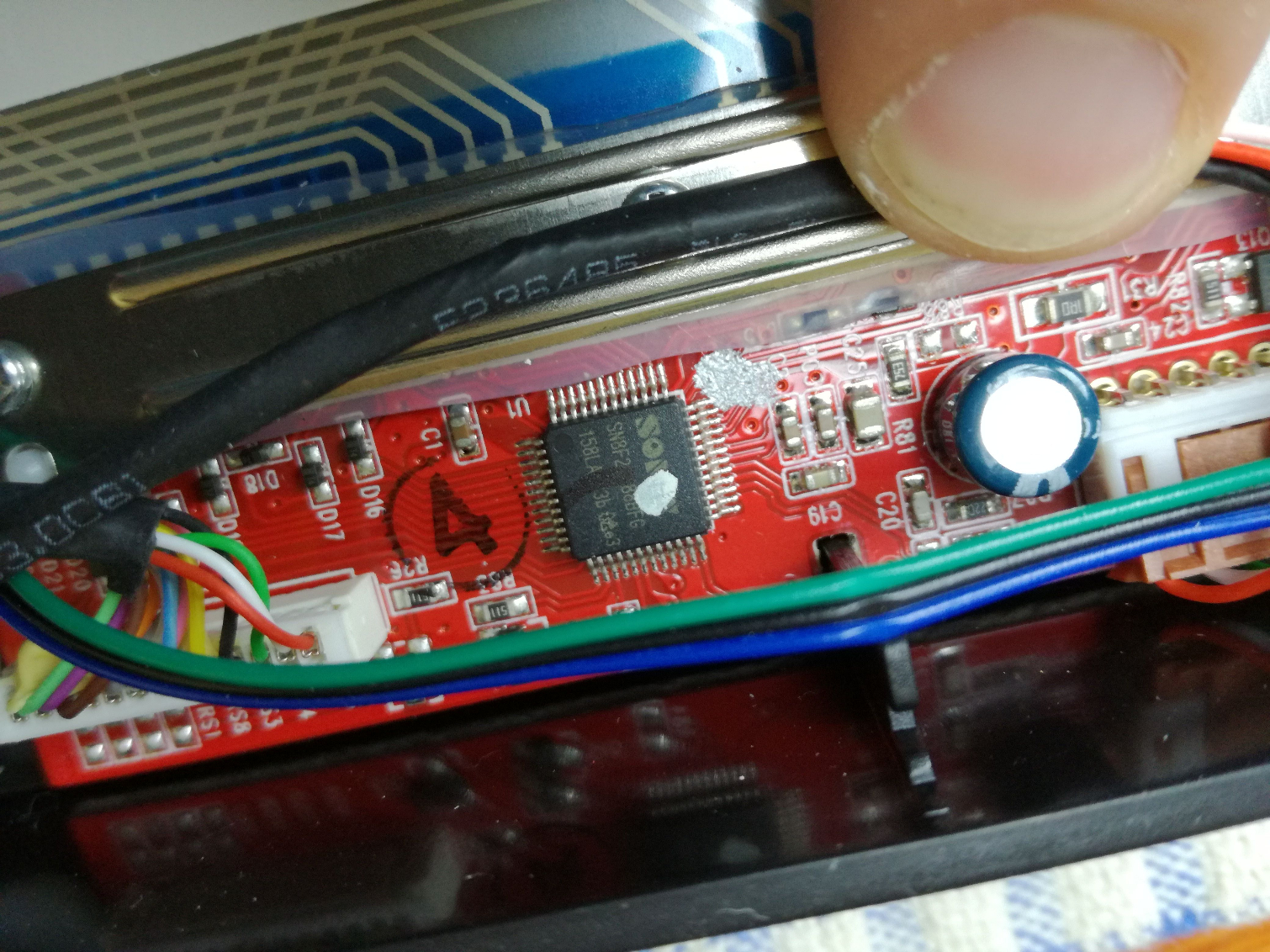

Inside, there’s a simple two-part case construction and several layers of membranes, topped by discrete rubber domes. There are two small PCBs; one is for the controllers and lock lights, and the other is for the LK Optic switches and is screwed into a hole in the membranes. As there is barely any solderwork present on the keyboard, it’s hard to comment on its quality, but we noticed no obvious imperfections.

The B188 is marketed as being water resistant due to being “double secured” - the membranes are sealed and there are water drainage holes - but the case is not sealed, and the controller and the PCB that mounts the optic switches do seem to be completely unprotected, so it’s unclear as to how these could survive in an aqueous medium. There are also no drainage channels that guide the water towards the holes, which in fact are raised out of the bottom case, so it appears most unlikely these will effectively clear out water.

The water-resistant feature should therefore be regarded with some suspicion. It should be noted that theoretically, optical switches should be more water-resistant than contact-based switches, although Bloody did not mentioned anything along those lines in the product description.

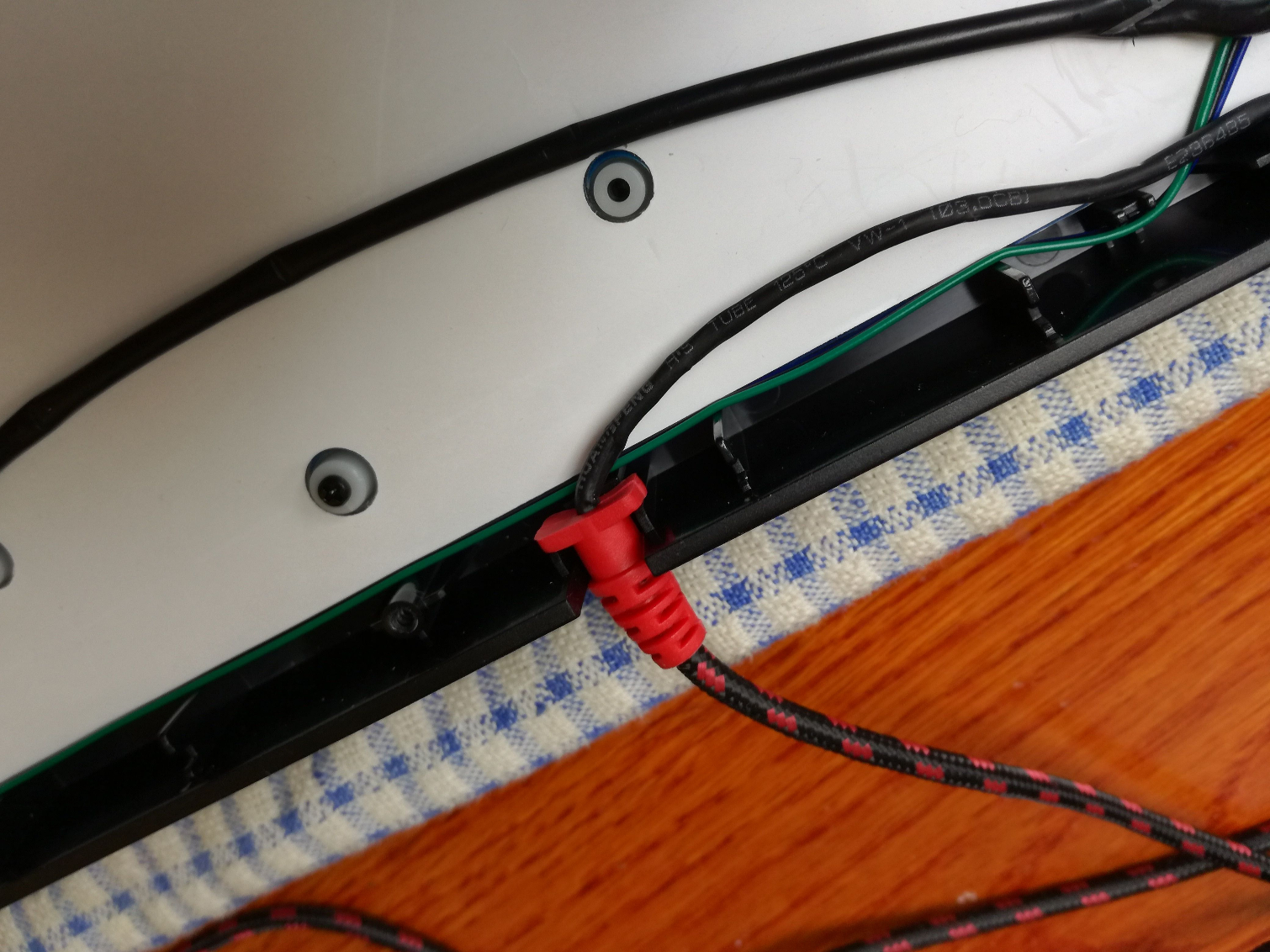

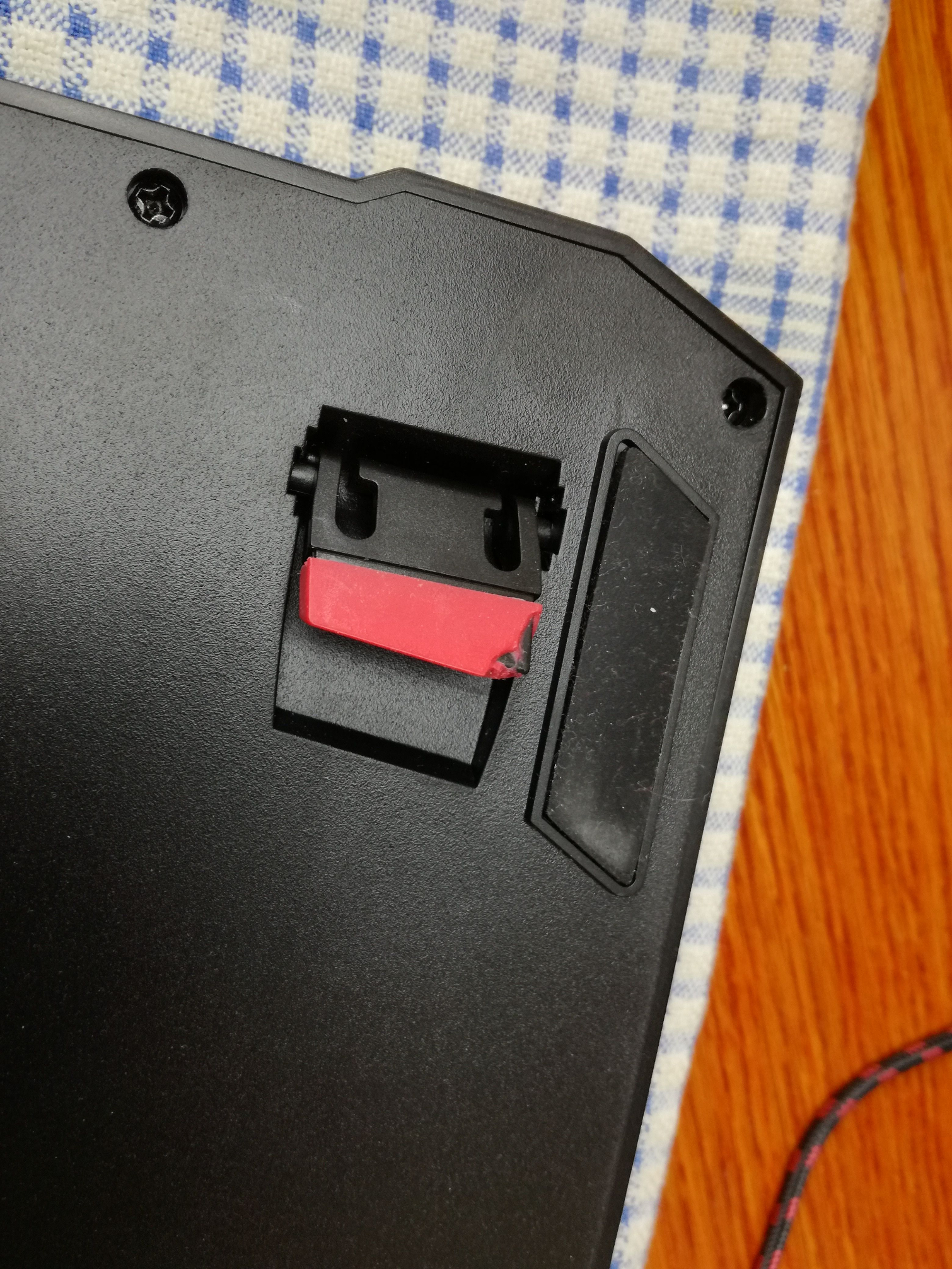

The flip-out feet (which are mounted sideways rather than vertically) are rubber-shod to aid with stability. It’s a nice feature that helps prevent the keyboard from slipping. However, the rubber used is rather hard, and after just a week or so of use, one of the feet on ours had partially crumbled.

As you can guess from the B188’s low weight for a fullsize keyboard (under one kilogram), there are no metal plates present in the keyboard, and very little in the way of added rigidity or structural integrity. At 2.5mm thickness, the plastic of the case is not the thinnest out there. Neither the strong flexing the keyboard displays when you twist it nor the all-plastic construction inspire much confidence in the build quality.

The B188 also features a “screw enhanced” spacebar, which is a feature we’d never heard of before. When we inquired about its purpose, Bloody responded that it was used for anti-knocking resistance purposes, which honestly didn’t help me much. After the teardown, it became clear that this boils down to the spring holders being screws rather than loose pegs, as is common on other spacebar designs. Regardless, it’s unclear to us how this design is beneficial.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

MORE: Best Deals

MORE: How We Test Mechanical Keyboards

MORE: Mechanical Keyboard Switch Testing Explained

MORE: All Keyboard Content

-

ZRace Chinese marketing is just ridiculous. Apparently nobody cares what the marketing says about a product over there, so they just threw together some random keyboard stuff to appeal western clients (that's at least how it reads).Reply

In the end, I'd very much like a review of a fully optical keyboard, as it seems those might be quite interesting! -

shrapnel_indie ISO or modified ISO isn't the key layout I prefer. (Give me an ANSI layout.) I think, for me though, the biggest issue for it (besides layout preferences for me) is that this specific model is mostly (vast majority) membrane keys, I like the price, but if I hunt hard enough, I can get a cheap fully mechanical keyboard.Reply -

hauser01 I have both the BLOODY B188 and the corsair K70 RGB red mechanical switches .The Bloody B188 is much more responsive (faster response) WASD keys than Corsair in game. You can actually see and feel the difference . For normal every day typing computing i see no difference.I purchased 2 B188 on sale for $10.00 each.It has been 8 months and the B188 works as new i play online 12 to 15 hours a day.I recommend the B188 for gamers every were as it takes a beating and still works great. I have Razer ,corsair and logitech i would buy this keyboard over those companies any day. I as well have the Bloody V8 mouse and it is awesome as well. I no longer use my G502 Proteus core its a good paper weight now .Reply -

Blazer1985 -Honey where is your mouse?Reply

-It's right next to my bloody keyboard

-Ok... calm down... -

grumpigeek There has been a lot of focus here lately on mechanical keyboards.Reply

I am not a gamer but would like a simple standard, full size backlit keyboard.

I don't need a wireless keyboard and want the F1 to F12 keys illuminated as F1 to F2, not just the alternative functions like the Logitech K740 does.

The Logitech K800 looks OK but seems very expensive.

I was wondering if there are any other options. -

cryoburner Reply19965878 said:I purchased 2 B188 on sale for $10.00 each.It has been 8 months and the B188 works as new i play online 12 to 15 hours a day.

Welcome to the site, person who just joined the other day and will probably never be heard from again. : P

I do question whether someone who games for 12 to 15 hours a day would use a keyboard they got for $10 though. Also, these aren't normally $10 keyboards. At $10, they could be a great value for a rubber dome keyboard with some enhanced gaming keys. Even at around $25 they might be an alright product for someone looking for an inexpensive gaming keyboard. The problem is that this keyboard is currently priced $40 on Amazon, with $80 listed as its supposed MSRP, and on Newegg its priced $55, with a $100 MSRP, and those prices are a lot less competitive considering that most of the keyboard isn't even mechanical. You can find quite a few fully-mechanical keyboards on Amazon with cherry-clone switches for around $40 or less, so paying that much for just a handful of mechanical keys on an otherwise rubber-dome keyboard seems a bit much.

Also, on that topic, it would be nice to see Tom's Hardware do a roundup of cheap mechanical keyboards in the sub-$50 range. It would be interesting to see how these keyboards compare to those costing two or three times as much. Is the variance between switches substantially worse? How does the overall build quality compare? I get the impression that there may be some keyboards in that price range that are nearly as good as some of the higher-priced models. -

ZRace Reply19979230 said:Please go to the BLOODY website

While I can sort of agree with what you're saying, I don't with this part.

After all that has been said about the marketing from Bloody in this article, I wouldn't trust anything stated on their website. Better search for independent tests in this case. -

shrapnel_indie Reply19979230 said:How old are you 12 or is that your IQ .

Whoa. That was quick. Toes stepped on? He was just questioning, not attacking you personally.

Unfortunately for you, the only people I know that react like that, are usually not very mature and/or have no real facts to back up what they say. Should I accuse you of falling in that group? Should I accuse you of being a paid shill for your promotion of the BLOODY brand of keyboards? If I was to do so, not really knowing you and only basing it on two messages, wouldn't say much of me. (Personally, I don't see the Bloody B188 8 keyboard worth more than $25 USD and not worth it for my usage. But that is beside the point.) Please show me that you're better than those types.

-

rgd1101 Reply19980484 said:19979230 said:How old are you 12 or is that your IQ .

Whoa. That was quick. Toes stepped on? He was just questioning, not attacking you personally.

Unfortunately for you, the only people I know that react like that, are usually not very mature and/or have no real facts to back up what they say. Should I accuse you of falling in that group? Should I accuse you of being a paid shill for your promotion of the BLOODY brand of keyboards? If I was to do so, not really knowing you and only basing it on two messages, wouldn't say much of me. (Personally, I don't see the Bloody B188 8 keyboard worth more than $25 USD and not worth it for my usage. But that is beside the point.) Please show me that you're better than those types.

Next time just alert the mod, with the

hauser01, read the forum rule.

http://www.tomshardware.com/faq/id-2668512/tom-forums.html

http://www.tomshardware.com/forum/id-2083458/read-forum-rules-styling-posts.html