Sponsored by QUE Publishing

Hard Drives 101: Magnetic Storage

Capacity Measurements, Areal Density, And PMR

Capacity Measurements

In December 1998, the International Electrotechnical Commission (IEC)—the leading international organization for worldwide standardization in electrotechnology—approved as an IEC International Standard the names and symbols for prefixes for binary multiples for use in the fields of data processing and data transmission. Prior to this, a lot of confusion had existed as to whether a megabyte stood for 1 million bytes (106) or 1 048 576 bytes (220). Even so, these new prefixes have yet to be widely adopted and confusion still reigns. The industry-standard abbreviations for the units used to measure the capacity of magnetic (and other) drives are shown in the following table.

Standard Abbreviations and Meanings | |||

|---|---|---|---|

Abbreviation | Description | Power | Value |

K | Kilo | 103 | 1000 |

Ki | Kibi | 210 | 1024 |

M | Mega | 106 | 1 000 000 |

Mi | Mebi | 220 | 1 048 576 |

G | Giga | 109 | 1 000 000 000 |

Gi | Gibi | 230 | 1 073 741 824 |

T | Tera | 1012 | 1 000 000 000 000 |

Ti | Tebi | 240 | 1 099 511 627 776 |

P | Peta | 1015 | 1 000 000 000 000 000 |

Pi | Pebi | 250 | 1 125 899 906 842 624 |

According to this prefix standard, 1 mebibyte (1 MiB = 220 B = 1 048 576 B) and 1 megabyte (1 MB = 106 B = 1 000 000 B) are not equal. Because these prefixes are not in widespread use (and they might never be), M in most cases can indicate both decimal millions of bytes and binary megabytes. Similarly, G is often used to refer to decimal billions of bytes and binary gigabytes. In general, memory values are expressed by using the binary values, although disk capacities can go either way. This often leads to confusion in reporting disk capacities because many manufacturers tend to use whichever value makes their products look better. For example, drive capacities are often rated in decimal billions (G - Giga), whereas most BIOS chips and operating system utilities, such as the Windows FDISK, rate the same drive in binary gigabytes (Gi - Gibi). Note also that when bits and bytes are used as part of some other measurement, the difference between bits and bytes is often distinguished by the use of a lower- or uppercase B. For example, megabits are typically abbreviated with a lowercase b, resulting in the abbreviation Mb/s for megabits per second, whereas MB/s indicates megabytes per second.

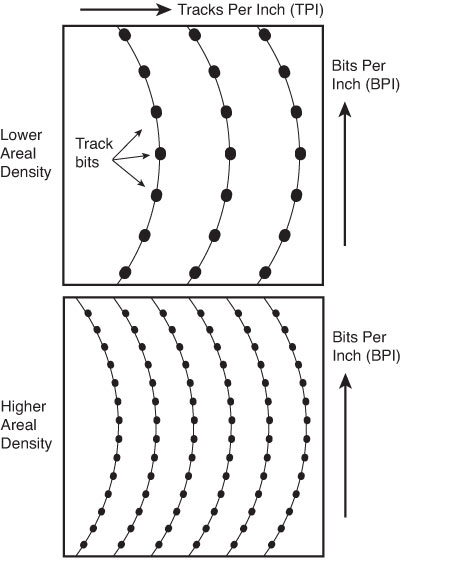

Areal Density

Areal density is often used as a technology growth-rate indicator for the hard disk drive industry. Areal density is defined as the product of the linear bits per inch (BPI), measured along the length of the tracks around the disk, multiplied by the number of tracks per inch (TPI), measured radially on the disk (see the first image below). The results are expressed in units of megabits or gigabits per square inch (Mb/sq. inch or Gb/sq. inch) and are used as a measure of efficiency in drive recording technology. Current high-capacity drives record at areal densities exceeding 400 Gb/sq. inch.

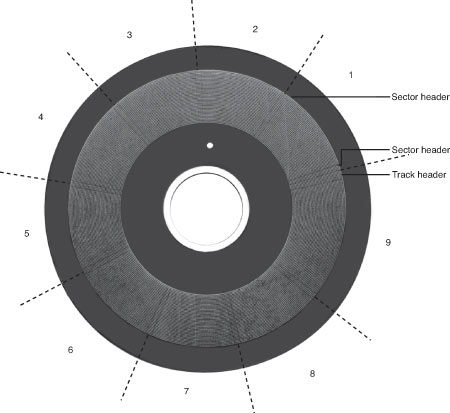

Drives record data in tracks, which are circular bands of data on the disk. Each track is divided into sectors. The second image below shows an actual floppy disk sprayed with magnetic developer (powdered iron) such that an image of the actual tracks and sectors can be clearly seen. The disk shown is a 5 1/4-inch 360 KB floppy, which has 40 tracks per side, with each track divided into nine sectors. Note that each sector is delineated by gaps in the recording, which precede and follow the track and sector headers (where ID and address information resides). You can clearly see the triple gap preceding the first sector, which includes the track and sector headers. Then following in a counterclockwise direction, you see each subsequent sector, preceded by gaps delineating the header for that sector. The area between the headers is where the sector data is written.

Notice that sector 9 is longer than the others; this is to enable rotational speed differences between drives, so that all the data can be written before running into the start of the track. Also notice that a good portion of the disk surface isn’t used because it is simply impractical to have the heads travel in and out that far, and the difference in length between the sectors on the inner and outer tracks becomes more of a problem.

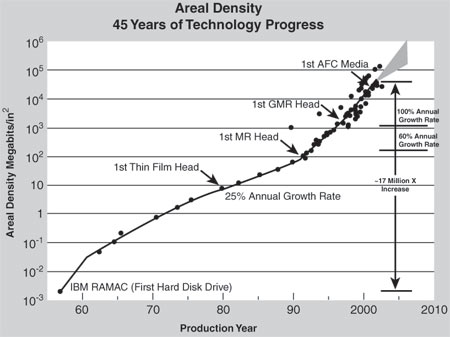

Areal density has been rising steadily since the first magnetic storage drive (the IBM RAMAC, featuring an areal density of 2 Kb/sq. inch) was introduced in 1956. Density initially grew at a rate of about 25% per year (doubling every four years); then in the early 1990s the rate accelerated to a growth rate of about 60% per year (doubling every year and a half). The development and introduction of MR heads in 1991, GMR heads in 1997, and AFC pixie dust media in 2001 (see the next section) subsequently drove a further increase in the areal density growth rate to 100% annually. The result of all this growth in density is amazing. In just slightly more than 50 years since the RAMAC drive was introduced, the areal density of magnetic storage has increased more than 200 million fold, from 2 Kb/sq. inch in the 1956 RAMAC (5 MB of storage on fifty 24-inch platters) to beyond 500 Gb/sq. inch in 3 TB drives in 2010.

Current drives have used perpendicular recording techniques to go well past what was previously considered the point at which the superparamagnetic effect takes place. This is an effect in which the magnetic domains become so small that they are intrinsically unstable at room temperature. Techniques such as perpendicular recording combined with extremely high coercivity media are being employed to enable future magnetic storage densities of up to 1000 Gb/sq. inch or more, but beyond that, scientists and engineers might have to look toward other technologies. One such technology being considered for the future is patterned media, in which a disk is preformatted with magnetic domains that can be more tightly packed without interfering with each other. Another possible future technology is holographic storage, in which a laser writes data three-dimensionally in a crystal plate or cube.

The figure below shows how areal density has increased by a factor of more than 200 million times from when magnetic storage was developed (1956 RAMAC) to the present.

To increase areal density while maintaining the same external drive form factors, drive manufacturers have developed media and head technologies to support these higher areal densities, such as ceramic/glass platters, GMR heads, pseudo-contact recording, and PRML electronics, as discussed earlier in this chapter. The primary challenge in achieving higher densities is manufacturing drive heads and disks to operate at closer tolerances. Improvements in tolerances and the use of more platters in a given form factor continue to fuel improvements in drive capacity, but drive makers continue to seek even greater capacity increases, both by improving current technologies and by developing new ones.

To fit more data on a platter of a given size, you must place the tracks more closely together, and the heads must be capable of achieving greater precision in their placements over the tracks. This also means that, as hard disk capacities increase, heads must float ever closer to the disk surface during operation. The gap between the head and disk is as close as 10 nanometers (0.01 microns) in some drives, which is approximately the thickness of a cell membrane. By comparison, a human hair is typically 80 microns in diameter, which is 8000 times thicker than the gap between the head and disk in some drives. The prospect of actual contact or near contact recording is being considered for future drives to further increase density.

PMR

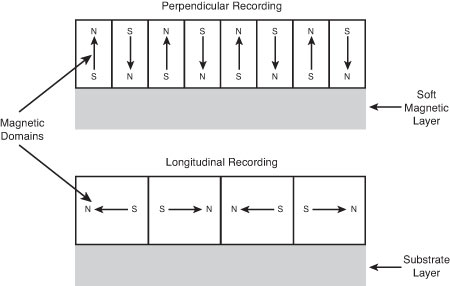

Originally all hard drives and other types of magnetic media recorded data using longitudinal recording, which stores magnetic bits horizontally across the surface of the media. Today, however, perpendicular recording, which aligns magnetic signals vertically on the media surface, is being incorporated in modern drives to achieve higher data densities. This process works because vertically oriented magnetic bits use less space than longitudinally stored bits. Virtually all the major drive vendors are working with perpendicular recording as a way to achieve signal density surpassing that is achievable even with AFC pixie dust media.

Conventional magnetic recording places magnetic domains longitudinally, meaning the domains lie end to end on the disk. This not only limits the density of the domains, but also helps to enable the superparamagnetic effect. Long ago it was realized that if one could place the domains perpendicular to the media (also called avertical recording), the density could be increased, as could the resistance of the domains to the superparamagnetic effect. Although the concept was easy to understand, actually implementing it has been difficult.

Unlike GMR heads and AFC media—both of which can be added relatively easily to existing drive technologies—perpendicular recording requires entirely new read/write head designs. The image below shows the difference between perpendicular and longitudinal recording. You can get at least twice the number of magnetic domains in the same space with perpendicular recording.

Using perpendicular recording, the heads are designed to write deep into the media, using a thicker soft magnetic underlayer as a return path for the magnetic field. This enables the domains to be vertically aligned, and thus placed much more closely together without unwanted interaction problems.

Perpendicular recording was first demonstrated in the late nineteenth century by Danish scientist Valdemar Poulsen, who was also the first person to demonstrate that sound could be recorded magnetically. There weren’t many advances in perpendicular recording until 1976 when Dr. Shun-ichi Iwasaki (president of the Tohoku Institute of Technology in Japan) verified the distinct density advantages in perpendicular recording. Then in 1978, Dr. T. Fujiwara began an intensive research and development program at the Toshiba Corporation that eventually resulted in the perfection of floppy disk media optimized for perpendicular recording and the first commercially available magnetic storage devices using the technique.

The first use of perpendicular recording in PCs was with the 3 1/2-inch, 2.88 MB ED (extra-high density) floppy format developed by Toshiba and officially announced in 1987, with the ED drives and disks finally reaching production in 1989. IBM officially adopted these drives in its PS/2 systems in 1991, and a number of manufacturers began making them for IBM and other PC manufacturers, including Toshiba, Mitsubishi, Sony, and Panasonic. Because a 2.88 MB ED drive can fully read and write 1.44 MB HD disks (due to BIOS manufacturers fully integrating 2.88 MB floppy support in the BIOS) and because DOS 5.0 and later included support for the 2.88 MB format, the change to 2.88 MB was an easy one. Unfortunately, due to high media costs and a relatively low increase in data capacity at a time when floppy disks were being replaced by writable CDs, these drives never caught on.

Despite the 2.88 MB ED floppy’s failure in the marketplace, Toshiba and other companies continued developing perpendicular magnetic recording for other media, especially hard disk drives. Unfortunately, they would find that perpendicular recording technology was too far ahead of its time when it came to hard drives, where the existing technology was well entrenched, and where density evolution was already progressing at rates almost too fast for the industry to assimilate. It would take almost 20 more years before the existing longitudinal recording would begin to run out of steam as it reached 100 Gb/sq. inch, and the looming superparamagnetic limit would cause drive engineers to finally find justification for switching to perpendicular recording.

In April 2002, Read-Rite Corporation, a major maker of read/write heads, reached areal densities of 130 Gb/sq. inch in a prototype drive using media provided by Maxtor subsidiary MMC Technology. In November 2002, Seagate Technology announced it had achieved areal densities of more than 100 Gb/sq. inch in a prototype drive using this technology as well. According to two independent studies published in 2000, perpendicular recording was projected to enable densities of up to 1000 Gb (1 terabit) per square inch in the future, a prediction that is well on its way to becoming true.

Perpendicular recording finally became commercially available in hard disk drives on August 16, 2005, when Toshiba’s Storage Device Division announced shipment of the world’s first hard disk using PMR technology. These were 1.8-inch drives used primarily in portable consumer electronics devices—most notably the Apple iPod media players, but also found in some of the smallest laptop PCs, such as the Toshiba Libretto series. The first 1.8-inch drives using PMR were the 40 GB and 80 GB models, which store 40 GB on a single platter and are available in single-platter 40 GB and dual-platter 80 GB versions. These drives featured the highest areal density of any drives then on the market at 133 Gb/sq. inch (206 Mb/sq. mm). Although not normally used in PCs, these drives can be found in some of the extremely small and lightweight laptop systems such as the Toshiba Libretto.

In June 2006, Toshiba introduced a 200 GB 2.5-inch PMR drive only 9.5 mm thick and weighing only 98 grams. This became the highest capacity 2.5-inch drive available at the time, and it featured the world’s highest areal density (178.8 Gb/sq. inch or 277 Mb/sq. mm) in a production drive. In October 2006, Toshiba announced it had produced more than one million drives using PMR technology.

Seagate introduced the world’s first 2.5-inch PMR-based hard disk with the Momentus 5400.3 160, a 160 GB 2.5-inchdrive designed primarily for laptops. Although Seagate announced the drive in June 2005, it wasn’t actually available for purchase until January 2006. In April 2006, Seagate introduced the Barracuda 7200.10 drive, which was both the first 750 GB drive on the market as well as the first 3.5-inch drive to use perpendicular recording.

Other manufacturers have also developed PMR drives; in fact, virtually all hard drive manufacturers have shifted the bulk of their product to PMR-based drives to continue the incredible capacity growth trends in magnetic storage. In January 2007, Hitachi introduced the Deskstar 7K1000, which used perpendicular recording to achieve the milestone of being the world’s first 1 TB (terabyte) drive. At the introduction, Hitachi noted that it took the storage industry 35 years to move drive capacity from 5 MB to 1 GB (1956 to 1991), 14 more years to get to 500 GB (1991 to 2005), and only two more years (2005 to 2007) to hit 1 TB. This clearly shows Moore’s Law in effect for magnetic storage. Later, in June 2007, Hitachi introduced the 5K250, a 250 GB 2.5-inch drive storing data at 205 Gb/sq. inch areal density. Western Digital introduced the first 2 TB drive in early 2009, and in 2010 both Seagate and Western Digital introduced the first 3 TB drives (external and internal, respectively), and Samsung has indicated it will release the first 4 TB drive in 2011. These new high-capacity drives store data at areal densities of 500 Gb/sq. inch or higher.

Current page: Capacity Measurements, Areal Density, And PMR

Prev Page Data-Encoding: Run Length Limited Encoding And Coding Scheme ComparisonsGet Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Tom's Hardware is the leading destination for hardcore computer enthusiasts. We cover everything from processors to 3D printers, single-board computers, SSDs and high-end gaming rigs, empowering readers to make the most of the tech they love, keep up on the latest developments and buy the right gear. Our staff has more than 100 years of combined experience covering news, solving tech problems and reviewing components and systems.

-

soccerdocks "Density initially grew at a rate of about 25% per year (doubling every four years)"Reply

If density grows at 25% per year it would actually double in just barely over 3 years. At 4 years it would be 144% greater. -

joytech22 Replywhen passed over magnetic flux transitions.

I somehow expected "Flux capacitors" instead. -

johnners2981 soccerdocks"Density initially grew at a rate of about 25% per year (doubling every four years)"If density grows at 25% per year it would actually double in just barely over 3 years. At 4 years it would be 144% greater.Reply

No you're wrong, how embarrassing :). You're using compound interest. Quit trying to be a smartass -

Device Unknown johnners2981No you're wrong, how embarrassing . You're using compound interest. Quit trying to be a smartassReply

I'm no math guy, in fact i suck at it, but I see his point, why wouldn't it be compound? and even at compound interest is 144 still accurate? please enplane

-

soo-nah-mee I believe soccerdocks is right - example...Reply

Beginning value: 10

After one year: 12.5

After two years: 15.625

After three years: 19.531 (Almost double)

After four years: 24.41 -

johnners2981 Device UnknownI'm no math guy, in fact i suck at it, but I see his point, why wouldn't it be compound? and even at compound interest is 144 still accurate? please enplaneReply

Please enplane??? Compound interest is used to calculate interest and not things like density.

They were right in saying "doubling every four years" and he was trying to correct them when there was no need so showed him who's boss, oh yeah -

johnners2981 soo-nah-meeI believe soccerdocks is right - example...Beginning value: 10After one year: 12.5After two years: 15.625After three years: 19.531 (Almost double)After four years: 24.41Reply

His calculation is right not the application, why is he using compound interest to calculate the percentage increase in density? It doesn't make sense. -

soo-nah-mee johnners2981His calculation is right not the application, why is he using compound interest to calculate the percentage increase in density? It doesn't make sense.It's not compound "interest", but it is compounding. If you say something increases 25% each year, you can't just keep adding 25% of the original value! Silly.Reply

-

striker410 soo-nah-meeIt's not compound "interest", but it is compounding. If you say something increases 25% each year, you can't just keep adding 25% of the original value! Silly.I agree with the others on this one. Since it's adding 25% each year, it is compound. You are thinking of it from the wrong angle.Reply